Negative pole piece with coating layer as well as preparation method and application of negative pole piece

A negative pole piece and coating technology, which is applied in the field of high-energy-density all-solid-state batteries, can solve the problems of reducing the transmission efficiency of lithium metal and sulfide ions, large changes in electrode volume, and failure of all-solid-state batteries. energy, increase energy density, and improve electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

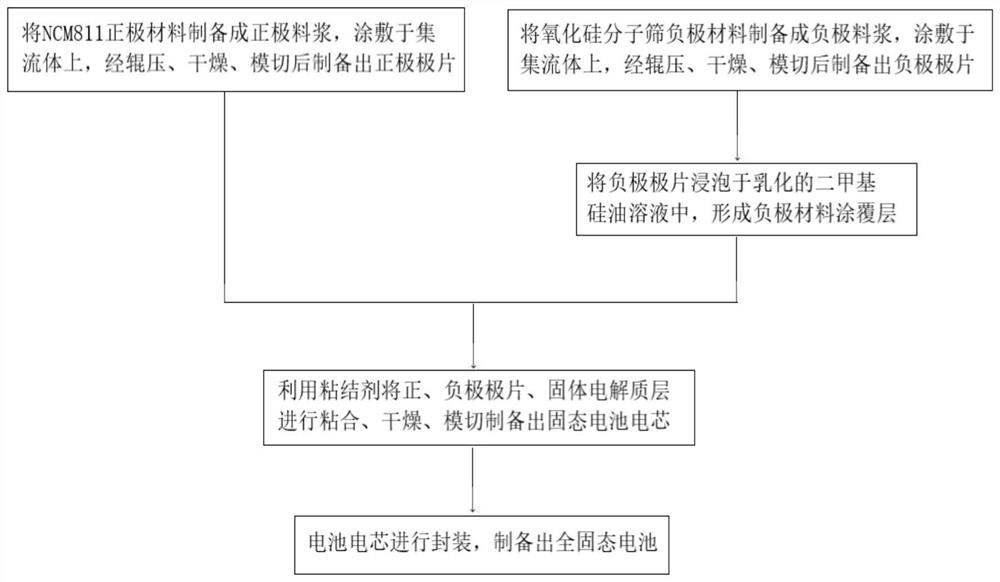

Image

Examples

Embodiment 1

[0066] This embodiment provides a negative electrode sheet with a coating layer and a preparation method thereof. The negative electrode sheet includes a negative electrode current collector, and a negative electrode material layer and a coating layer sequentially located on both sides of the negative electrode current collector. The thickness of the layer is 20 μm.

[0067] The preparation method of the negative pole piece comprises the following steps:

[0068] Select silicon oxide molecular sieve as the negative electrode material with a porosity of 30%. Mix the negative electrode material and the conductive agent (SFG-6) evenly, and then mix them with the binder (SBR). The amount of the binder added is the mass of the negative electrode mixture %, the amount of conductive agent added is 5% of the mass of the negative electrode mixture material, mixed to prepare negative electrode slurry, coated on 12μm copper foil, moved to a vacuum oven with a vacuum degree of 0.6Mpa, vac...

Embodiment 2

[0075] This embodiment provides a negative electrode sheet with a coating layer and a preparation method thereof. The negative electrode sheet includes a negative electrode current collector, and a negative electrode material layer and a coating layer sequentially located on both sides of the negative electrode current collector. The thickness of the layer was 22 μm.

[0076] The preparation method of the negative pole piece comprises the following steps:

[0077] Select silicon oxide molecular sieve as the negative electrode material with a porosity of 28%. Mix the negative electrode material and conductive agent (SFG-6) evenly, and then mix them with the binder (SBR). The amount of binder added is the mass of the negative electrode mixture material 2 %, the amount of conductive agent added is 5% of the mass of the negative electrode mixture material, mixed to prepare negative electrode slurry, coated on 12μm copper foil, moved to a vacuum oven with a vacuum degree of 0.7Mpa,...

Embodiment 3

[0083] This embodiment provides a negative electrode sheet with a coating layer and a preparation method thereof. The negative electrode sheet includes a negative electrode current collector, and a negative electrode material layer and a coating layer sequentially located on both sides of the negative electrode current collector. The thickness of the layer was 23 μm.

[0084] The preparation method of the negative pole piece comprises the following steps:

[0085] Select silicon oxide molecular sieve as the negative electrode material with a porosity of 25%. Mix the negative electrode material and conductive agent (SFG-6) evenly, and then mix them with the binder (SBR). The amount of binder added is the mass of the negative electrode mixture material 2 %, the amount of conductive agent added is 5% of the mass of the negative electrode mixture material, mixed to prepare negative electrode slurry, coated on a 12 μm copper foil, moved to a vacuum oven with a vacuum degree of 0.4M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com