Air volume adjusting valve with novel structure

An air volume control valve, a new structure technology, applied in the valve shell structure, lift valve, valve details and other directions, can solve the problems of complex structure, bulky, complex assembly structure, etc., to reduce manufacturing costs and maintenance costs, realize automation, achieve the effect of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

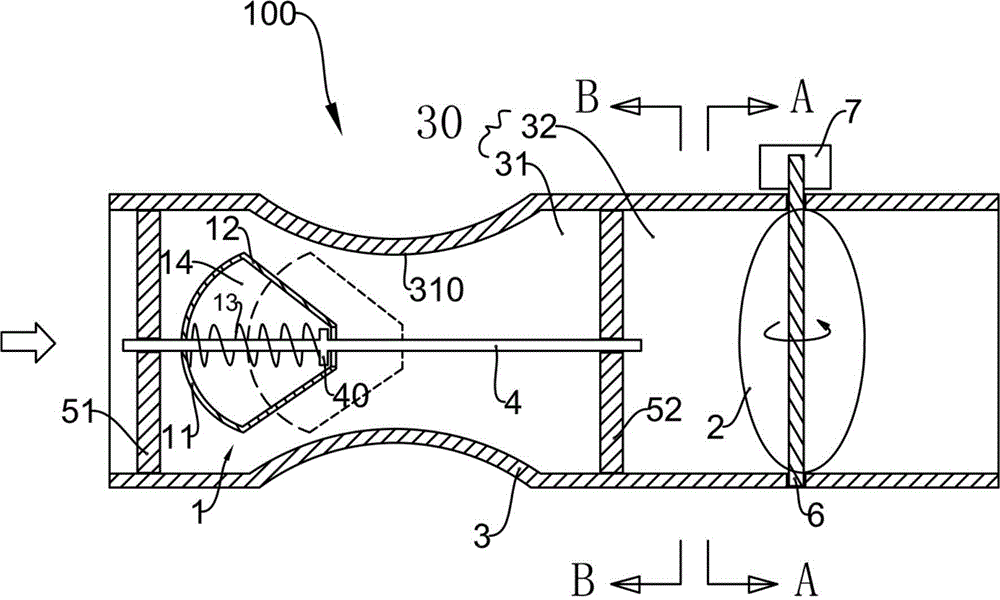

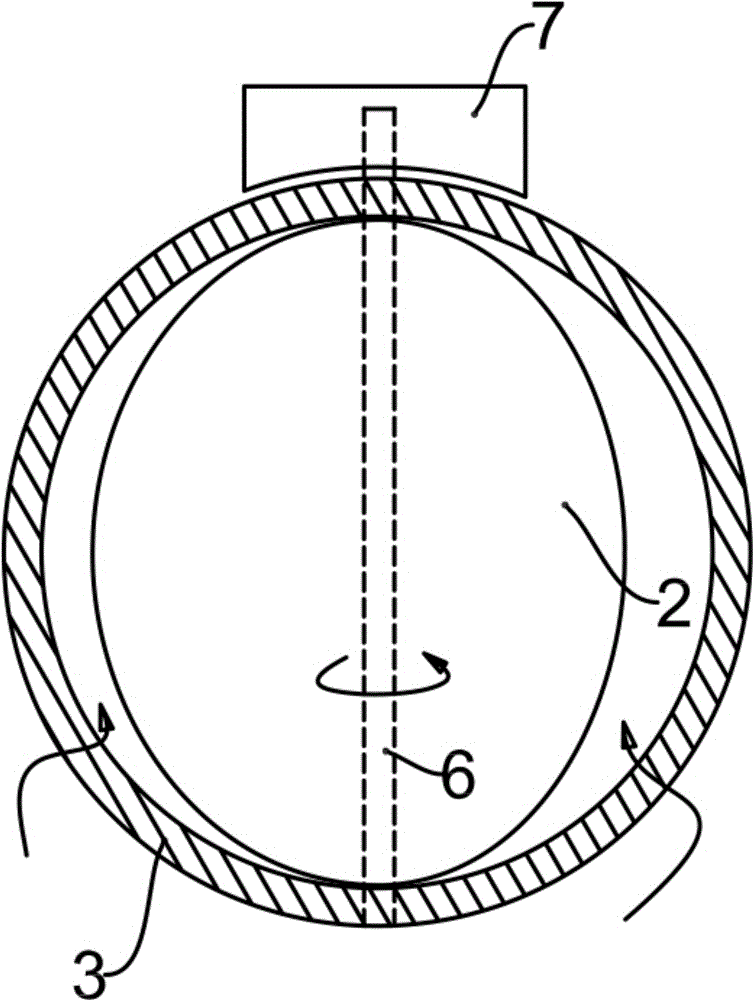

[0041] The structure of the air volume regulating valve with a new structure applying the technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

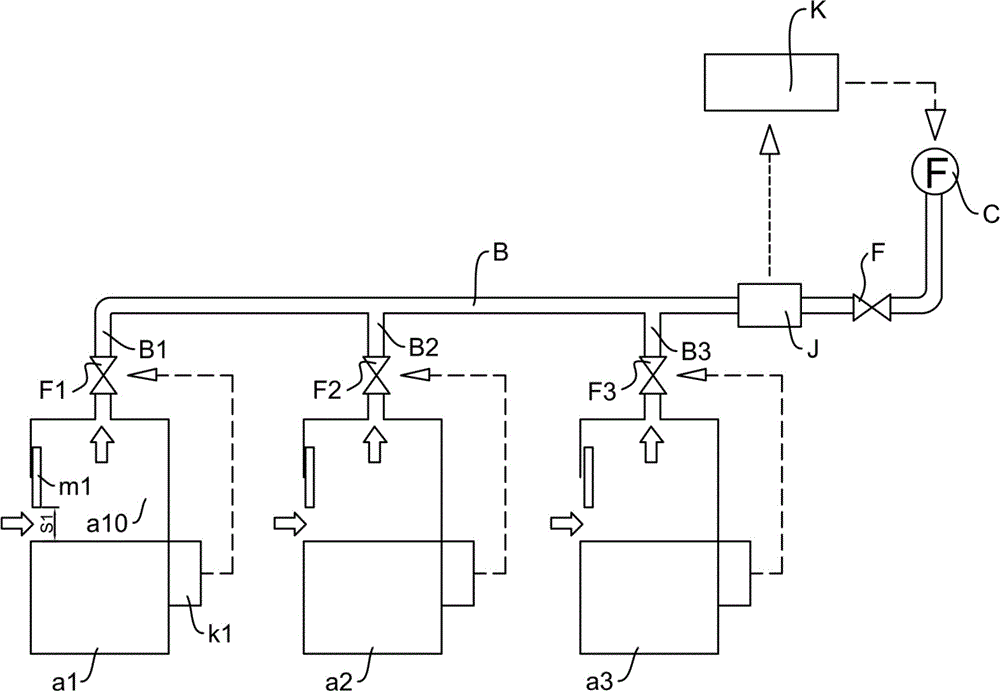

[0042] Such as figure 1 As shown, the schematic diagram of the layout structure of the ventilation system applied in the laboratory, as the description given above, in the process of using the fume hood a1, when there are self-interference factors or external interference factors, the air volume is required The regulating valve F1 quickly resolves the change of the external air volume to not only maintain the face velocity of the fume hood a1 in a constant state, but also reduce the opening of the fume hood a1 to other fume hoods (a2) connected to the total exhaust channel B. , a3). In the present invention, an air volume regulating valve 100 with the following novel structure is used as the air volume regulating valve F1 in the ventilation system.

[0043] The st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com