Birotor beater disintegrating machine

A hammer-type pulverizer and double-rotor technology, which is applied in the direction of grain processing, etc., can solve the problems that the relative linear velocity between the hammer and the material cannot be increased, and the pulverization efficiency of the pulverizer is limited, so as to increase the high-efficiency striking area, improve the pulverization efficiency, Improve the effect of striking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

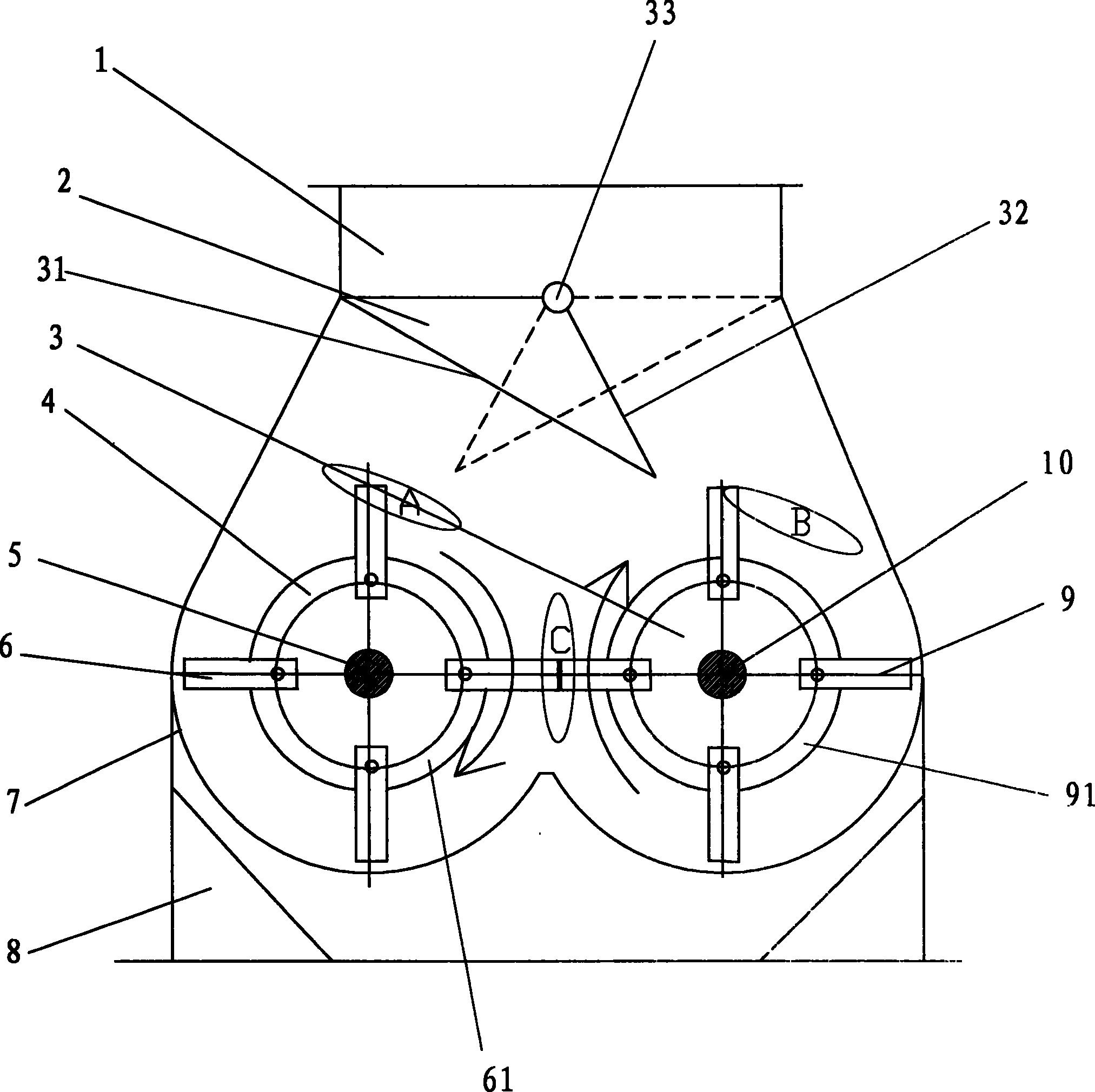

[0014] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

illustration:

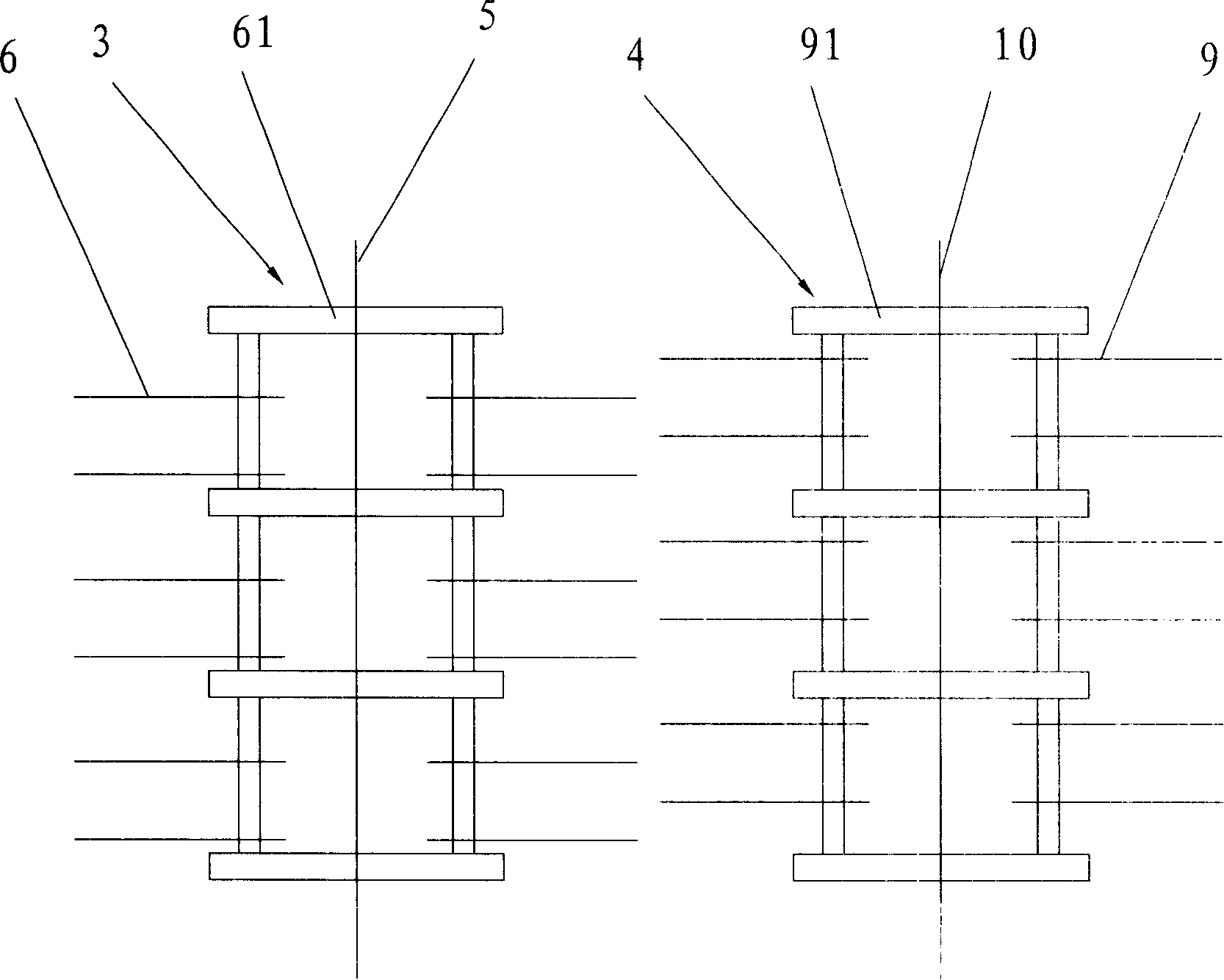

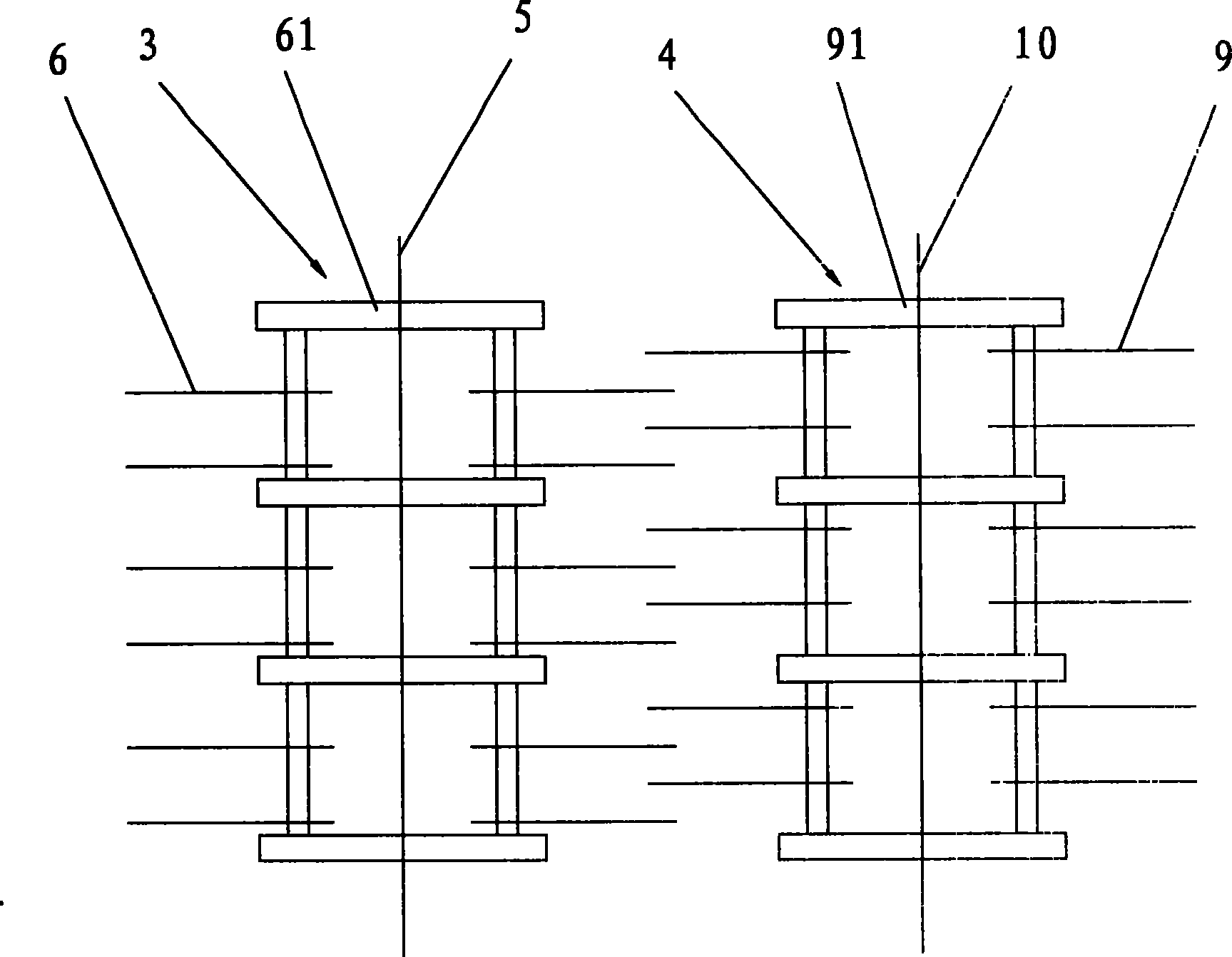

[0015] 1. Raw material import; 2. Material guiding device; 3. Right rotor assembly; 4. Left rotor assembly; 5. Left main shaft; 6. Left hammer; 61. Left hammer bracket; 7. Case ; 8, machine base; 9, right hammer; 91, right hammer support; 10, right main shaft; 31, retaining surface; 32, guide surface; 33, rotating shaft.

[0016] See figure 1 , figure 1 It is a schematic cross-sectional structure diagram of an embodiment of the present invention; it is a double-rotor hammer mill, including a feed inlet 1, a guide device 2, a machine base 8, a casing 7 and rotor assemblies 3, 4 , the casing 7 is located on the machine base 8, the feed inlet 1 is located on the casing 7, and two horizontal rotor assemblies 3, 4 parallel to each other are arranged in the casing 7; the two rotor assemblies 3, 4 The hammers 6 and 9 are located on the ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com