A device for high-frequency vibration rolling to strengthen laser cladding layer and its application method

A technology of laser cladding and high-frequency vibration, which is applied in coating, metal material coating process, etc., can solve problems such as high economic cost and difficult machining, achieve uniform solute, short transmission path, and reduce segregation and defects the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

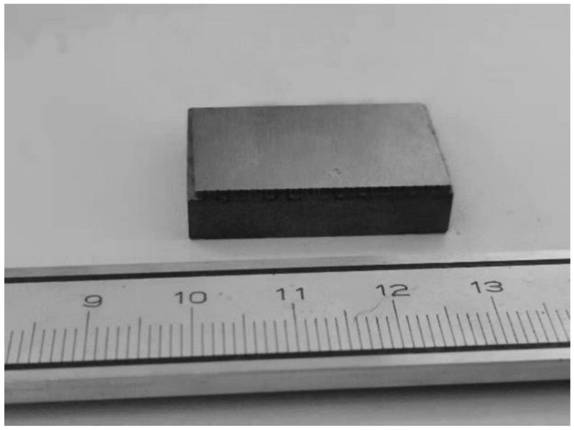

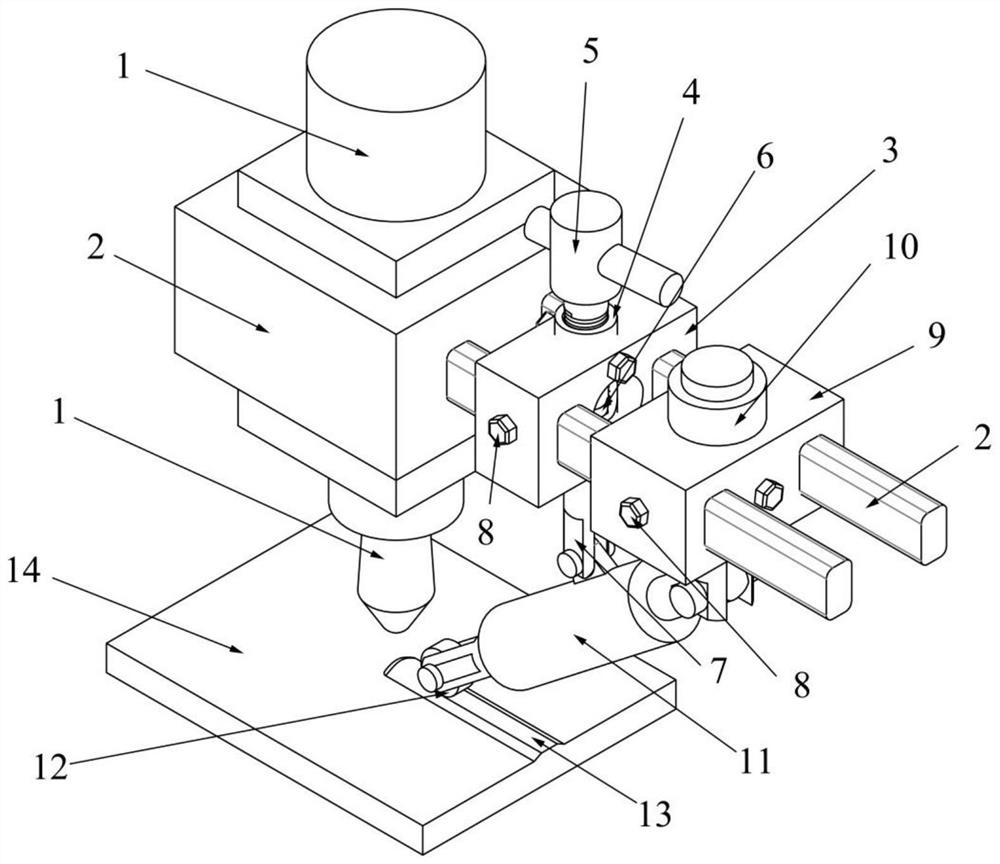

Embodiment 1

[0053] The substrate of the cladding sample is polished and cleaned with metallographic sandpaper. The substrate of the sample is H13 steel with a specification of 6mm×15mm×30mm, and the cladding material used is Ni60+30%Wc powder. The sample is installed on the cladding equipment, and the parameters of laser cladding are as follows: the laser power is 3000W×70%; the scanning speed is 0.06mm / s; the speed of the powder feeder is 0.8rpm; The defocus amount is 12mm; the vibration frequency is 20kHz; the pressure rolling force is 10N; The experimental results are attached Figure 8 The physical map of the cladding sample prepared in this example; attached Image 6 The metallographic diagram of the coating prepared in this example shows that the Ni60+30%Wc coating has uniform composition distribution, uniform and dense grains, no cracks, no pores and shrinkage holes, and the average hardness can reach 800HV, the maximum hardness difference is less than or equal to 5HV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com