Lithium battery structure and assembly method thereof

A lithium battery and component technology, applied in the field of lithium battery structure and assembly, can solve the problems of lithium battery short circuit lithium battery, etc., to achieve the effect of improving energy density, saving consumption, and avoiding the risk of short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

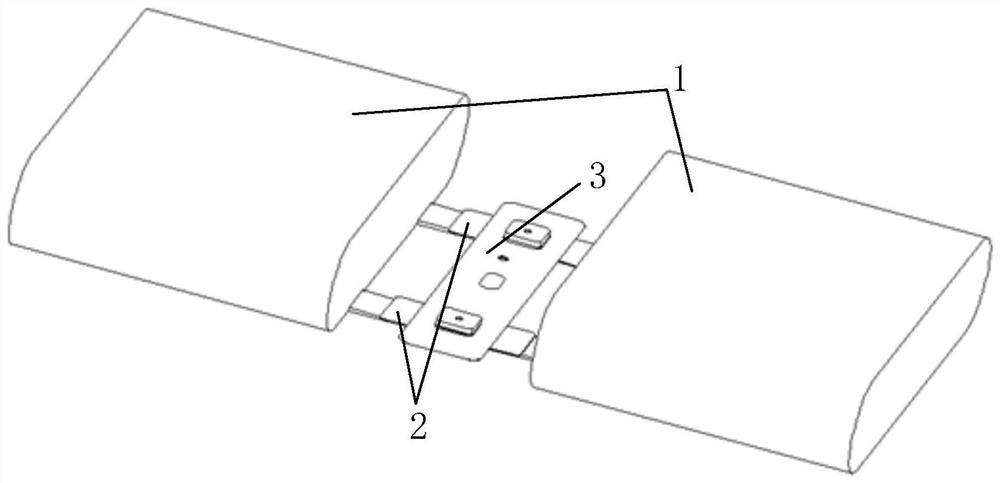

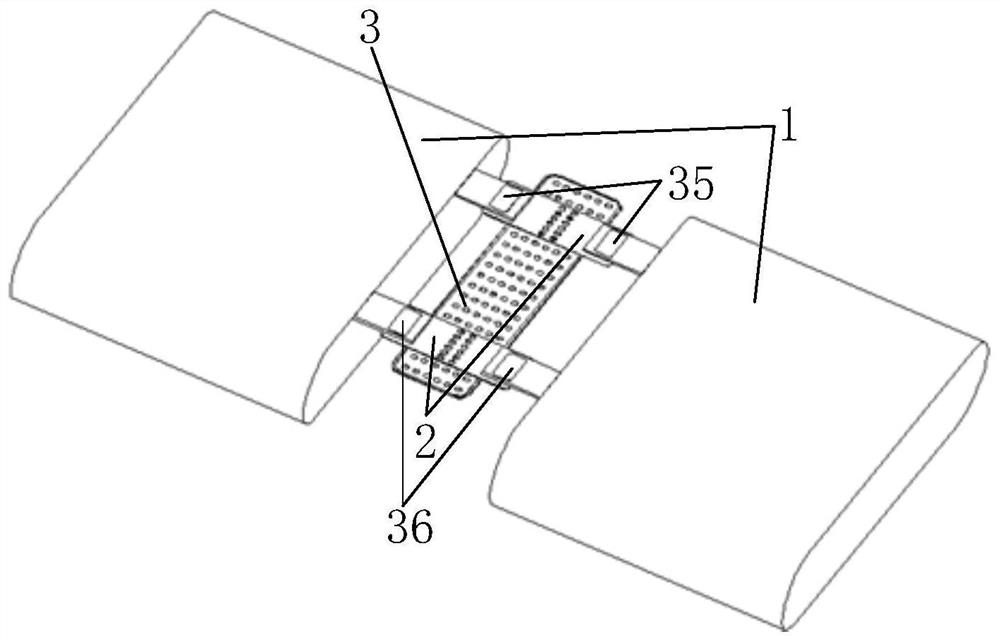

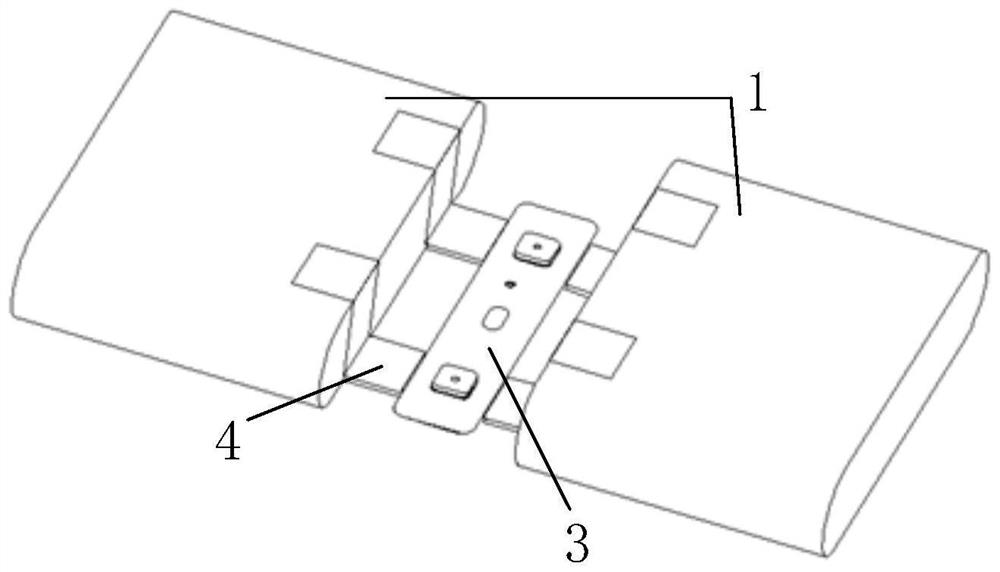

[0069] see Figure 1 to Figure 8 , a lithium battery structure disclosed in the present invention includes two winding core components 1, a connecting piece component 2, a cover plate component 3, an insulating tape 4, an insulating film 5 and an aluminum shell component 6; the winding core component 1 and the connecting piece component 6; 2 is fixedly connected, the connecting piece assembly 2 is fixedly connected with the cover plate assembly 3, the insulating tape 4 covers the connection between the winding core assembly 1 and the connecting piece assembly 2, and the insulating film 5 covers the outside of the multiple winding core assemblies The winding core assembly 1 , the connecting piece assembly 2 , the insulating tape 4 and the insulating film 5 are all placed in the aluminum shell assembly 6 , and the aluminum shell assembly 6 is fixedly connected with the cover plate assembly 3 .

[0070] see Figure 9 , the core assembly 1 includes a core body 11 and a pole lug, ...

Embodiment 2

[0085] see Figure 22 and Figure 23 , the same as the first embodiment, the difference is that the number of winding core assemblies 1 in this embodiment is four; Close together, and then the two tabs are placed between the connecting piece and the protective piece, and then the two tabs, the connecting piece and the protective piece are fixed by welding.

[0086] see Figure 1 to Figure 23 , the assembling method of a lithium battery structure disclosed in this embodiment is the same as that of the first embodiment, and the difference is step S3 and step S4;

[0087] S3: as Figure 22 and Figure 23 As shown, first bend the same end of the positive electrode connecting piece 21 and the negative electrode connecting piece 22 along the bending stress hole 23 toward the back of the cover plate assembly 3 by 90 degrees. At this time, the two core assemblies 1 follow the connecting piece. The bending is also folded 90 degrees toward the back of the cover plate assembly 3, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com