Rotary-cutting column type deposit sampler

A sediment and sampler technology, applied in the field of sediment collection, can solve the problems of large disturbance of sediment samples, sample loss collection efficiency, complex structure, etc., achieve good layered sampling effect, easy maintenance and portability, and simplify operation steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further described in detail through the following embodiments in conjunction with the accompanying drawings, but the technical content described in this embodiment is illustrative rather than restrictive, and should not limit the protection scope of the present invention in turn.

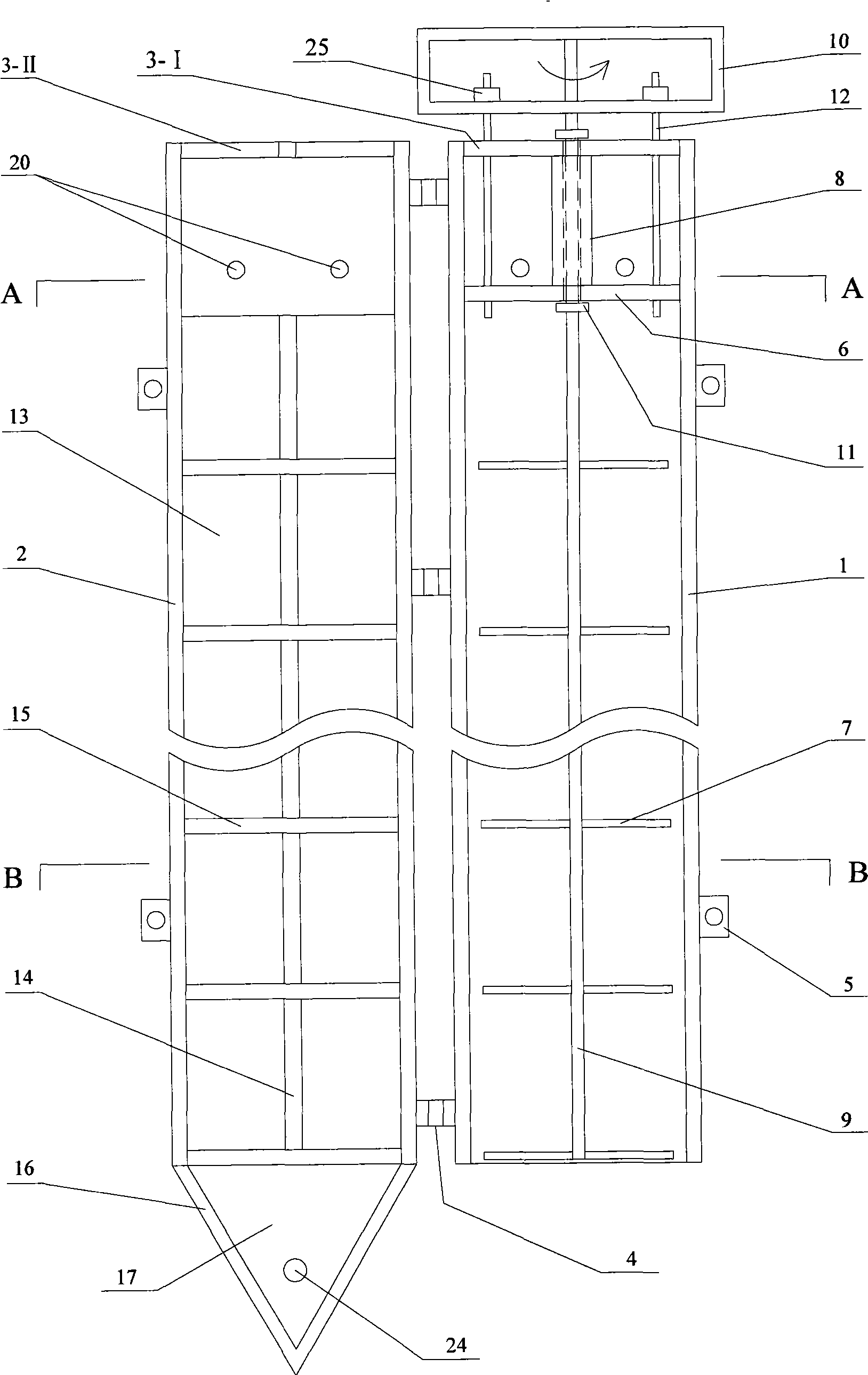

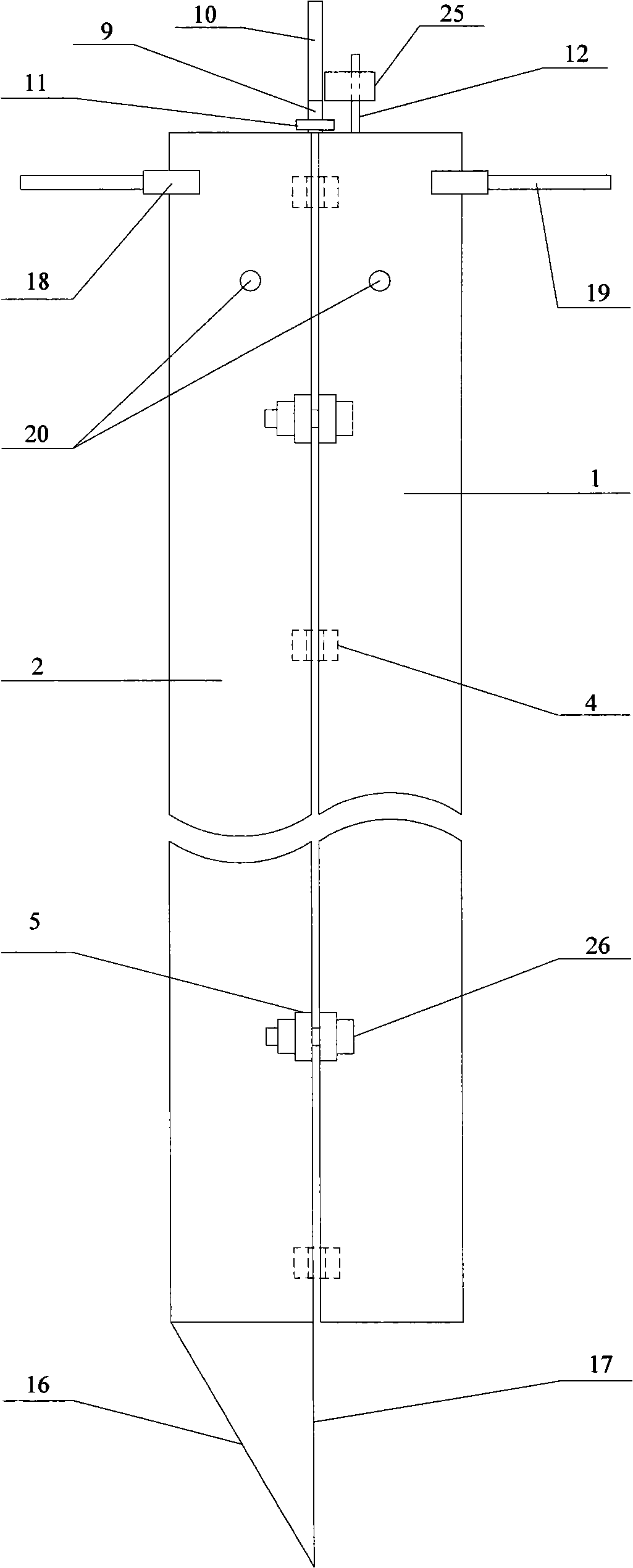

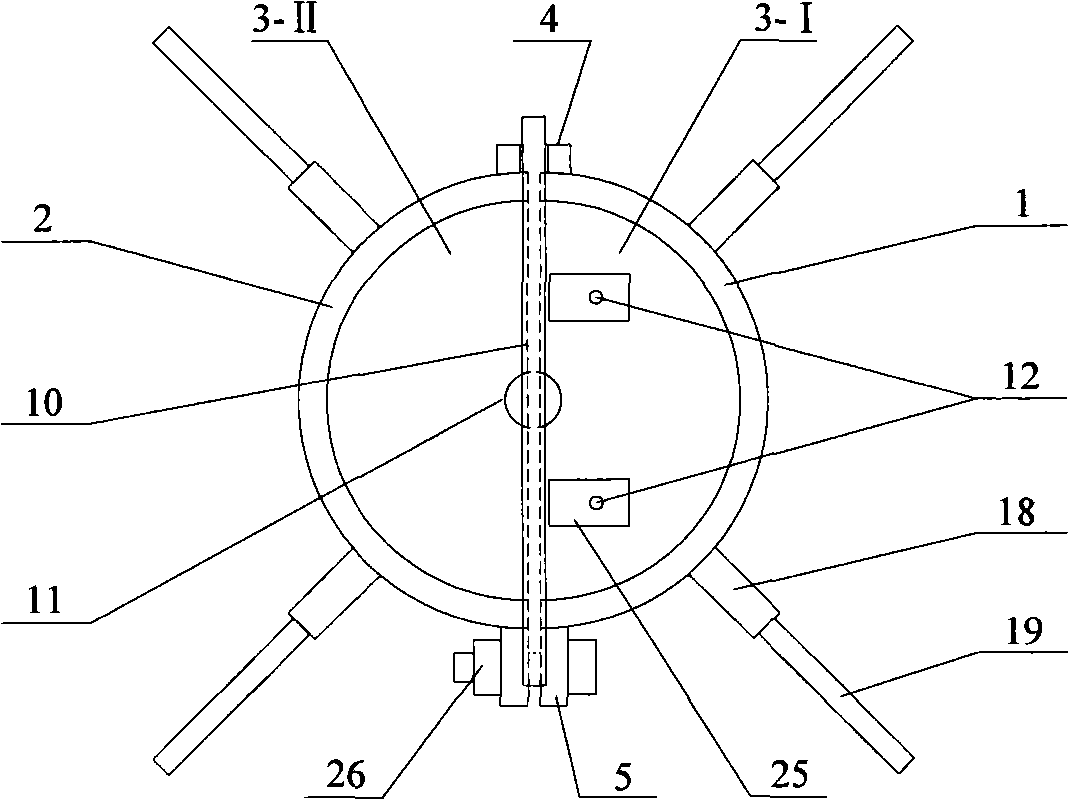

[0022] A rotary-cut columnar sediment sampler, which is composed of a sampling tube, a rotary-cutting system and a support plate; The pipe 1 and the distribution half pipe 2 are two parts which are divided equally by a circular pipe along the axial direction. Nuts 26 are connected to form a cylindrical body that can be opened and closed. The top cover 3 is composed of two semicircular plates 3-I and II that are respectively fixed on both sides of the positive half pipe and the distribution half pipe. -The centers of I and II are respectively provided with semicircular grooves along the axial direction of the sampling tube. When the positive half pipe 1 and the matchin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com