Patents

Literature

78results about How to "Improve the strike effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

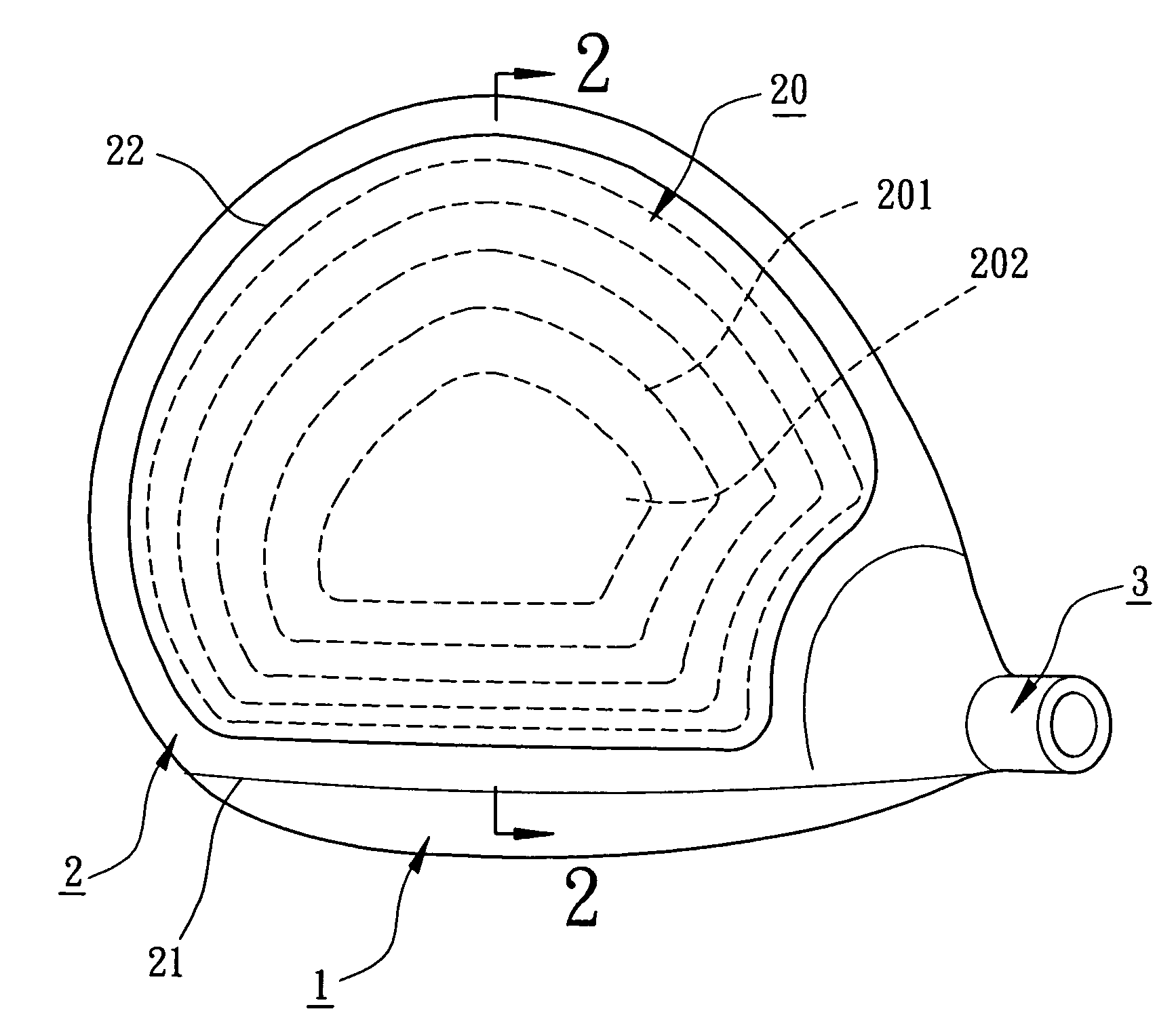

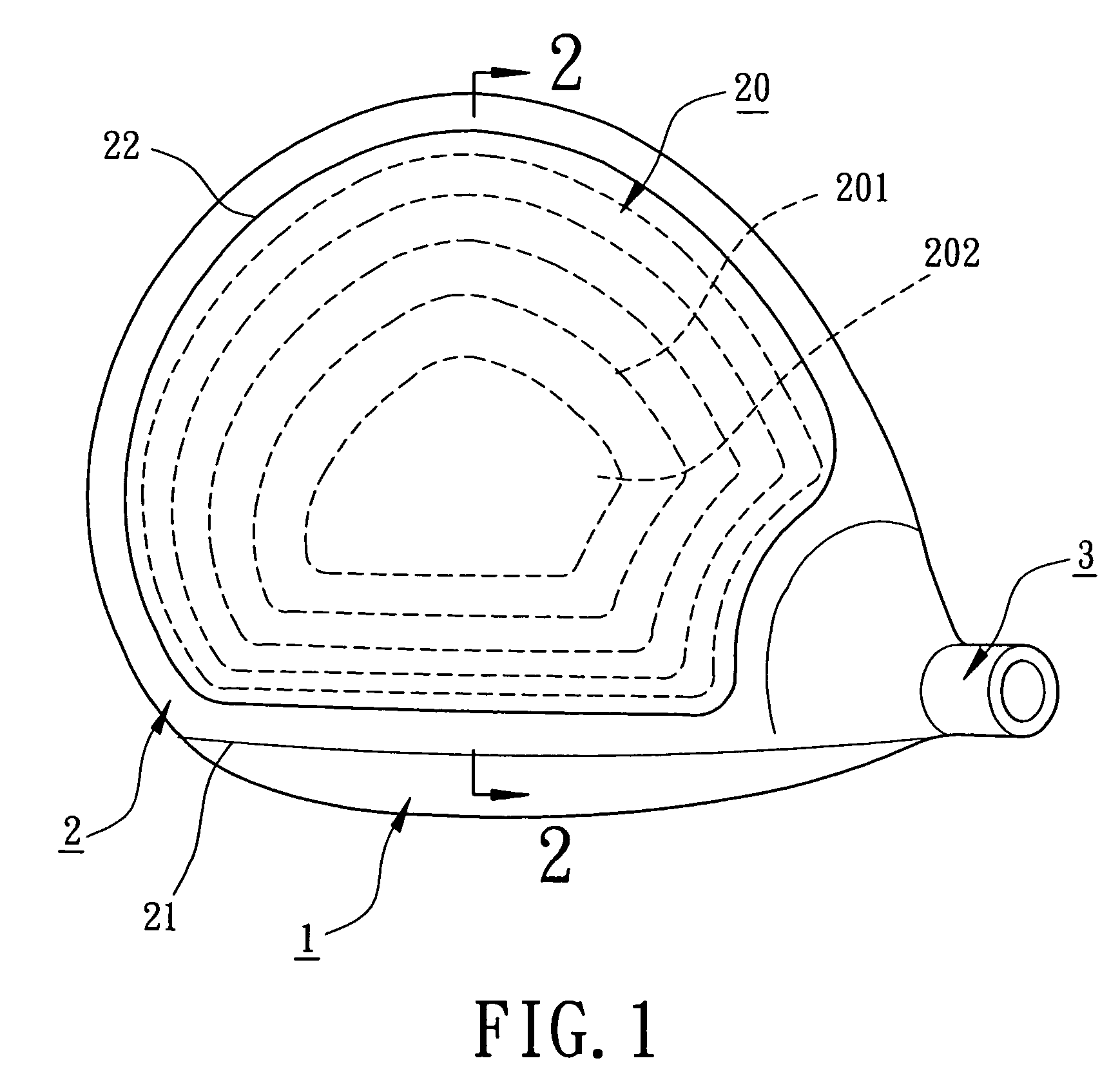

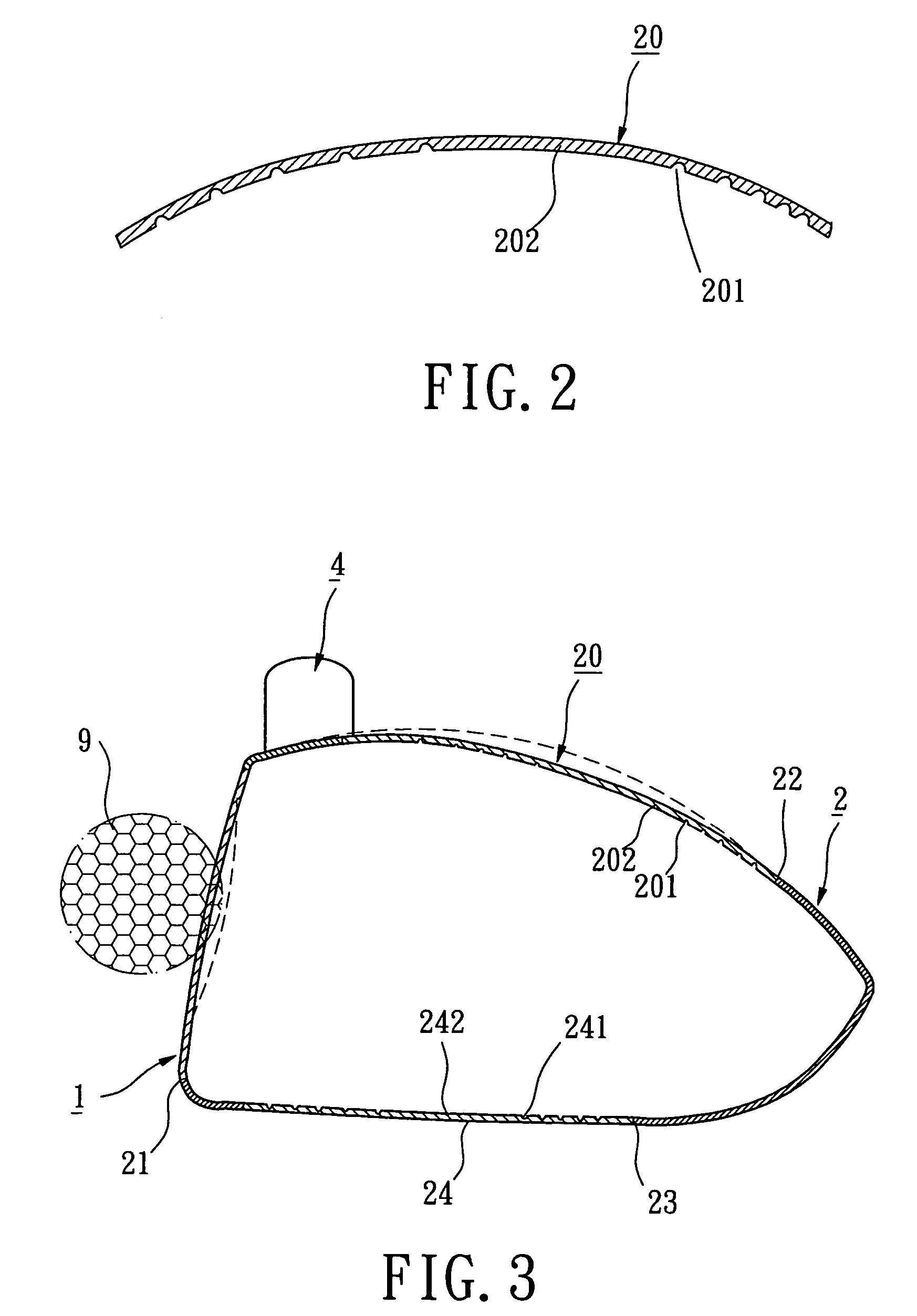

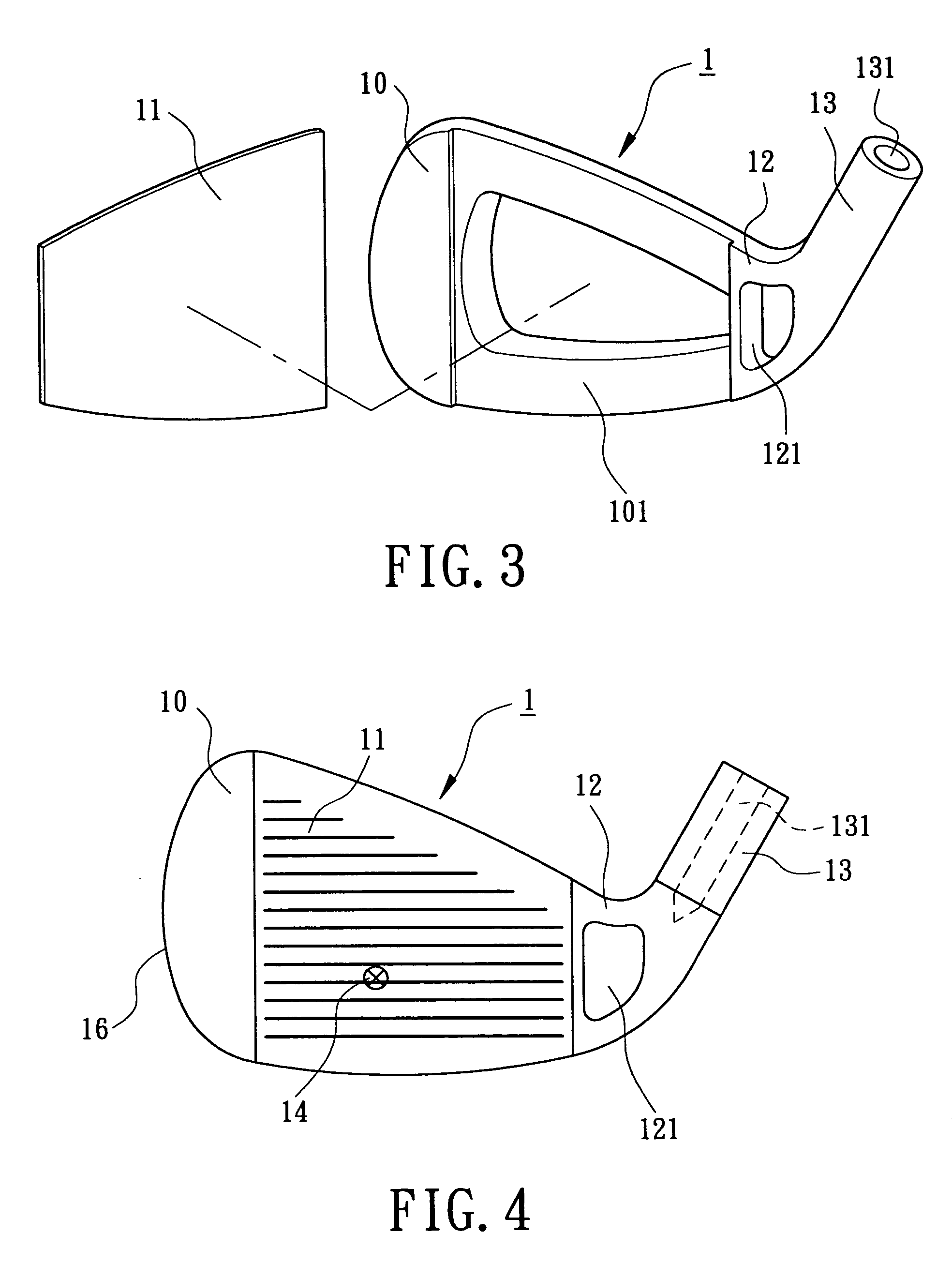

Wood type golf club head

InactiveUS7250007B2Improve the strike effectHigh strengthGolf clubsStringed racketsGolf BallGolf club

A golf club head includes a striking plate, a golf club head body and a plurality of annular flexible portions. In assembling, the striking plate mechanically connects to a front side of the golf club head body. The golf club head body forms a crown portion, a sole portion, a toe portion, a heel portion and a side portion to constitute a body member. The annular flexible portions are provided on an inner surface of the golf club head body. Thereby, the annular flexible portions can increase an elastic deformation of the golf club head body.

Owner:FUSHENG IND CO LTD

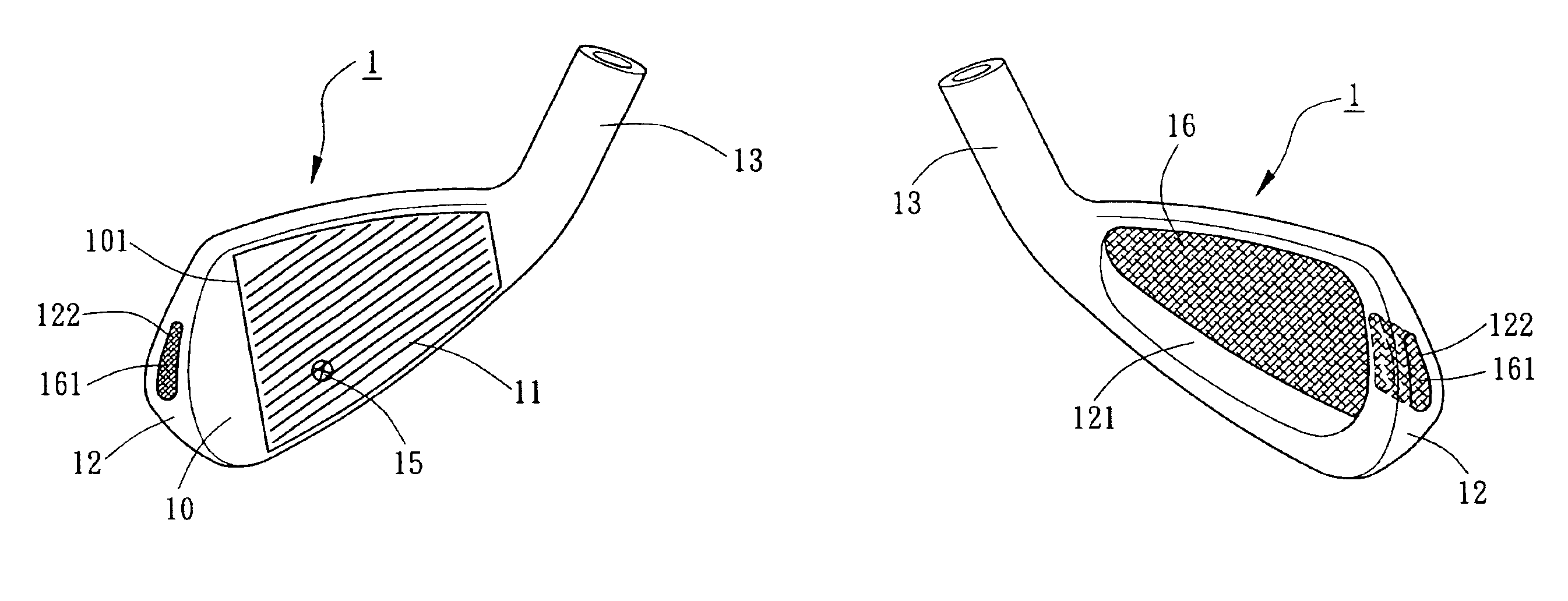

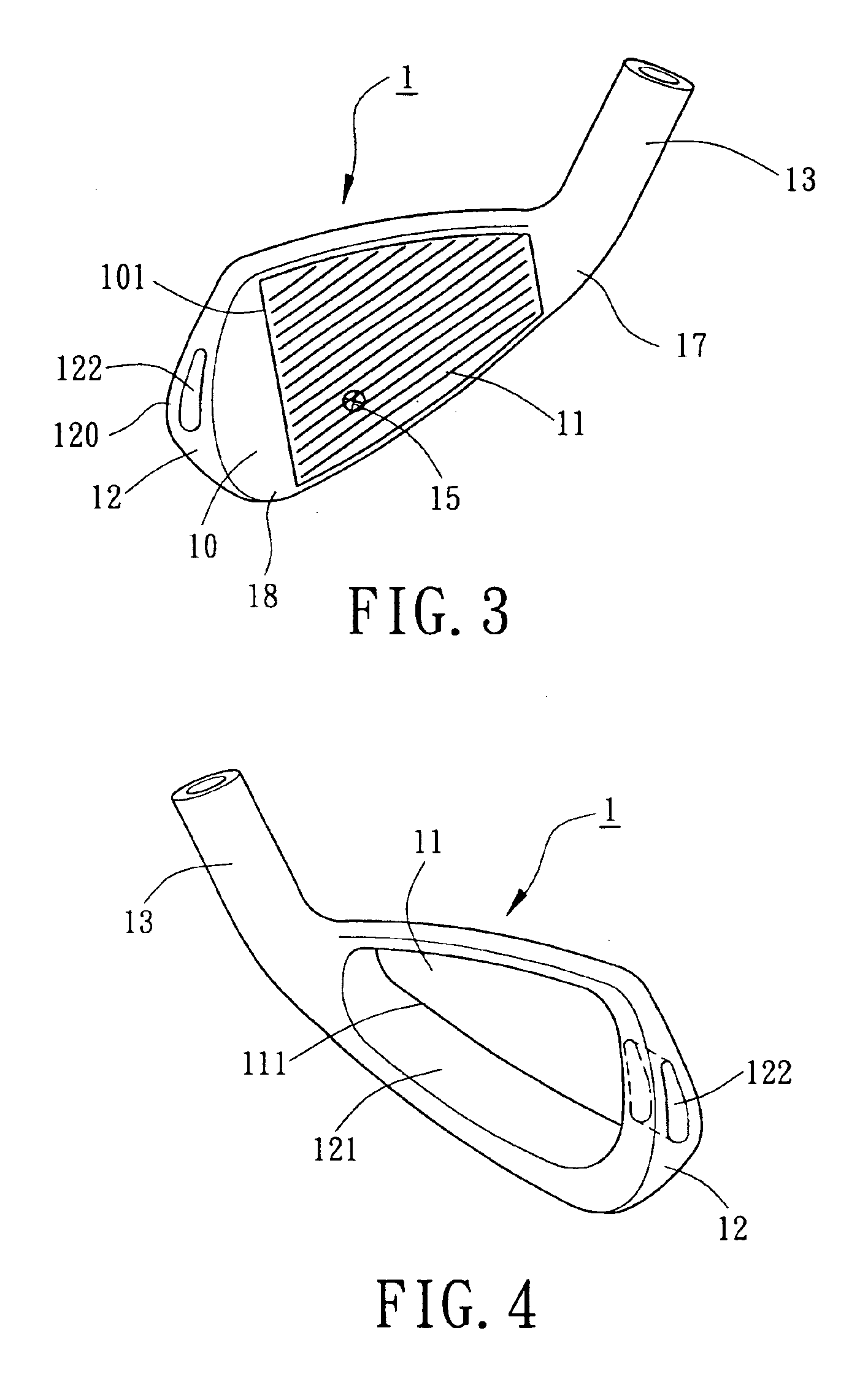

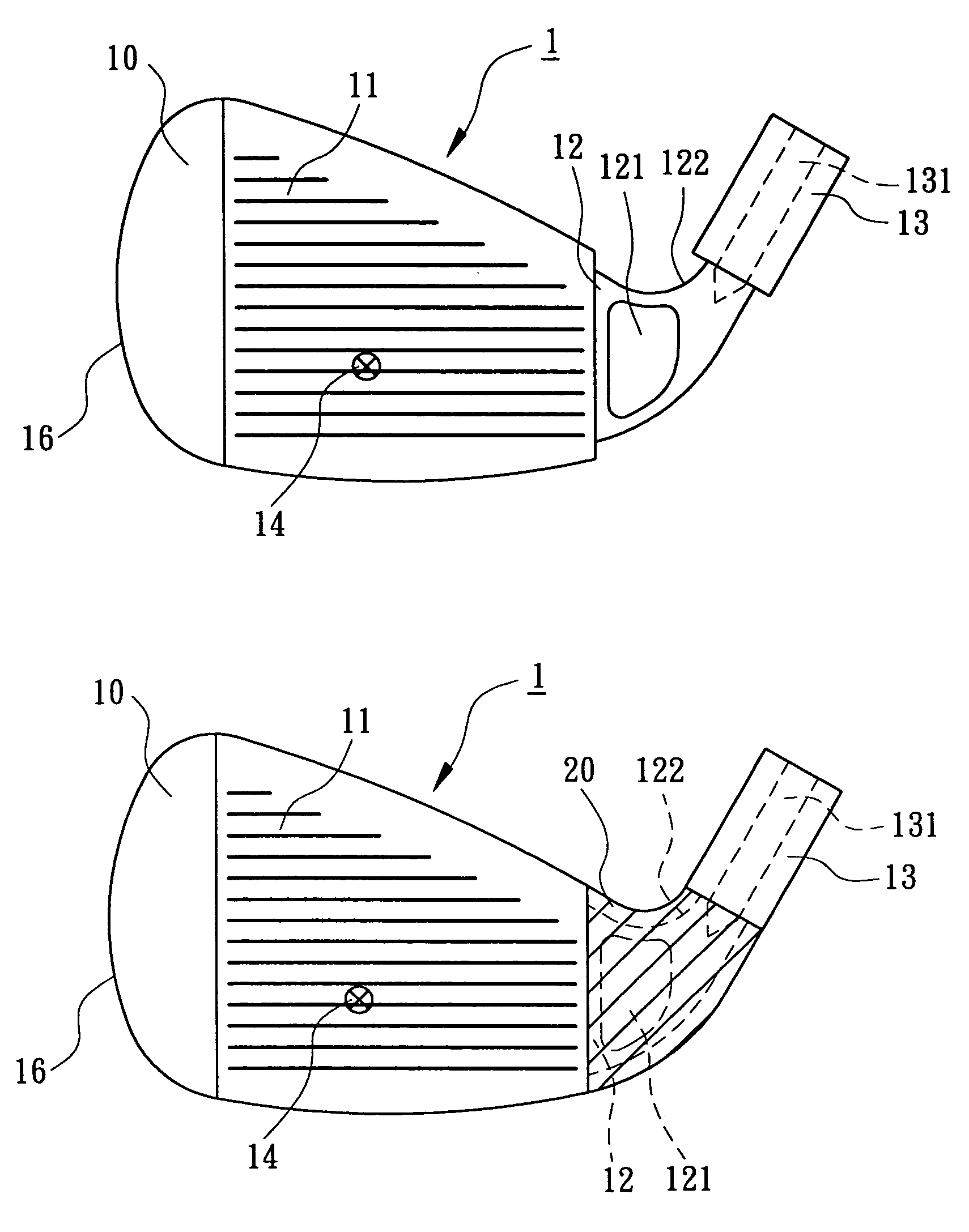

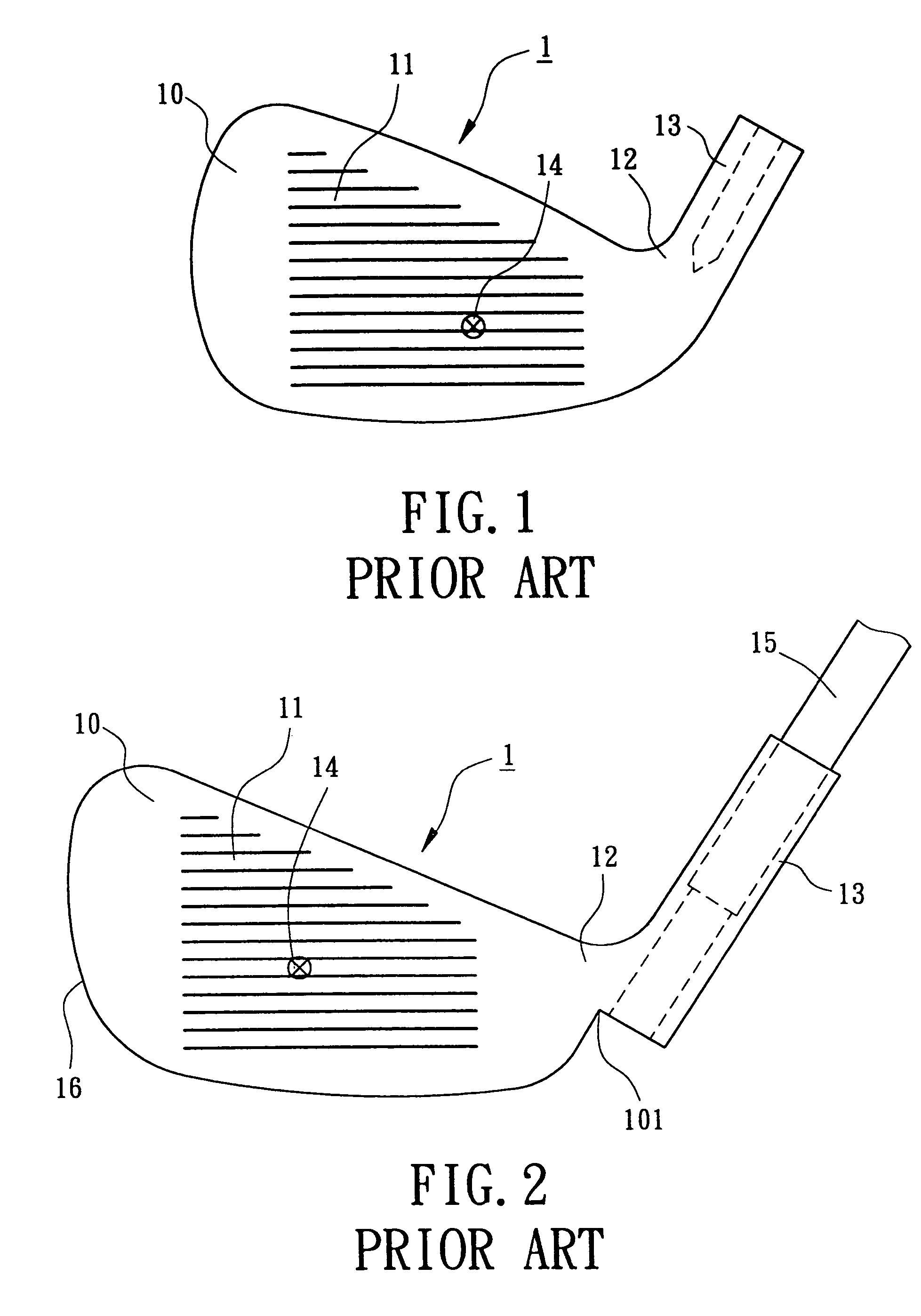

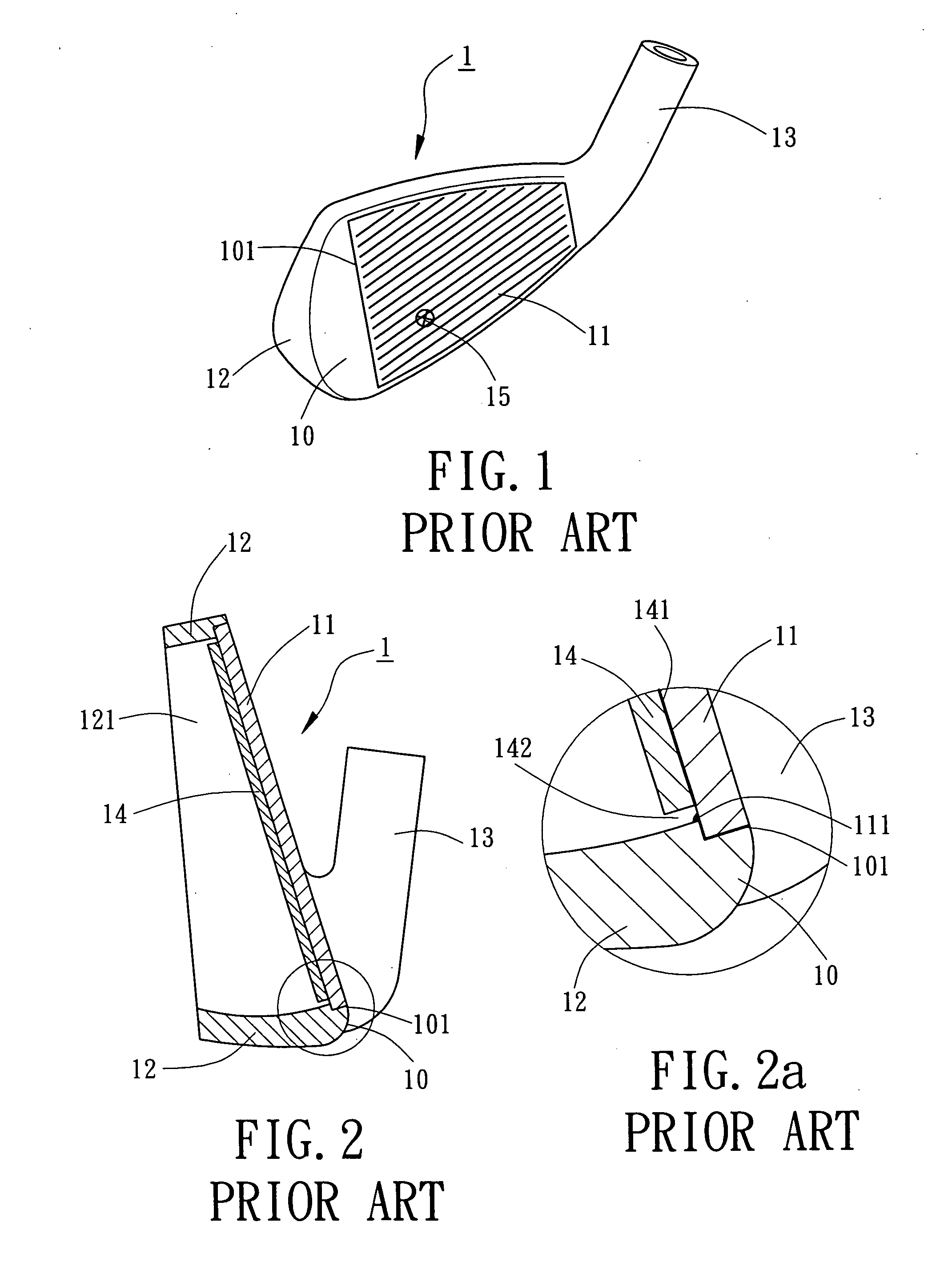

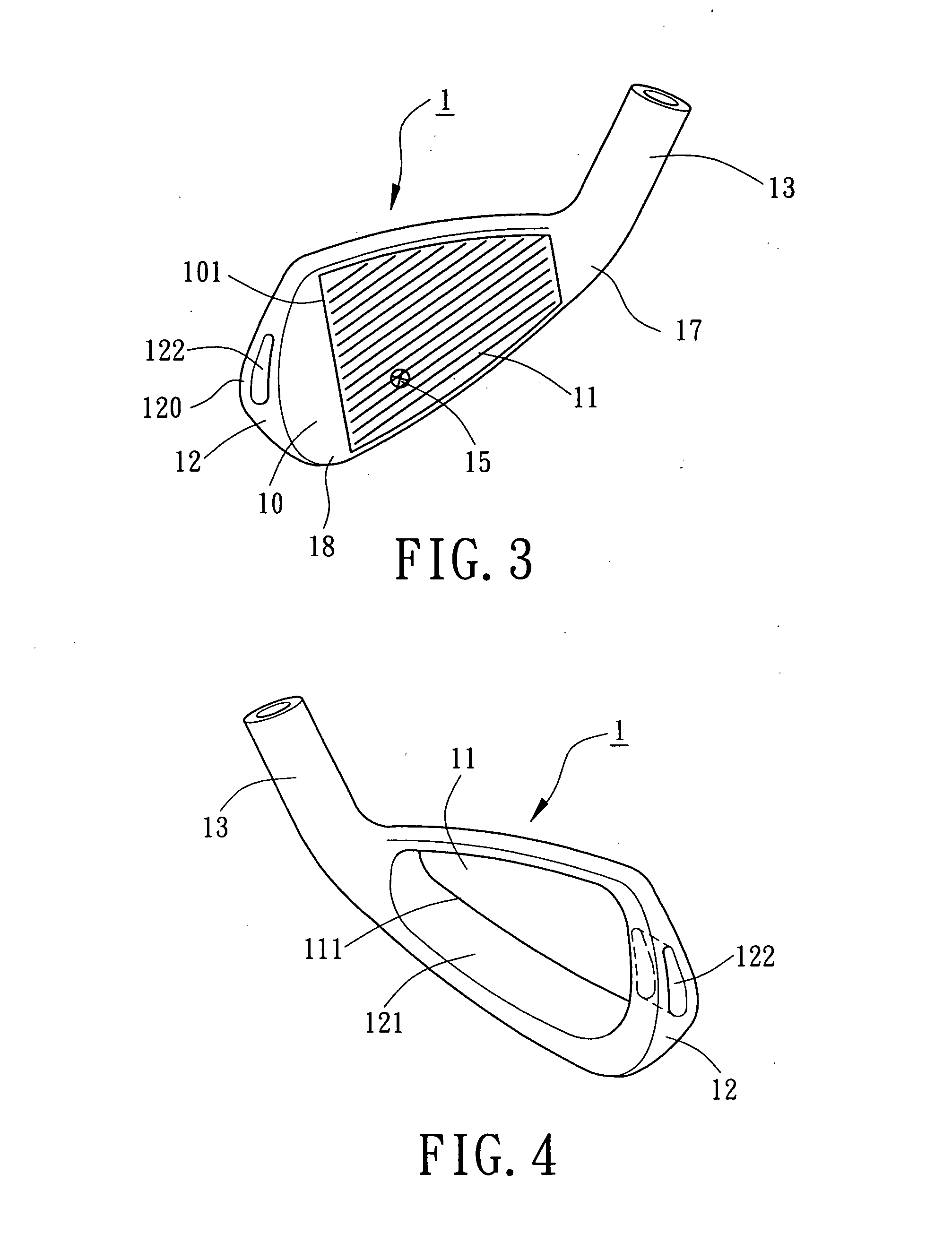

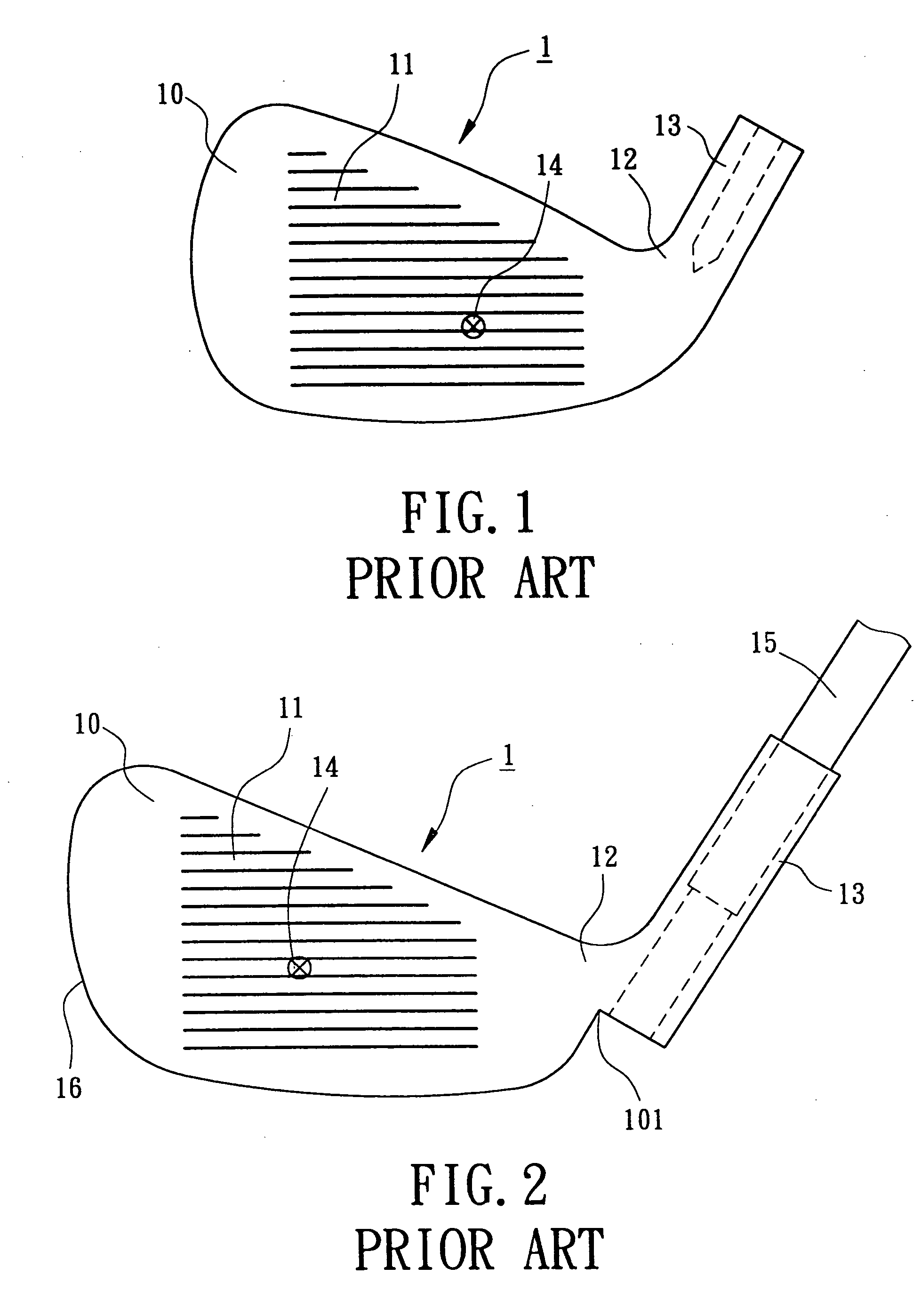

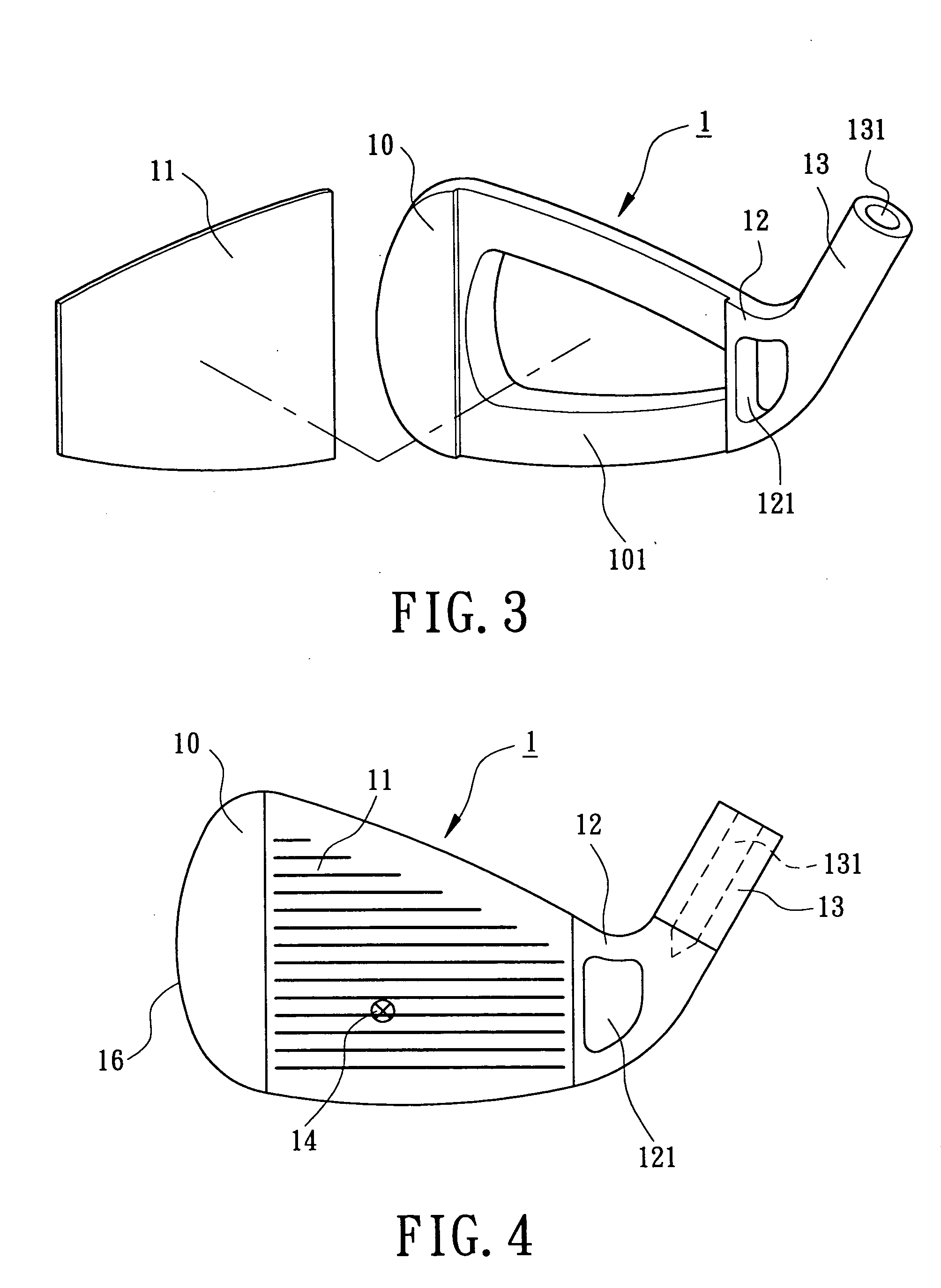

Golf club head

InactiveUS6932717B2Increased inertial momentImprove the strike effectGolf clubsRacket sportsEngineeringGolf Ball

A golf club head includes a golf club head body, a striking plate mounted to a front side of the golf club head body, and a perimeter wall extending rearward along a perimeter of the golf club head body. At least one hole is defined in a toe of the perimeter wall to reduce the weight of the upper part of the golf club head body, thereby shifting the center of gravity of the golf club head downward toward the heel and thereby increasing the inertial moment of the golf club head.

Owner:FUSHENG PRECISION

Golf club heads

InactiveUS7090590B2Increasing inertial momentumImprove the strike effectGolf clubsRacket sportsEngineeringGolf club

Owner:FUSHENG PRECISION

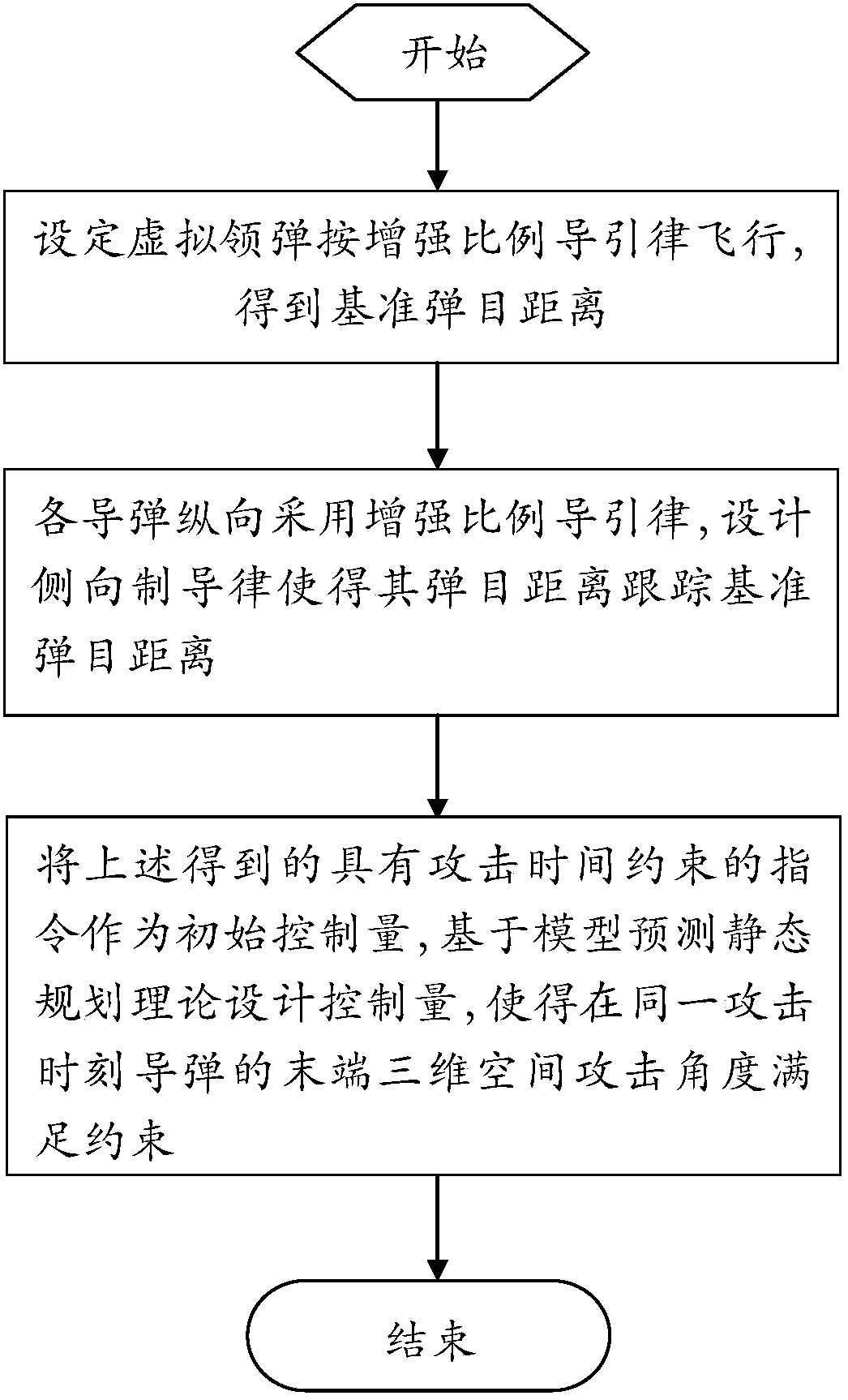

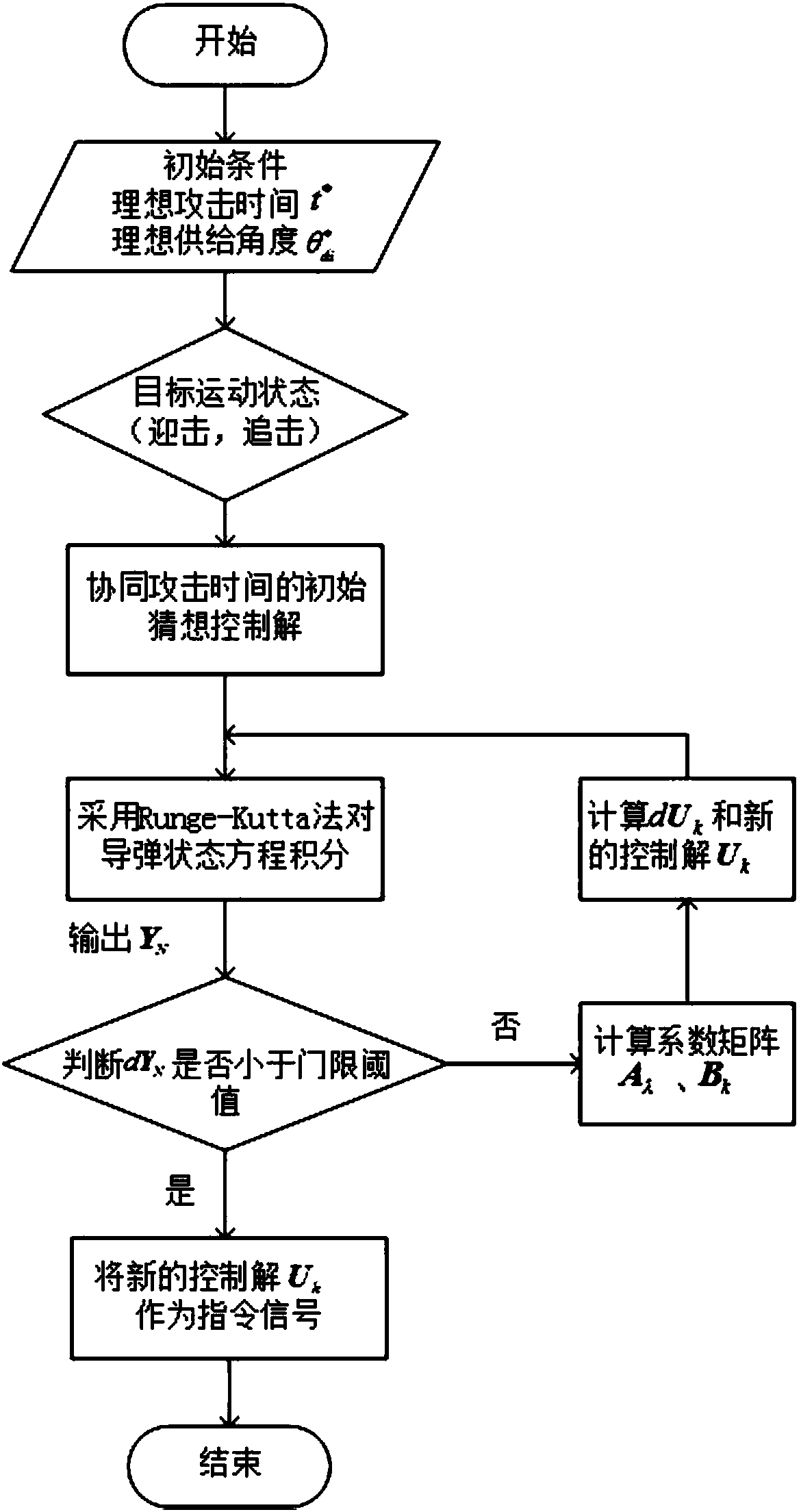

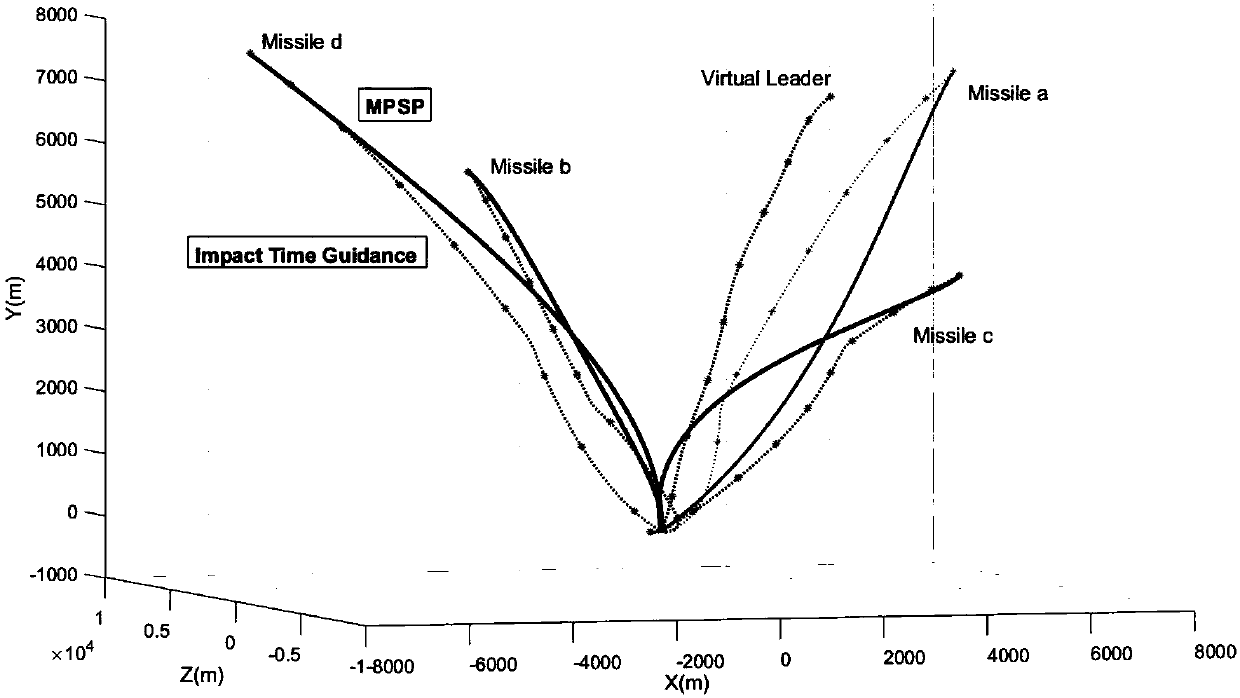

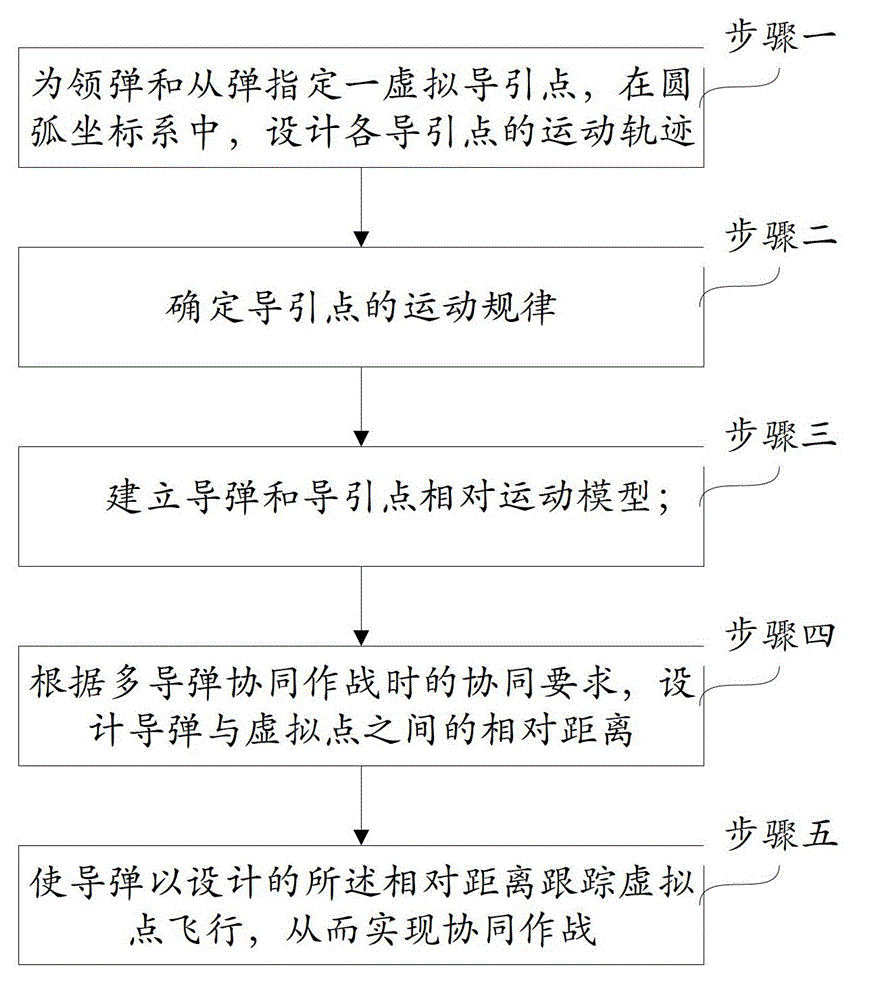

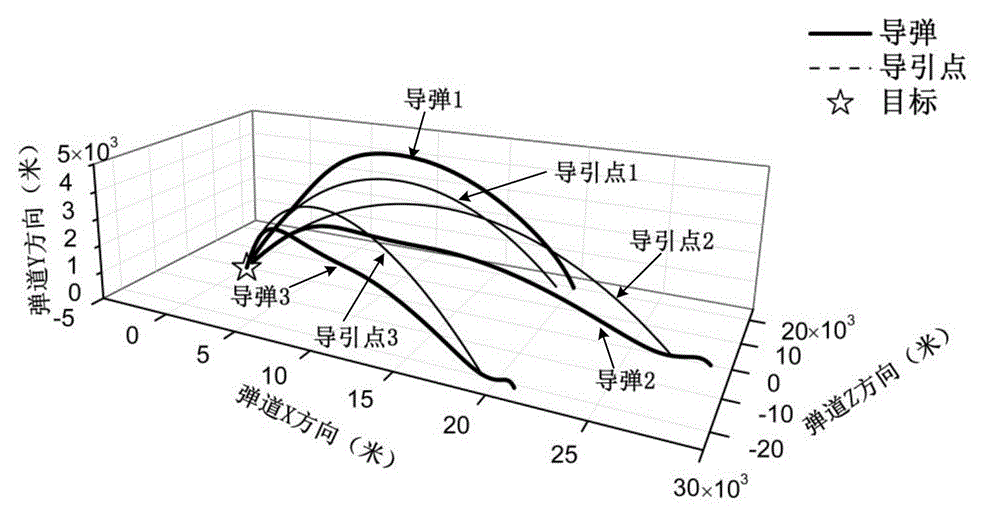

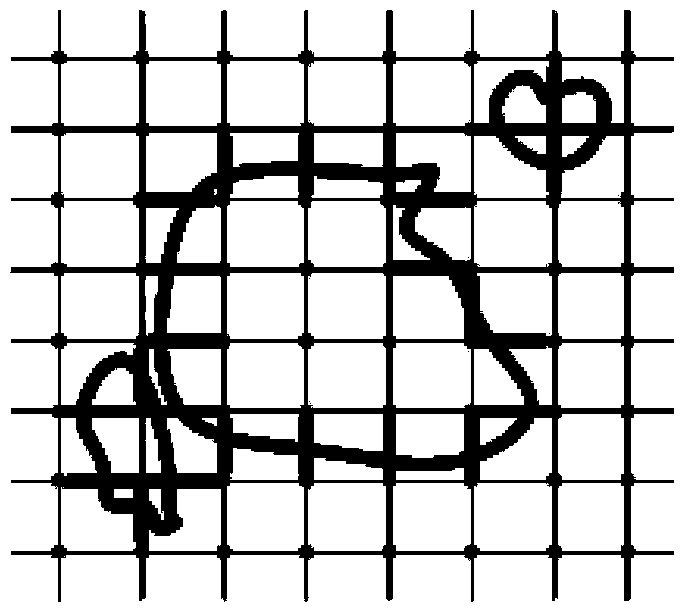

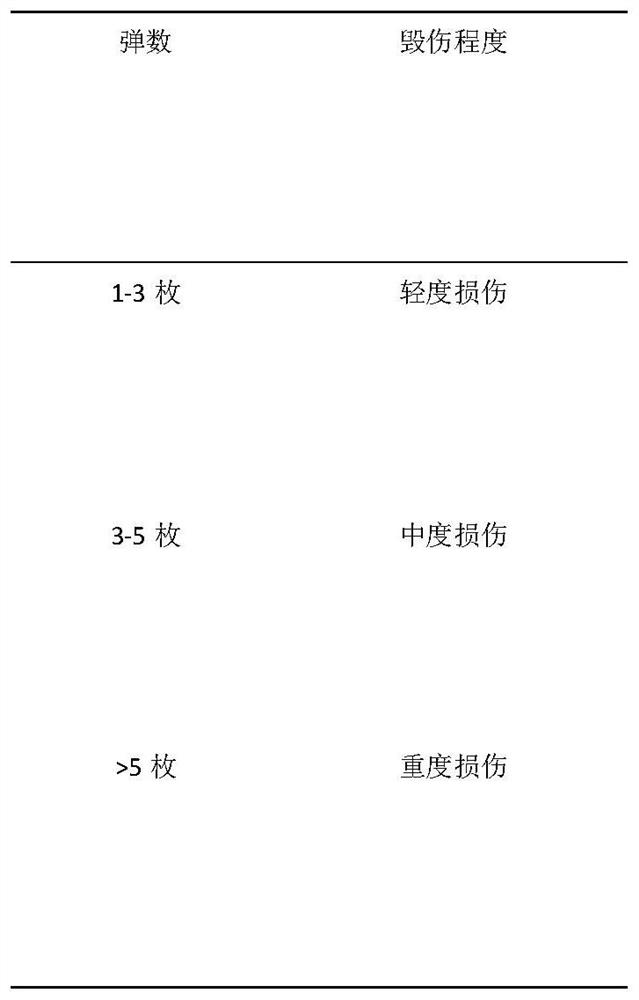

Control method of cooperative multi-missile combat

ActiveCN108168381AIncrease the probability of penetrationImprove the strike effectSelf-propelled projectilesComputation complexityThree-dimensional space

The invention discloses a control method of a cooperative multi-missile combat. Multiple missiles can be controlled to simultaneously strike a static or moving object with specified falling angles from different directions in a three-dimensional space, so that a breakthrough probability of the missiles and a striking ability on the object are greatly improved, and the object is saturation-attackedomnidirectionally. The method can be applied to multiple types of missiles, not only can be used for attacking a fixed object with a high value point, but also can be used for attacking the moving object, and has higher robustness for various interference types due to low computation complexity and high computation efficiency of an algorithm different from a traditional optimized algorithm used for on-line trajectory optimization; and the control method of the cooperative multi-missile combat has the characteristics of flexibility in application and stronger functions, and has a wide militaryapplication prospect.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

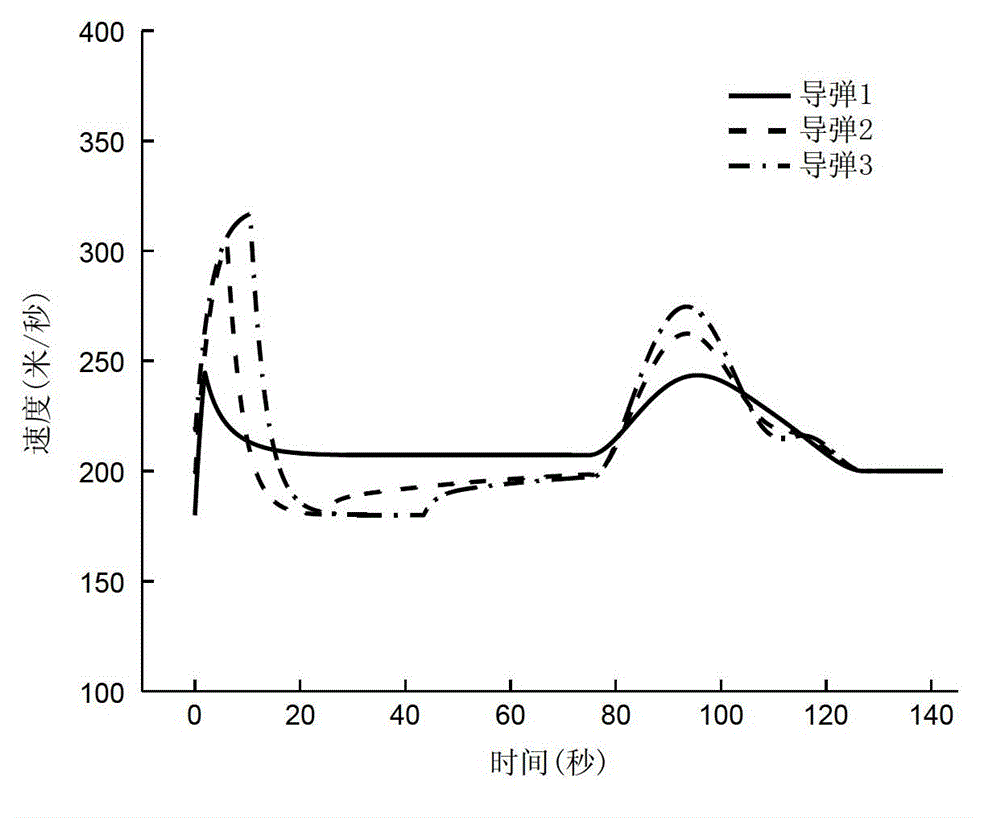

Method for controlling coordinated operation of multiple missiles

ActiveCN102980449AIdeal attack speedIdeal hitSelf-propelled projectilesAngular degreesKinetic theory

The invention provides a method for controlling coordinated operation of multiple missiles, which can accurately control the position, attack time, attack angle and attack velocity of each of the multiple missiles. The method comprises the following steps: selecting one missile from the multiple missiles to serve as a driving missile, and defining the rest missiles as driven missiles; assigning a virtual lead point to the driving missile as well as each of the driven missiles, and designing the path of motion of each lead point; determining the law of motion of the lead points in an arc coordinate system; establishing a model of relative motion of missiles and the lead points; designing the relative distances xr, yr and zr between the missles and the virtual lead points according to the needs of the missiles for cooperation in terms of position, attack angle and attack velocity; and designing a tracking controller based on the relative kinetics theory and allowing the missiles to fly in a way of tracking the virtual lead points with the designed relative distances, so as to perform coordinated operation. The method has the advantages of convenience in application and flexibility in use and has broad application prospects in the military field.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

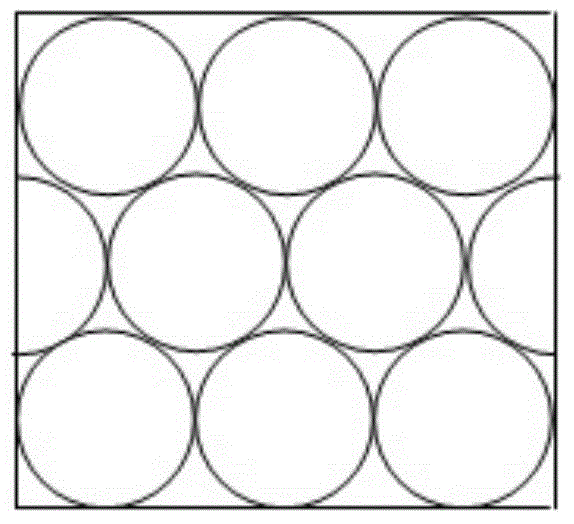

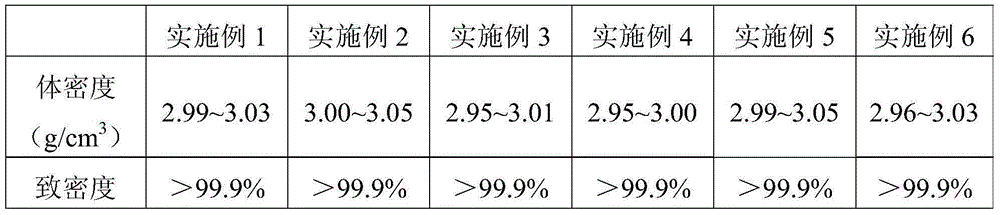

Aluminum-silicon carbide composite ceramic materials and preparation method and application thereof

ActiveCN105039912AImproves wetting and bindingImprove material performanceVacuum evaporation coatingSputtering coatingCeramic particleAluminium

The invention relates to aluminum-silicon carbide composite ceramic materials and a preparation method and application thereof. The aluminum-silicon carbide composite ceramic materials are prepared through the following steps that (1) silicon carbide ceramics are dispersed and buried in metal titanium powder, heated to 1000-1100 DEG C in a vacuum environment, kept at the temperature for 1-3h, and then cooled, so that ceramic particles with surfaces plated with metal titanium layers in an evaporation mode are obtained; (2) the ceramic particles with the surfaces plated with the metal titanium layers in the evaporation mode are put into a container, arranged tightly to form a ceramic array, heated and then put into a compression casting machine, and metal aluminum melt is cast into the ceramic array; and (3) after mold release, the surfaces of the ceramics are cleaned, and the aluminum-silicon carbide composite ceramic materials are obtained and can be used for manufacturing bulletproof plates. Compared with the prior art, the composite ceramic materials have the characteristics of being compact in combination, simple in preparation method, suitable for industrial enlargement and the like.

Owner:ZHEJIANG LIGHT TOUGH COMPOSITE MATERIALS

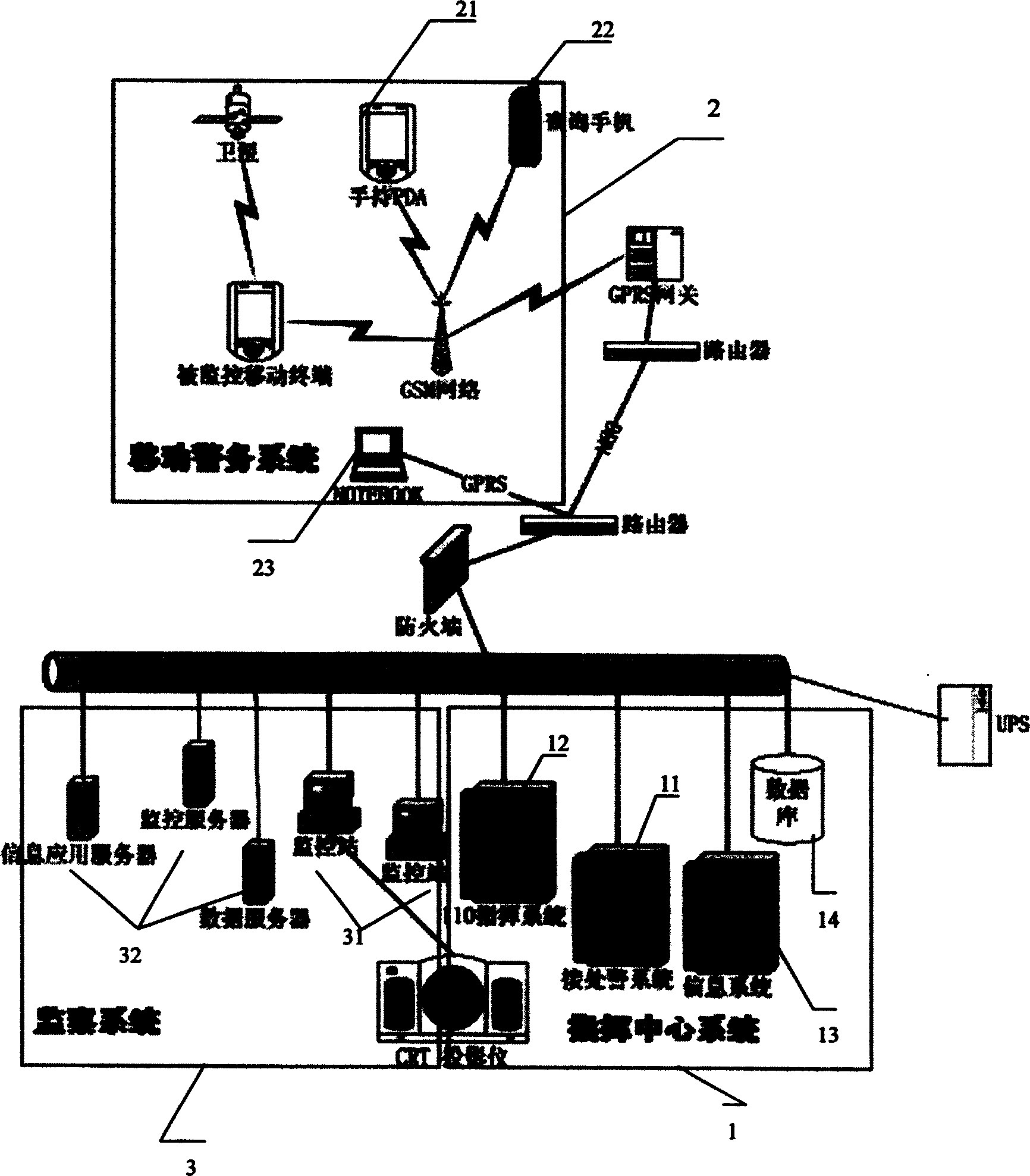

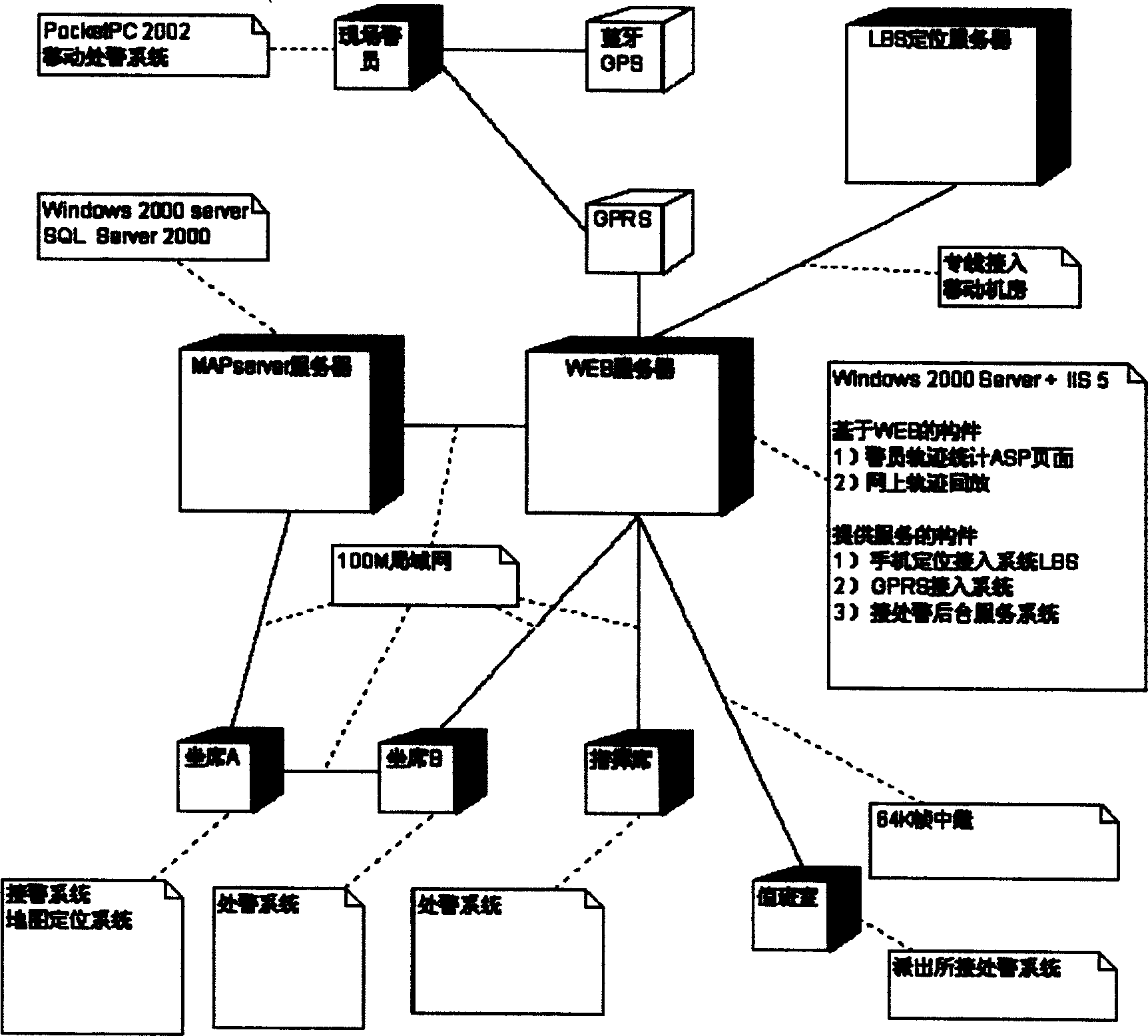

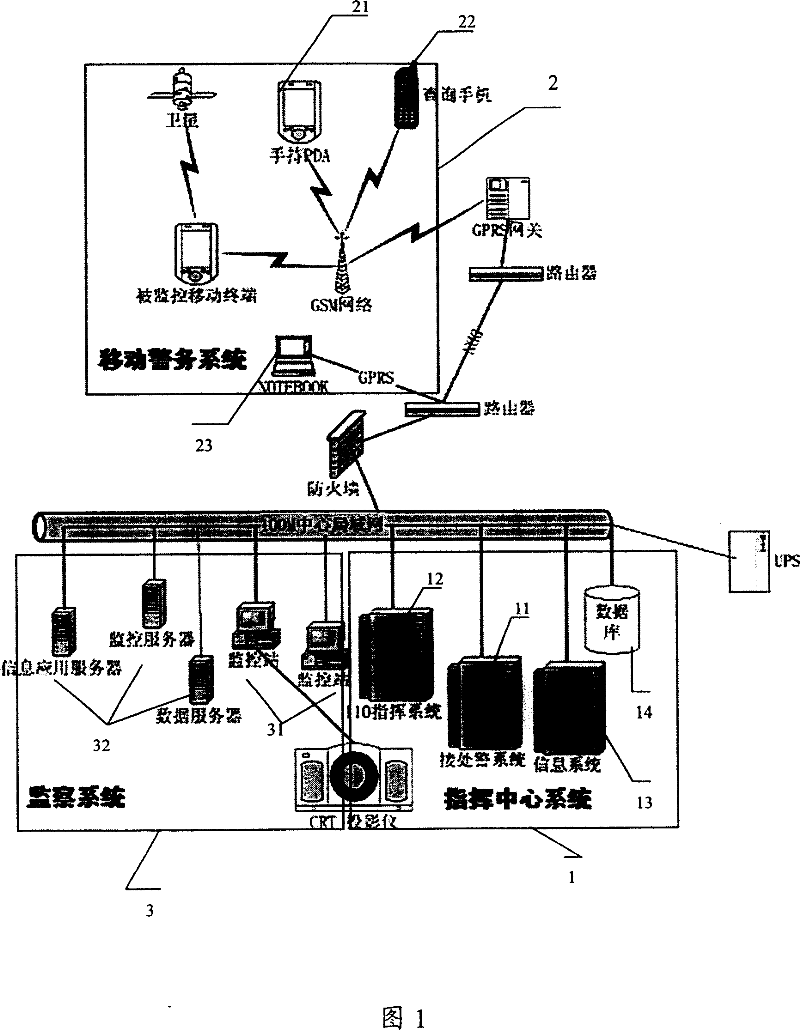

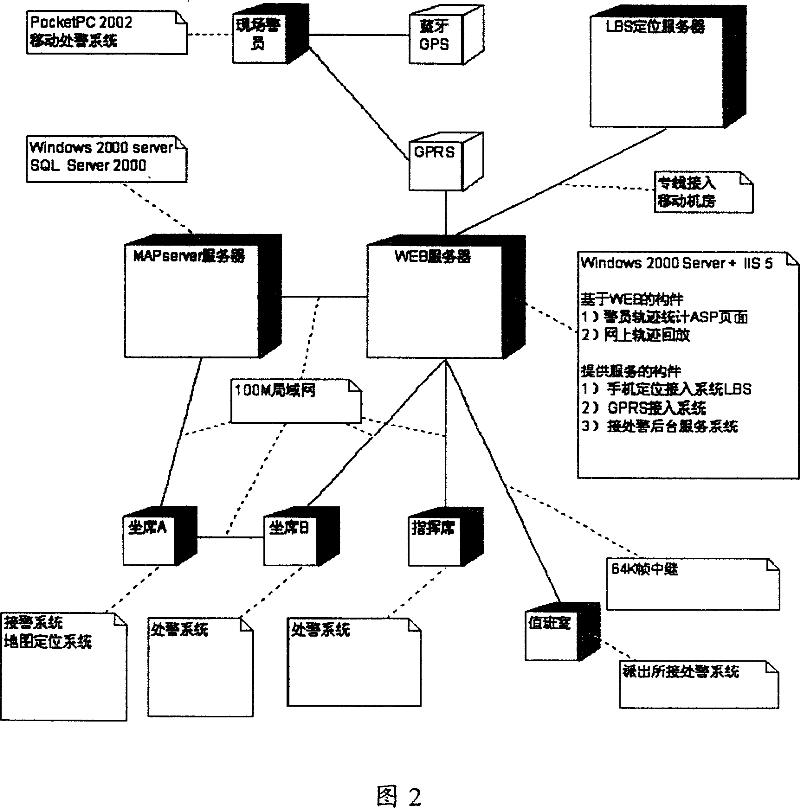

Police strength dispatching arrangement control system

InactiveCN1609883AReduce police timeReduced injuries and casualtiesSpecial data processing applicationsService systemInformation technology

The police strength dispatching and controlling system includes command center system, mobile police service system and supervision system. The mobile police service system completes the GPS signal receiving and analysis via GPS and universal grouped radio service network, GPRS network signal connection and police service treatment, and returning the GPS information to the command center system. The supervision system is used in supervising the information exchange between the mobile police service system and the command center system and the information exchange inside the command center system. The present invention may be used widely for various classifications of police, and has the advantages of low cost, high practicability, high performance / cost ratio, etc.

Owner:深圳市公安局龙岗分局 +1

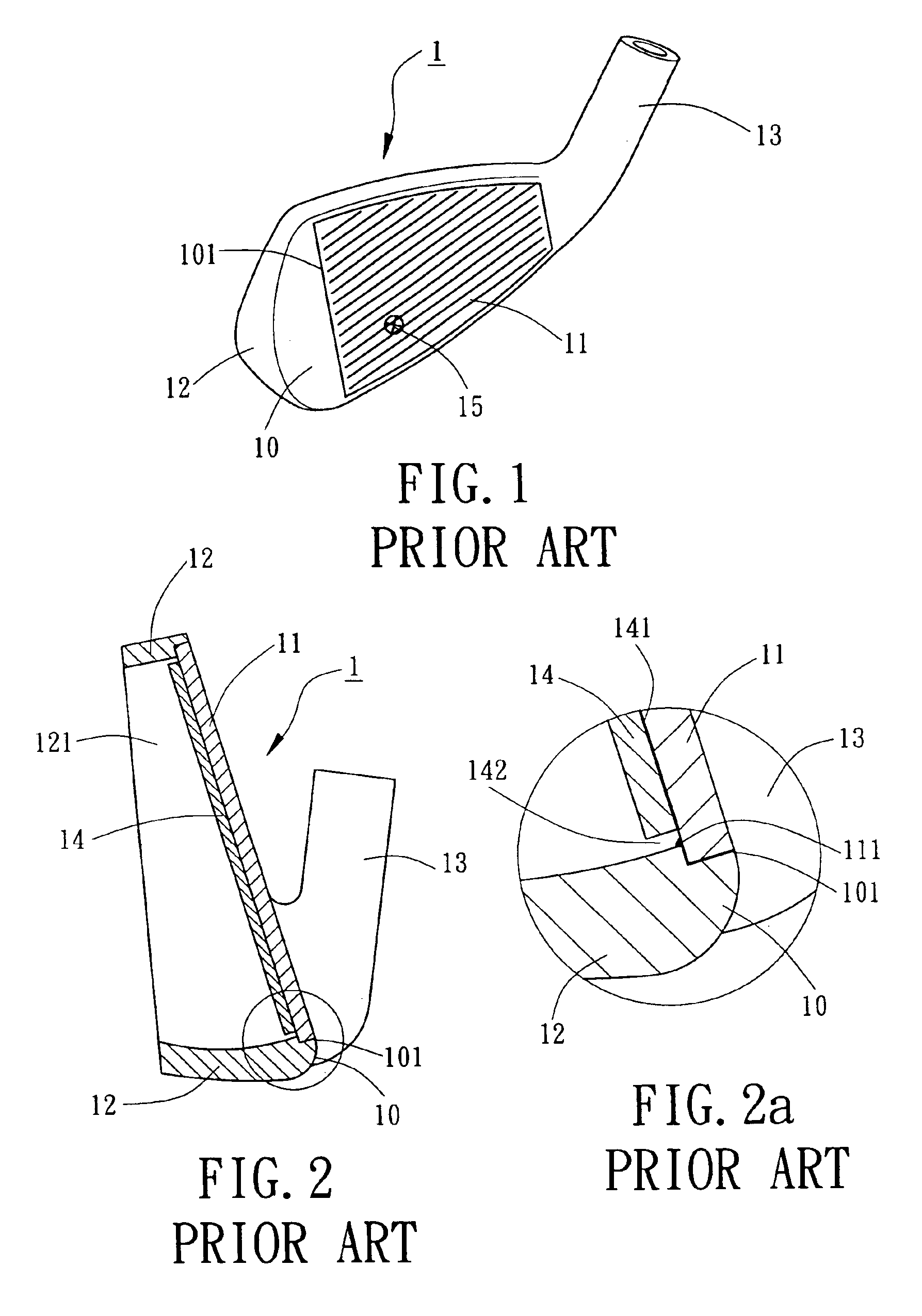

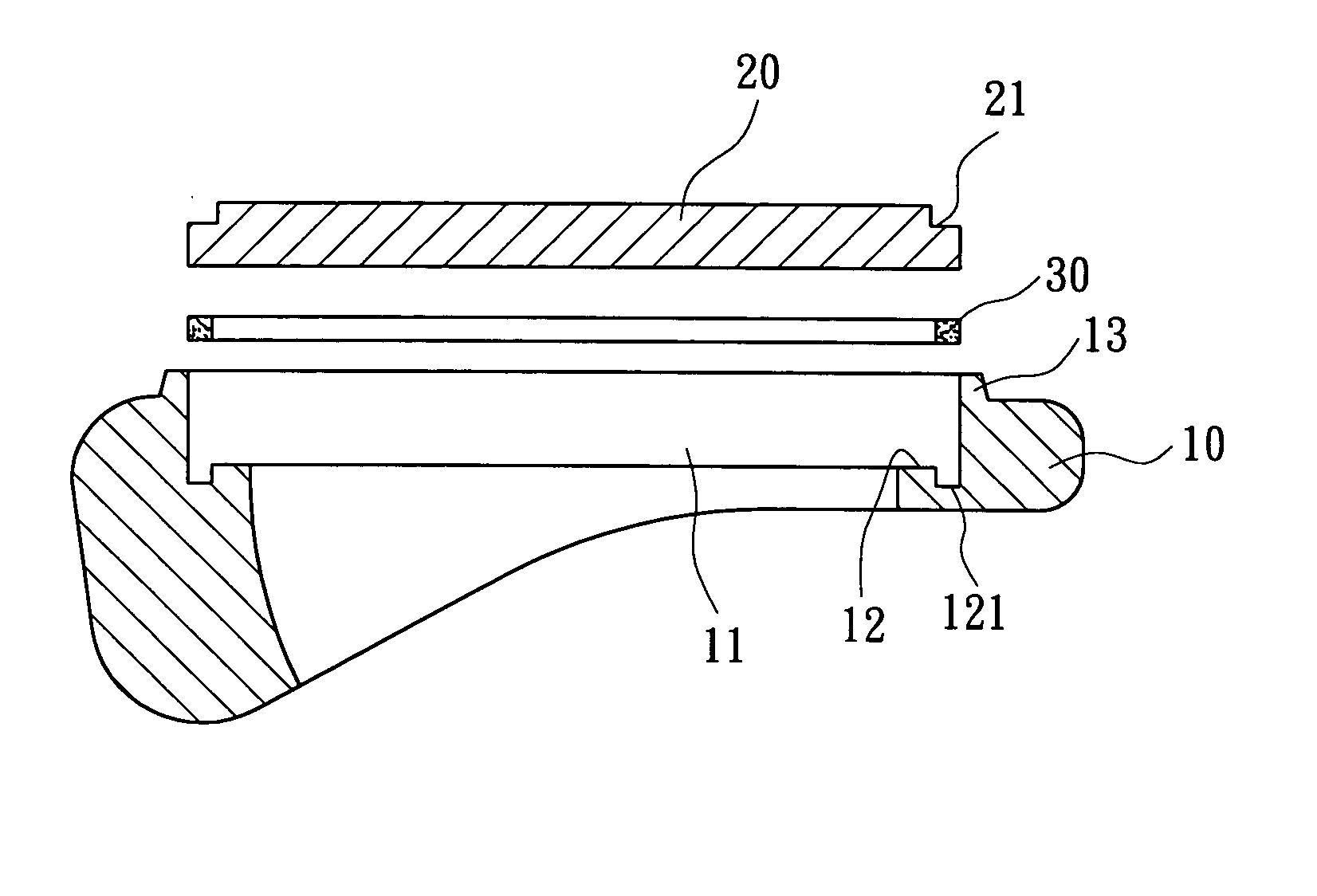

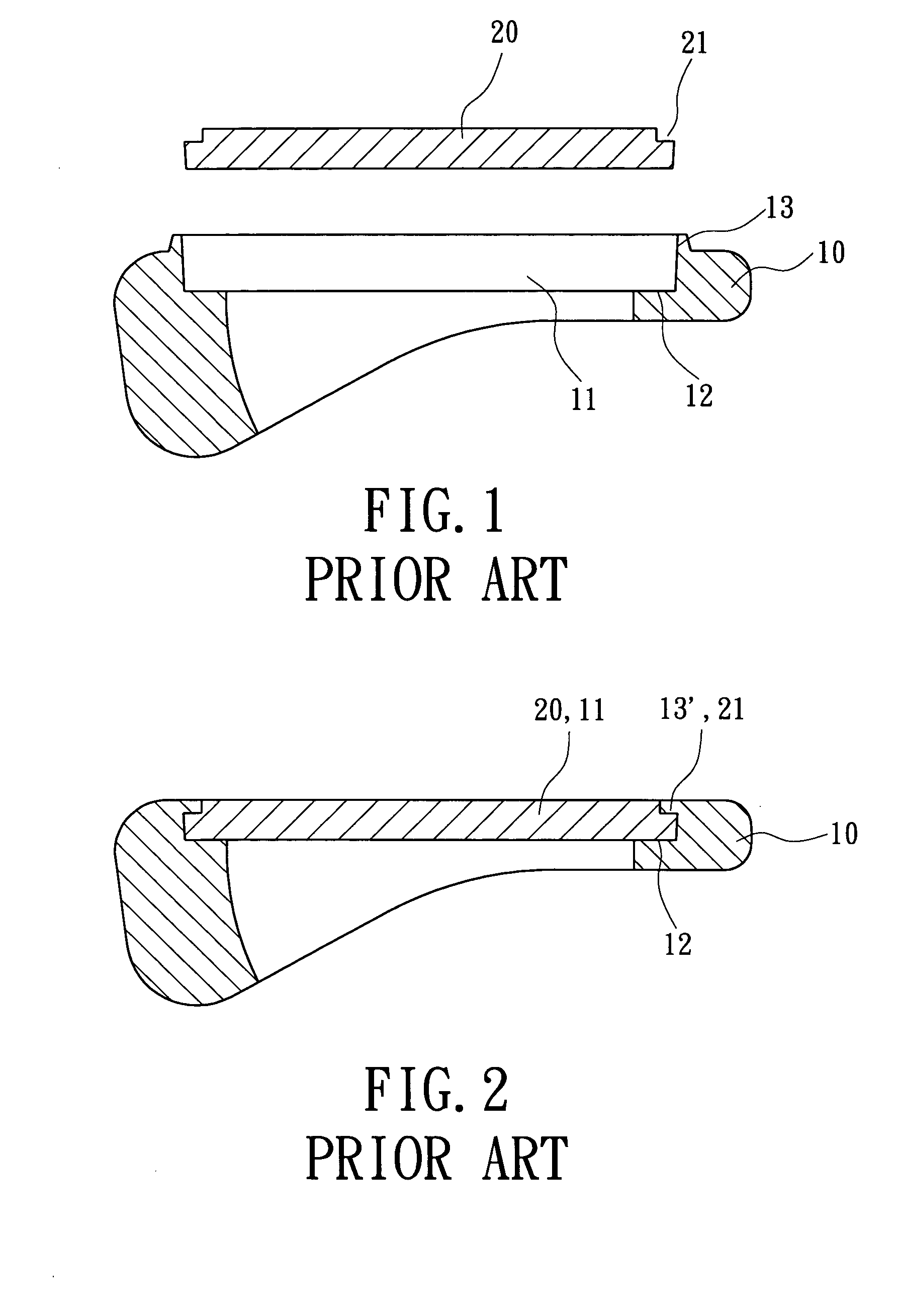

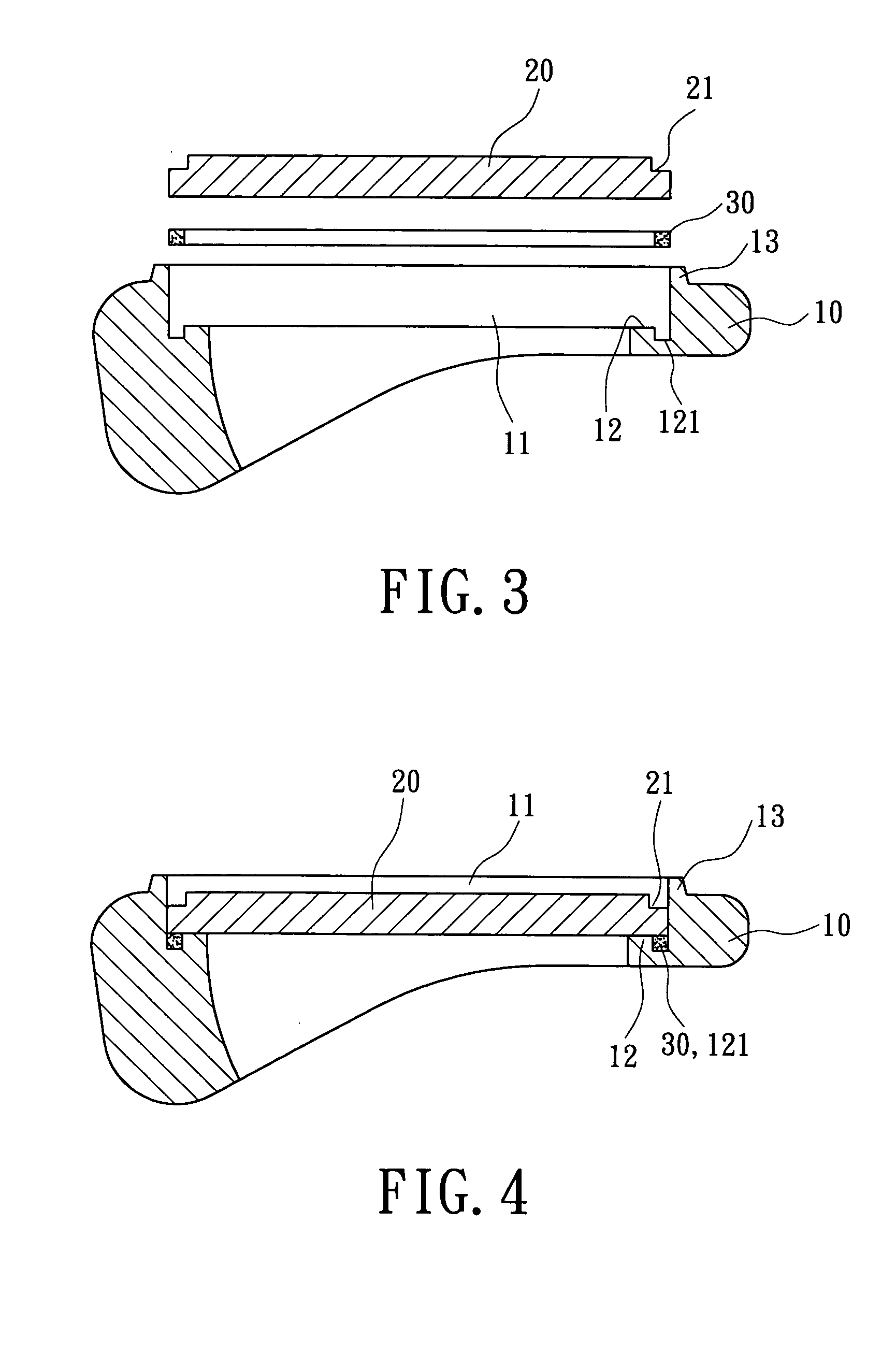

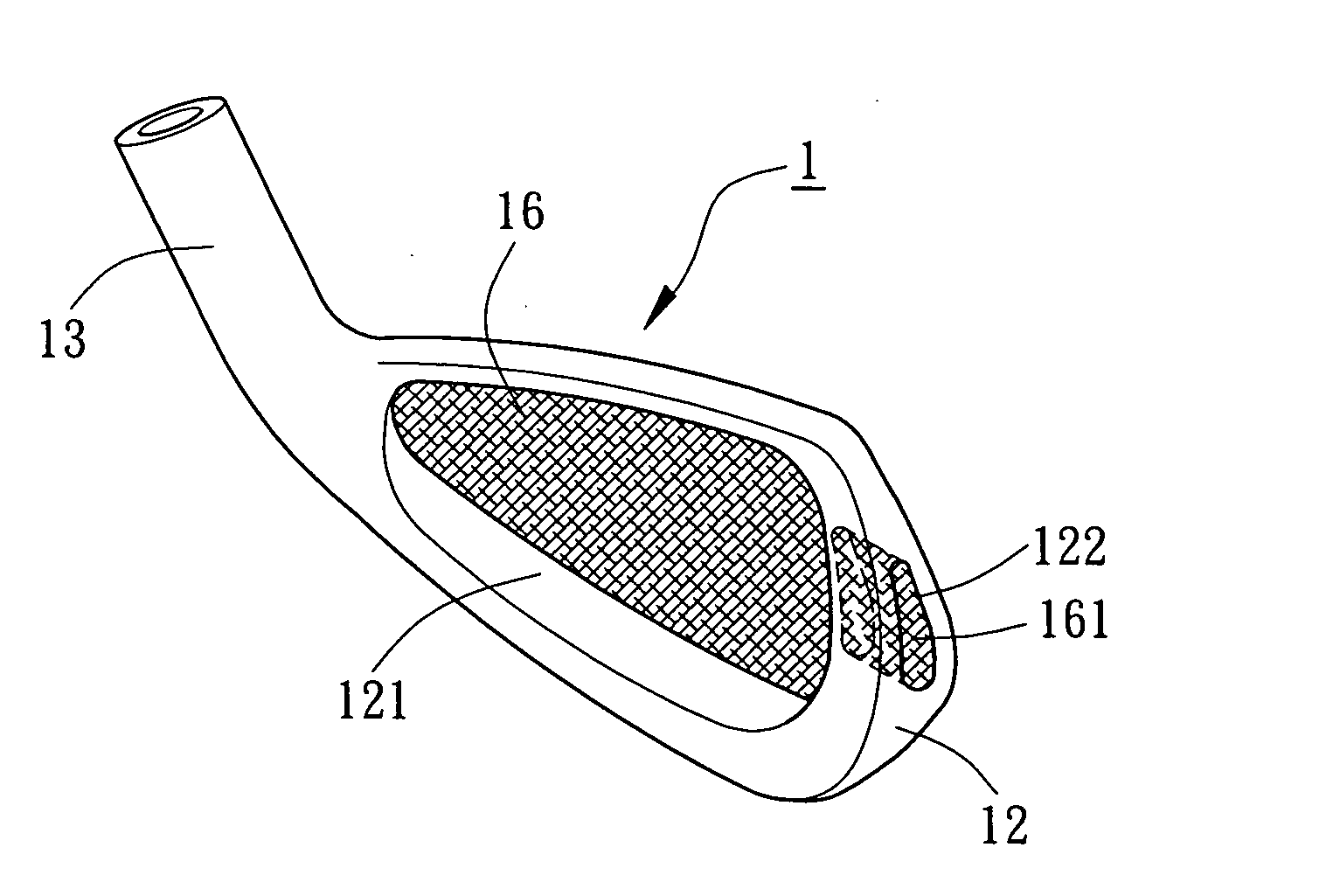

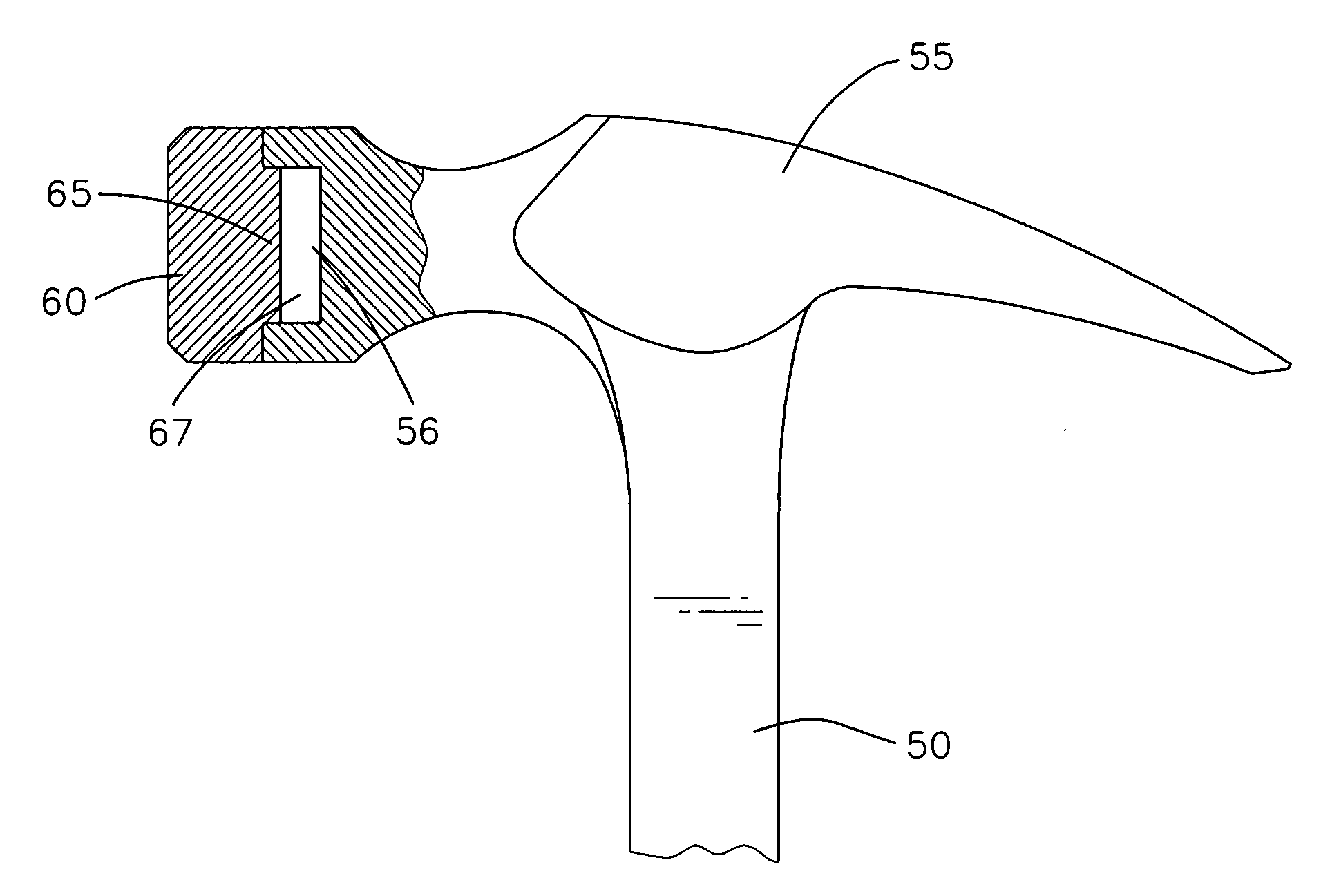

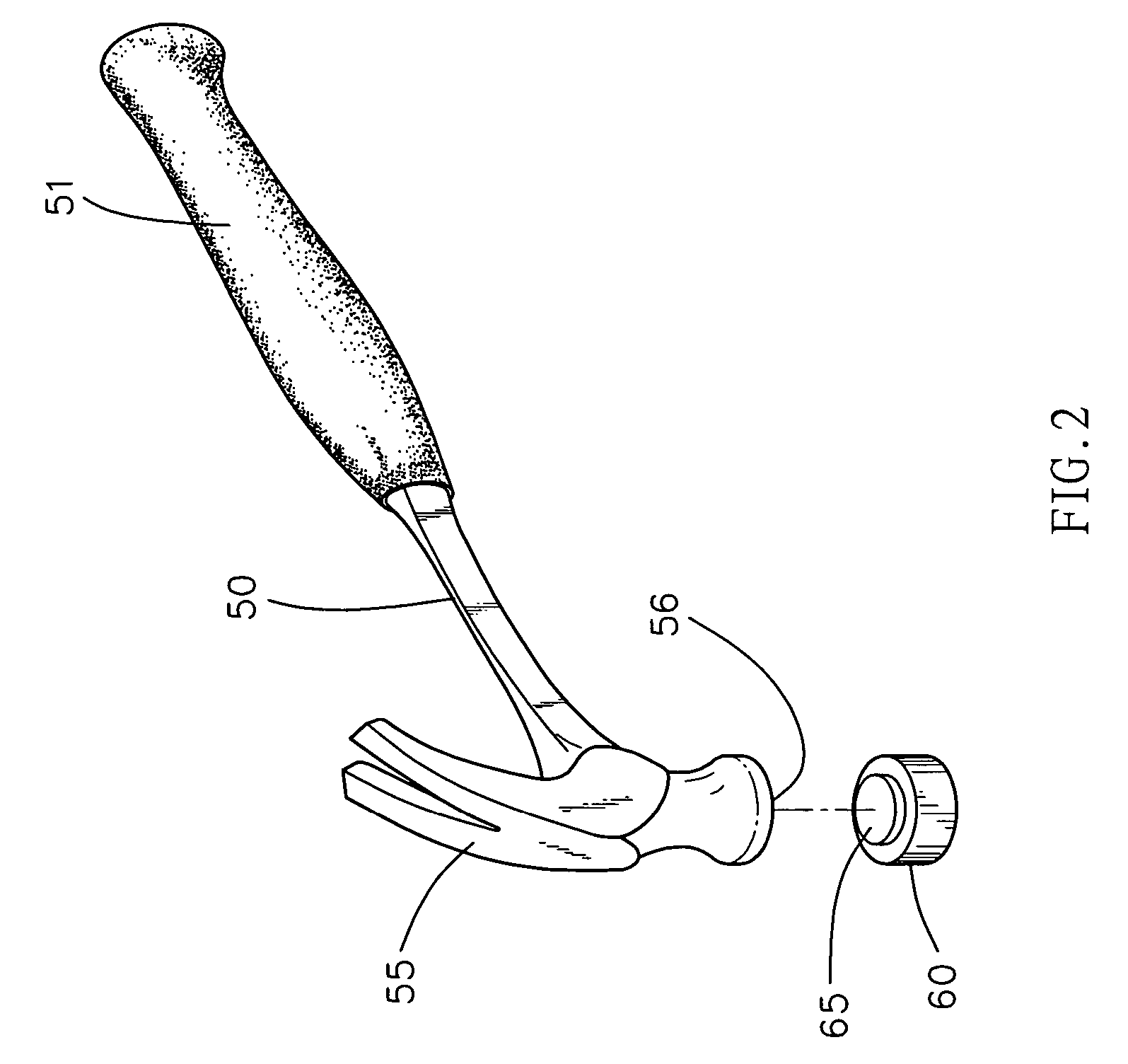

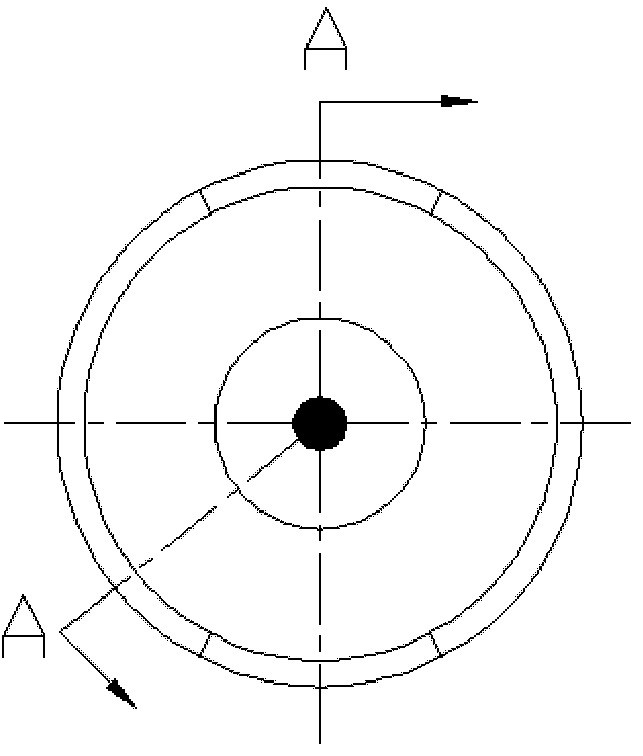

Connecting structure for a striking plate of a golf club head

A golf club head includes a golf club head body, a ring, and a striking plate. The golf club head body includes a recession in a side thereof, the recession including a shoulder on an inner peripheral edge thereof. The ring is mounted on the shoulder of the golf club head body. The striking plate is mounted in the recession of the golf club head body and securely engaged with the ring, with the ring supporting a rear side of the striking plate. The striking plate and the golf club head body have a relatively small contact area therebetween to thereby reduce an amount of the striking stress of the striking plate absorbed by the golf club head body, thereby assuring high deformability of the striking plate.

Owner:NELSON PRECISION CASTING

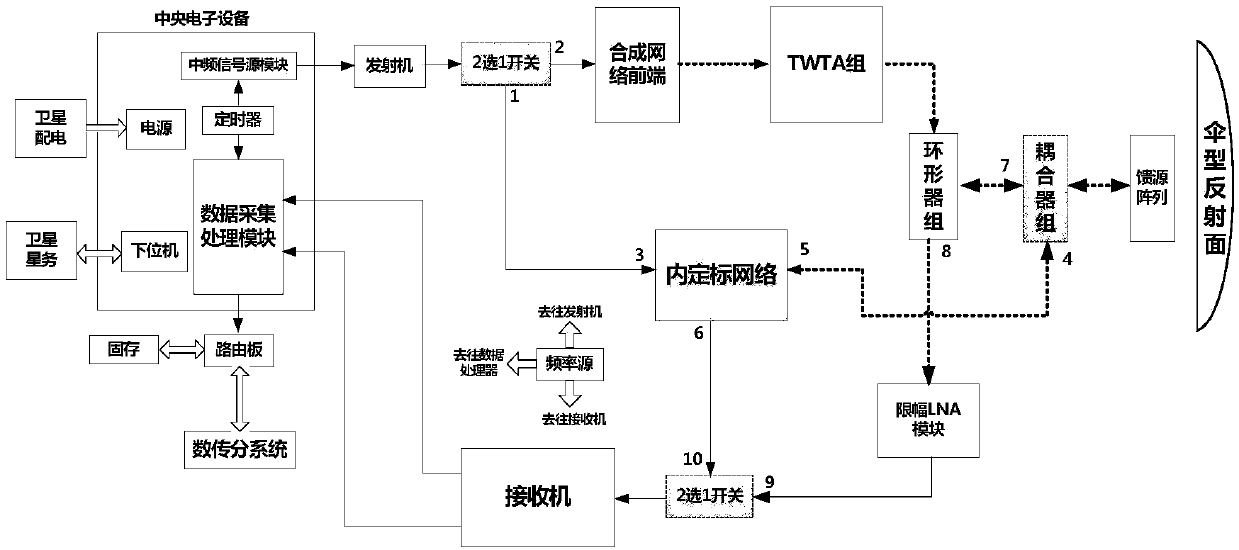

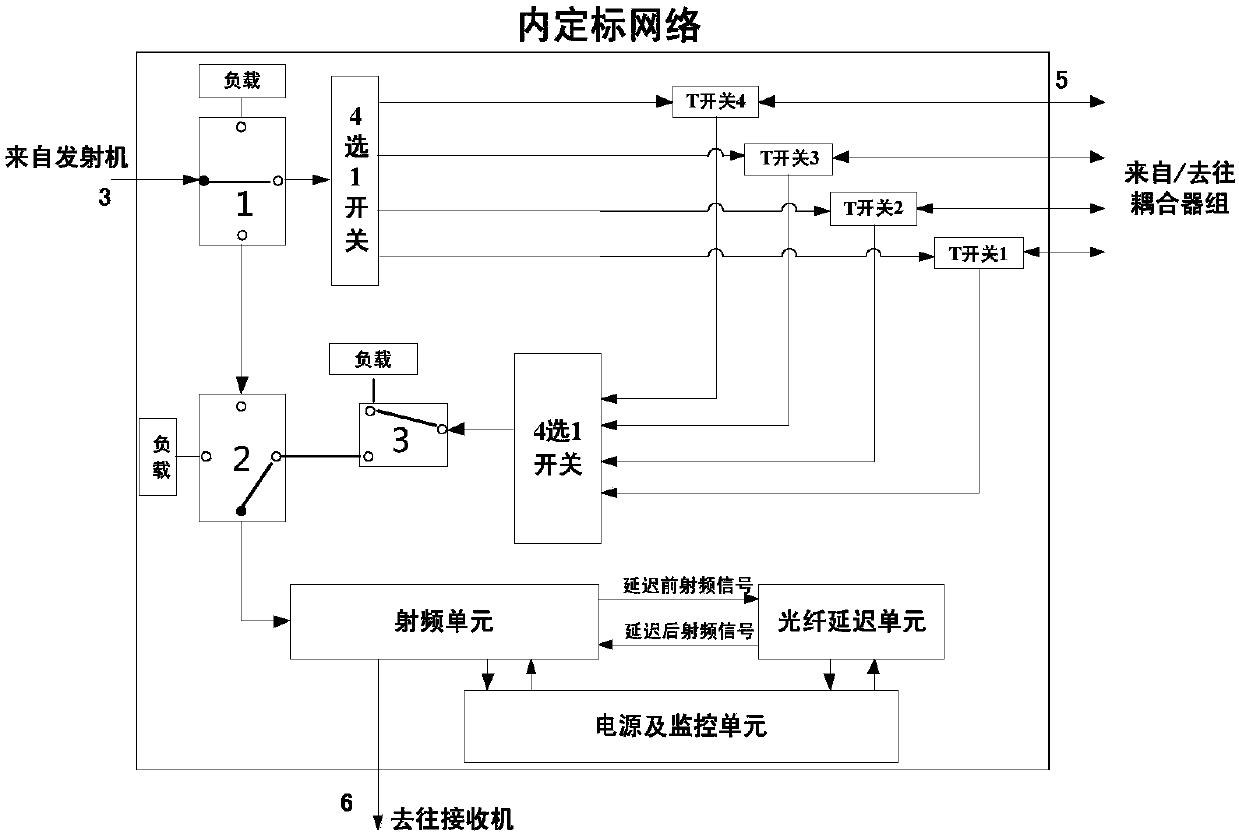

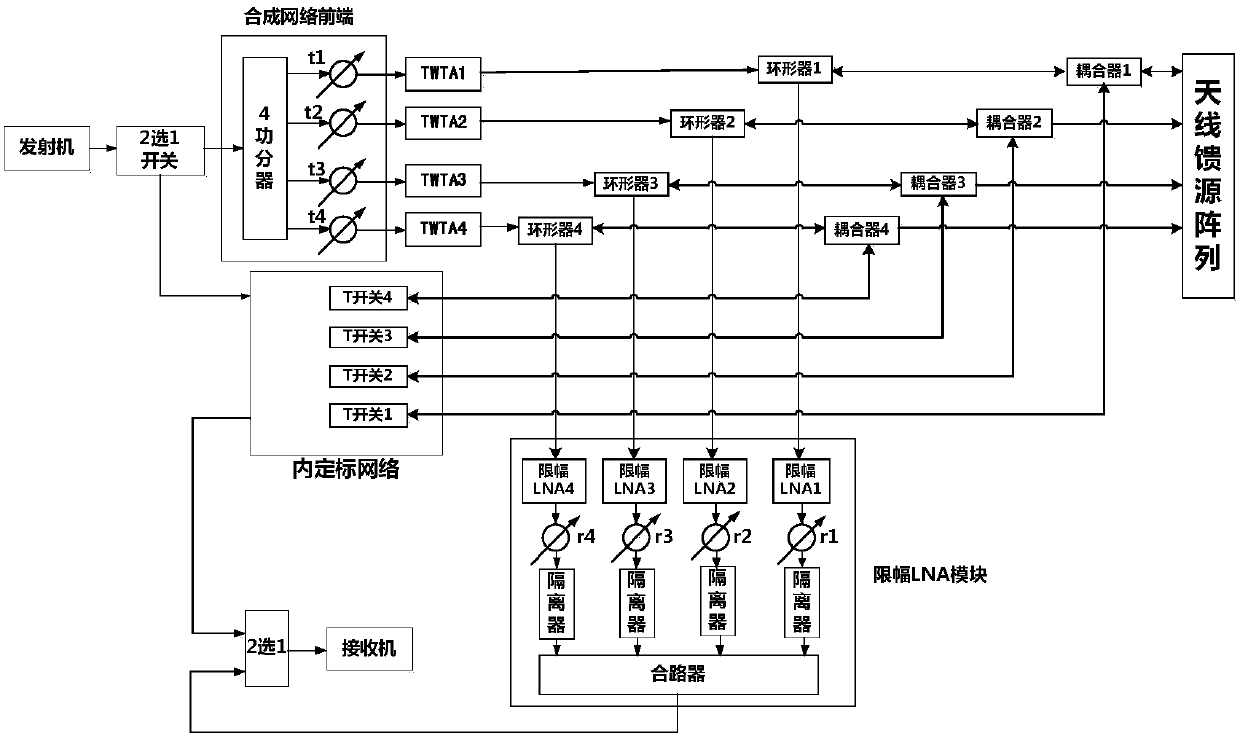

Internal calibration network unit for reflective surface satellite-borne SAR system and internal calibration method

ActiveCN108562880AImprove image signal-to-noise ratioImprove signal-to-noise ratioRadio wave reradiation/reflectionUltra-widebandSignal-to-noise ratio (imaging)

The invention relates to an internal calibration network unit for an SAR system and an internal calibration method matched with the internal calibration network unit, and realizes internal calibrationof an ultra-wideband reflective surface satellite-borne SAR by adding the internal calibration network unit in the SAR system. According to the invention, a purpose of improving an SAR imaging effectis achieved by correcting a channel deviation to increase a signal-to-noise ratio of an SAR image; calibration of magnitude-phase characteristics of all transmitting channels and receiving channels can be realized by using an internal calibration network; firstly, phase calibration is performed by transmitting dot frequency pulse signals to ensure phase consistency; and then, channel magnitude-phase characteristics of sweep-frequency pulse signals are transmitted to ensure accuracy of the calibration.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

Golf club head

InactiveUS20050096150A1Increase inertial momentImprove striking effectGolf clubsRacket sportsEngineeringGolf club

A golf club head includes a golf club head body, a striking plate mounted to a front side of the golf club head body, and a perimeter wall extending rearward along a perimeter of the golf club head body. At least one hole is defined in a toe of the perimeter wall to reduce the weight of the upper part of the golf club head body, thereby shifting the center of gravity of the golf club head downward toward the heel and thereby increasing the inertial moment of the golf club head.

Owner:FUSHENG PRECISION

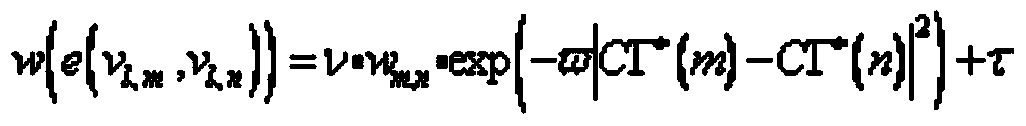

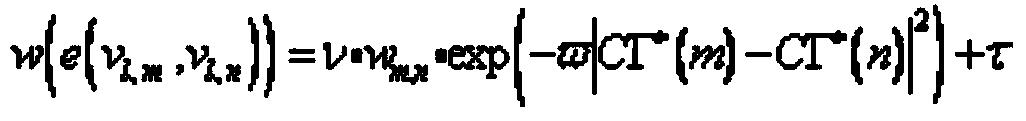

Method for optimizing multilayer image segmentation of multiclass color texture images based on variation model

InactiveCN104091332AStrong edge detection capabilityStrong interferenceImage analysisPattern recognitionColor texture

The invention discloses a method for optimizing double-layer image segmentation of multiclass color texture images based on a variation model. The method comprises the steps of establishing a multiclass variation active contour model, obtaining an energy function of the multiclass variation active contour model, carrying out disperse expression on the energy function of the multiclass variation active contour model, establishing a multilayer image segmentation model, solving the energy function of the multiclass variation active contour model after disperse expression to obtain a globally near optimal solution, and carrying out multi-layer image segmentation minimality optimization on multiclass disperse variation active contour energy in an iteration mode to achieve stable segmentation.

Owner:HUANGHE S & T COLLEGE

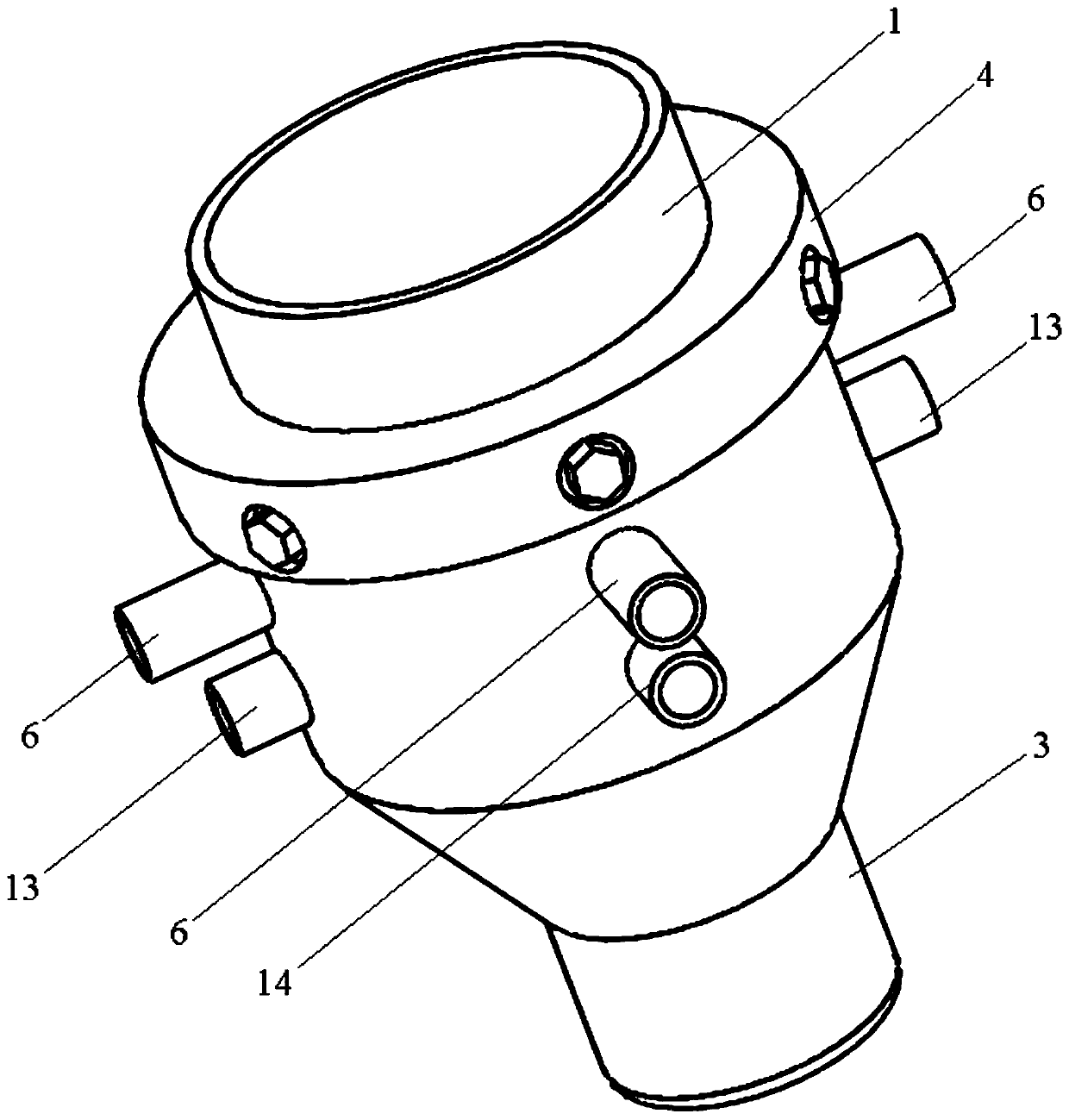

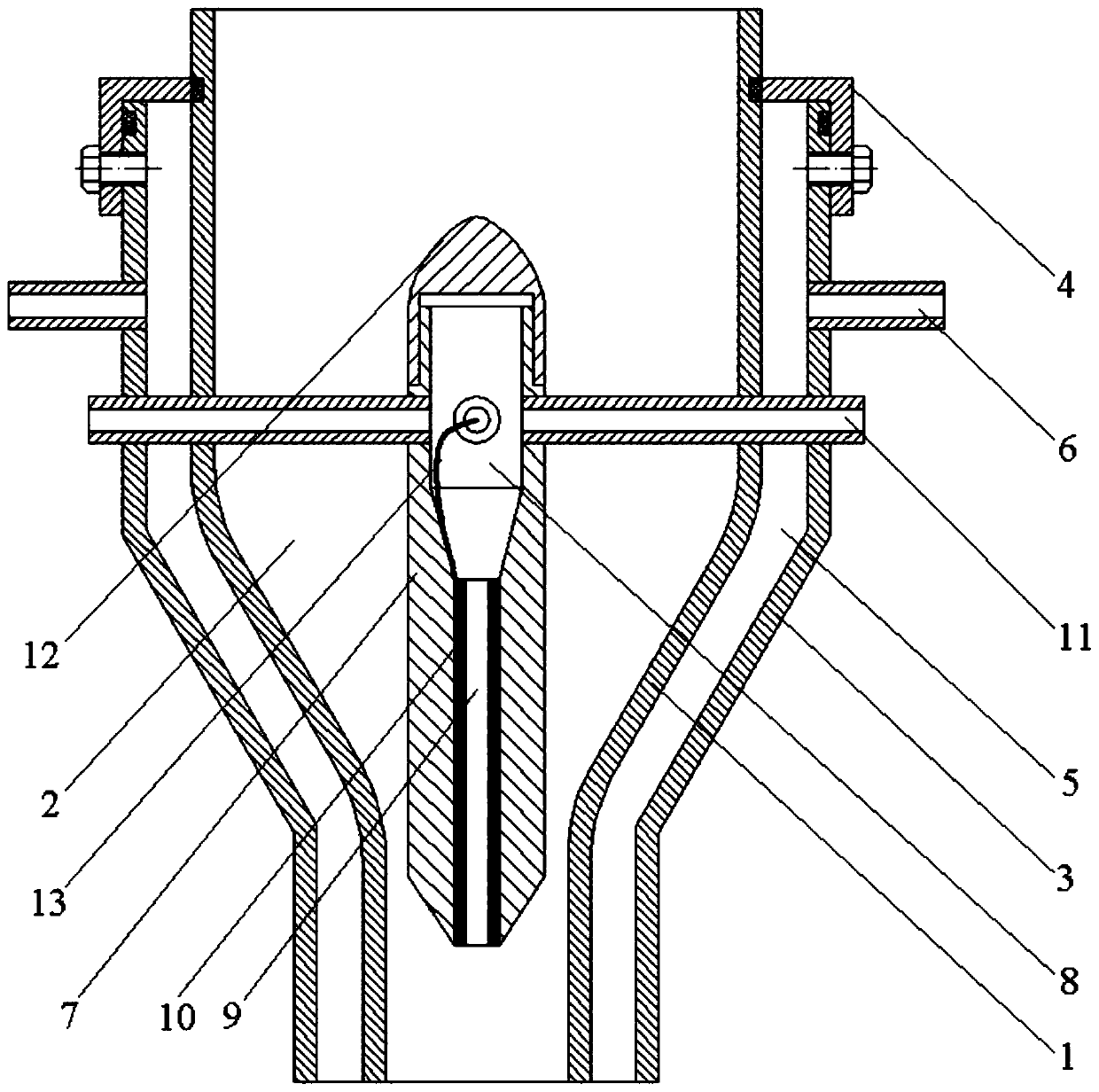

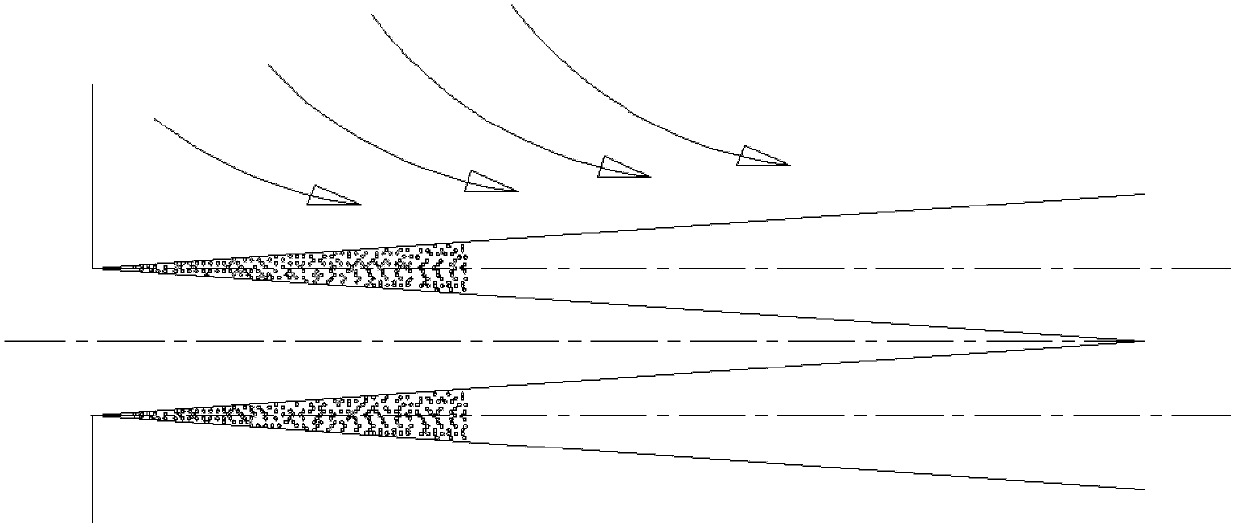

Efficient double-cavitation abrasive material jet flow nozzle

The invention relates to an efficient double-cavitation abrasive material jet flow nozzle. The efficient double-cavitation abrasive material jet flow nozzle comprises a high-pressure nozzle, a low-pressure nozzle, a center body main body and two connecting pipes which are oppositely arranged left and right. The interior of the high-pressure nozzle is hollow along the axis of the high-pressure nozzle, and a high-pressure cavity is formed. The high-pressure nozzle is coaxially sleeved with the low-pressure nozzle, the high-pressure nozzle and the low-pressure nozzle are connected and sealed through an end cover, and a low-pressure cavity is formed. The low-pressure nozzle is provided with a plurality of fluid inlets at intervals in the ring direction of the low-pressure nozzle, and the fluid inlets communicate with the low-pressure cavity. The center body main body is coaxially sleeved with the high-pressure nozzle, the interior of the center body main body is hollow along the axis of the center body main body, and an abrasive material slurry cavity is formed. One ends of the connecting pipes sequentially penetrate through the high-pressure nozzle, the low-pressure nozzle and the side wall of the center body main body and communicate with the abrasive material slurry cavity. According to the efficient double-cavitation abrasive material jet flow nozzle, the characteristics of low pressure and strong turbulent flow of fluid in the tail area of the center body main body in the high-pressure nozzle are ingeniously utilized, abrasive material slurry and double-cavitation jet flow are sufficiently mixed, accordingly, double-cavitation abrasive material jet flow is formed through mixing, and accordingly the jet flow hitting effect is improved.

Owner:WUHAN UNIV

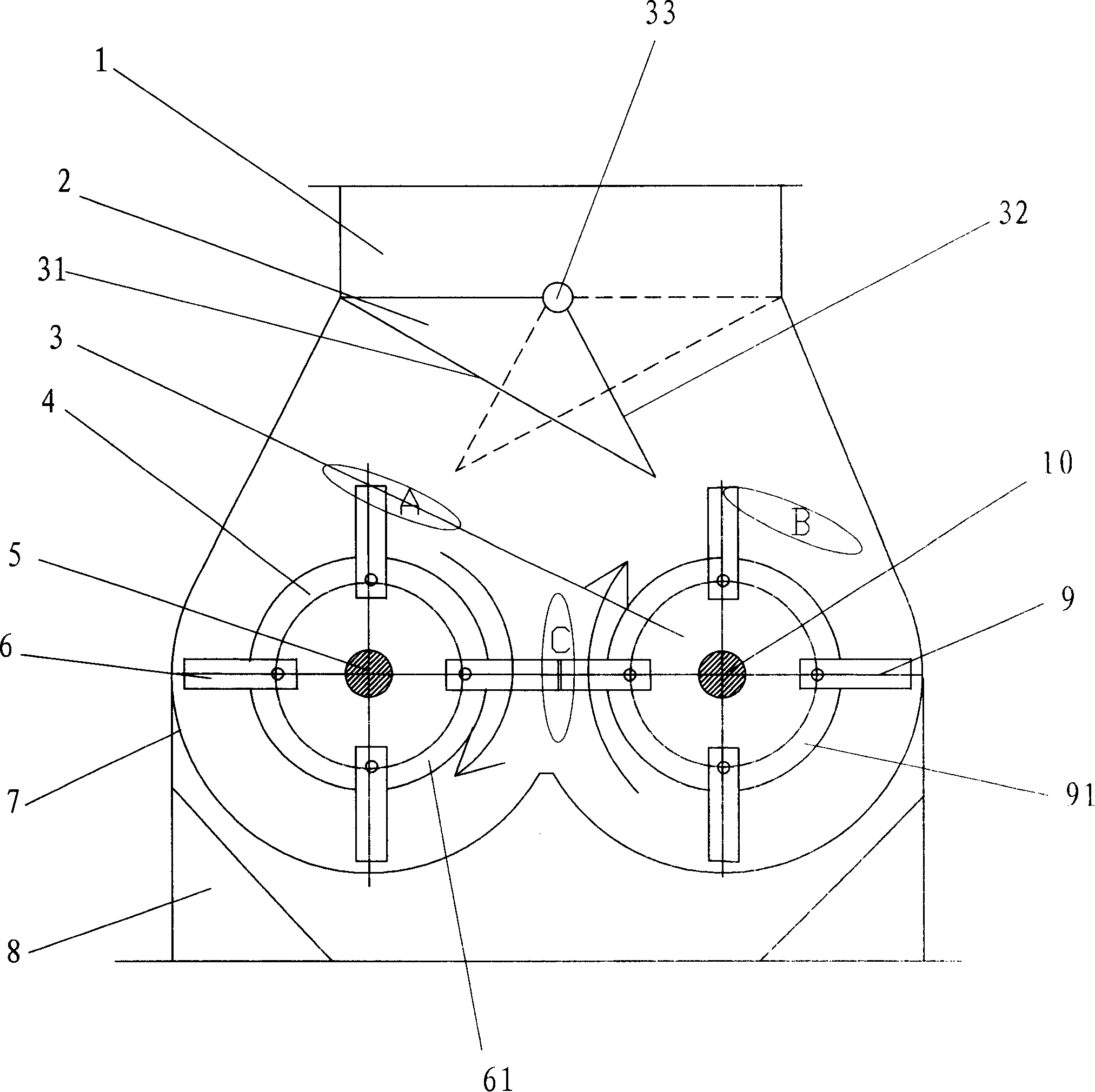

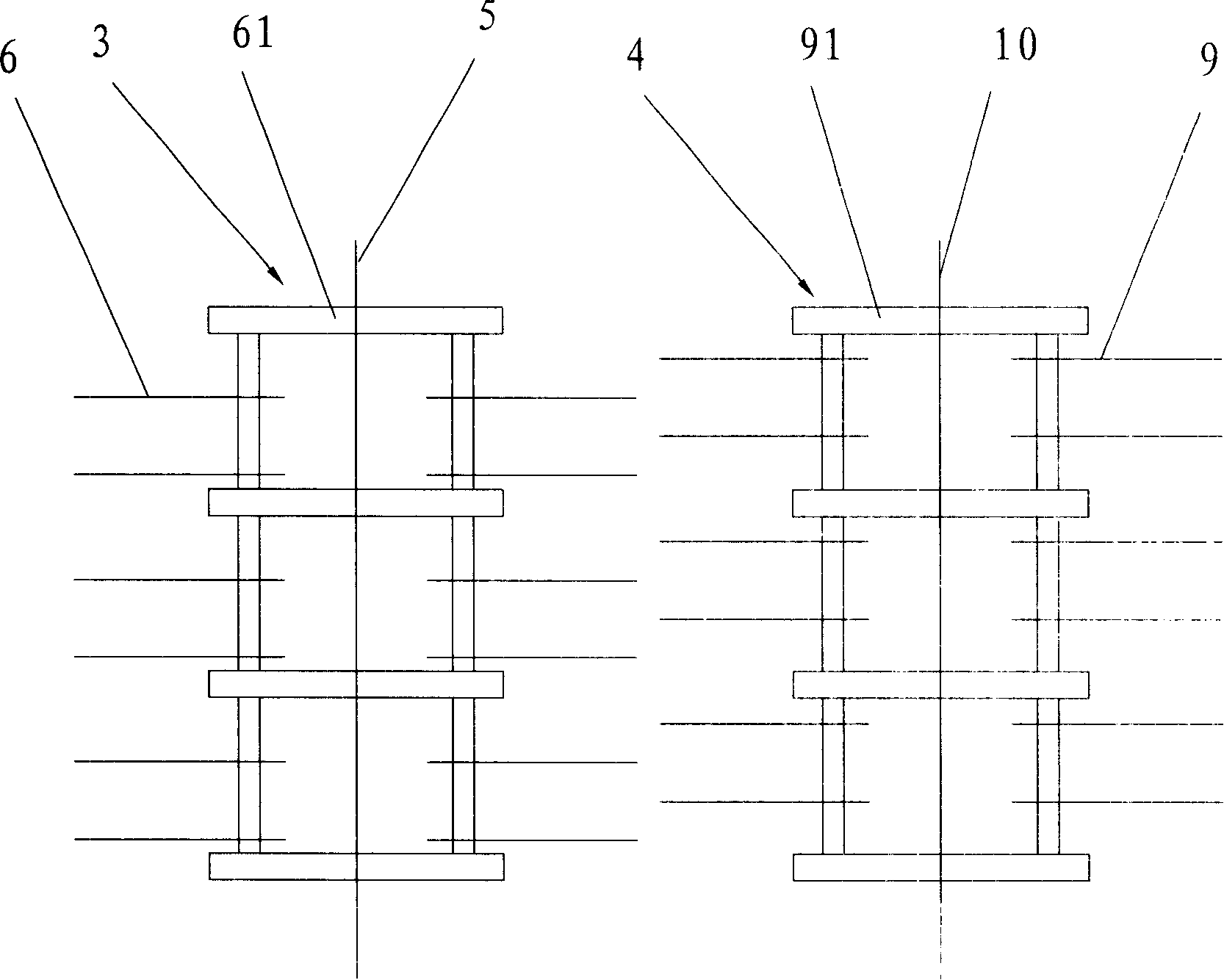

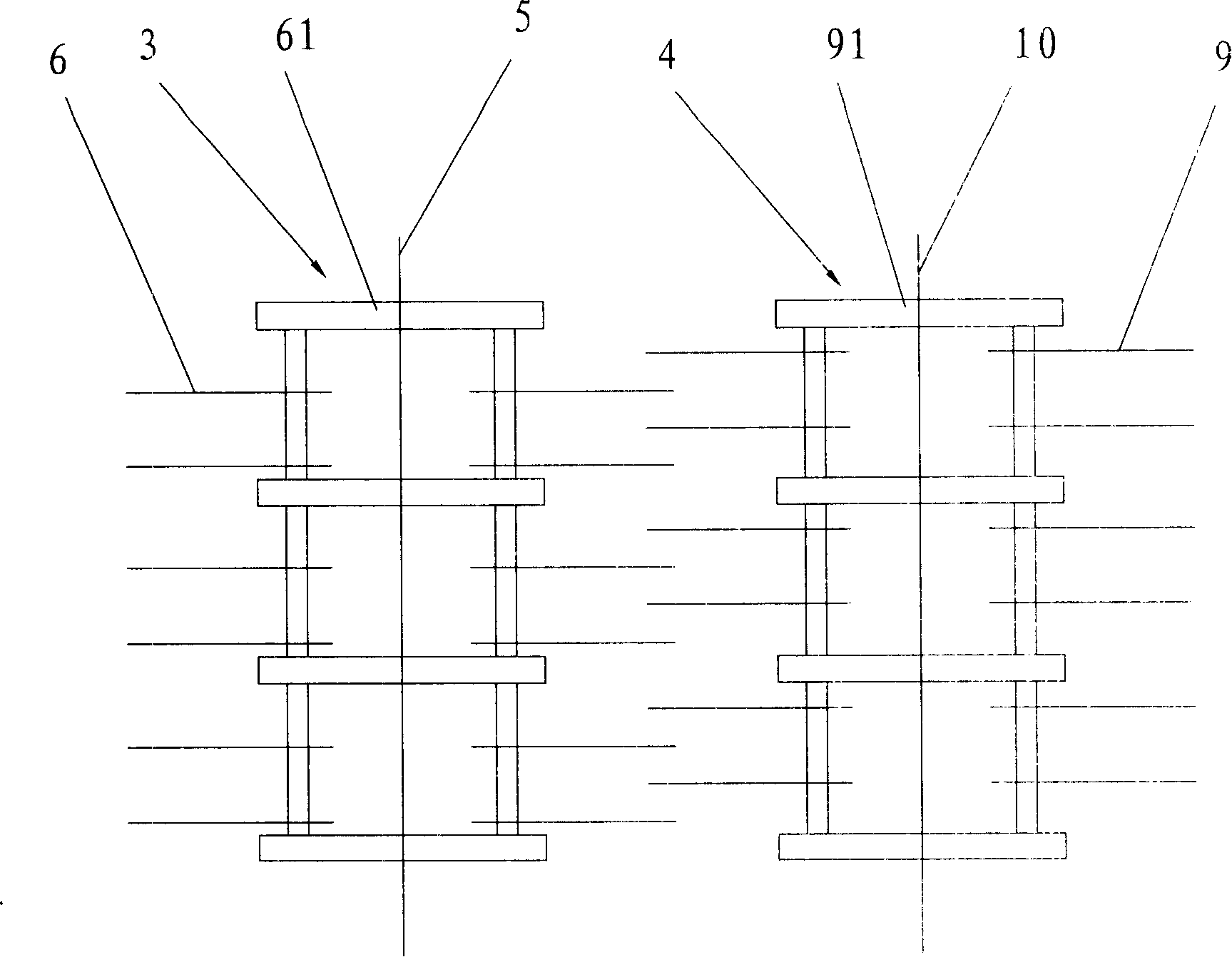

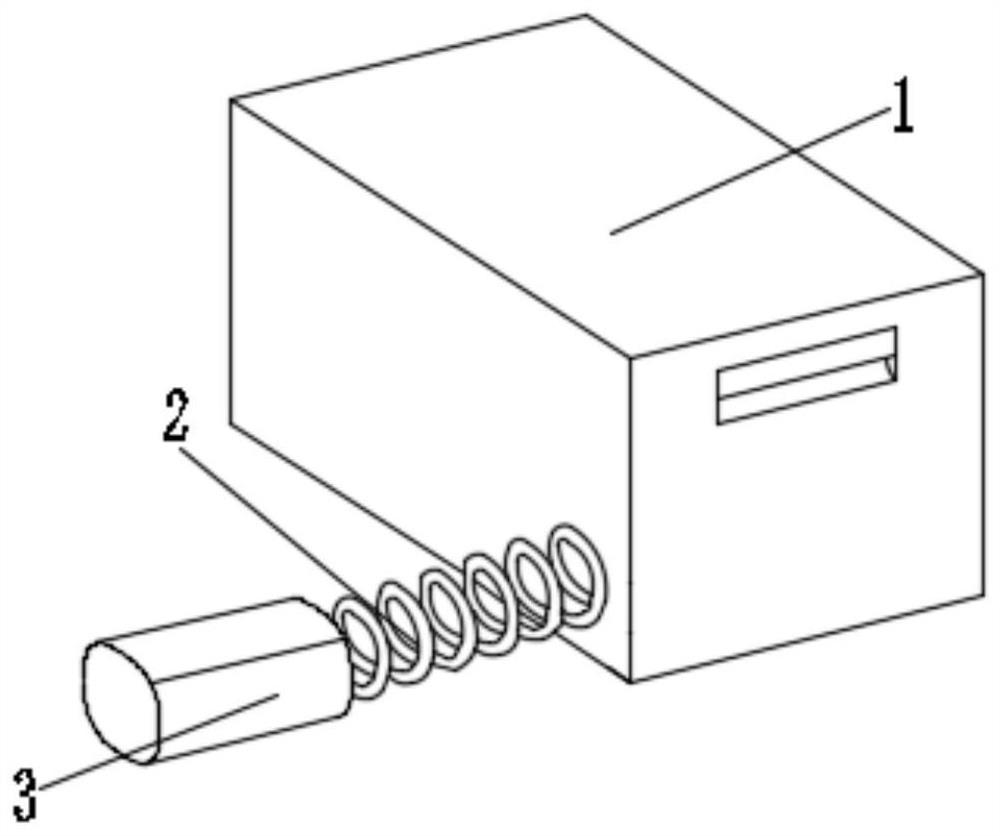

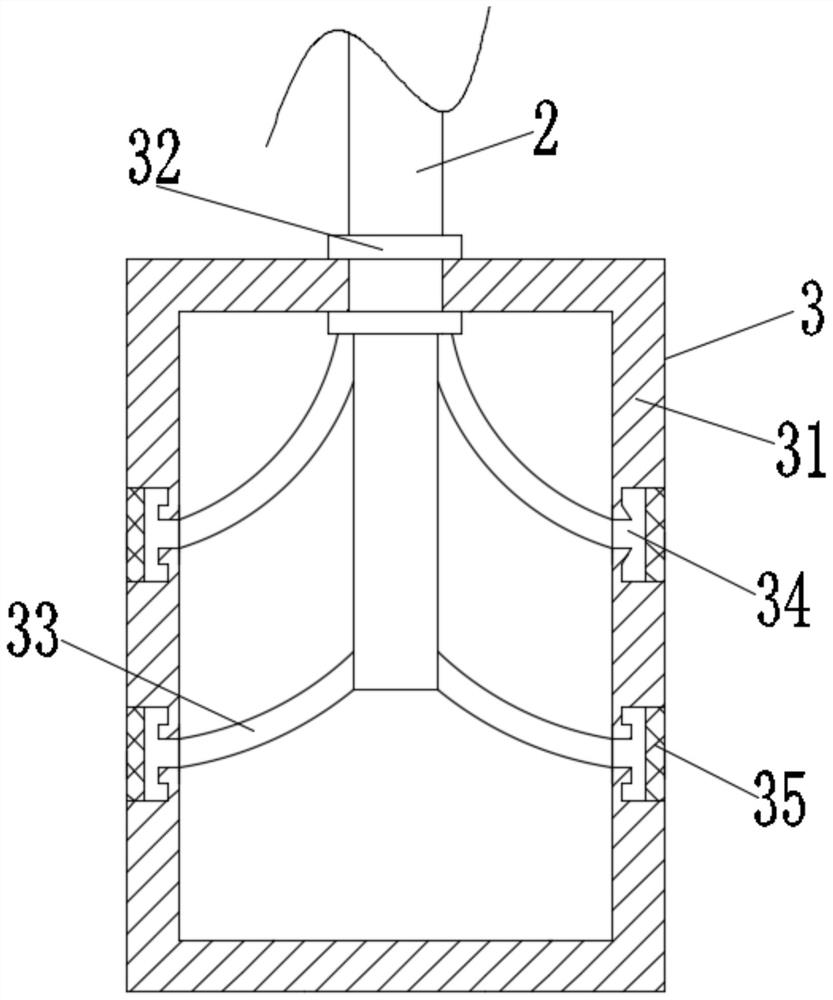

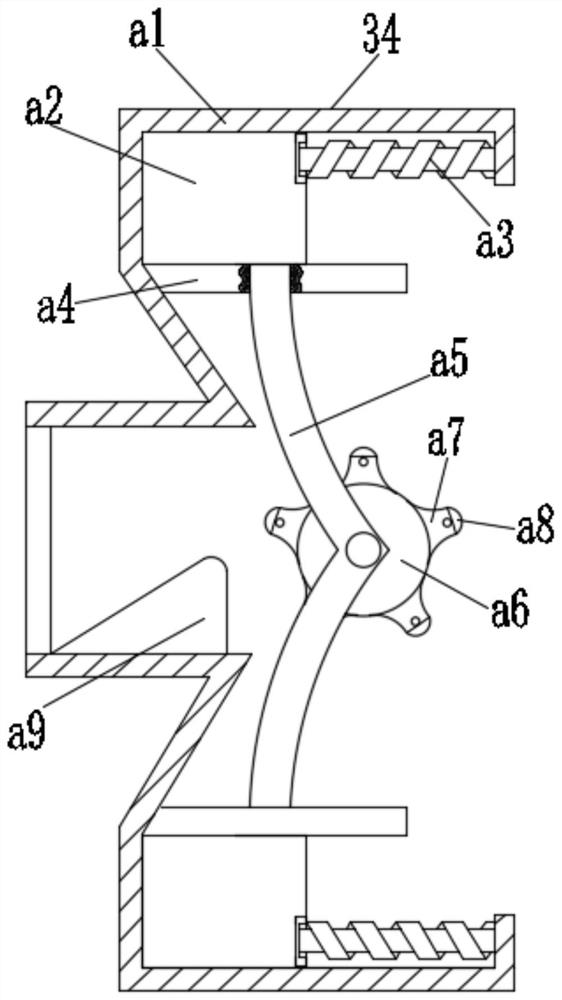

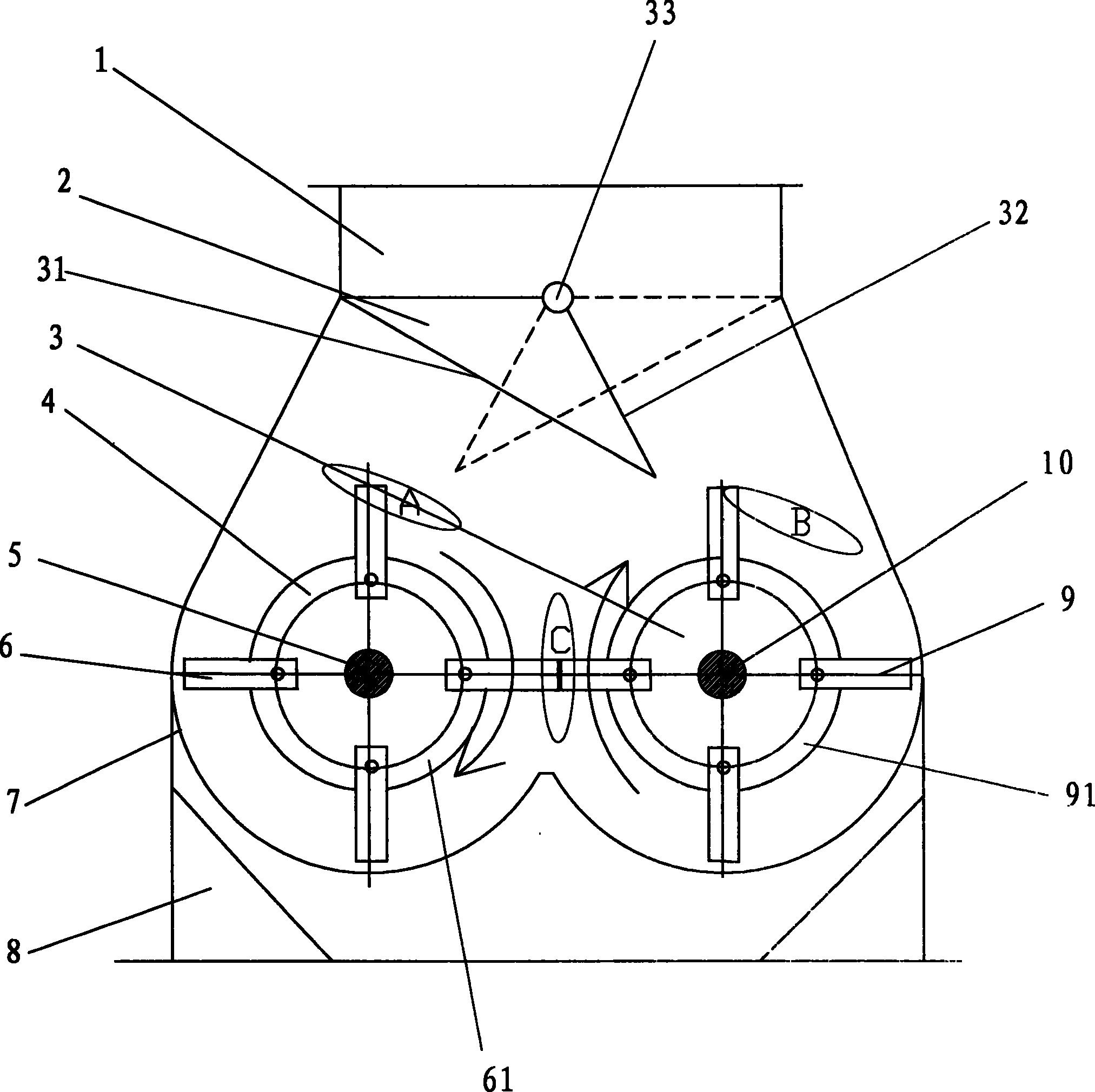

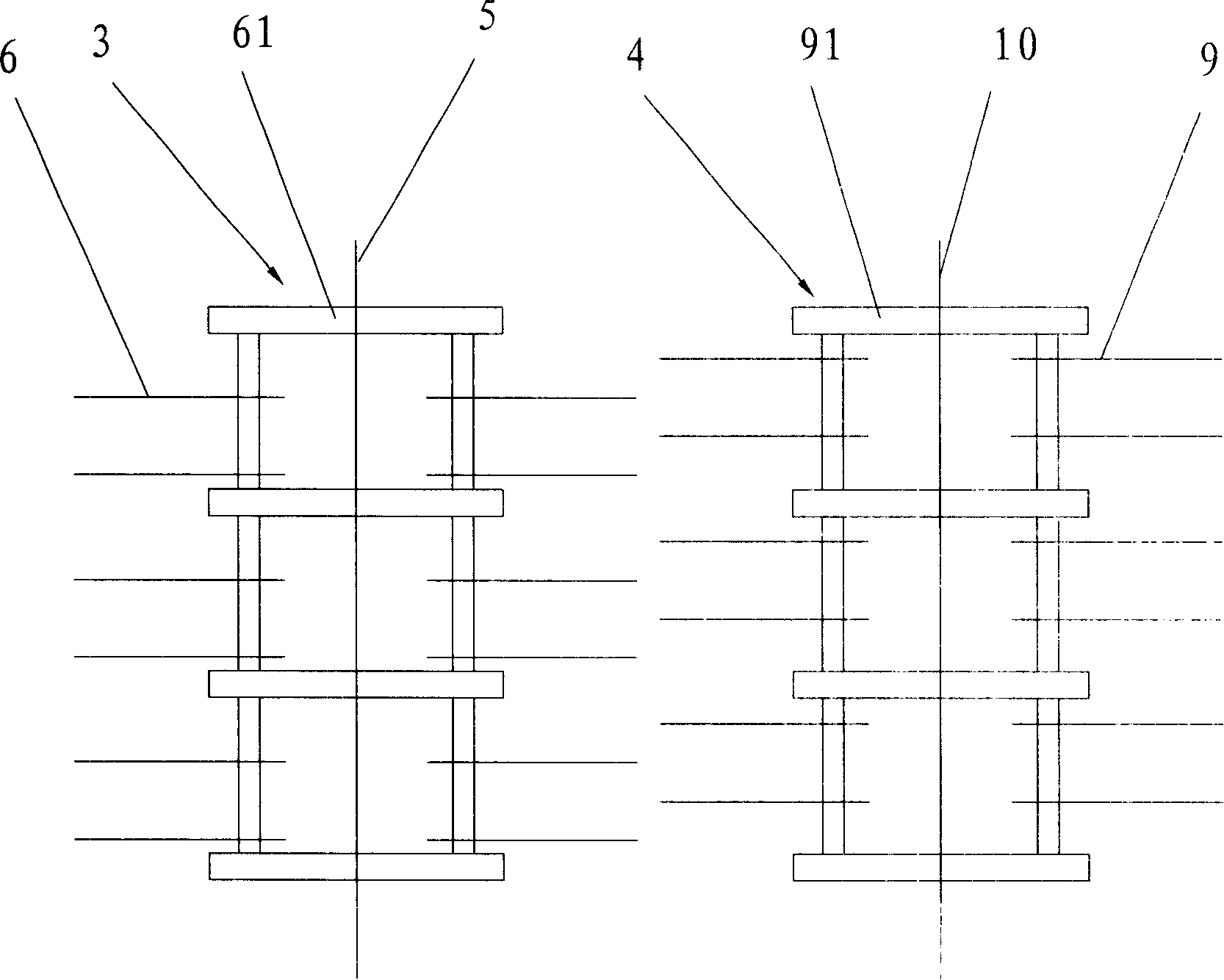

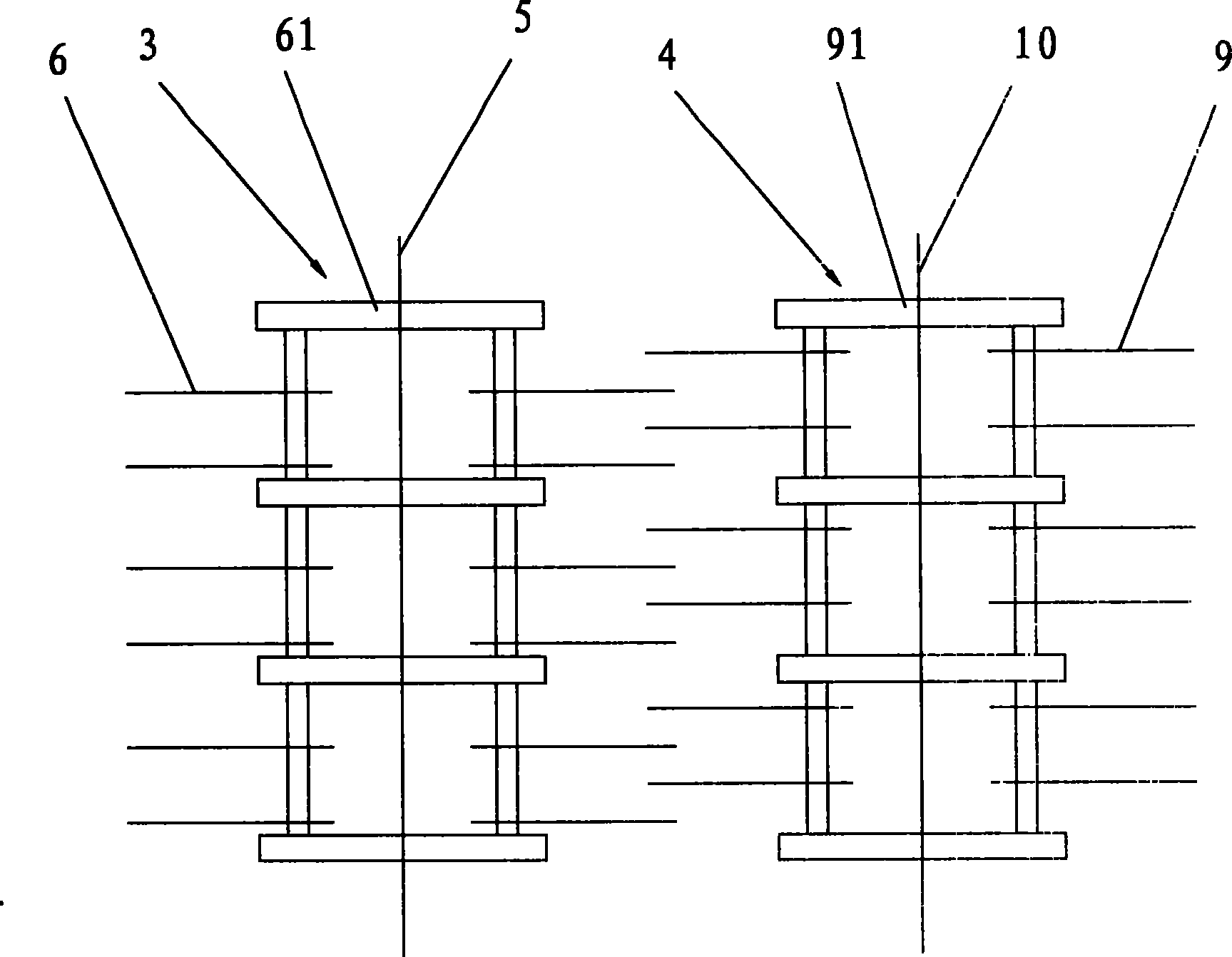

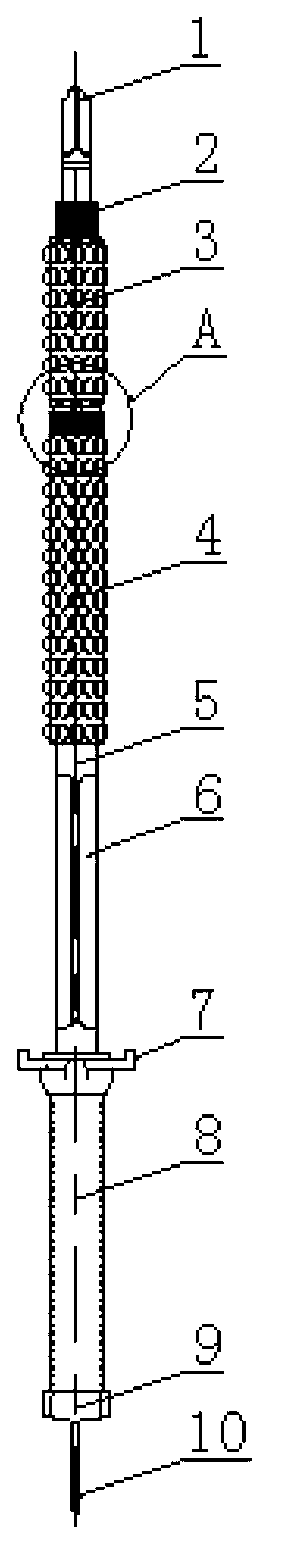

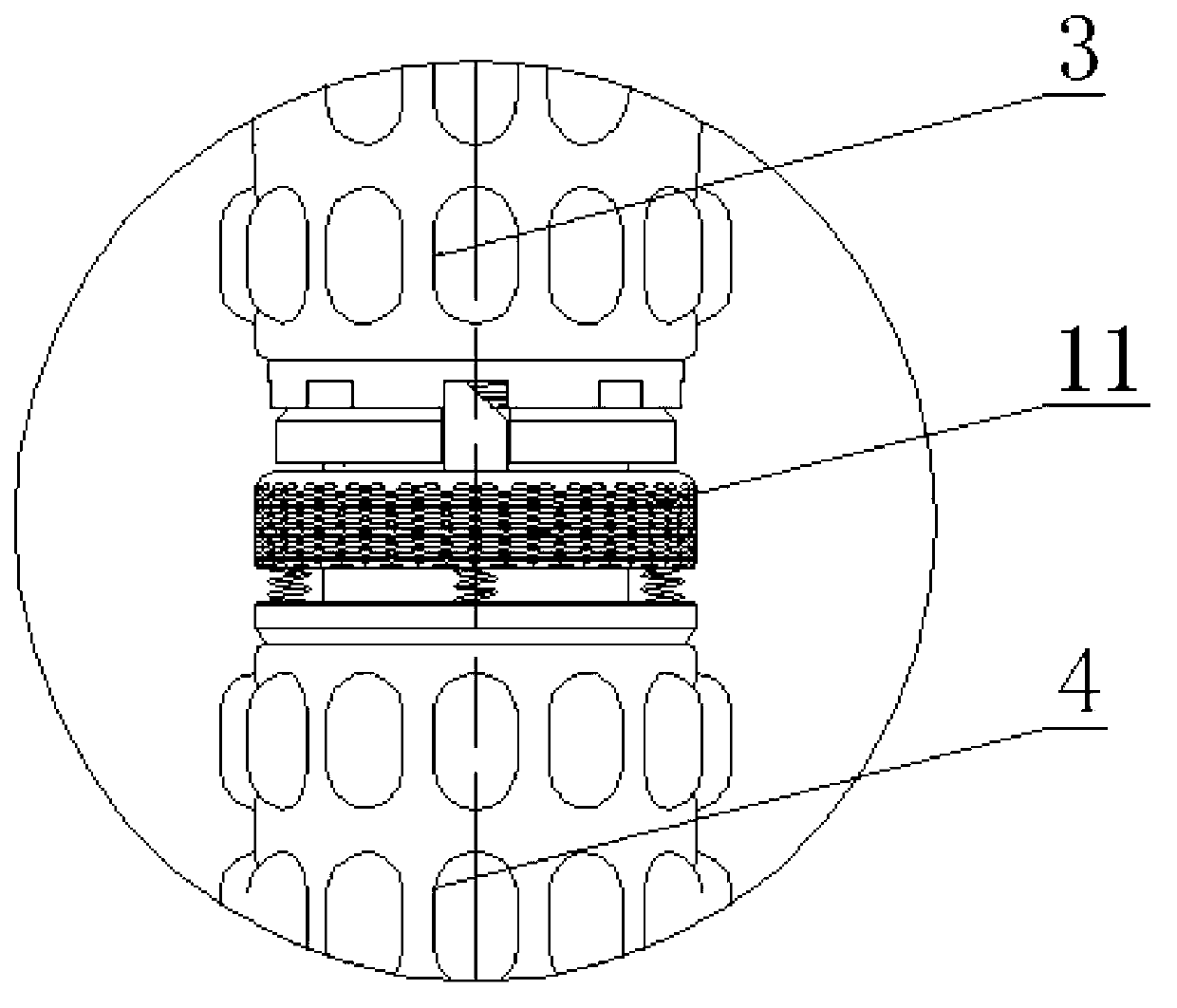

Birotor beater disintegrating machine

ActiveCN101190419APrevent opposite motionImprove crushing efficiencyGrain treatmentsCrusherPulverizer

The invention provides a dual-rotor hammer slice crusher, comprising a material inlet 1, a material guide device 2, a machine foundation 8, a casing 7 and two rotor assemblies 3 and 4. the casing 7 is arranged on the machine foundation 8; the material inlet 1 is arranged on the casing 7 which is internally provided with the two rotor assemblies 3 and 4 which are horizontally parallel to each other; the hammer slices 6 and 9 of the two rotor assemblies 3 and 4 are axially staggered; the cross-section of the material guide device 2 is a isosceles triangle with a material retaining surface 31 at the end face and material guide surfaces 32 at the two bevels; the top angle of the material guide device 2 is movably positioned on the material inlet 1 by a rotary shaft 33. The invention is provided with two high-efficiency crushing areas A and B, and an ultra-high efficiency crushing area C; when the hammer head of the hammer slices axially staggered with the dual-rotor assembly has partial superposition, the highest relative linear speed between material and the hammer slices can reach 2 times of the designed hammer slice speed, thus greatly improving crushing efficiency.

Owner:TIANMEN JINJIANG FOOD MACHINERY

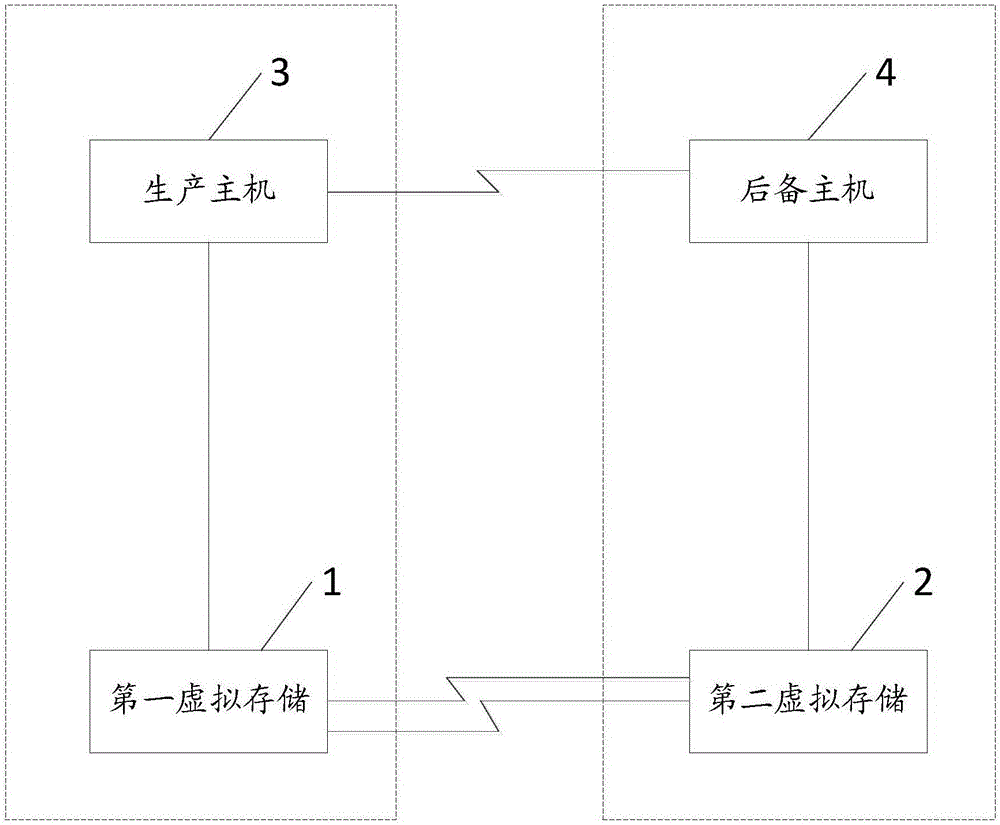

Disaster tolerance system

InactiveCN106407047AAchieve integrationImprove disaster backup capabilitiesInput/output to record carriersRedundant operation error correctionVirtualizationData center

The invention discloses a disaster tolerance system which comprises a first virtual storage and a second virtual storage. The first virtual storage is positioned at a main data center and is connected with a production host, and the second virtual storage is positioned at a backup data center and is connected with a backup host, wherein the first virtual storage is used for integrating and virtualizing all storage devices of the main data center, and reproducing data on a data volume LUN of the main data center to the second virtual storage; and the second virtual storage is used for integrating and virtualizing all storage devices of the backup data center, carrying out backing-up on the data reproduced by the first virtual storage, and carrying out data recovery to the main data center after the main data center has a fault and is recovered. Application-level disaster tolerance is implemented, disaster backup capacity is improved, and when a production node suffers from a serious disaster and is recovered, the second virtual storage can carry out data recovery on the first virtual storage, a service application is rapidly recovered, and resistance to disaster strike is improved.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

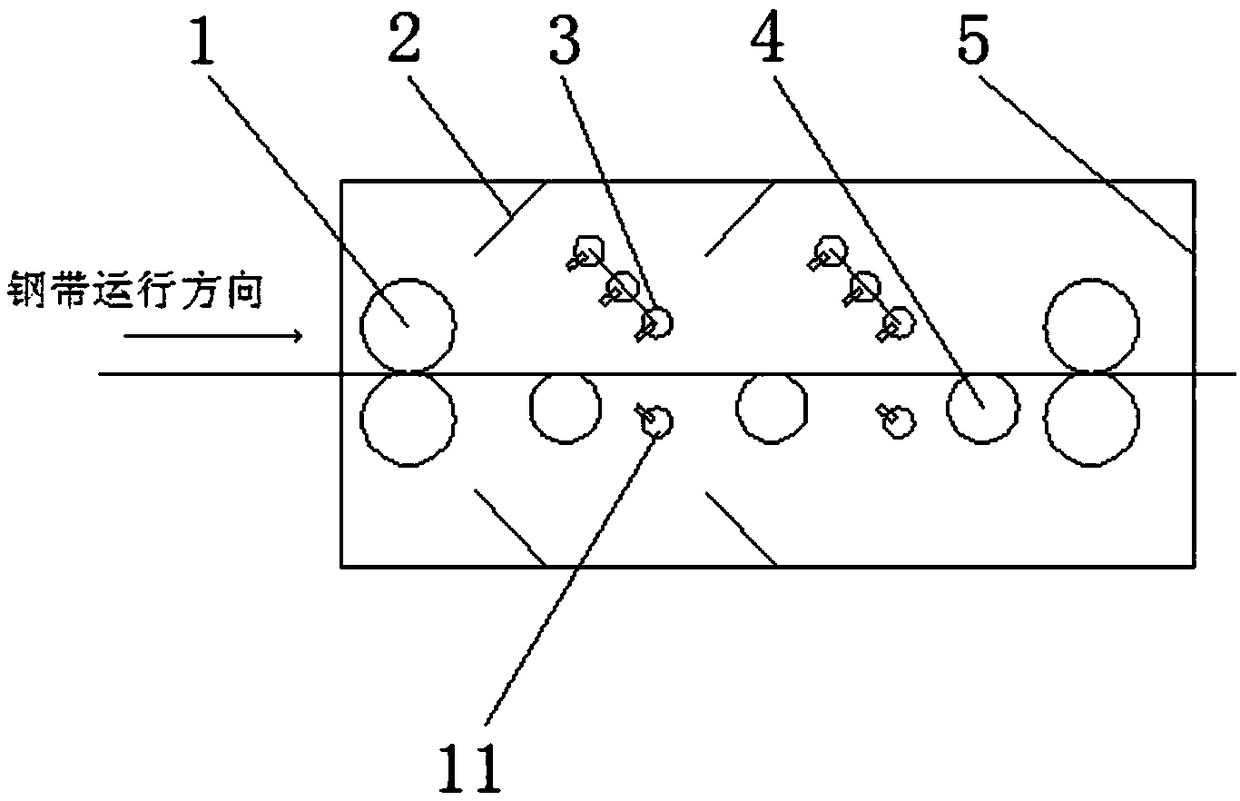

High-pressure-water descaling box

ActiveCN108160726AImprove the strike effectHigh removal rateWork treatment devicesMetal rolling arrangementsSpray nozzleSteel frame

The invention discloses a high-pressure-water descaling box. The high-pressure-water descaling box comprises a descaling box body, wherein a conveying roller and a sealing roller are arranged in the descaling box body; an upper jet nozzle assembly and a lower jet nozzle assembly are arranged in the descaling box body and are correspondingly positioned at two sides of a rolling line; the upper jetnozzle assembly comprises a jet nozzle set A, a jet nozzle set B and a jet nozzle set C which are distributed from top to bottom in the height direction of a steel frame; the steel frame is obliquelyfixed to a framework in the descaling box body, and the steel frame in the length direction is vertical to the rolling line; the jet nozzle set A, the jet nozzle set B and the jet nozzle set C comprise a plurality of jet nozzles which are mounted at intervals on the same straight line in the steel frame length direction. The high-pressure-water descaling box has the beneficial effects that the three jet nozzle sets with different jetting distance are arranged; the jet nozzle with the proper jetting distance and the high-pressure-water jetting pressure are selected based on a steel strip with different thickness, thus the effect of impacting oxide scales can be obviously improved, and as a result, the oxide scales removing rate can be increased, and the quality of the surfaces of subsequenthot-rolled boards can be ensured.

Owner:武汉钢铁有限公司

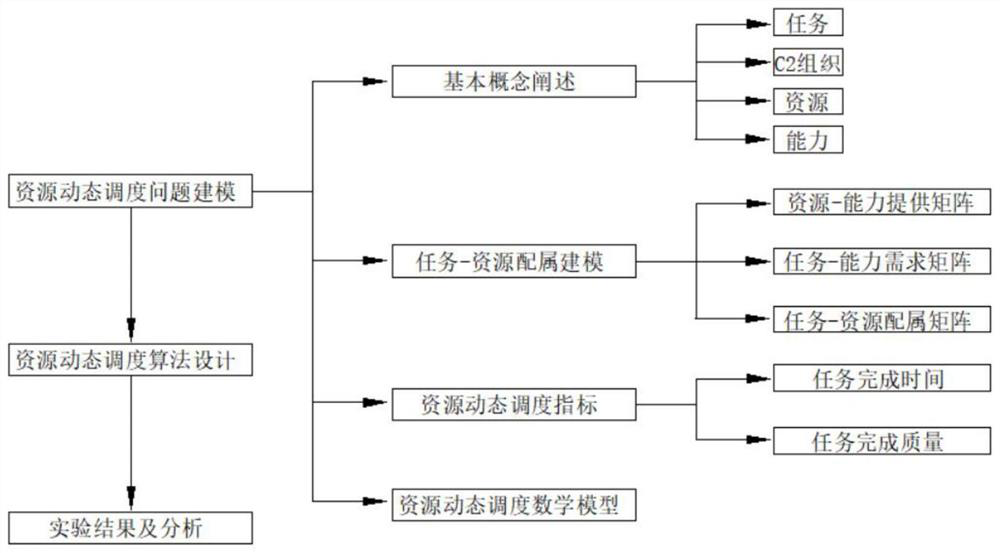

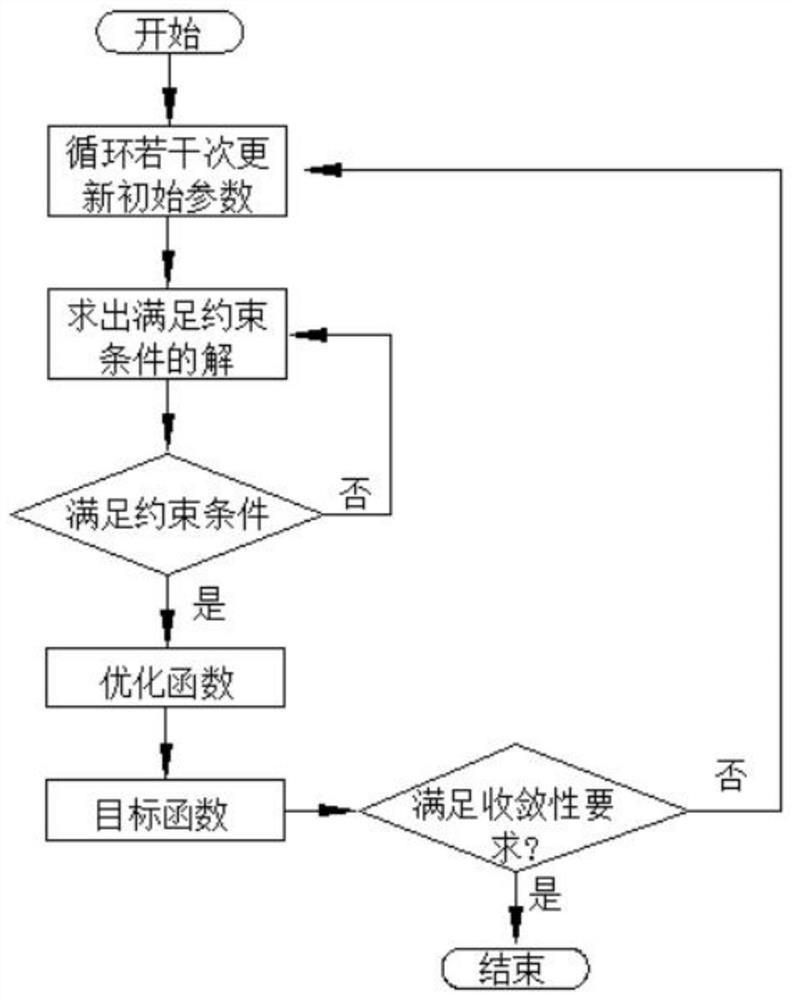

C2 organization resource dynamic scheduling method for time-sensitive target strike

PendingCN112734278ALess hitImprove the strike effectArtificial lifeResourcesTask completionImproved algorithm

The invention discloses a C2 organization resource dynamic scheduling method for time-sensitive target strike. The method includes taking task completion quality and task completion time as resource scheduling measurement; constructing a multi-target C2 organization resource dynamic scheduling model; and solving the model by adopting an improved quantum particle swarm algorithm. The result shows that by considering task completion time measurement, a time-sensitive target striking window can be reduced; three-level optimal adaptation modeling is carried out through task resource capacity, a multi-target dynamic optimization model is established, a quantum particle swarm optimization algorithm is further designed to solve the multi-target optimization problem, and therefore the time-sensitive target strike capacity can be remarkably improved.

Owner:NAT UNIV OF DEFENSE TECH

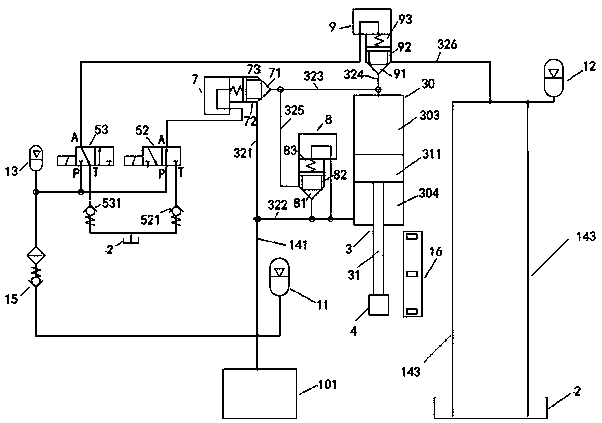

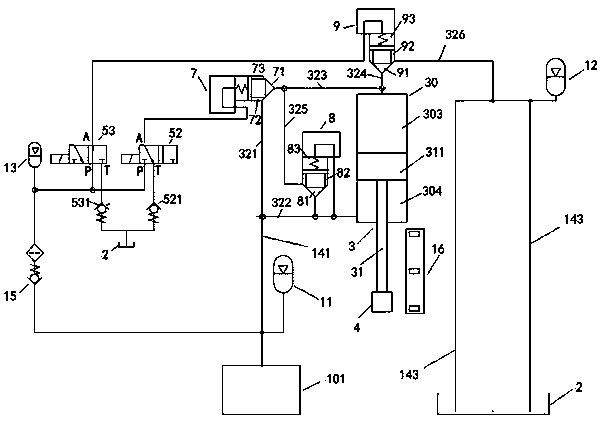

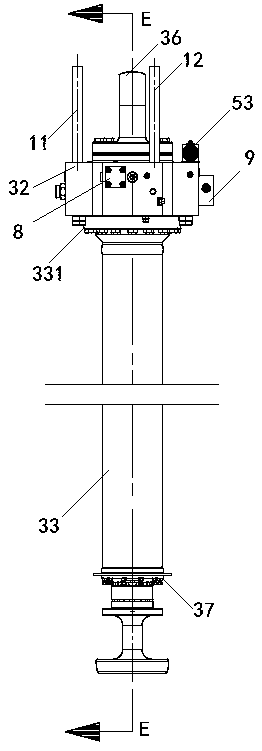

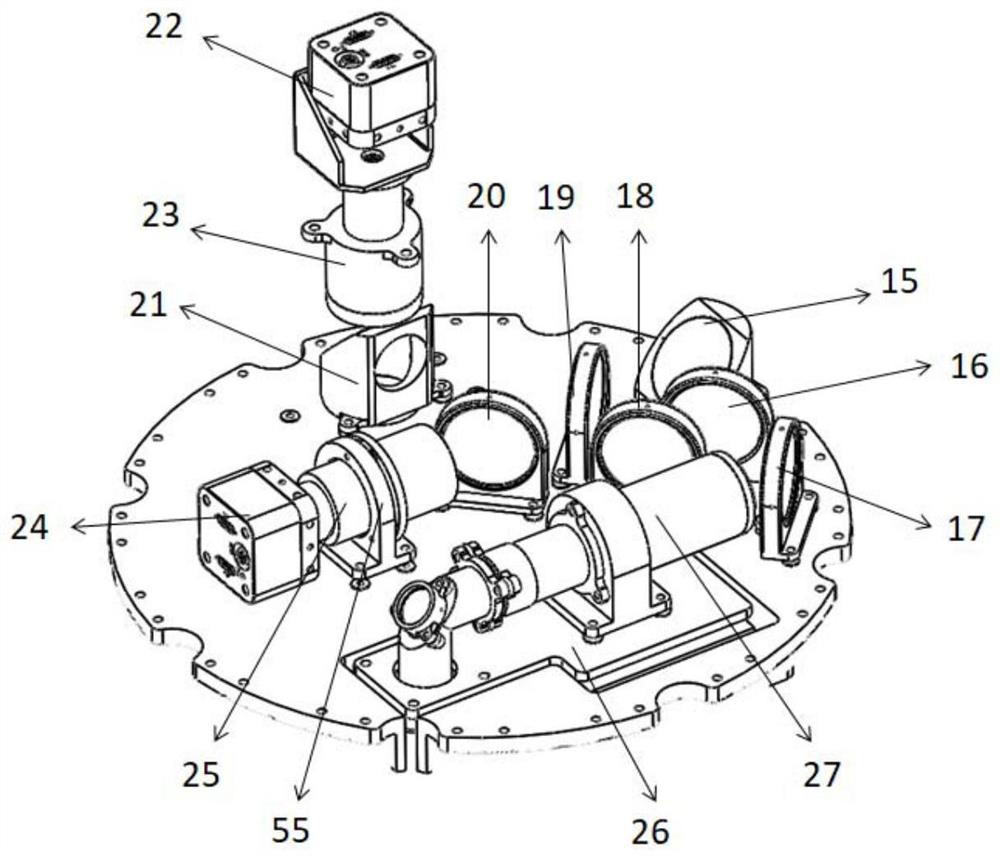

Hydraulic system for hydraulic hammer

PendingCN110985483ASpeed up the flowImprove high-speed reciprocating motion requirementsServomotor componentsFluid-pressure actuator componentsCheck valveImpact hammer

The invention discloses a hydraulic system for a hydraulic hammer. The hydraulic system comprises a power source, an oil tank, a lifting oil cylinder, an impact hammer core, a second electromagnetic reversing valve, a third electromagnetic reversing valve, a second plug-in valve, a third plug-in valve, a one-way plug-in valve, a second energy accumulator, a third energy accumulator, a fourth energy accumulator, a second check valve, a third check valve, a fourth check valve, a high-pressure pipeline, a low-pressure pipeline, a travel switch and a control unit, wherein the lifting oil cylinderis positioned in the central pit of a valve block through the inner cylinder barrel and the outer cylinder barrel of the lifting oil cylinder and is fastened with a cylindrical boss; the bottom of theinner cylinder barrel is provided with a plurality of oil holes for communicating a lower hydraulic cavity communicates with an annular oil channel; an upper hydraulic cavity and the lower hydrauliccavity communicate through switching on the one-way plug-in valve; and the second plug-in valve, the third plug-in valve and the one-way plug-in valve are independently installed on installation positions between a first oil channel and a third oil channel, between a fourth oil channel and a sixth oil channel as well as between a second oil channel and a fifth oil channel on the valve block. The hydraulic system has the characteristics of large blow energy, small hydraulic oil reversing pressure fluctuation, a low hydraulic element damage rate, small hydraulic pipeline vibration, high piling efficiency and the like, and is suitable for the high-speed flowing and the timely reversing of hydraulic oil.

Owner:上海工程机械厂有限公司 +1

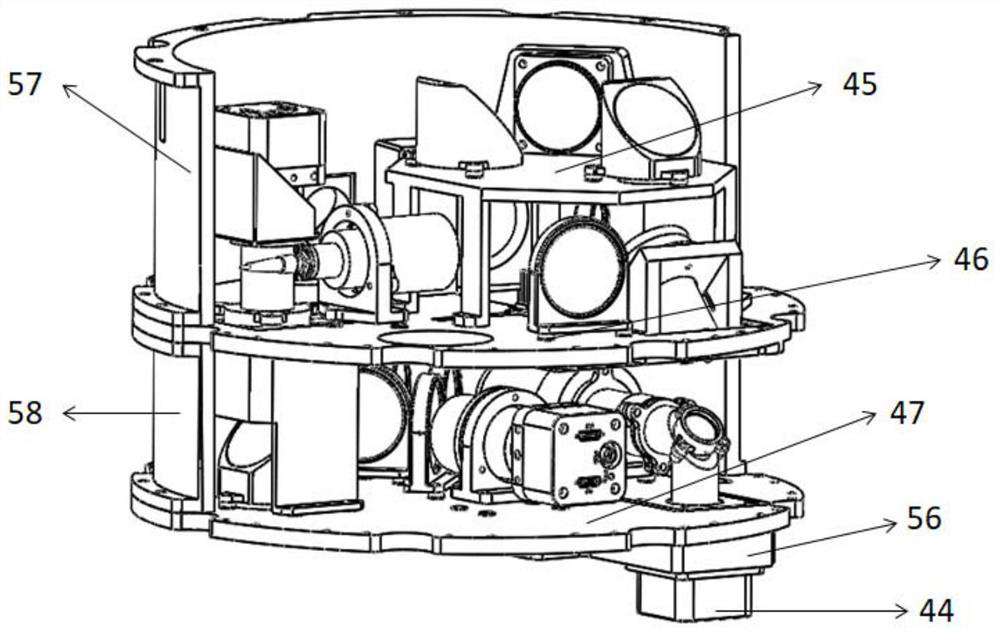

Small airborne laser weapon high-precision light beam control device and control method

ActiveCN113295044AGuaranteed Energy DensityRealize location monitoringSighting devicesTraining adaptationBeam splitterLight spot

The invention provides a small airborne laser weapon high-precision light beam control device and control method, belongs to the field of photoelectric tracking aiming of laser weapons, and solves the problems that a traditional photoelectric tracking and pointing system is slow in response, low in precision and weak in high-dynamic tracking capacity, the influence of high-energy laser transmitted in the atmosphere on the laser wave surface cannot be reduced, the energy density is low when the high-energy laser irradiates a target, and the striking effect is reduced. The device comprises a light beam control device and a control method. The light beam control device comprises a fine tracking assembly, a self-adaptive optical assembly, a main laser detector, a reflector and spectroscope assembly and a mounting base station assembly, and the control method comprises the following steps: calibrating a Hartmann detector; carrying out fine tracking on the light spots; carrying out self-adaptive adjustment; and carrying out laser striking. The device and method are mainly used for small airborne laser weapons.

Owner:CHANGCHUN UNIV OF SCI & TECH

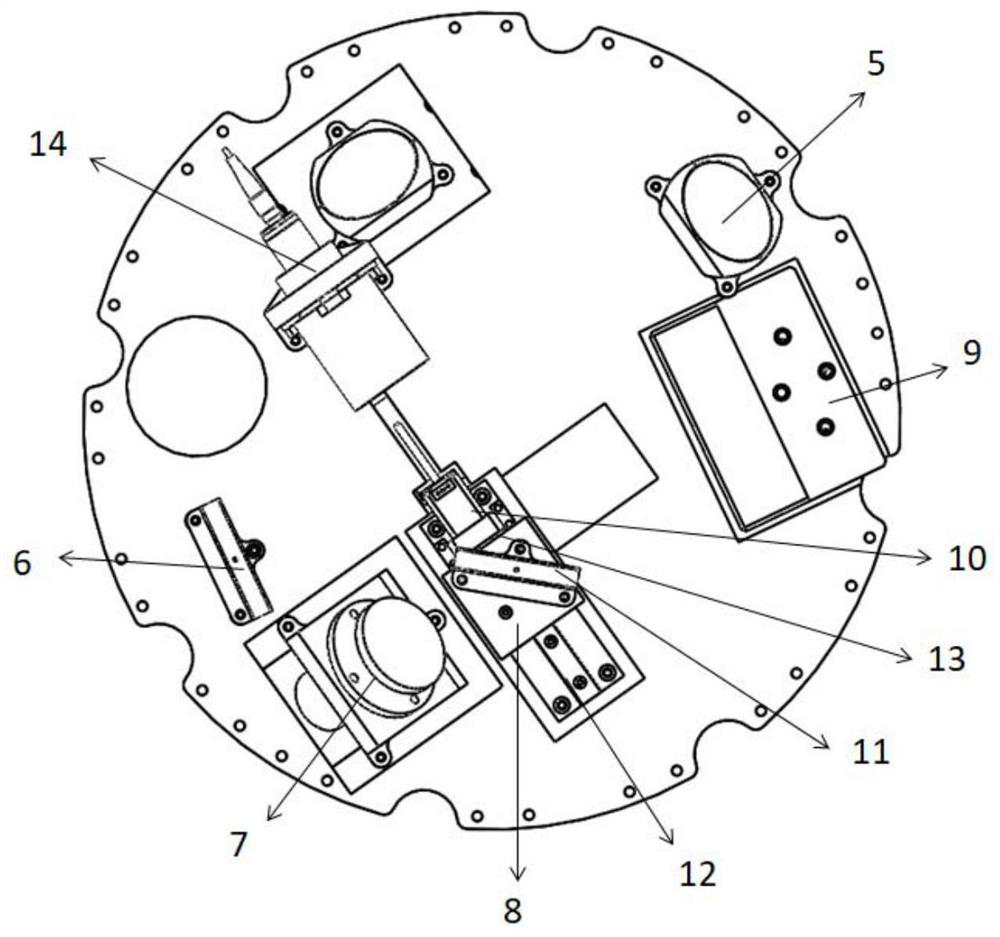

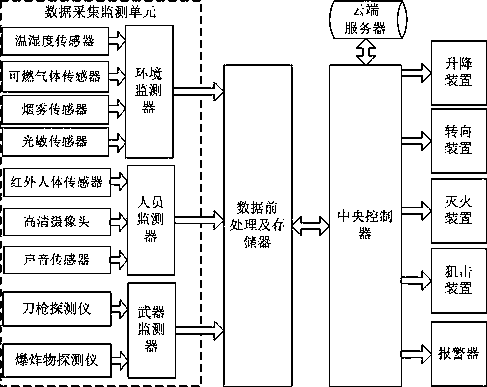

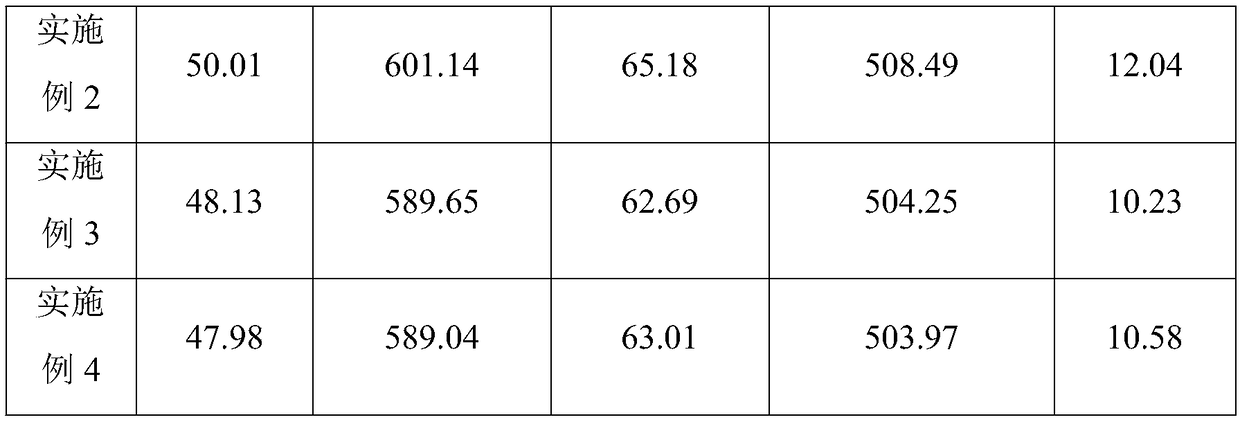

Anti-terrorist unmanned aerial vehicle control system

InactiveCN107807587AImprove the detection effectImprove the strike effectProgramme controlComputer controlIlluminanceControl system

The invention discloses an anti-terrorist unmanned aerial vehicle control system. The system can monitor parameters such as temperature, humidity, combustible gas concentration, smoke concentration and illuminance, controls various devices through a central controller, has the functions of environment monitoring, person monitoring, alarm prompting, weapon monitoring and automatic adjustment, accordingly improves the investigation and hitting capability of an anti-terrorist unmanned aerial vehicle, also has a remote control function and is stable, reliable and convenient to maintain and manage.

Owner:HANGZHOU HONGCHENG ENERGY SAVING TECH

Golf club heads

InactiveUS20050075194A1Increasing inertial momentumImprove the strike effectGolf clubsRacket sportsEngineeringGolf club

A golf club head includes a golf club head body having a toe and an engaging portion to which a striking plate is mounted, a hosel mounted to a side of the golf club head body, and a heel between the hosel and the engaging portion of the golf club head body. The heel includes a hole for reducing a weight of the heel, thereby shifting a center of gravity of the golf club head toward the toe of the golf club head body and increasing an inertial momentum of the golf club head.

Owner:FUSHENG PRECISION

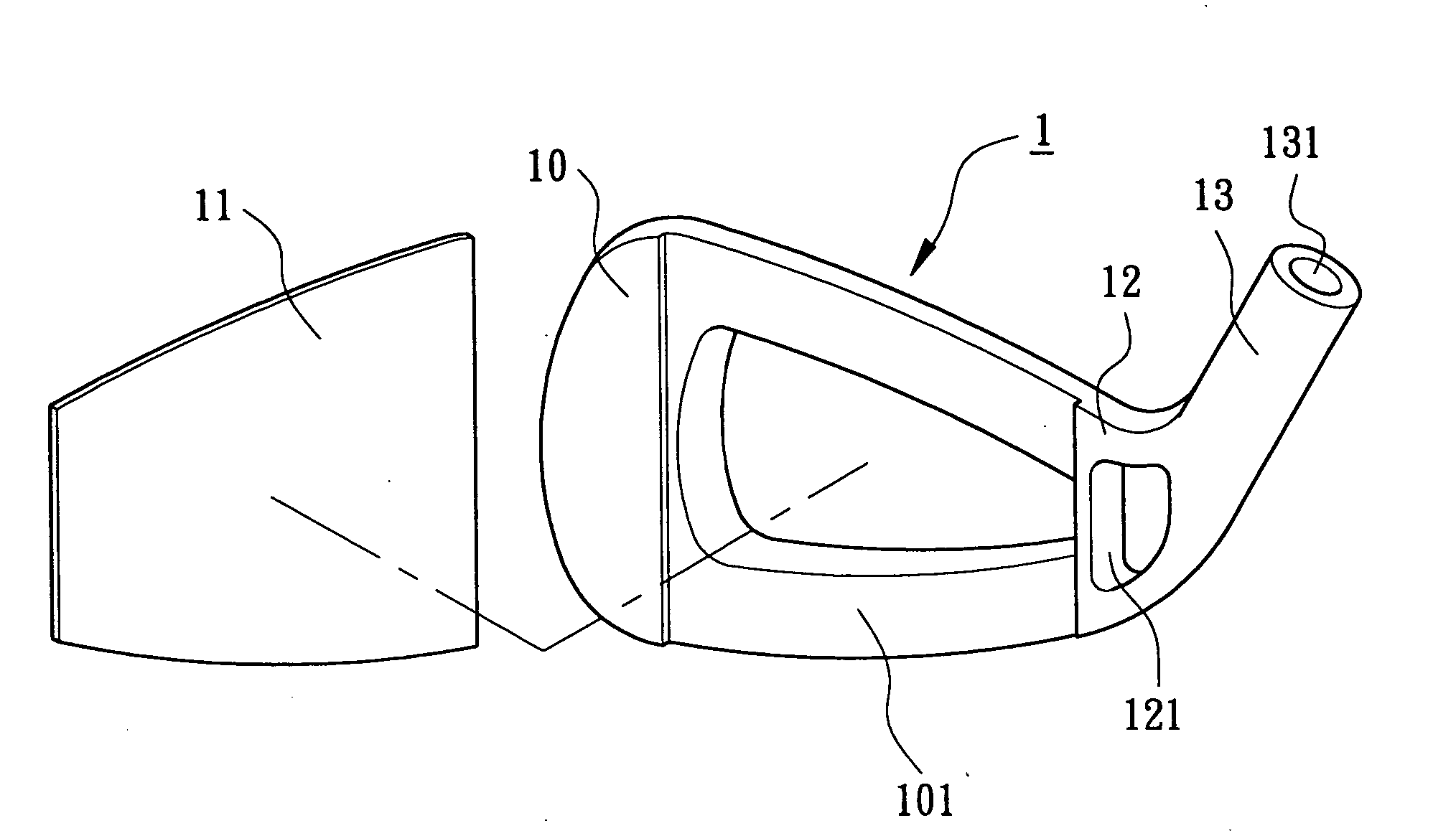

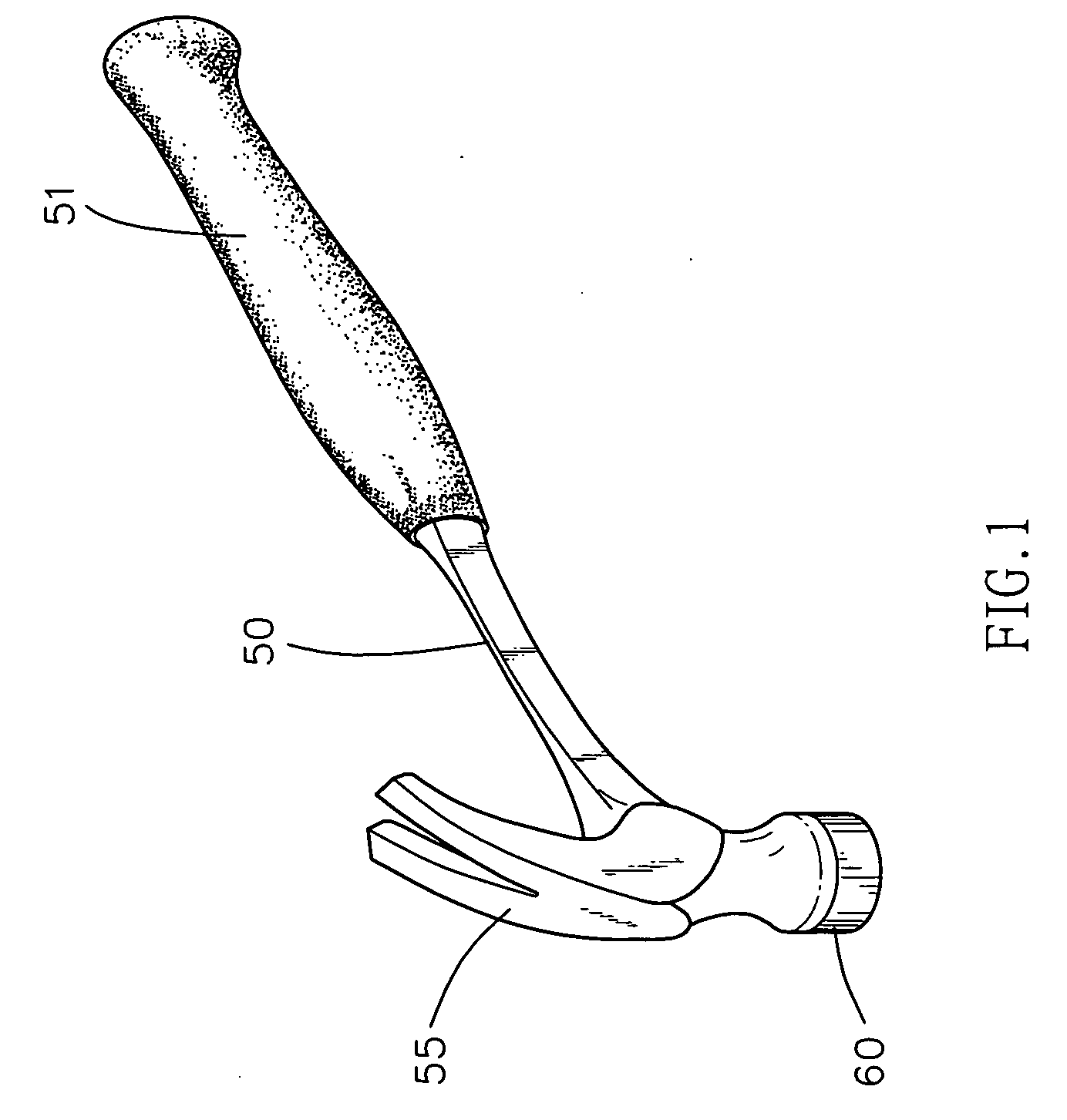

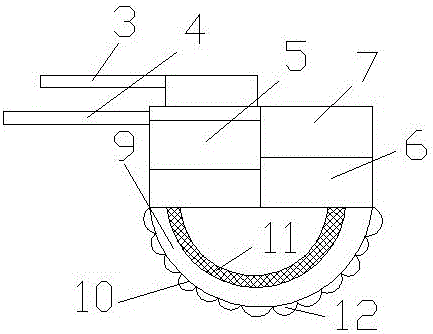

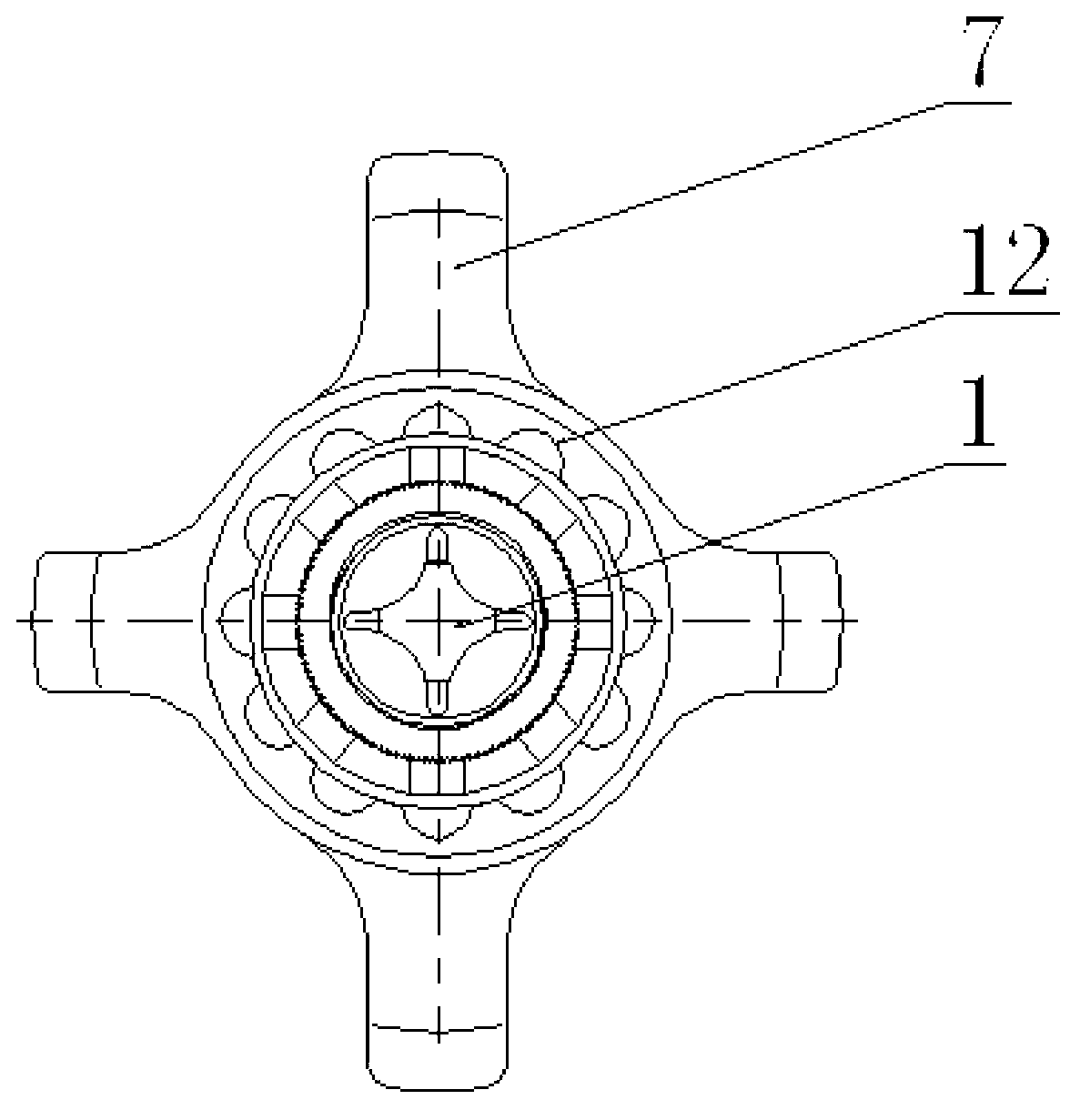

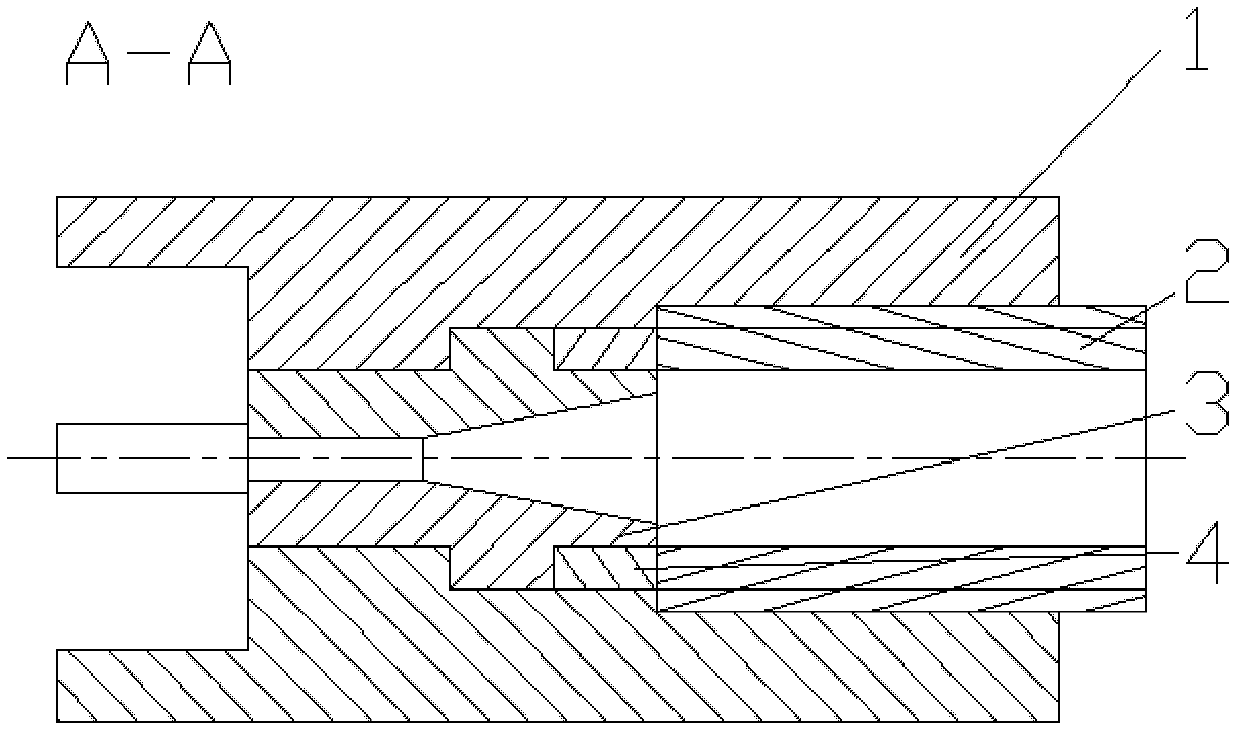

Hammer having vibration absorbing effect

InactiveUS20060037439A1Mitigate and obviate disadvantageImprove the strike effectHand hammersMetal-working hand toolsCushioningEngineering

A hammer includes a handle, a head mounted on the handle and having a distal end having an end face formed with an insertion recess, and a striking portion mounted on the distal end of the head and having an end face formed with an insertion block inserted into the insertion recess of the head. Thus, the cushioning gap between the striking portion and the head provides a vibration absorbing and cushioning effect during operation of the hammer, so that the hammer is operated smoothly and stably, thereby enhancing the striking effect of the hammer, and thereby facilitating a user operating the hammer.

Owner:CHEN JOHN

Oxygen supply device for fish farm

InactiveCN113455458AImprove rotation efficiencyIncrease the strike frequencyPisciculture and aquariaFisheryEngineering

The invention discloses an oxygen supply device for a fish farm. The oxygen supply device for the fish farm comprises an oxygen supply device, a first air pipe is arranged on the left side of the oxygen supply device, and an oxygen outlet device is arranged at one end, far away from the oxygen supply device, of the first air pipe; the oxygen outlet device internally comprises a square block, sealing rings, a second air pipe, a cleaning mechanism and a filter screen, the number of the sealing rings is two, a sealing ring located at the top is arranged at the top of the outer surface of the square block, the sealing ring located at the bottom is arranged at the top of the inner wall of the square block, and the first air pipe penetrates through the two sealing rings and extends into the square block; according to the oxygen supply device for the fish farm, by arranging the cleaning mechanism, sand and dust accumulated on the filter screen can be cleaned, the phenomenon that the filter screen cannot be blocked and cannot be used is avoided, the flowing direction of oxygen conveyed into the filter screen can be limited through a triangular check block, and therefore the rotating efficiency of a first cylinder is improved, a spring rod is arranged; and a rotating mechanism can be in contact with the filter screen only when the oxygen flows.

Owner:向长银

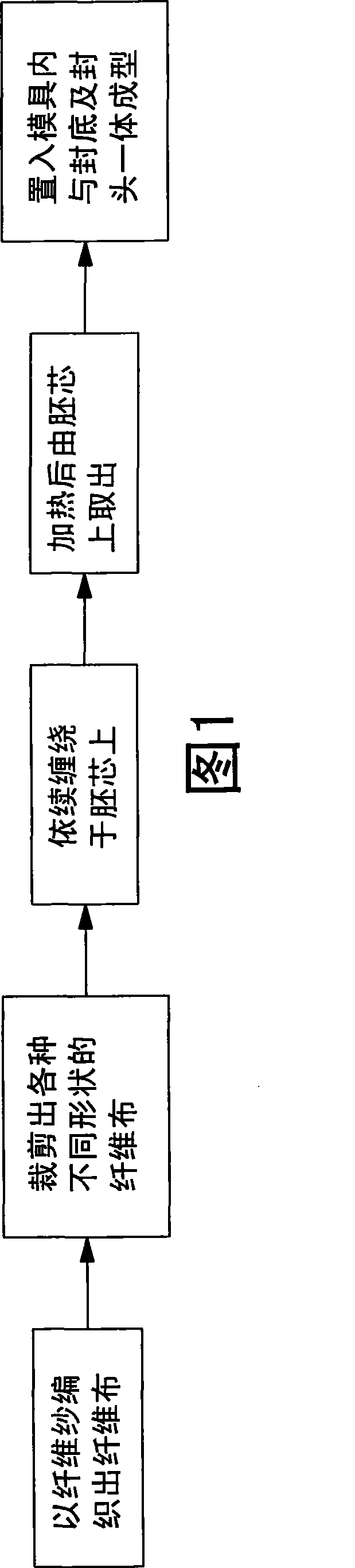

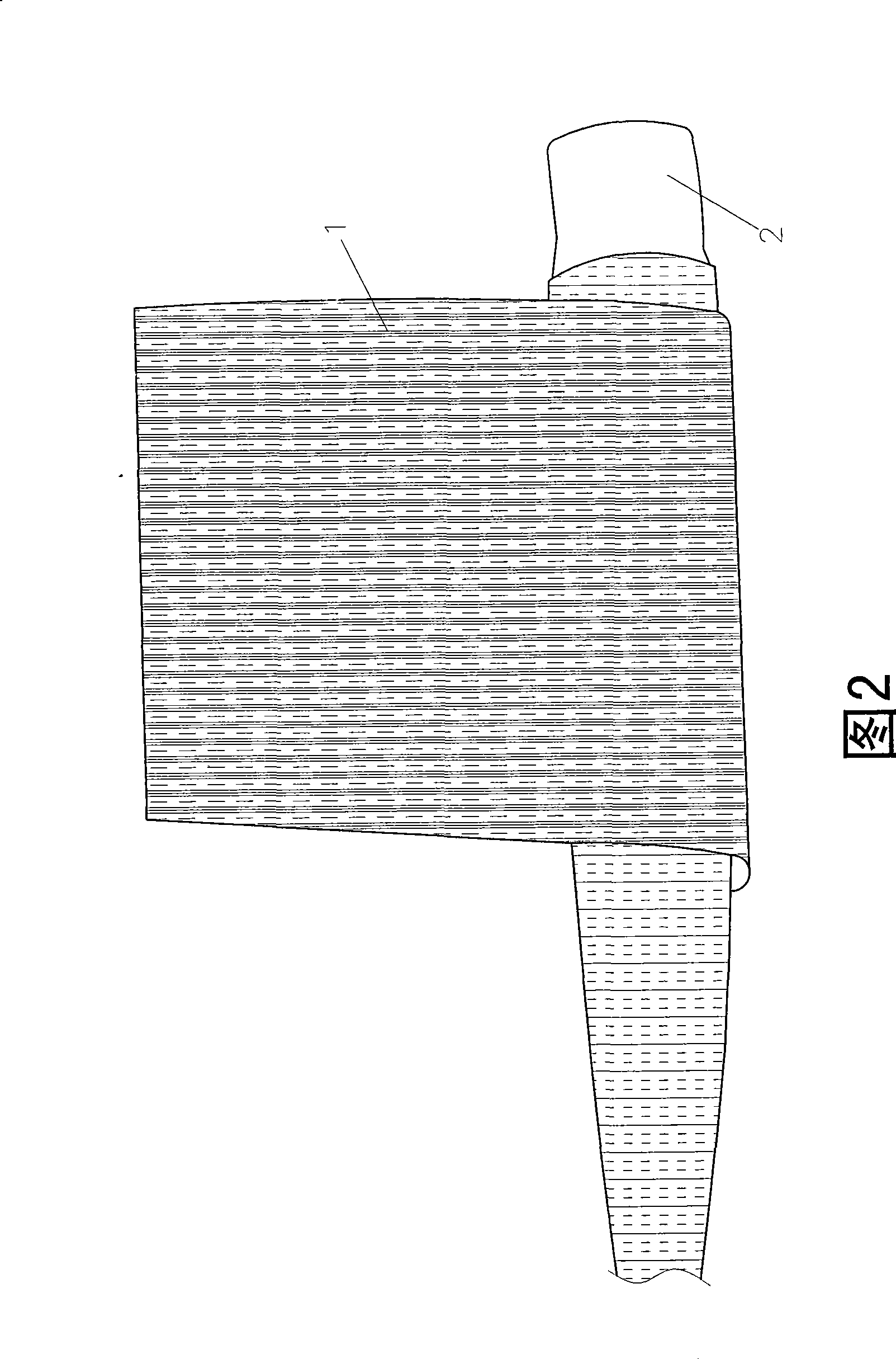

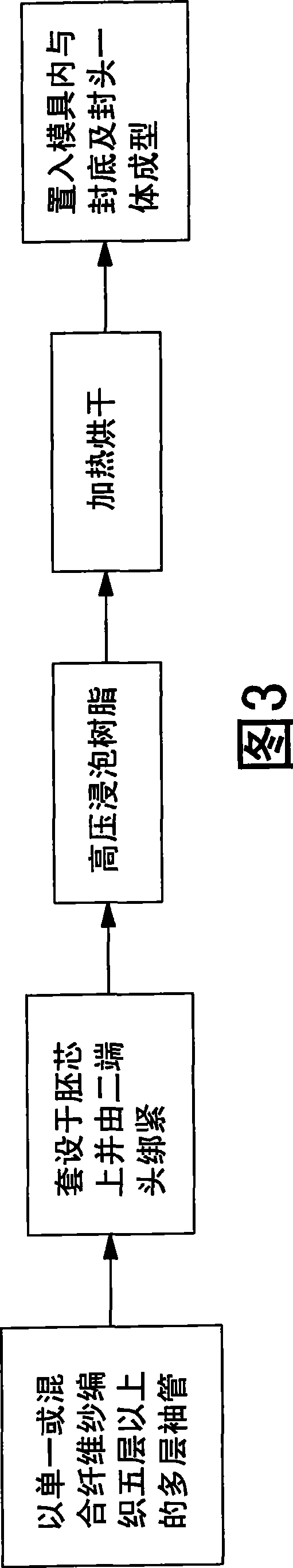

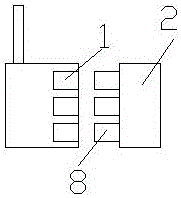

Method for making composite material bat

InactiveCN101456274AResin infiltrationSave man hoursLamination ancillary operationsLaminationEngineeringHigh pressure

The invention relates to a method for manufacturing a composite material bat. The method comprises: firstly, weaving a single-layer woven hose; secondly, sleeving a plurality of layers of the woven hoses onto a core material and fixing the two ends of the woven pipes; placing the woven hoses and the core material in a resin groove to allow the resin to penetrate the woven hoses uniformly by resin impregnation (high pressure or vacuum) mode; heating and drying the woven hoses, drawing the woven hoses away from the core material and placing the woven hoses into a mould to form the bat. The method can save labor hours, increase the bat strength, reduces the deflection angle of the bat when the bat is lift to hit a ball and improves the hitting effect.

Owner:WELL JET INT

Novel cannonball auto-loading tank

InactiveCN105737676AImprove combat capabilityImprove the strike effectArmoured vehiclesAmmunition loadingTime efficientEnergy storage

The invention discloses a novel cannonball auto-loading tank. The novel cannonball auto-loading tank is characterized in that a plurality of cannonball loading cavities are arranged in the tank; a cannonball loading vehicle is correspondingly arranged beside the cannonball loading cavities; cannonballs on the vehicle are transported into the tank through the cannonball loading cavities; a cannonball firing device is arranged on the tank; a machine cannon firing device is correspondingly arranged at the upper end of the cannonball firing device; a transportation device is arranged below the tank; a driving cavity is arranged between the transportation device and the tank; the driving cavity is a symmetrical structure and is distributed inside the tank; and an energy storage device and a power device are arranged beside the driving cavity. According to the novel cannonball auto-loading tank, the cannonball loading cavities are arranged in the tank, so that the cannonballs can be quickly loaded; the cannonball loading vehicle beside the tank can timely supplement cannonballs, so that the cannonballs can be automatically transported into the tank; by virtue of the cannonball loading manner, the time can be saved, the cannonball loading efficiency is improved, and the casualties are avoided; and a machine cannon is arranged on the tank, so that the combat capability of the tank is strengthened, and the strike capability of the tank is improved.

Owner:金嵩

Birotor beater disintegrating machine

InactiveCN101190419BPrevent opposite motionImprove crushing efficiencyGrain treatmentsEngineeringCrusher

The invention provides a dual-rotor hammer slice crusher, comprising a material inlet 1, a material guide device 2, a machine foundation 8, a casing 7 and two rotor assemblies 3 and 4. the casing 7 is arranged on the machine foundation 8; the material inlet 1 is arranged on the casing 7 which is internally provided with the two rotor assemblies 3 and 4 which are horizontally parallel to each other; the hammer slices 6 and 9 of the two rotor assemblies 3 and 4 are axially staggered; the cross-section of the material guide device 2 is a isosceles triangle with a material retaining surface 31 atthe end face and material guide surfaces 32 at the two bevels; the top angle of the material guide device 2 is movably positioned on the material inlet 1 by a rotary shaft 33. The invention is provided with two high-efficiency crushing areas A and B, and an ultra-high efficiency crushing area C; when the hammer head of the hammer slices axially staggered with the dual-rotor assembly has partial superposition, the highest relative linear speed between material and the hammer slices can reach 2 times of the designed hammer slice speed, thus greatly improving crushing efficiency.

Owner:TIANMEN JINJIANG FOOD MACHINERY

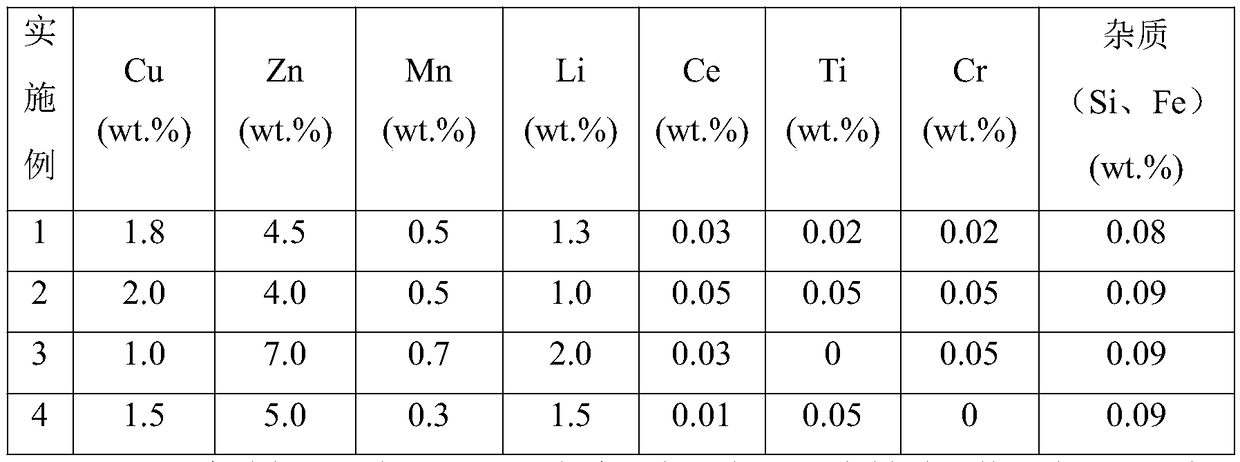

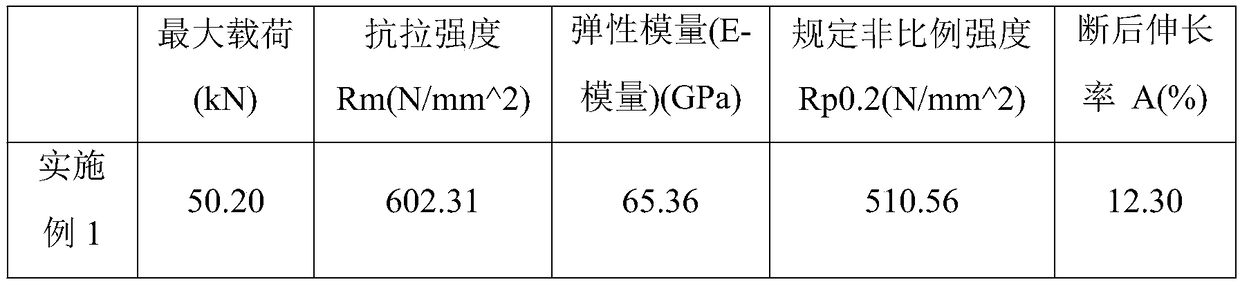

Light-weight aluminum alloy material and application thereof in preparation of bullet shells

The invention relates to the field of bullets and particularly relates to a light-weight aluminum alloy material and an application thereof in preparation of bullet shells. The aluminum alloy materialincludes, by weight, 4.0-7.0% Zn, 1.0-2.0% of Cu, 0.3-0.7% of Mn, 1.0-2.0% of Li, 0.01-0.05% of rare earths, 0-0.05% of Ti, 0-0.05% of Cr, and Al. The bullet shells have advantages of low density, high specific strength, great anti-corrosion performance and outstanding superplastic forming property, can bear chamber pressure of 400 MPa and instant high temperature of more than 1000 DEG C, can effectively avoid problems of cracking and ablation and can reach more than 1200 m / s in warhead initial speed; compared with a steel bullet shell, the bullet shell is reduced by more than 20% in total mass. The parameters can reach the standard of military, so that the bullet shell made of the aluminum alloy material can successfully replace a copper bullet shell or a steel bullet shell at present, thus reducing the weight of light weapons.

Owner:HUNAN UNIV OF TECH

Anti-terrorist unmanned aerial vehicle control system

InactiveCN106647549AImprove detection and strike capabilitiesThe system is stable and reliableProgramme controlComputer controlEngineeringAmbient monitoring

The invention discloses an anti-terrorist unmanned aerial vehicle control system. The system can monitor parameters such as temperature and humidity, combustible gas concentration, smog concentration and illuminance. By controlling various equipment through a central controller, the system has the functions of environment monitoring, personnel monitoring, warning and prompting, weapon monitoring and automatic adjusting, so that the detecting capacity and the strike capacity of an anti-terrorist unmanned aerial vehicle are improved. The system further has a remote control function, and is stable and reliable and convenient to maintain and manage.

Owner:桐乡匹昂电子科技有限公司

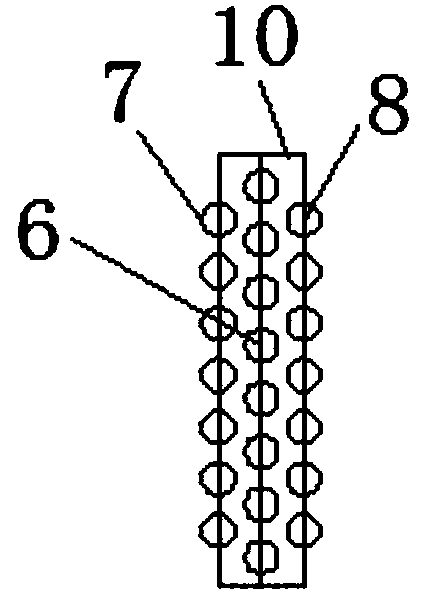

Combined-type baton and elongated combined-type baton

The invention relates to a combined-type baton. The combined-type baton comprises a striking part, a baton body, a front hand guard, a handle and a rear hand guard. The striking part is fixedly installed at the front end of the baton body; the rear end of the baton body is fixed with one end of the handle through the front hand guard; the rear hand guard is installed at the other end of the handle; an attack part is installed at the front end of the striking part, and comprises blunt thorns, a blunt thorn tail portion connecting pillar, an attack part body and a tail end connecting pillar; the front end of the attack part body is fixed with the blunt thorn tail portion connecting pillar; the rear end of the attack part body is connected with the tail end connecting pillar; the blunt thorns are fixedly installed at the front end of the blunt thorn tail portion connecting pillar; threads connected with the striking part in a meshing mode are arranged on the outer wall of the blunt thorn tail portion connecting pillar and the outer wall of the tail end connecting pillar. According to the combined-type baton, the attack part is designed in a hidden mode, and is installed in actions, and striking effect can be improved. The attack part does not need carrying in daily duties, and therefore the weight of the baton can be reduced and the baton is unlikely denounced by public opinions.

Owner:COMMANDING INST PEOPLES ARMED POLICE TROOPS +1

Cavitation type ultrahigh pressure water hammer type water gun sprayer

InactiveCN102513237BAccelerates the electrochemical corrosion processImprove the strike effectSpray nozzlesCavitationSelf-oscillation

The invention discloses a cavitation type ultrahigh pressure water hammer type water gun sprayer. Under the high pressure, a nozzle of the sprayer sprays out water hammer jet flow with cavitation proficiency. The sprayer comprises a sprayer cavity comprising an accordion cavity, a Helmholtz cavity and a conical nozzle outlet control section, wherein the accordion cavity and the Helmholtz cavity are axially through along the sprayer. A conical cavity transition section is formed between the accordion cavity and the Helmholtz cavity, high-speed fluid flows from the accordion cavity to a nozzle outlet to form water hammer flow with self-oscillation, and the water hammer flow produces vertex adhering wall effect at the nozzle outlet control section so that a cavitation phenomenon is induced at the nozzle outlet control section. The water jet flow sprayed out by the sprayer belongs to discontinuous cavitation water hammer flow, water attacking strength is in alternate tension with relaxation, alternating stress can be exerted on the surface of an attacked object, and the surface of the attacked object can be easily damaged or surrendered due to fatigue strength by means of the alternating stress and the cavitation effect. The cavitation type ultrahigh pressure water hammer type water gun sprayer is applied to occasions requiring rust removal, cleaning, scrabbing on the surface of concrete and the like.

Owner:天津开发区博新工贸有限公司

Police strength dispatching arrangement control system

InactiveCN100337240CEasy to judgeReduce lossesSpecial data processing applicationsControl systemComputer science

The police strength dispatching and controlling system includes command center system, mobile police service system and supervision system. The mobile police service system completes the GPS signal receiving and analysis via GPS and universal grouped radio service network, GPRS network signal connection and police service treatment, and returning the GPS information to the command center system. The supervision system is used in supervising the information exchange between the mobile police service system and the command center system and the information exchange inside the command center system. The present invention may be used widely for various classifications of police, and has the advantages of low cost, high practicability, high performance / cost ratio, etc.

Owner:深圳市公安局龙岗分局 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com