Preparation of fragment-resistant sandwich-structure aramid composite cloth

A sandwich structure, composite fabric technology, applied in protective equipment, protective clothing, synthetic resin layered products, etc., can solve the problem of bulletproof and stab-proof products such as poor flexibility and wearing comfort, poor comfort and flexibility, and insufficient market competitiveness. problem, to achieve the effect of dual performance guarantee of anti-stab, perfect functionality and comfort, and excellent anti-fragment performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Laminated with two layers of non-weft fabric and one layer of woven fabric

[0029] First, take 1000g of acrylate aqueous solution with a solid content of 50%, 100g of polychloroprene, 5g of blocked isocyanate crosslinking agent, 6g of coupling agent, and add 600g of water to prepare an adhesive with a solid content of 35%. Mix well and set aside. Prepare the longitudinal unidirectional fiber prepreg on the roller of the winding machine; rotate it 90°, spread it on the roller for the second layer preparation, and make a non-woven fabric composited by two layers of unidirectional fiber prepreg, The cloth sample is cut into a fixed version, after the surface of the two layers of non-weft cloth is coated with glue, the woven fabric is sandwiched in the middle and pressed to form a sandwich structure aramid fiber composite cloth, using a 0.5 MN pressure forming machine, at a temperature of 160, Compress under a pressure of 10MPa, deflate continuously for 3 to 5 times, and ...

Embodiment 2

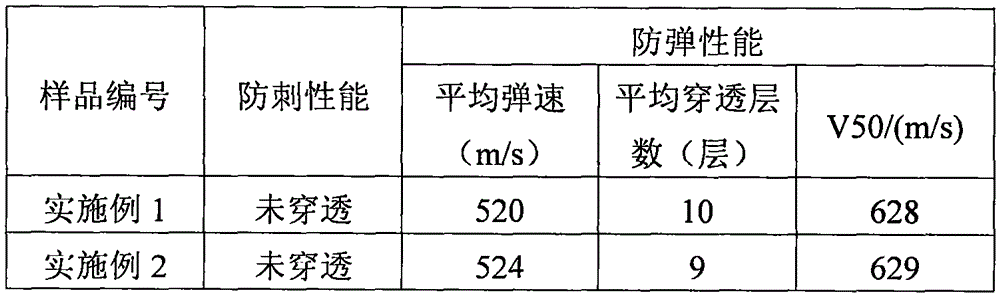

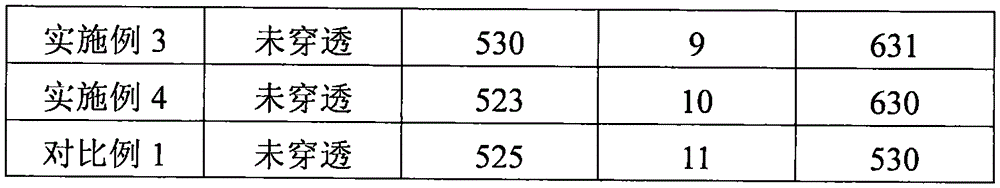

[0031] First, weigh 1000g of acrylate aqueous solution with a solid content of 50%, 100g of polychloroprene, 5g of blocked isocyanate crosslinking agent, and 6g of coupling agent, add water to form an adhesive with a solid content of 35%, and mix well for later use. Lay the woven fabric on the film-coated roller, prepare unidirectional fiber prepreg on it, rotate it 90° and spread it on the roller with the reverse side facing up, and prepare unidirectional fiber prepreg on it. Aramid composite cloth with sandwich structure was obtained, and the cloth sample was cut into a fixed version and then hot-pressed. A 0.5 MN pressure forming machine was used to press at a temperature of 160 and a pressure of 10 MPa. Cold pressing for 5 minutes. 27 layers + 1 layer of EVA are used to make bulletproof and stab-resistant target sheets. The bulletproof and stab-proof performances are tested according to the Ministry of Public Security GA141-2010 "Police Body Armor" and GA68-2008 "Police S...

Embodiment 3

[0033] Change the polychloroprene in embodiment 2 to 5g, the coupling agent to 5g, and all the other conditions remain unchanged. Bullet-proof and stab-proof performance are tested according to Ministry of Public Security GA141-2010 "Police Body Armor" and GA68-2008 "Police Stab-proof Clothing". The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com