Novel bulkhead gate

A flat gate, a new type of technology, applied in water conservancy engineering, marine engineering, coastline protection and other directions, can solve problems such as laborious door opening, easy damage to water stop, and cavitation in door grooves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention shall not be limited in any way, and any changes or improvements made based on the teaching of the present invention shall fall within the scope of protection of the present invention.

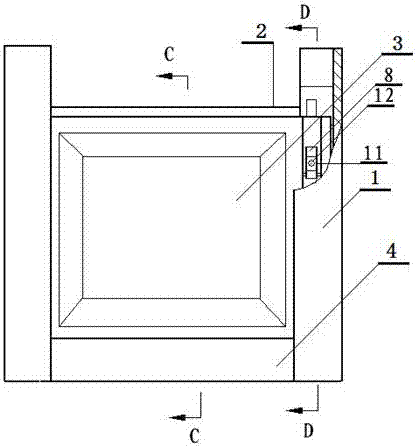

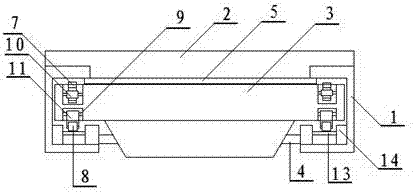

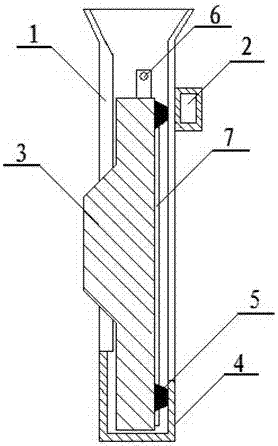

[0015] Such as Figure 1~6 As shown, the present invention comprises a grooved rail 1, a crossbeam 2, a door leaf 3, a bottom beam 4 and a door opening slider 7, the grooved rail 1 is vertically arranged on both sides of the bottom beam 4, and the crossbeam 2 is closed to form a door leaf A door leaf 3 is set in the door leaf frame, a positioning chute 14 and a shock-absorbing rubber plate 13 are arranged in the groove rail 1, a fixed groove is opened on one side of the working surface of the door leaf 3, and a fixed groove is set in the groove. Shaft 9 and damping bushing 8, the other side of the door leaf 3 opposite to the working surface is provided with a ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com