Cavitation type ultrahigh pressure water hammer type water gun sprayer

A technology of ultra-high pressure and nozzle, which is applied in the direction of spraying device, spraying device, etc., can solve the problems of lack, difficult dirt, etc., and achieve the effects of energy saving, high impact force, erosion and chiseling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in combination with specific embodiments.

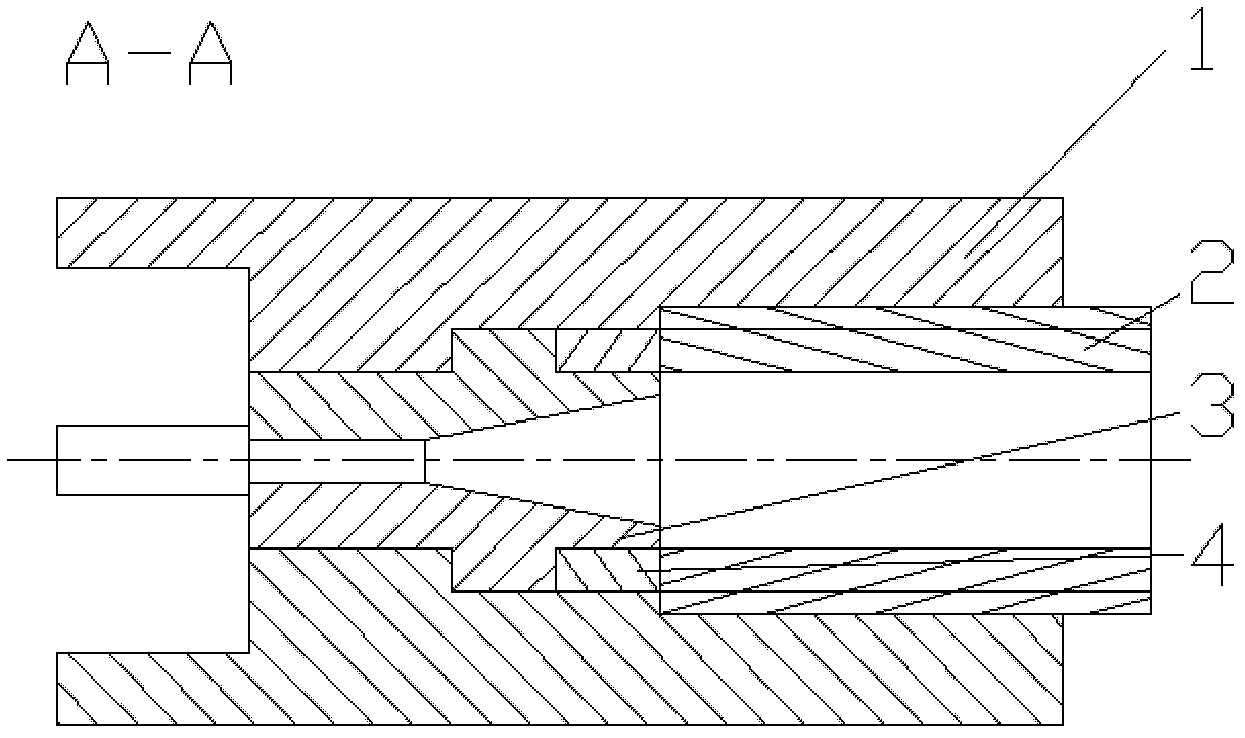

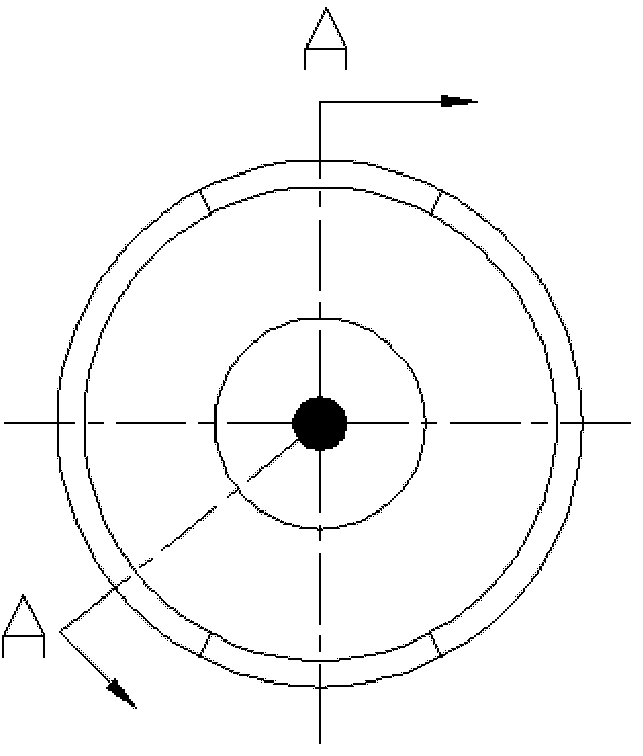

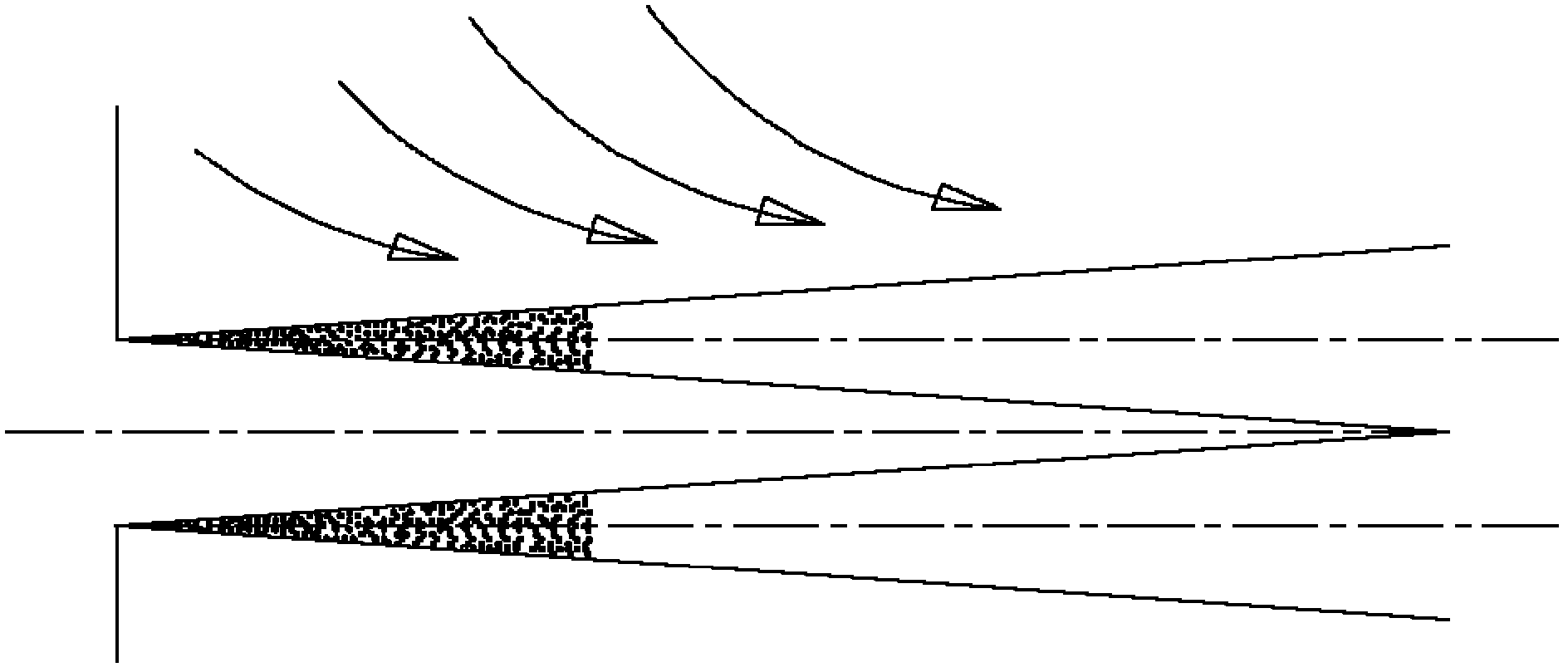

[0033] The design principle of the nozzle of the present invention is: because the characteristic of the water jet of general nozzle is as follows figure 2 The shown continuous jet, in order to enhance the effect of striking force, let the water jet become image 3 The water hammer jet shown in the figure is combined with the cavitation effect. Therefore, the nozzle of the present invention adopts the principle of fluid self-excited oscillation to make the high-speed water flow in the cavity generate pulsed oscillating water flow. The principle of self-excited oscillation is to adopt a shape design similar to the shape of an organ pipe or a Helmholtz tube, and when designing the curve of the cavity wall, try to make the fluid generate a separation vortex in the boundary layer and form a hydrodynamic excitation. Therefore, when the high-speed water flow passes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com