Stepless speed regulating mechanism

A stepless speed regulation, friction wheel technology, applied in mechanical equipment, belts/chains/gears, transmissions, etc., can solve the problems of reduced equipment performance, low equipment automation, and poor speed regulation accuracy. Simple structure, improved performance and automation level, accurate speed regulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

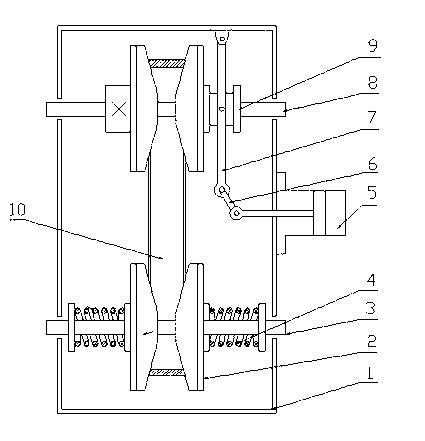

[0008] In the figure, the invention includes transmission box 1, friction wheel 2, driven shaft 3, spring 4, cylinder 5, connecting rod 6, lever 7, driving shaft 8, sliding sleeve 9, transmission belt 10, and the invention has a rectangular Transmission box 1, the driving shaft 8 and the driven shaft 3 parallel to each other are arranged up and down in the transmission box 1, and a pair of friction wheels 2 with opposite cone angles are respectively installed on the driving shaft 8 and the driven shaft 3, and the friction wheels 2 are opposite to each other. A "V"-shaped wheel groove is naturally formed between the cone angles, and the friction wheel 2 movably installed on the driven shaft 3 slides along the axis; two compression springs 4 are respectively installed on both sides of a pair of friction wheels 2 on the driven shaft 3 , the compression spring 4 squeezes two friction wheels 2 inwardly, and the friction wheels 2 installed on the driving shaft 8 are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com