Accelerator conveying and speed regulating control system and calibration method

A technology of control system and accelerator, applied in pump control, pipeline system, gas/liquid distribution and storage, etc., can solve the problems of easy oscillation, slow response of speed regulation, poor accuracy and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

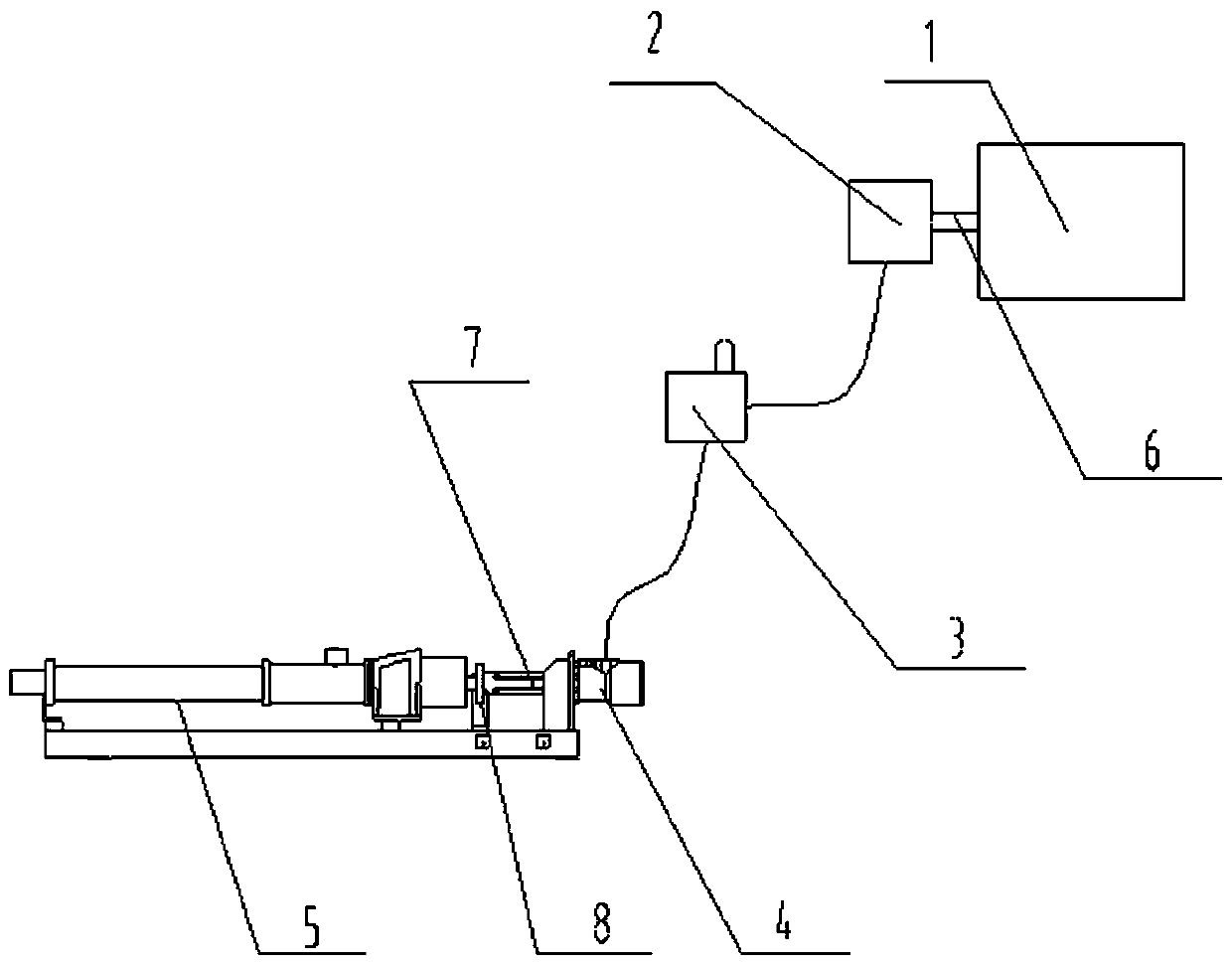

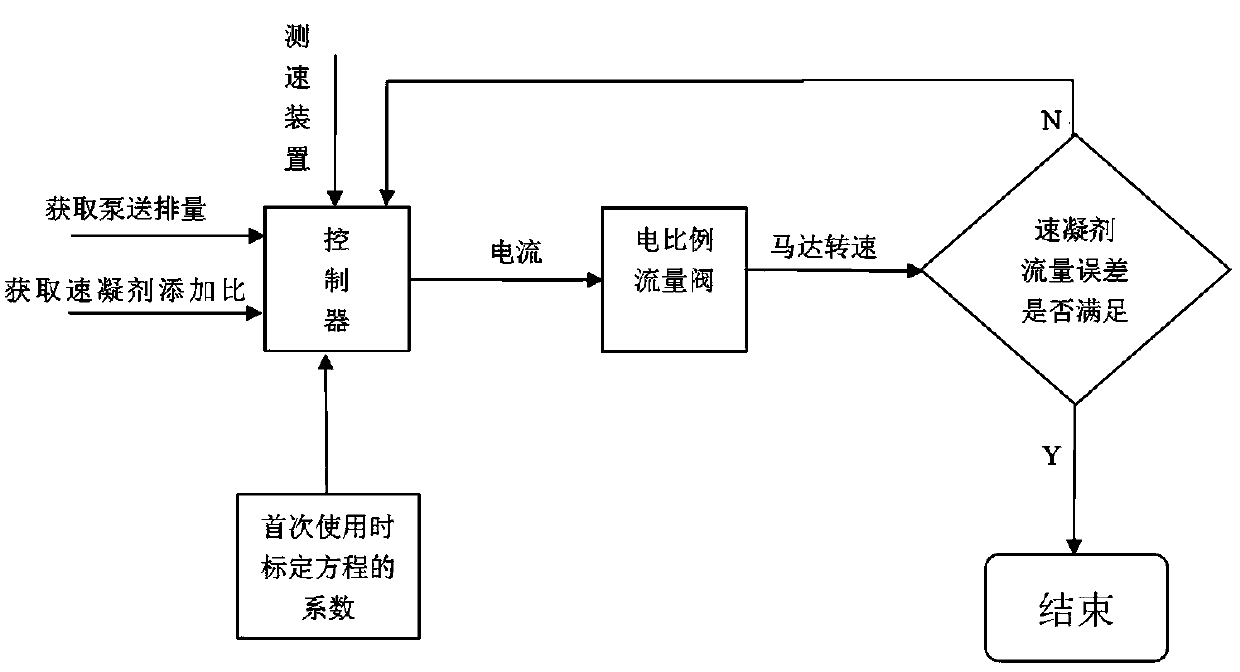

[0022] This embodiment includes a motor 1, an oil pump 2, an electric proportional flow regulating valve 3, a motor 4 and an accelerator pump 5, which are connected in sequence. The oil pump 2 is connected with the motor 1 through a coupling 16, and the accelerator pump 5 is connected to the motor 4 Through the coupling II 7 connection, the coupling II 7 is provided with a speed measuring device 8, the motor 1 drives the oil in the oil pump 2 to flow through the electric proportional flow regulating valve 3 and is sent to the motor 4, and the motor 4 is used to drive the accelerator pump 5 , by adjusting the electric proportional flow control valve 3 to change the oil supply of the motor 4 to change the speed of the accelerator pump 5 .

[0023] The speed-regulating control system for the delivery of accelerators also includes a controller 8 for controlling operations.

[0024] The accelerator pump 5 is a screw pump, and the relative movement of the stator and the rotor realiz...

Embodiment 2

[0030] The difference between this embodiment and Embodiment 1 is that the accelerator pump 5 is a peristaltic pump, which realizes fluid output by squeezing the hose through a cam. The speed measuring device 8 uses the photoelectric code disc speed measurement method, and is composed of a light source and a photoelectric code disc. The same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com