Small airborne laser weapon high-precision light beam control device and control method

A laser weapon and beam control technology, which is applied in the field of photoelectric tracking and aiming of laser weapons, can solve the problems of inability to reduce the impact of high-energy lasers, weak high-dynamic tracking ability, restricting the development of laser weapons, etc., so as to reduce the volume and weight and improve the strike effect. , the effect of reducing system complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

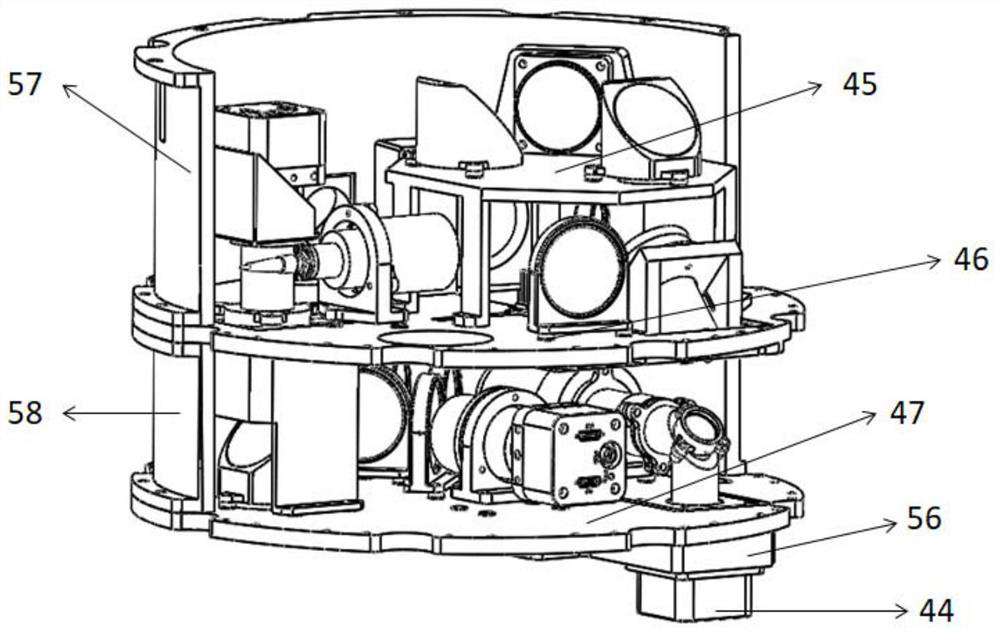

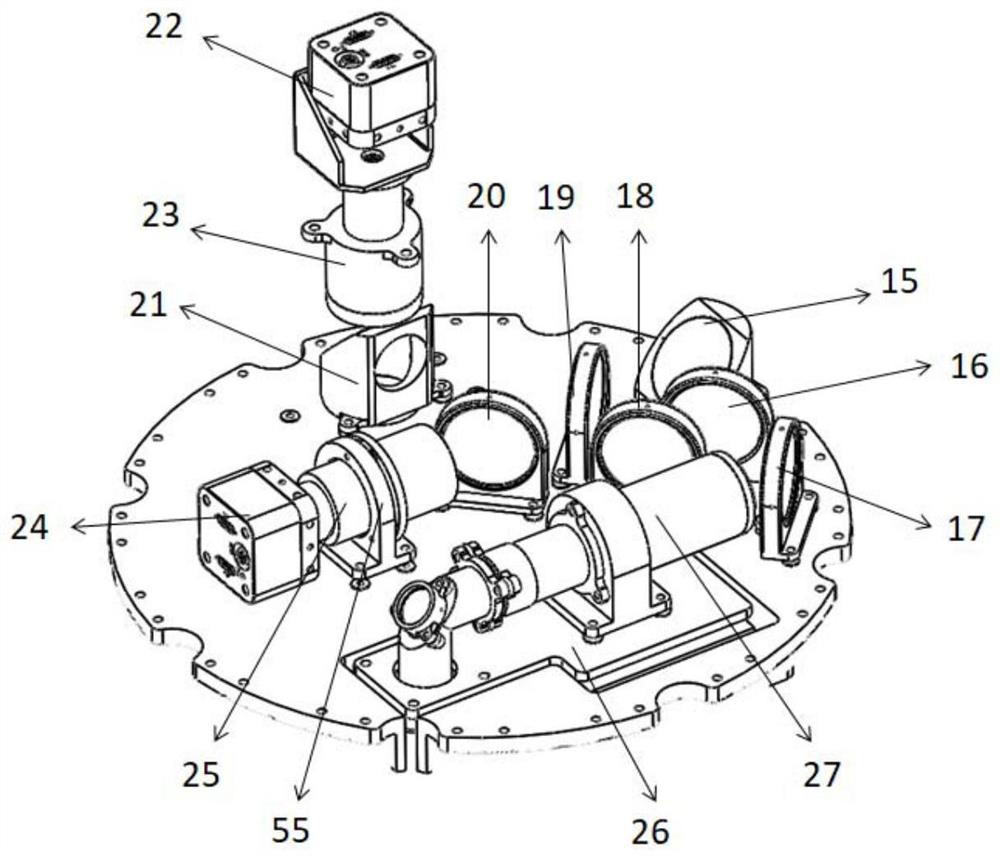

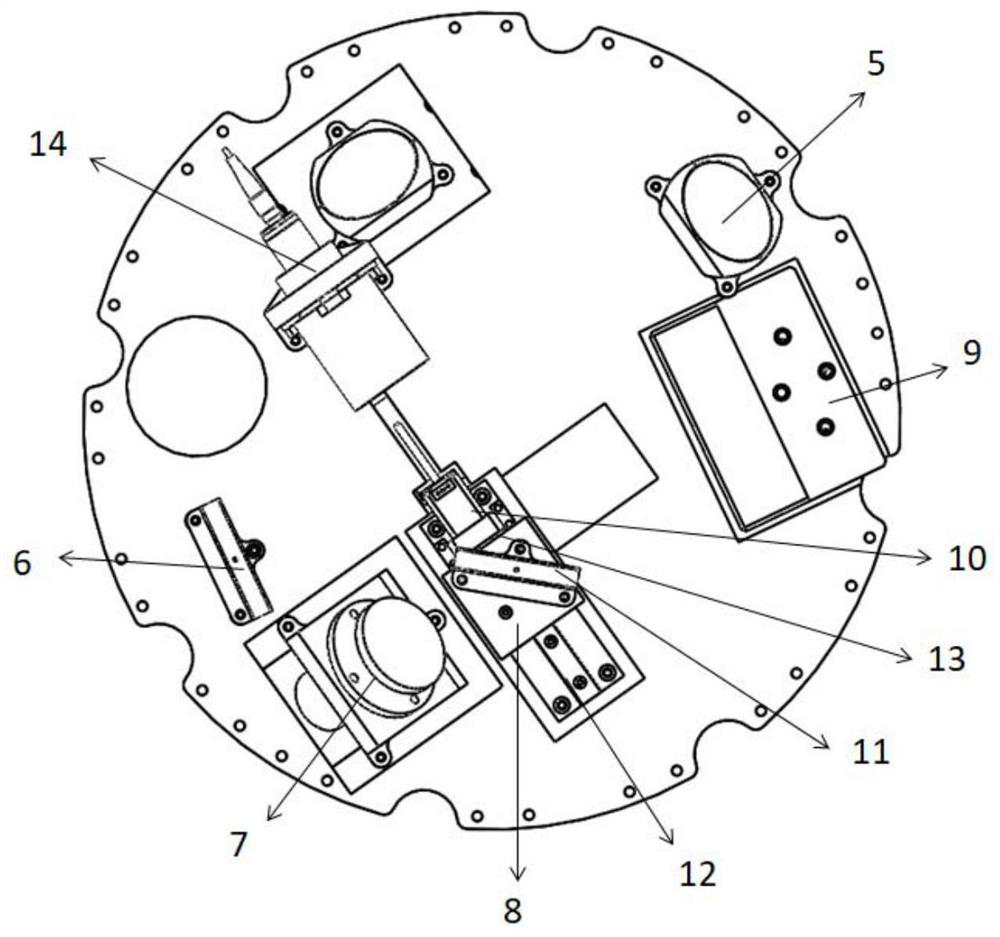

[0030] see Figure 1-5 Description of this embodiment, a high-precision beam control device for a small airborne laser weapon, which includes a fine tracking component, an adaptive optics component, a main laser detector 23, a reflector and a beam splitter component, and an installation base assembly, the installation base The assembly includes the first floor mounting plate 47, the second floor mounting plate 46 and the third floor mounting plate 45 connected sequentially from bottom to top, and the fine tracking assembly includes a fine tracking camera 24, a fine tracking lens 25, a fine tracking bracket 55 and a fine tracking The electromagnetic vibrating mirror 2, the fine tracking lens 25 is installed on the fine tracking bracket 55, the fine tracking bracket 55 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com