Cyclone type oil-gas separator of engine

An oil and gas separator, cyclone technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems affecting engine performance, valve carbon deposition, etc., to improve the effect of hitting the wall, reduce emissions, and reduce oil consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The structure of the present invention is described in detail below in conjunction with accompanying drawing:

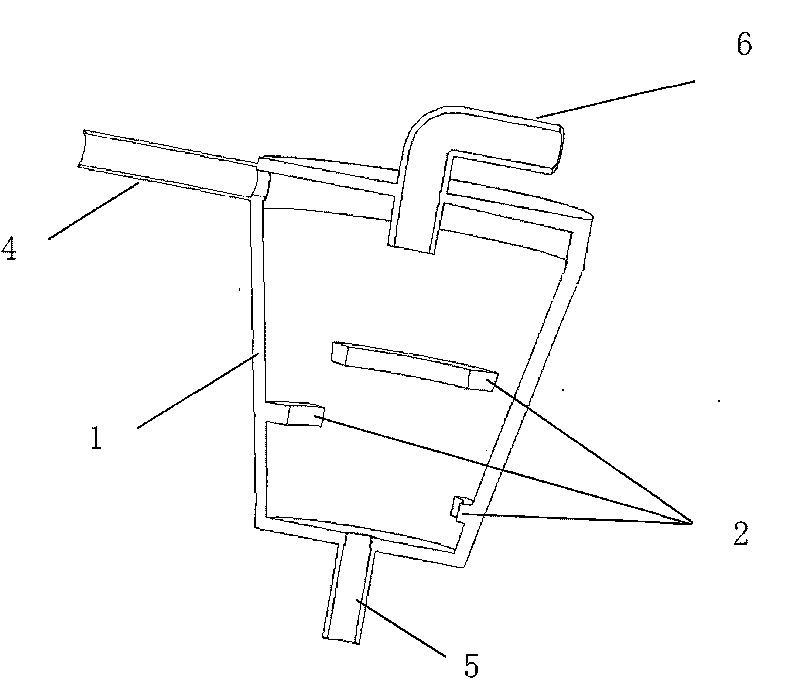

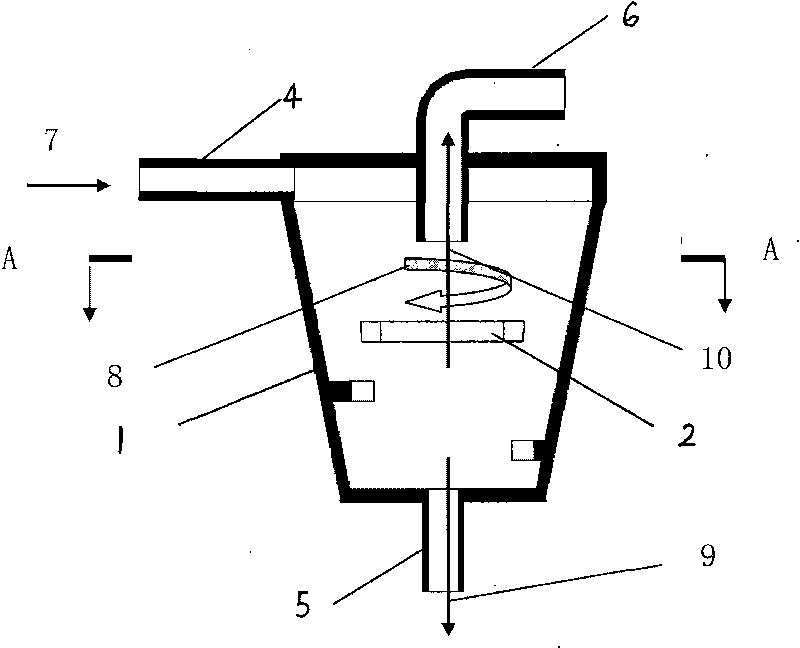

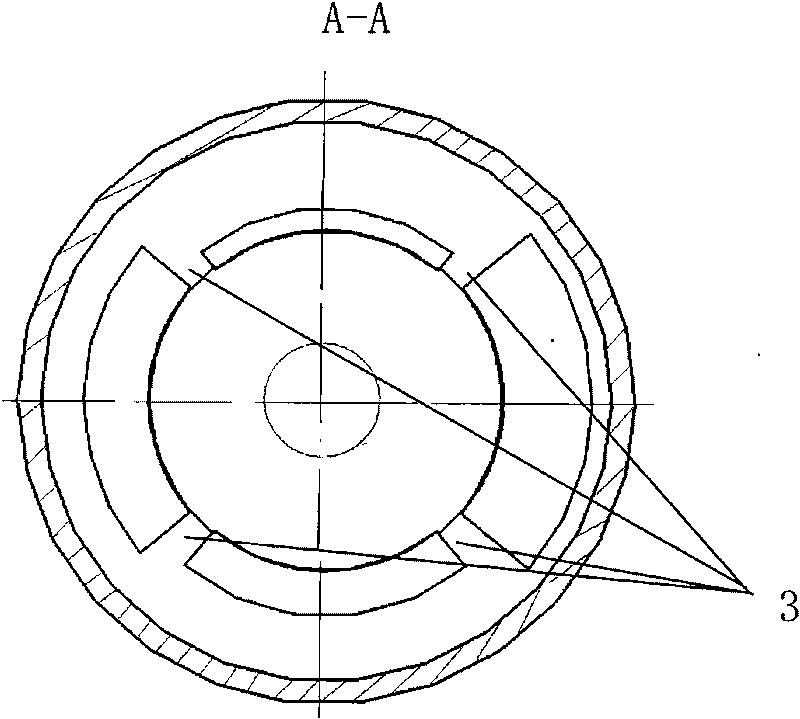

[0014] see figure 1 and figure 2 , the cyclone type oil-gas separator includes a conical cavity 1, the same as the existing similar oil-gas separator, the upper side wall of the conical cavity 1 is provided with a mixed oil-gas inlet pipe 4, the top has an exhaust port 6, and the bottom has Oil return port 5, they are all combined together by plastic molding process, and the whole cyclone oil-air separator is connected to the engine cylinder head by bolts. The difference is that the inner wall of the conical cavity 1 is not smooth, and a spiral labyrinth separation channel 2 is arranged on the inner wall of the conical cavity 1 from top to bottom, forming a spiral labyrinth structure. The spiral labyrinth separation channel 2 is a convex line formed on the inner wall surface of the conical cavity 1, spirally descends on the inner wall of the conical cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com