Novel cannonball auto-loading tank

An automatic loading and ammunition technology, applied in the field of tanks, can solve the problems that affect the combat efficiency of tanks, the inability to fill the shells, and the low efficiency of the filling method, so as to improve the loading efficiency, avoid casualties, and save time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

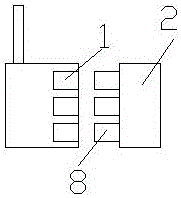

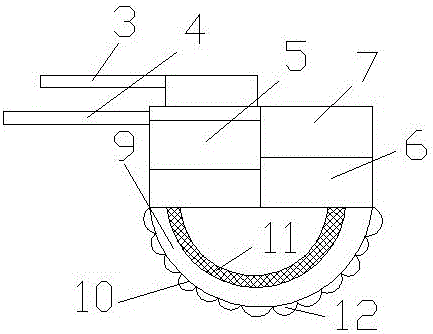

[0015] A new type of automatic shell loading tank, the tank is provided with several shell filling chambers 1, and a shell loading vehicle 2 is correspondingly arranged beside the shell filling chambers 1, and the shells on the vehicle are input into the tank through the shell filling chambers 1. A cannonball launching device 3 is provided, and the upper end of the cannonball launching device 3 is correspondingly provided with a mechanism launching device 4, and a conveying device is provided under the tank, and a driving chamber 5 is provided between the conveying device and the tank, and the driving chamber 5 is symmetrically distributed in the tank , the driving cavity 5 is provided with an energy storage device 6 and a power unit 7, the shell launching device 3 is a gun barrel, the gun barrel is a movable structure, and the gun barrel moves back and forth, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com