Connecting structure for a striking plate of a golf club head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Preferred embodiments of the present invention are now to be described hereinafter in detail, in which the same reference numerals are used in the preferred embodiments for the same parts as those in the prior art to avoid redundant description.

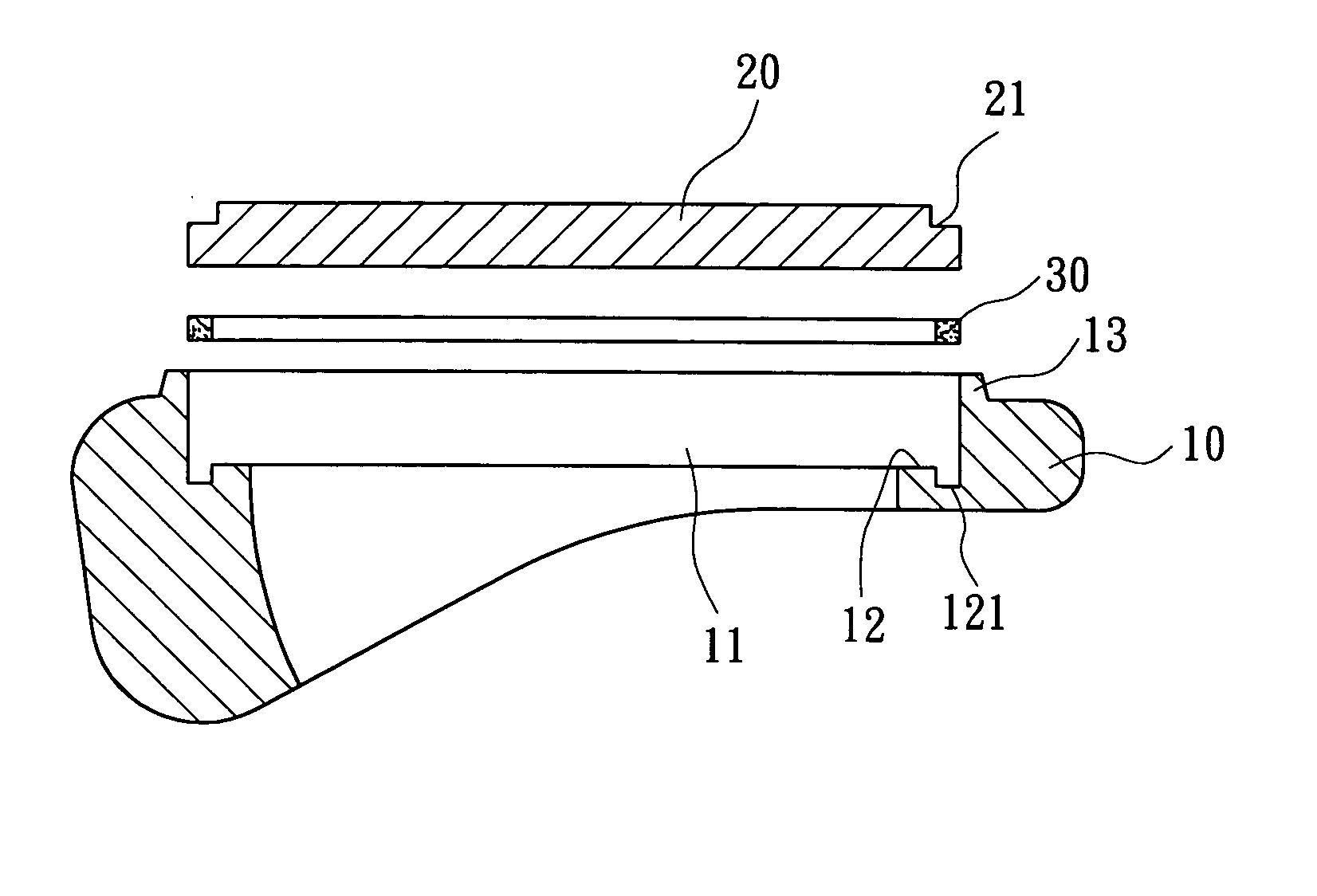

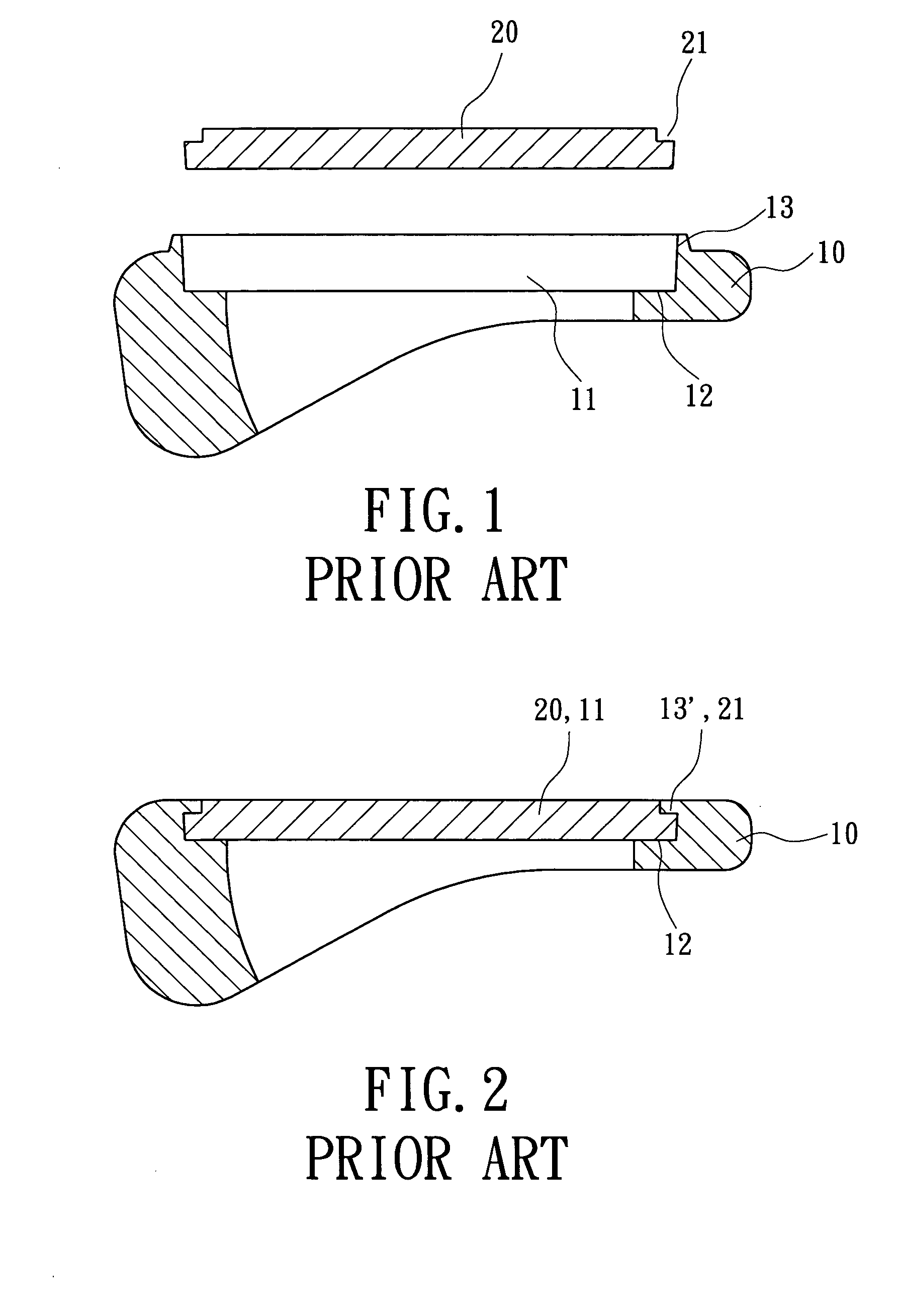

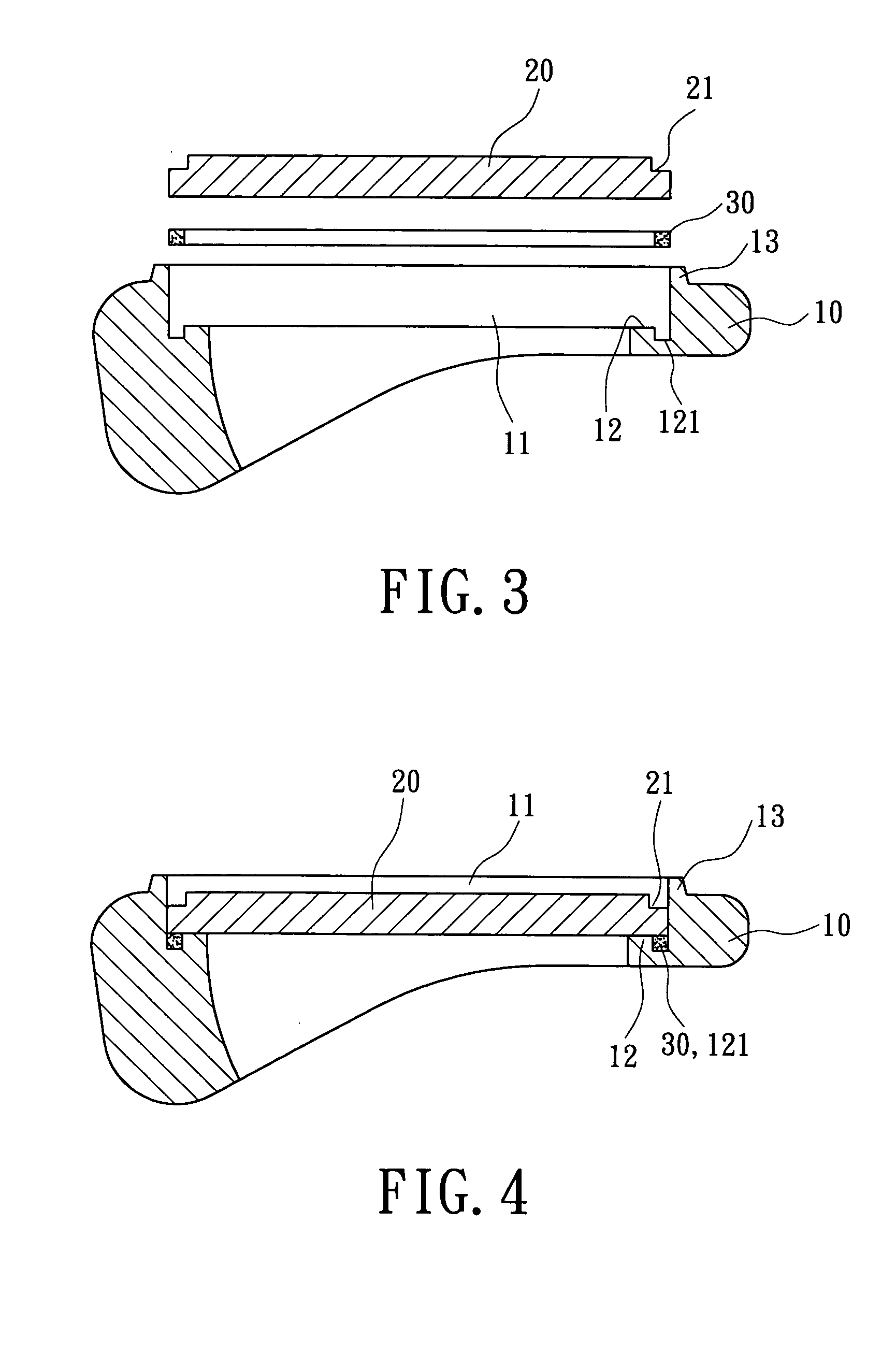

[0027]FIG. 3 is an exploded sectional view illustrating a golf club head in accordance with the present invention before processing. FIG. 4 is a sectional view of the golf club head in FIG. 3. FIG. 5 is a sectional view of the golf club head in accordance with the present invention after processing. FIG. 6 is an enlarged view of a circled portion in FIG. 5.

[0028] Referring to FIG. 3, the golf club head in accordance with the present invention includes a golf club head body 10, a striking plate 20, and a ring 30. The golf club head body 10 is made of a material having a Young's modulus greater than 3×107 psi, such as stainless steel, carbon steel, alloy steel, or Fe—Mn—Al alloy. The golf club head body 10 includes a recession 11 in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com