High-pressure-water descaling box

A descaling box and high-pressure water technology, which is applied to metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of easy damage to the nozzle drive device, unguaranteed descaling effect, and reduced service life, and achieve reduction Effects of failure rate, improvement of competitiveness, and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

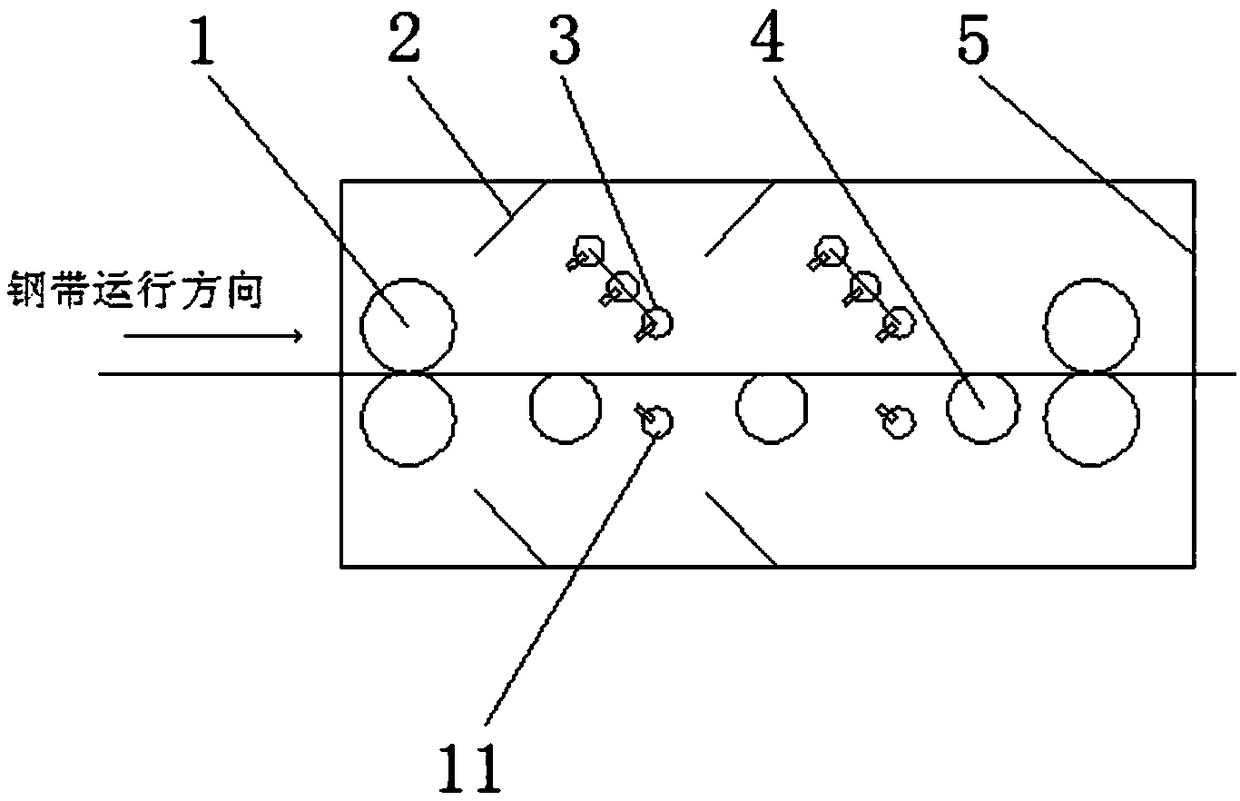

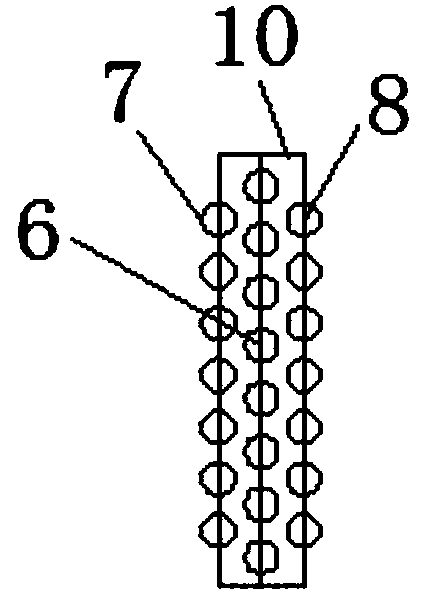

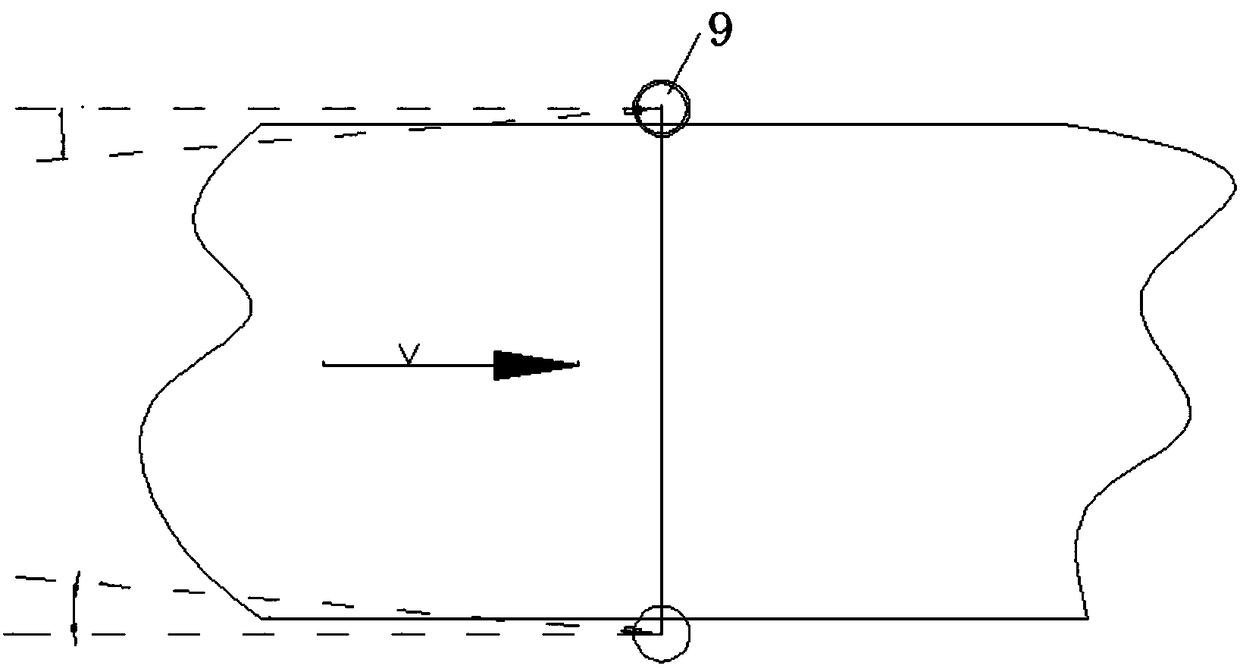

[0020] Such as figure 1 A high-pressure water descaling box shown includes a descaling box 5, and a transport roller 4 for conveying steel strips is arranged in the descaling box 5, and at the entrance of the descaling box 5 and the outlet of the descaling box 5 Sealing rollers 1 are respectively installed on both sides of the rolling line at the place; an upper nozzle assembly and a lower nozzle assembly 11 are arranged in the descaling box 5, and the upper nozzle assembly and the lower nozzle assembly 11 are respectively located on both sides of the rolling line; The above nozzle assembly includes nozzle group A7, nozzle group B6 and nozzle group C8, nozzle group A7, nozzle group B6 and nozzle group C8 are distributed from top to bottom along the height direction of the steel frame 10, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com