Sewage sedimentation device convenient for sludge discharge

A sedimentation device and sewage technology, which is applied to the feeding/discharging device of the settling tank, sedimentation separation, settling tank, etc., can solve the problems of short cleaning cycle, inconvenient operation, and poor sludge cleaning effect, and achieve improved mixing Uniformity and efficiency, the effect of accelerating precipitation formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

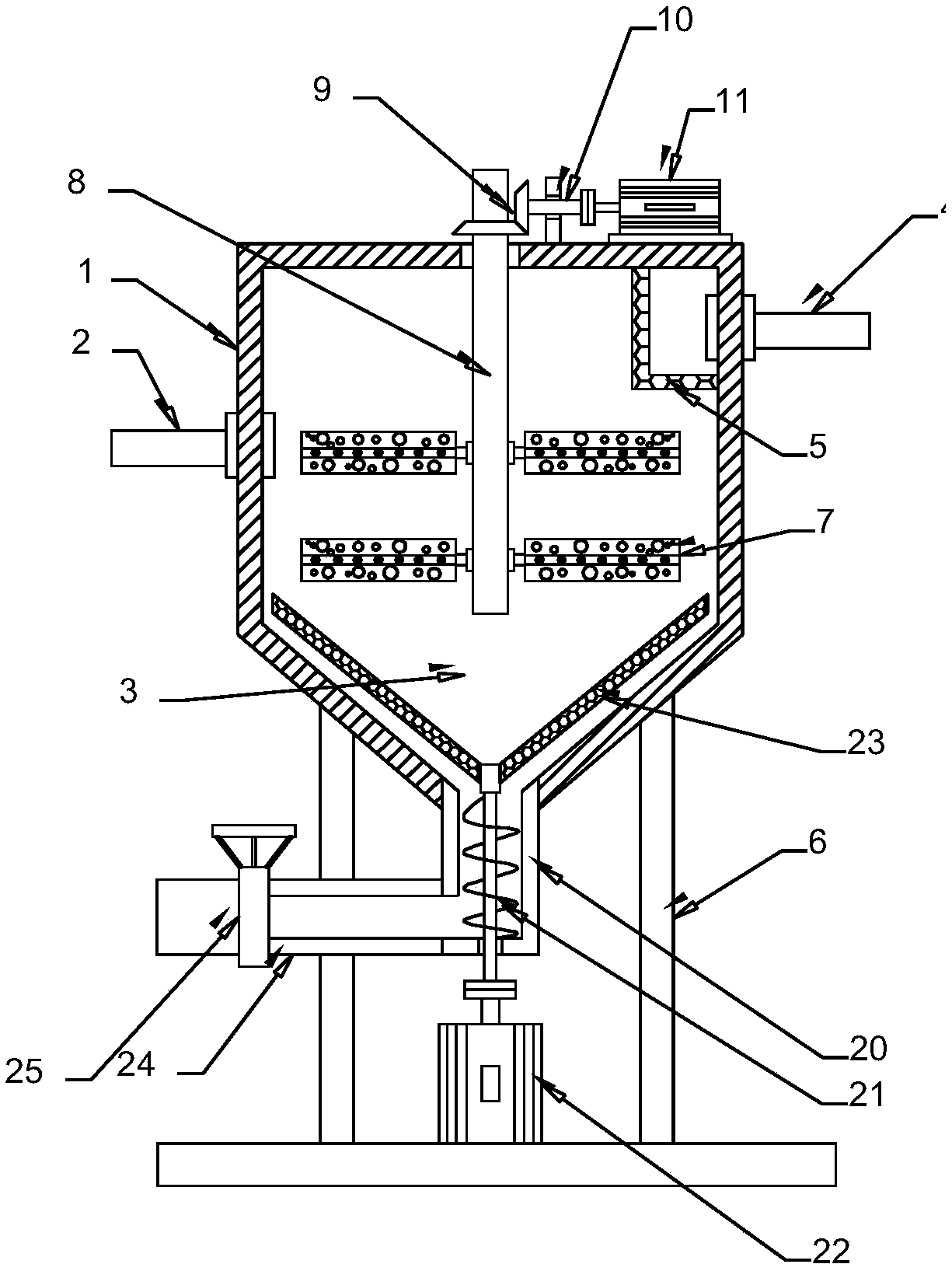

[0020] see Figure 1~3 , in the embodiment of the present invention, a kind of sewage sedimentation device that is convenient for sludge discharge comprises a box body 1, a water inlet pipe 2, a stirring plate 7 and a stirring shaft 8; The water pipe 2 enters the box body 1; the box body 1 is provided with a stirring shaft 8, the stirring shaft 8 is fixedly connected with the stirring plate 7, the stirring shaft 8 extends to the top of the box body 1 and is rotatably connected with the top plate of the box body 1 through a bearing, The upper end of the stirring shaft 8 is connected to the transmission shaft 10 through the transmission gear set 9, and the transmission shaft 10 is connected to the output shaft of the first driving motor 11 through a coupling, and the first driving motor 11 is fixed to the upper surface of the box body 1 by means of bolts. connection, the drive motor 11 is electrically connected with the external power supply, and the drive motor 11 drives the st...

Embodiment 2

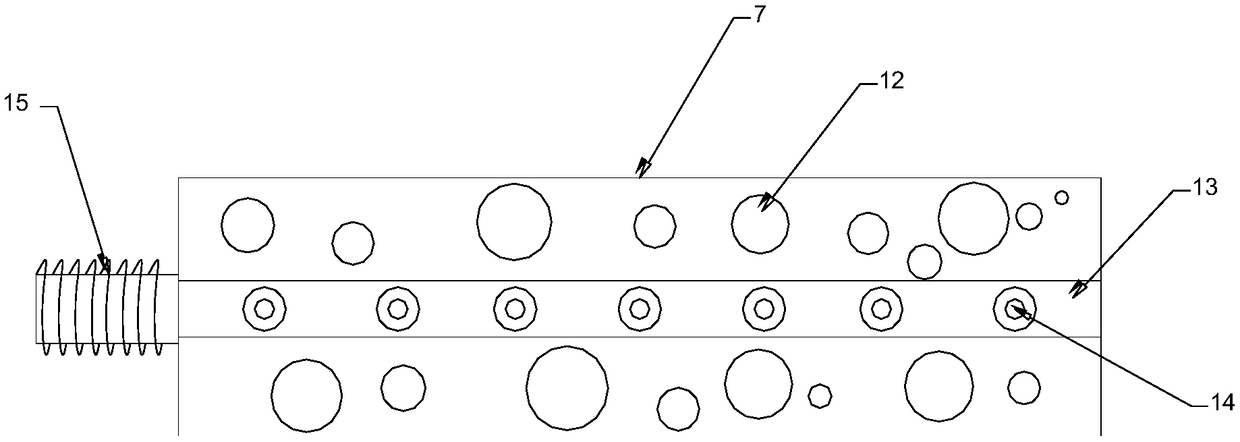

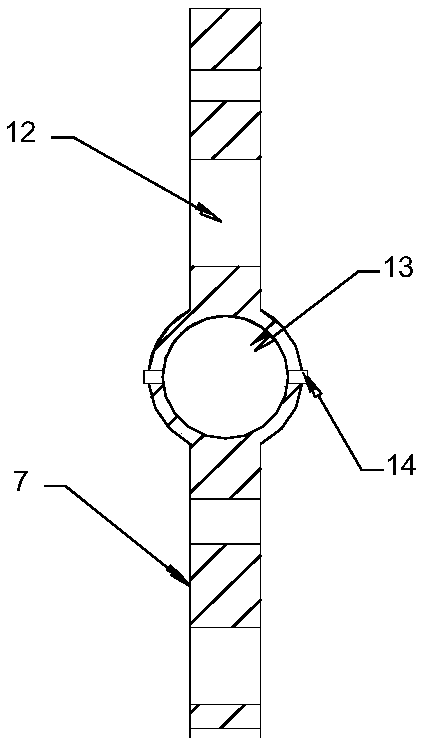

[0022] see Figure 4 The difference between this embodiment and Embodiment 1 is that the stirring plate 7 is provided with irregularly distributed through-holes 12, which facilitates the generation of turbulent flow during stirring and improves the stirring effect; the central position of the stirring plate 7 is provided with a central through-pipe 13. The surface of the center pipe 13 is provided with overflow holes 14 equidistantly distributed; the inner side of the stirring plate 7 is fixedly connected with a threaded cylinder 15, and the threaded cylinder 15 is a hollow cylinder with threads on the outer wall, and the threaded cylinder 15 is connected with the center pipe 13 connected; the threaded cylinder 15 is nested in the stirring shaft 8 and threadedly connected with the stirring shaft 8, the stirring shaft 8 is a hollow shaft, and the threaded cylinder 15 communicates with the inner cavity of the stirring shaft 8; the upper end of the stirring shaft 8 passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com