Patents

Literature

52results about How to "Fast auto switch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

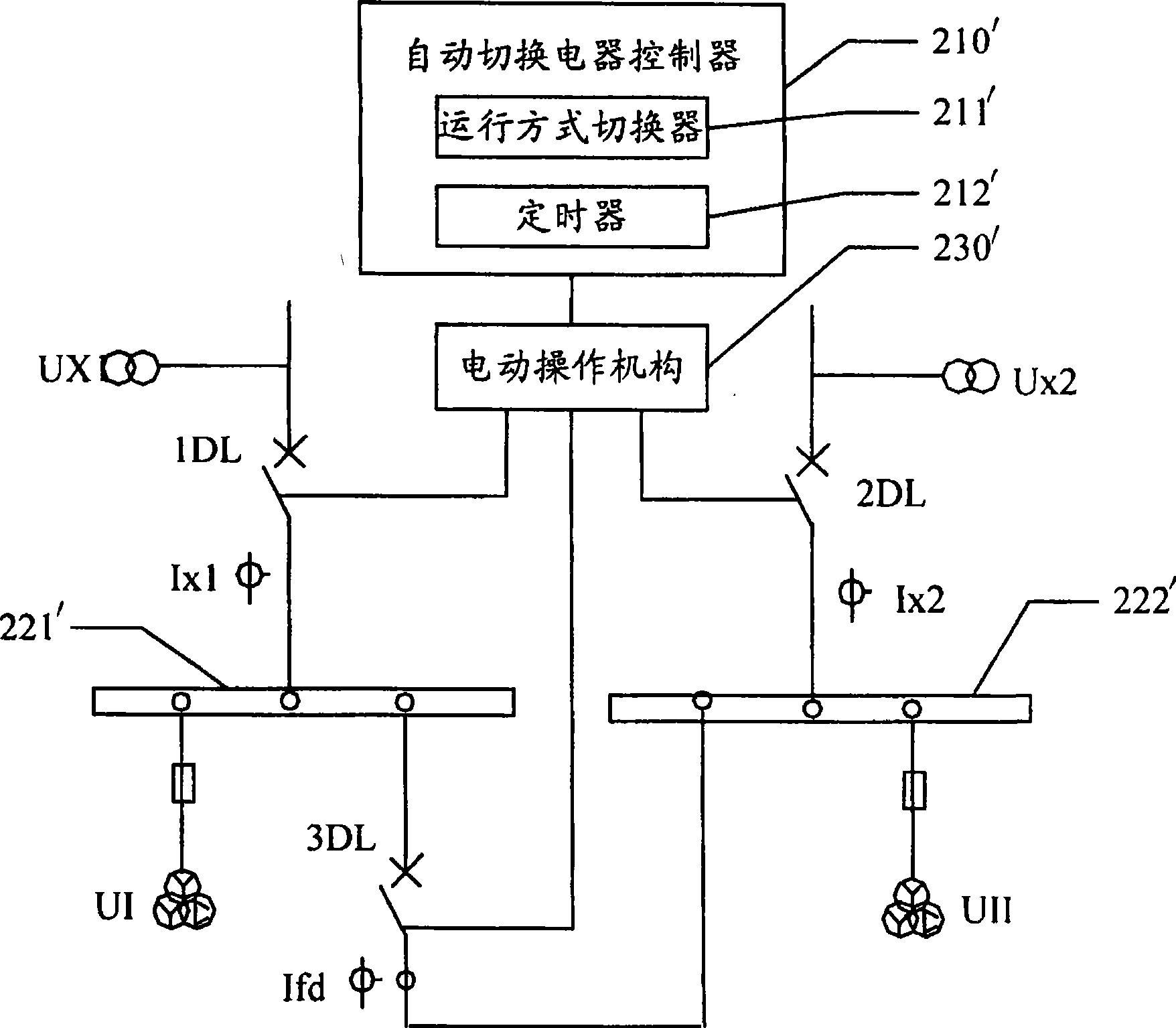

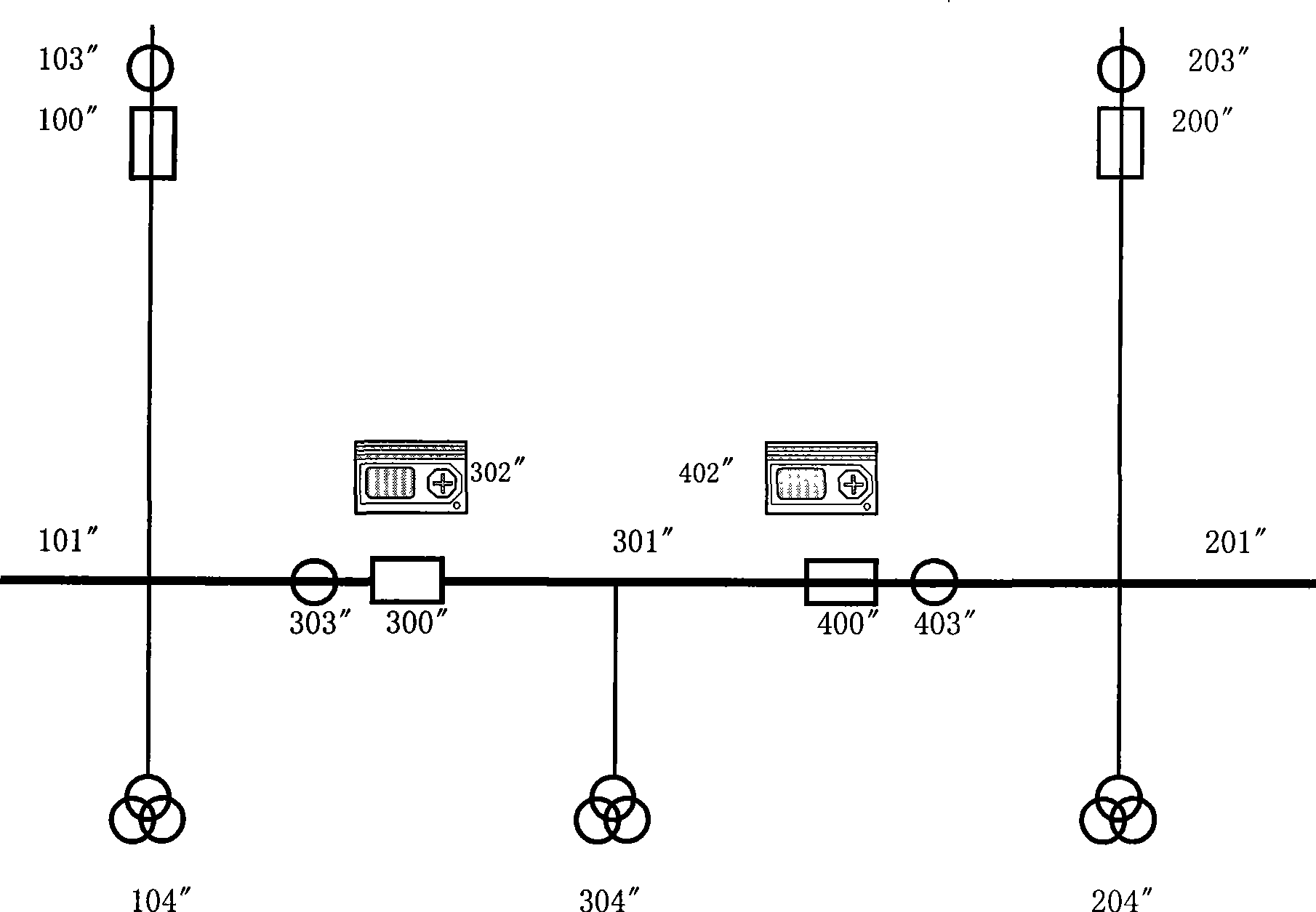

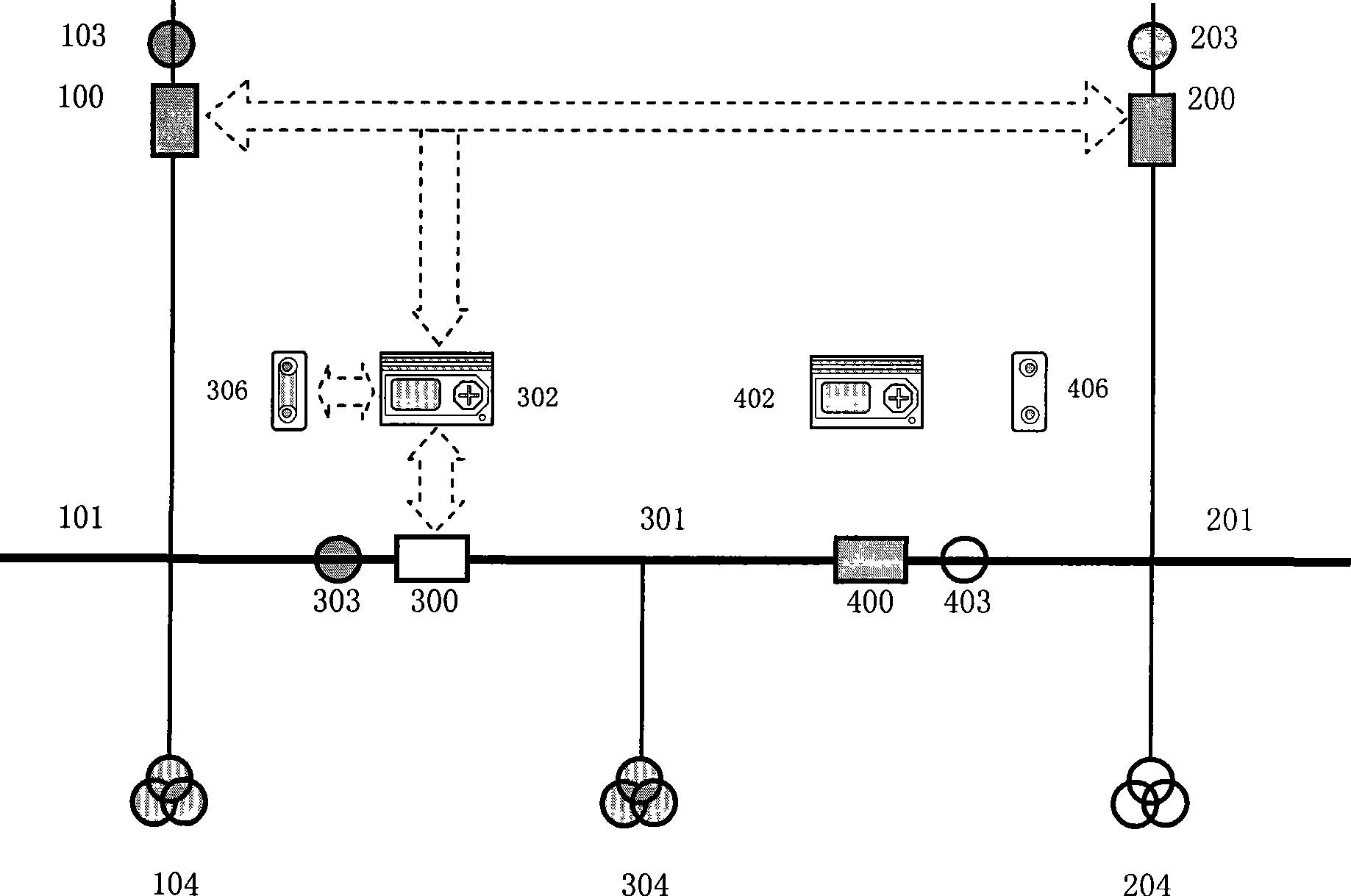

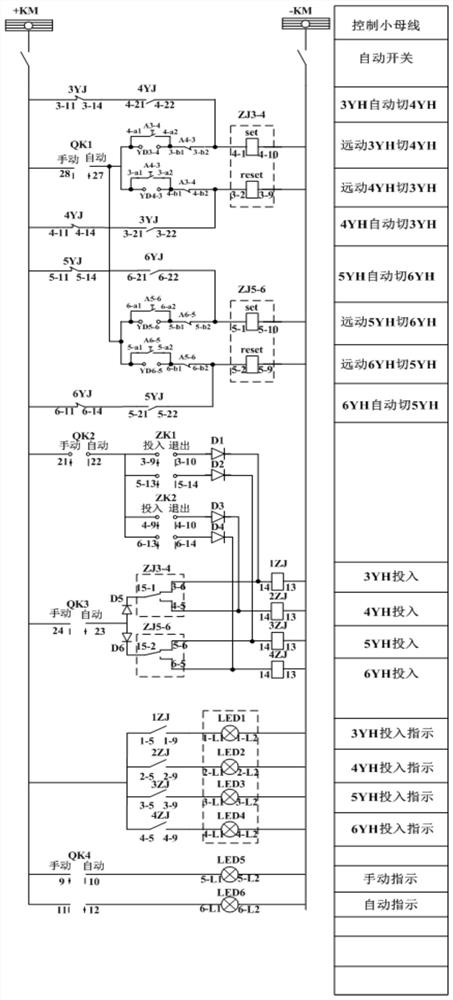

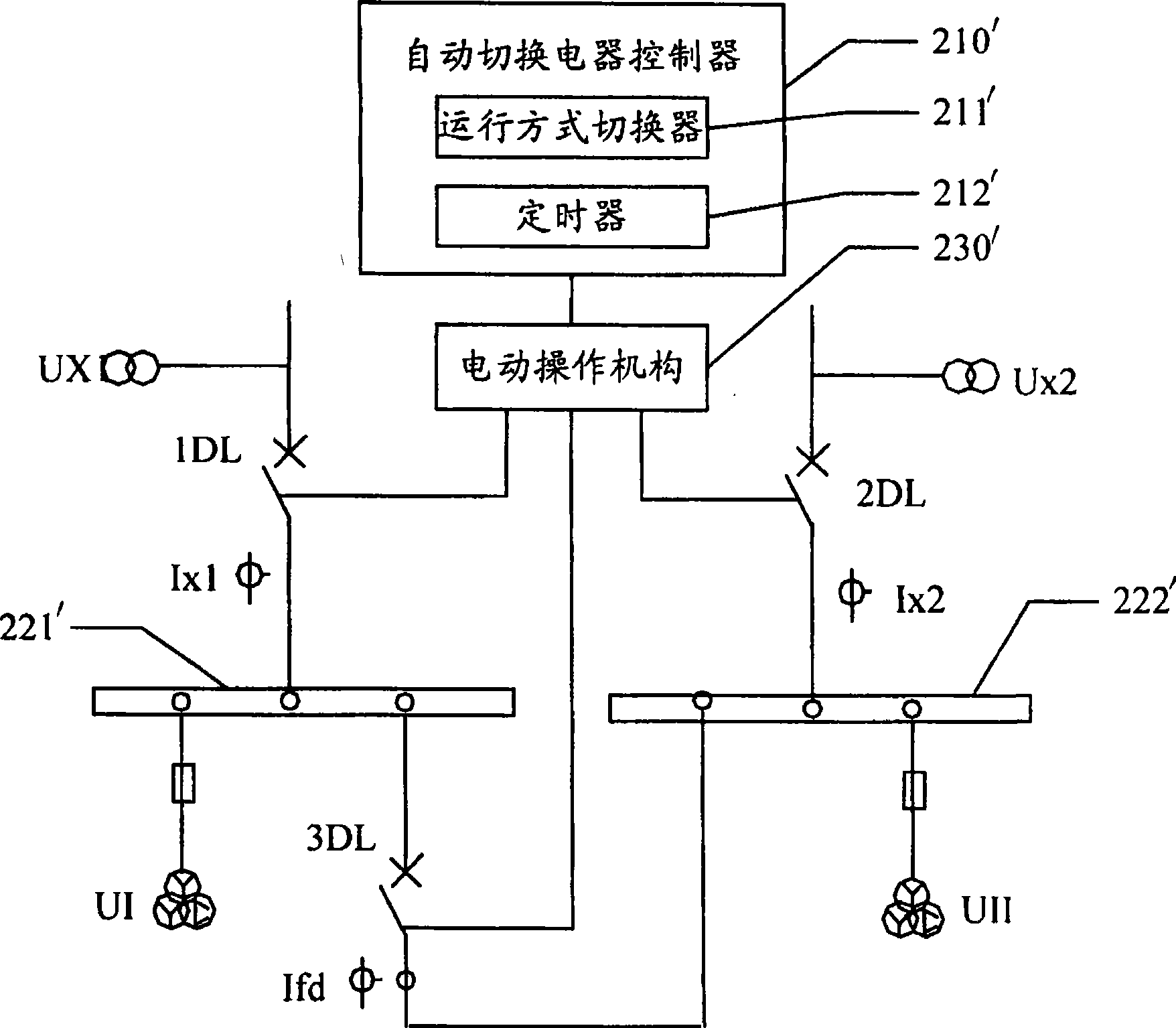

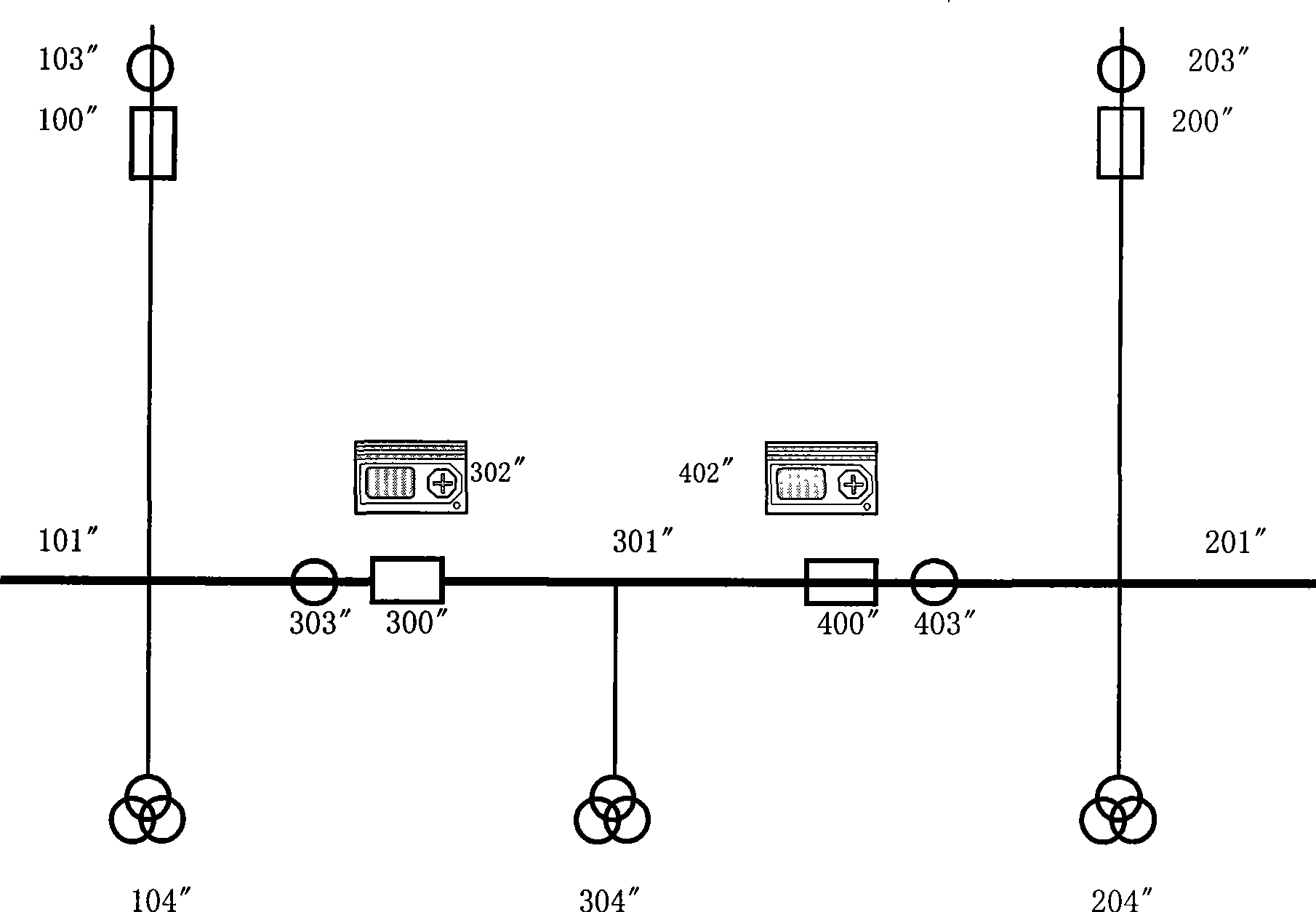

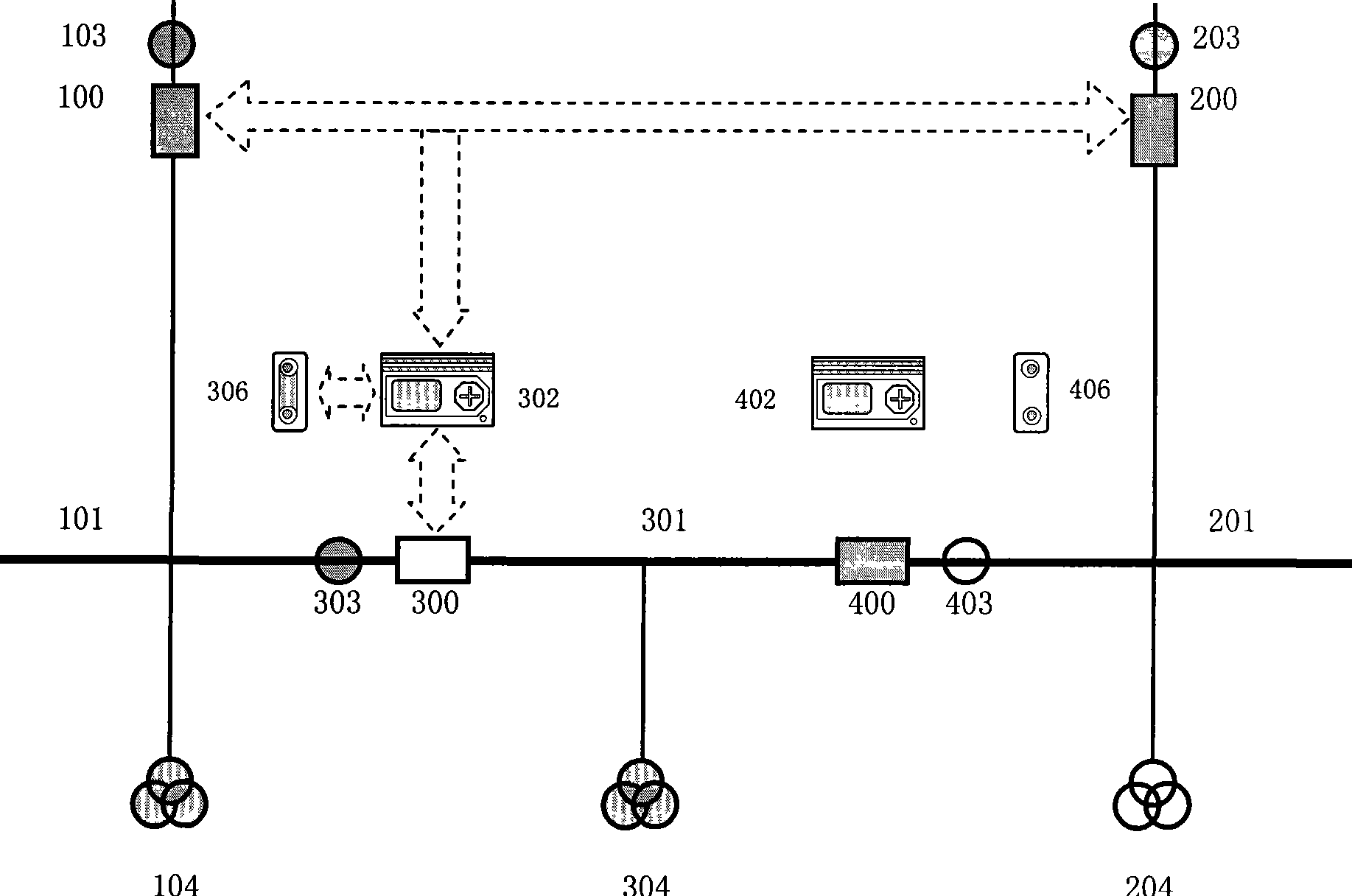

Spare power automatic switching device and method for three-segment bus two-segment switch

InactiveCN101369739AFast auto switchAvoid misuseEmergency power supply arrangementsBusbarStandby power

A three-busbar two-section switch standby self-casting apparatus, belonging to power distribution field, includes two power supply lead-in circuit breakers, three busbar segments and two section breakers. Two standby self-casting devices being mounted on the position of the two section breakers; the standby self-casting device being equipped with a current detection loop, a voltage detection loop and a control circuit; the current detection loop using the signal of a two-path lead-in current transformer as ''non stream'' criterion, and using the current signal of the corresponding section breaker as ''over current'' criterion; while the voltage detection loop using the voltage signals of the two busbar segments, neighboring the corresponding section breaker, as ''pressure / non-pressure'' criterion. The standby power supply self-casting device includes a electrification discrimination circuit, a first and a second startup condition judgment circuit, a standby self-casting motion circuit and a rear acceleration motion circuit. The invention also discloses standby self-casting method for the apparatus. The apparatus implements power supply rapid automatic switching when the lead-in is failure under different running modes of the three-section busbar, and ensures the power supply reliability under accidents status.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

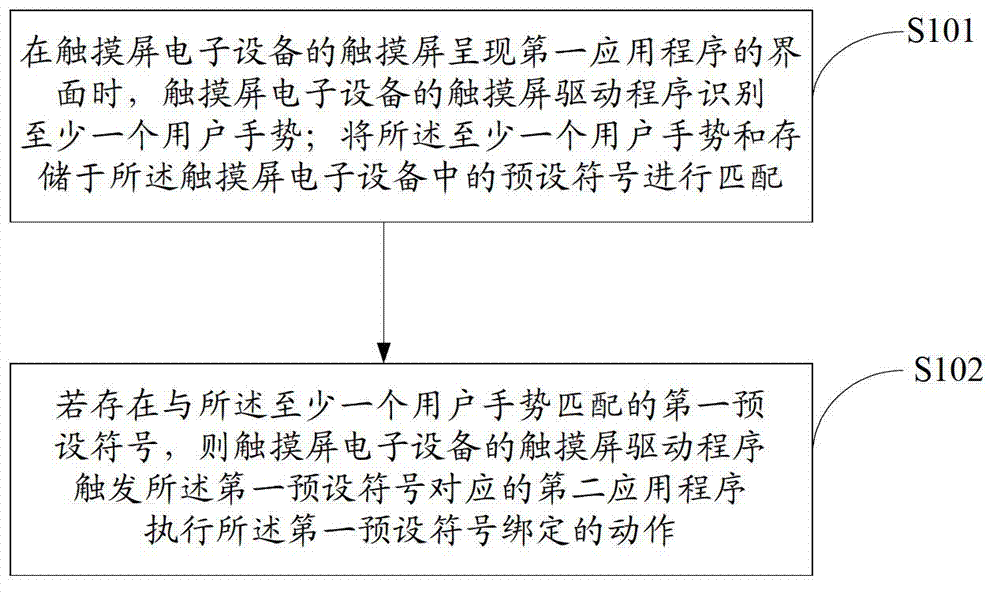

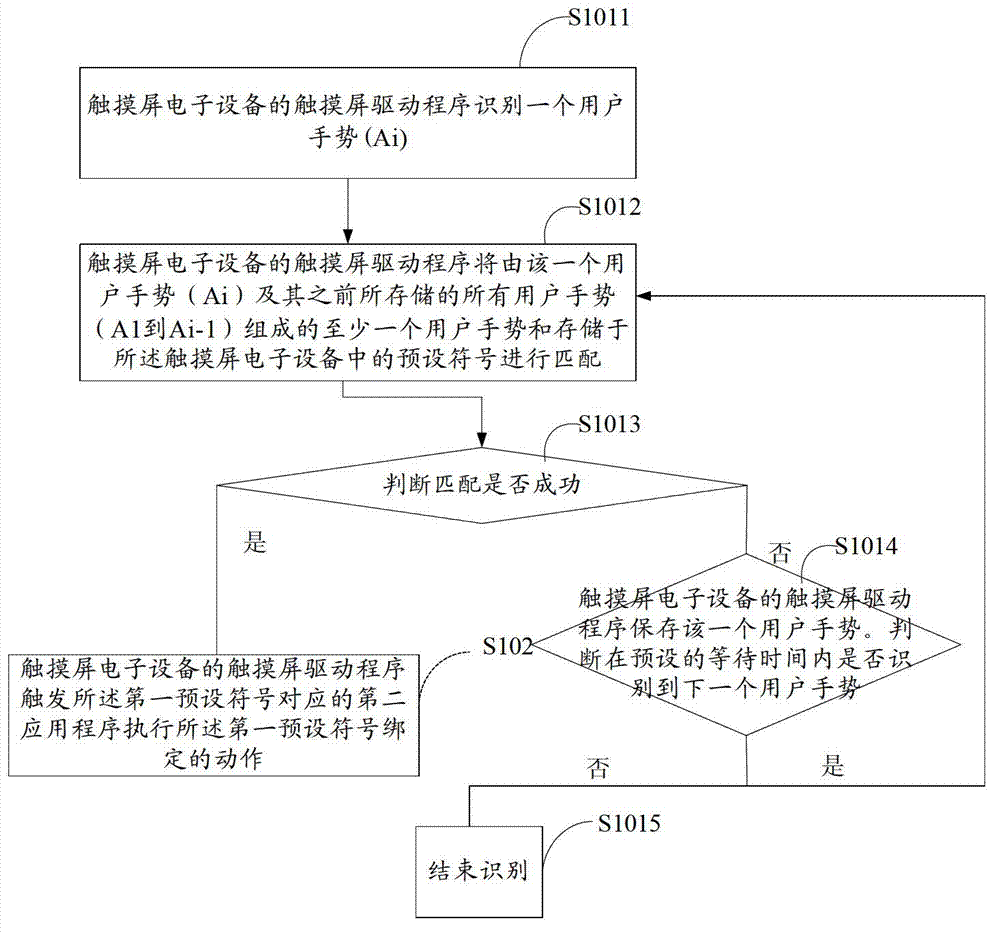

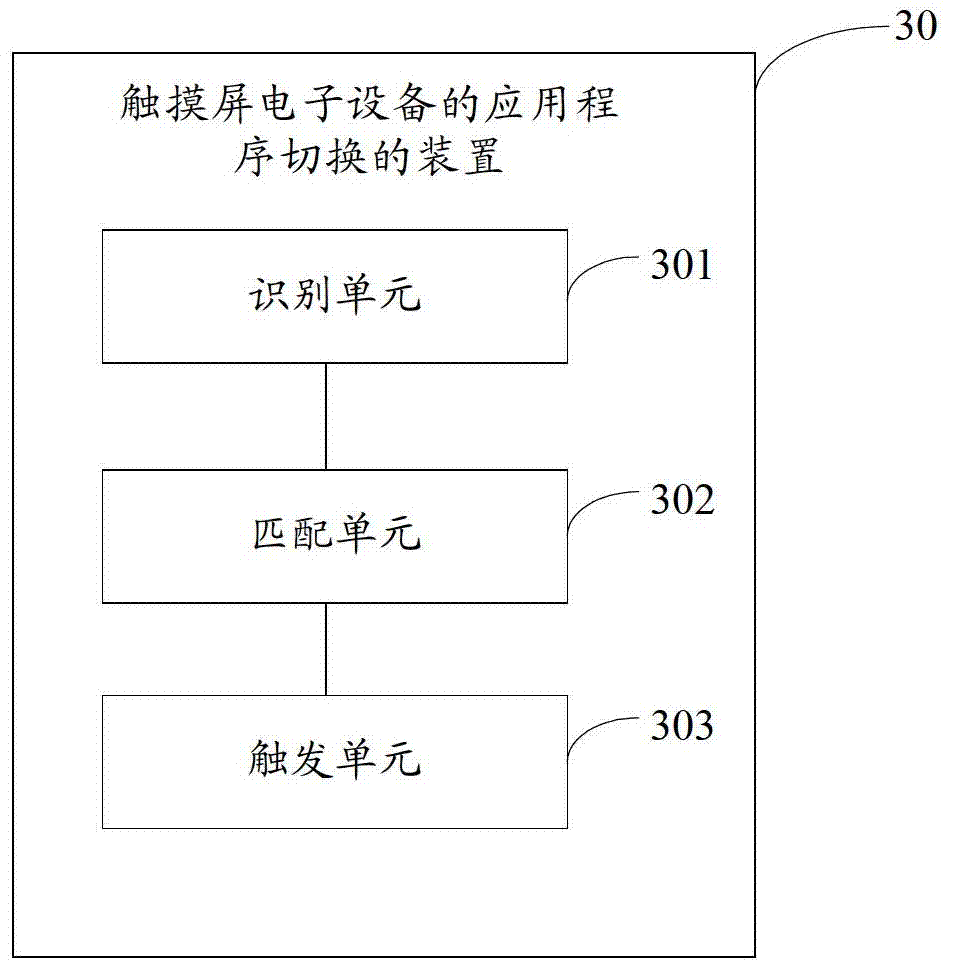

Application program switching method and device and touch-screen electronic device

ActiveCN102810049AFast auto switchProgram initiation/switchingExecution for user interfacesTouchscreenElectronic equipment

Owner:HUAWEI DEVICE CO LTD

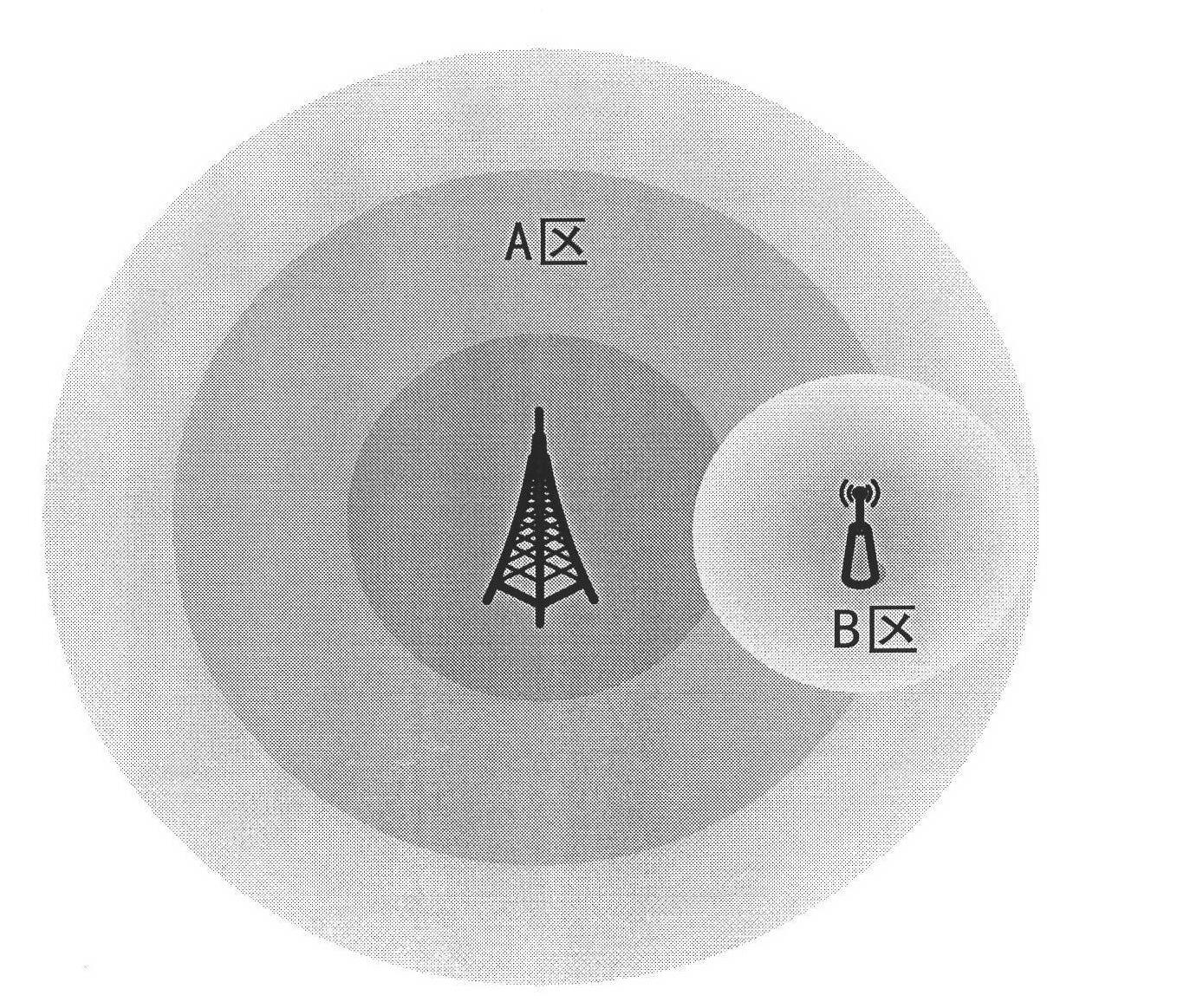

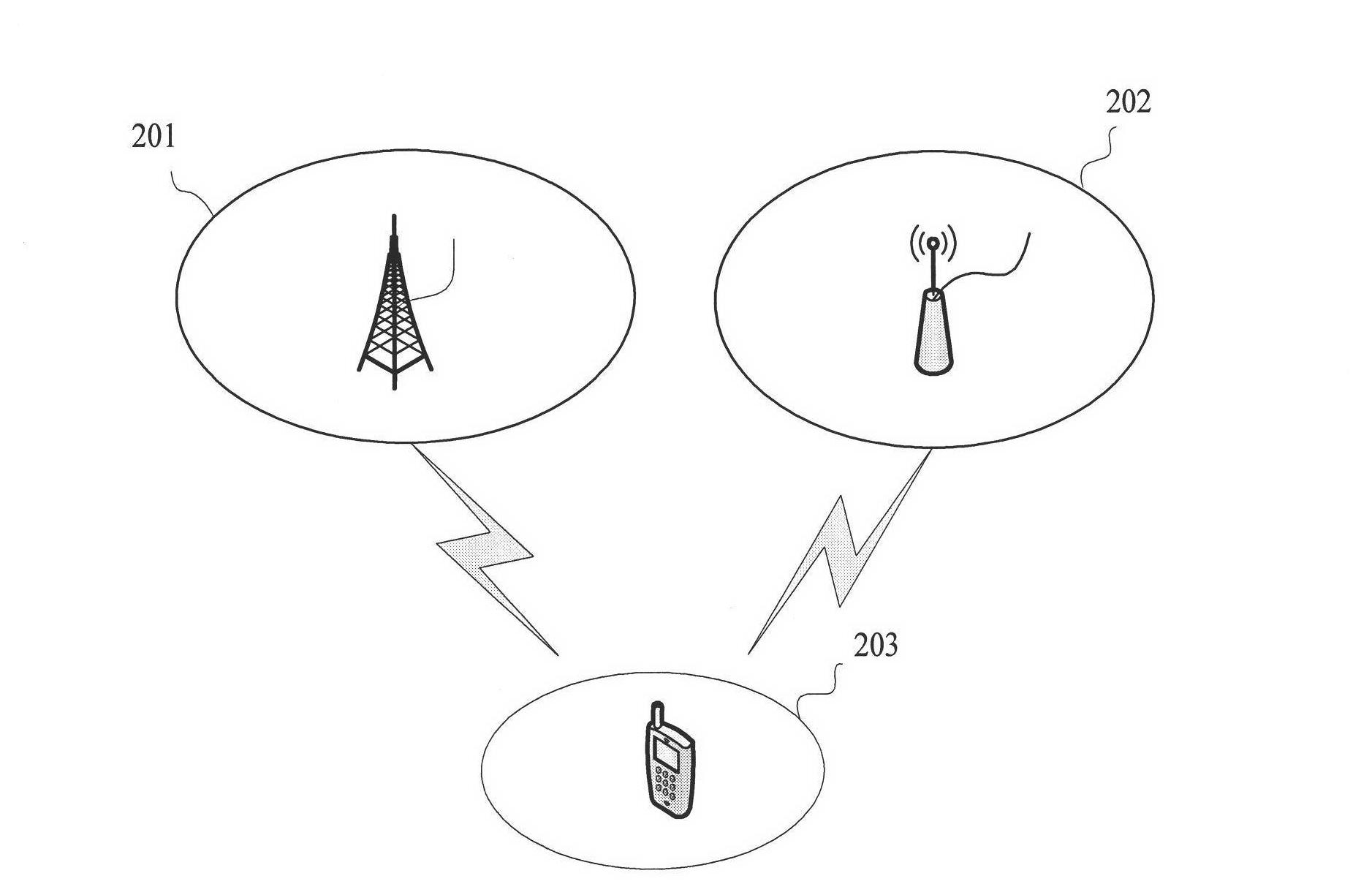

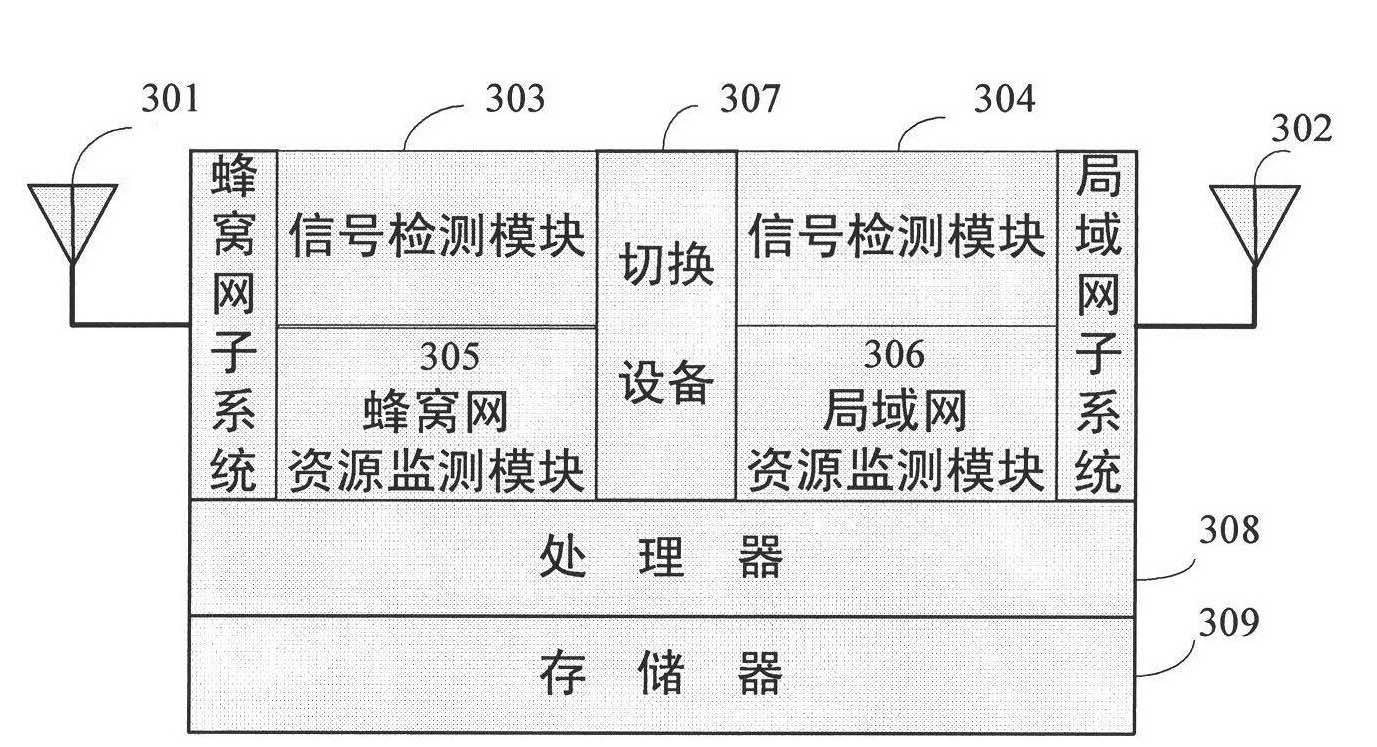

A method for realizing automatic switching between td-scdma cellular network and wireless local area network in heterogeneous network

InactiveCN102300276AAchieve preferential accessFast auto switchWireless communicationTD-SCDMAResource utilization

The invention provides a method for realizing automatic switch between time division-synchronization code multiple access (TD-SCDMA) cellular network and a wireless local area network in a heterogeneous network. In the method, simple hardware update on a wireless terminal, a cellular base station and a wireless access point is made on the basis of an original network; and the automatic switch between the two networks is realized by only redesigning part of frames in the two networks and by certain flow control. The method comprises the following steps of: firstly, judging the network coverage situation of an area where a terminal is positioned and judging whether the area wherein the terminal is positioned has an available network through real-time detection of the signal strength of the two networks; secondly, judging the resource utilization situation of respective network and judging whether the network can provide an available channel for the terminal through the real-time detection of the frequency band resource remaining amount of the two networks; and finally, automatically selecting an available network for access according to detection results by the terminal.

Owner:SHENZHEN TINNO WIRELESS TECH

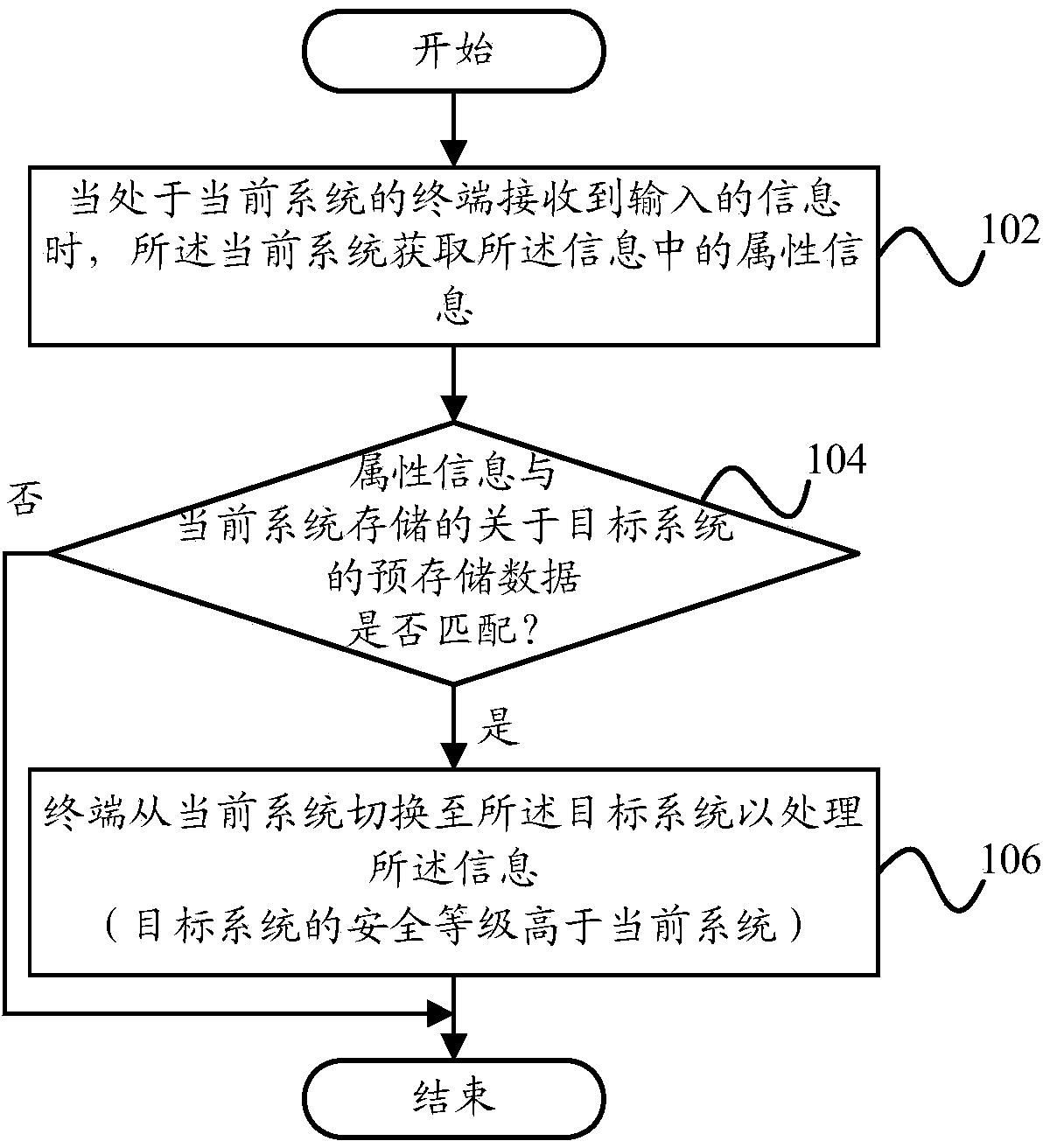

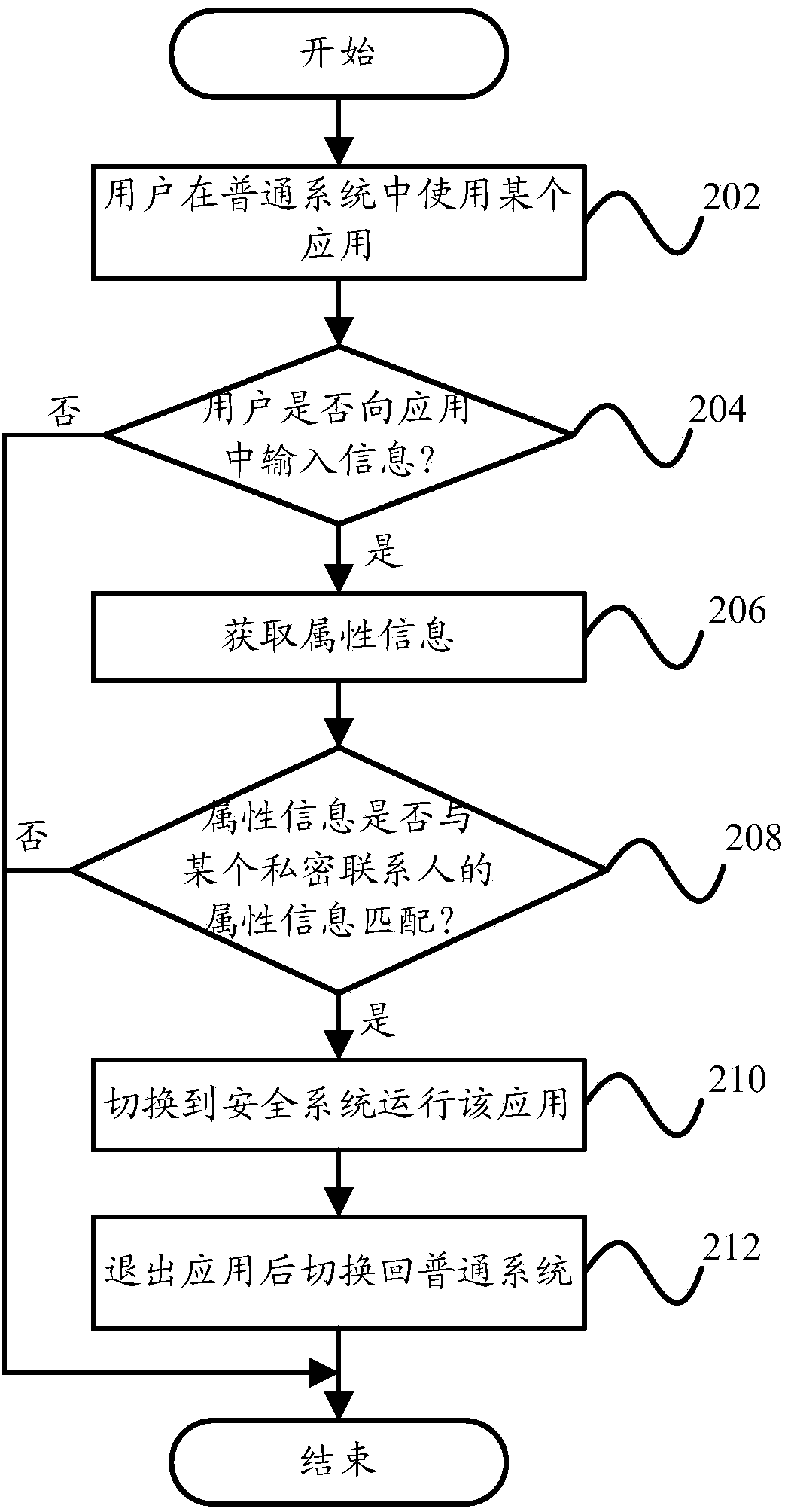

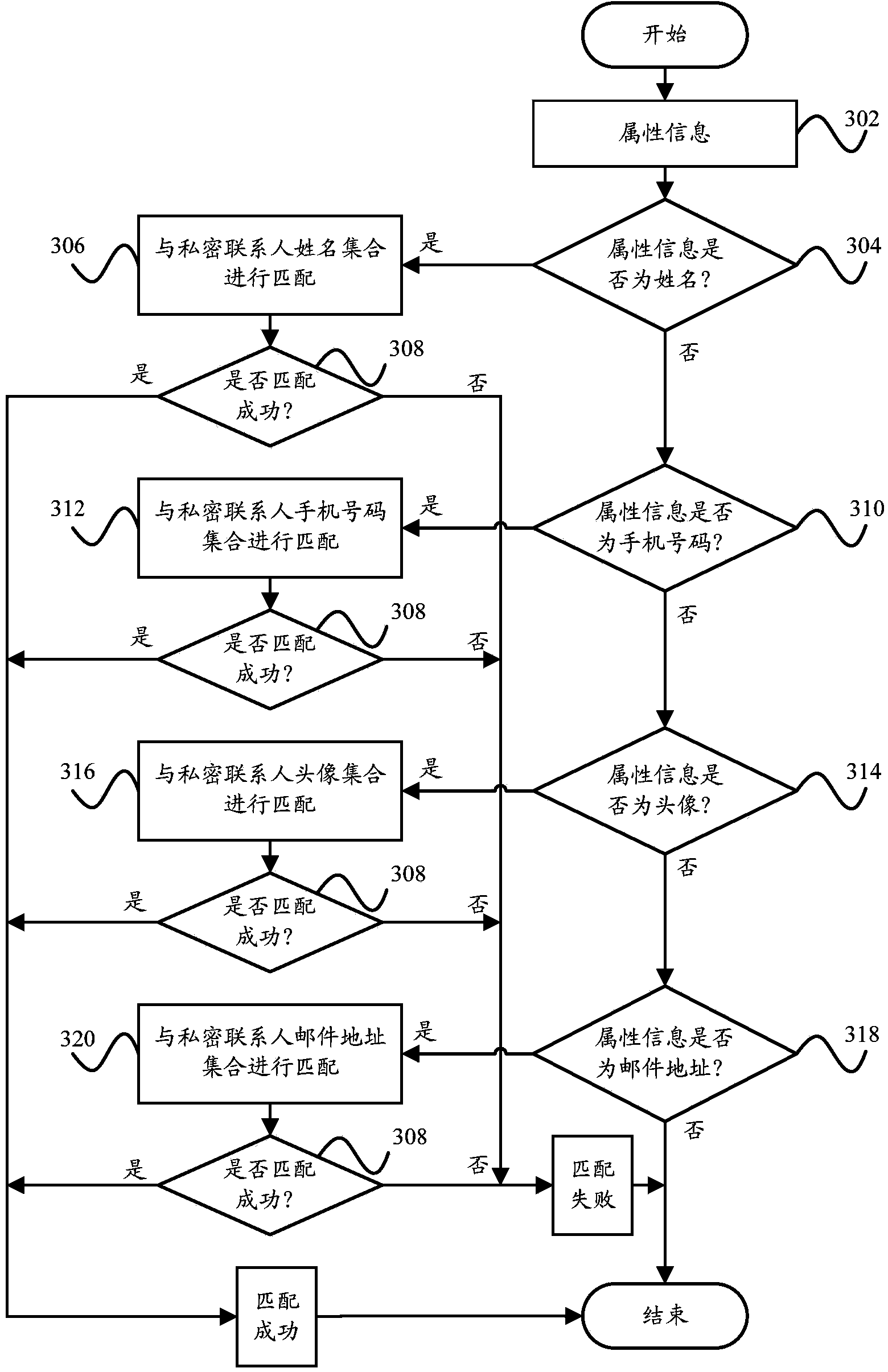

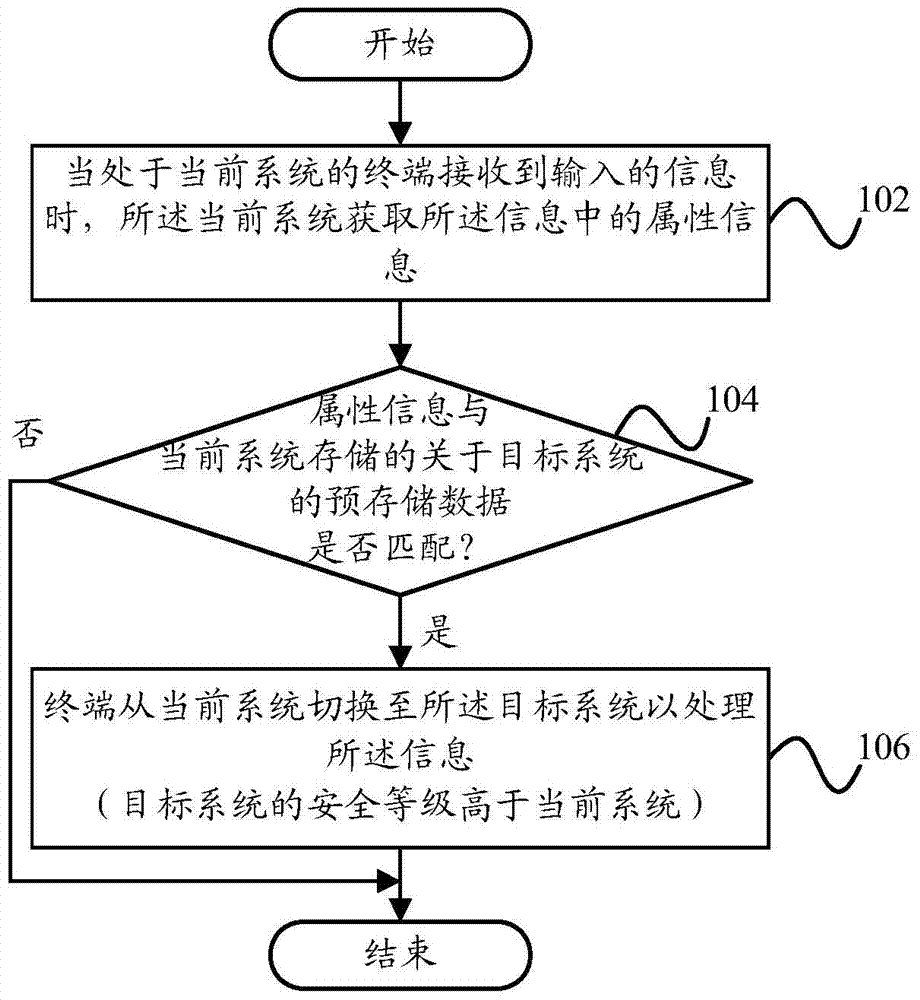

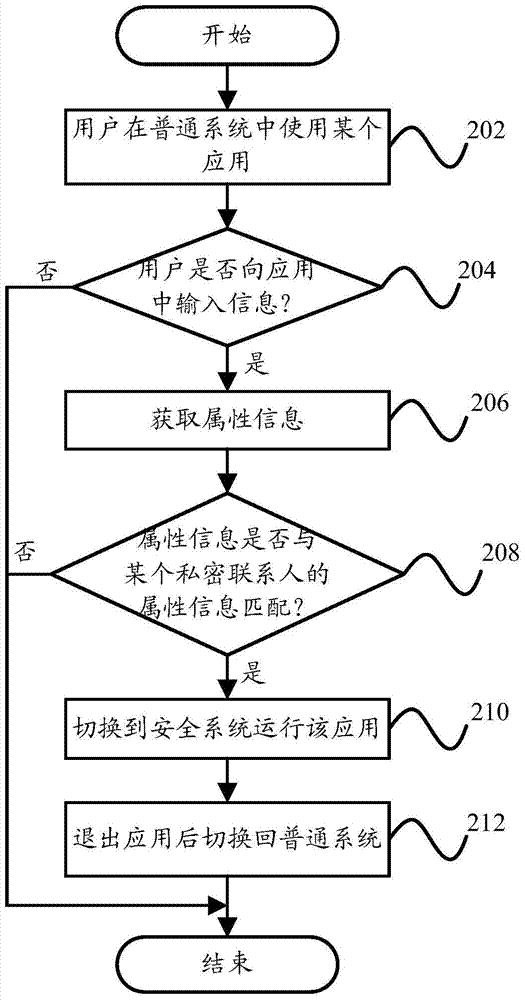

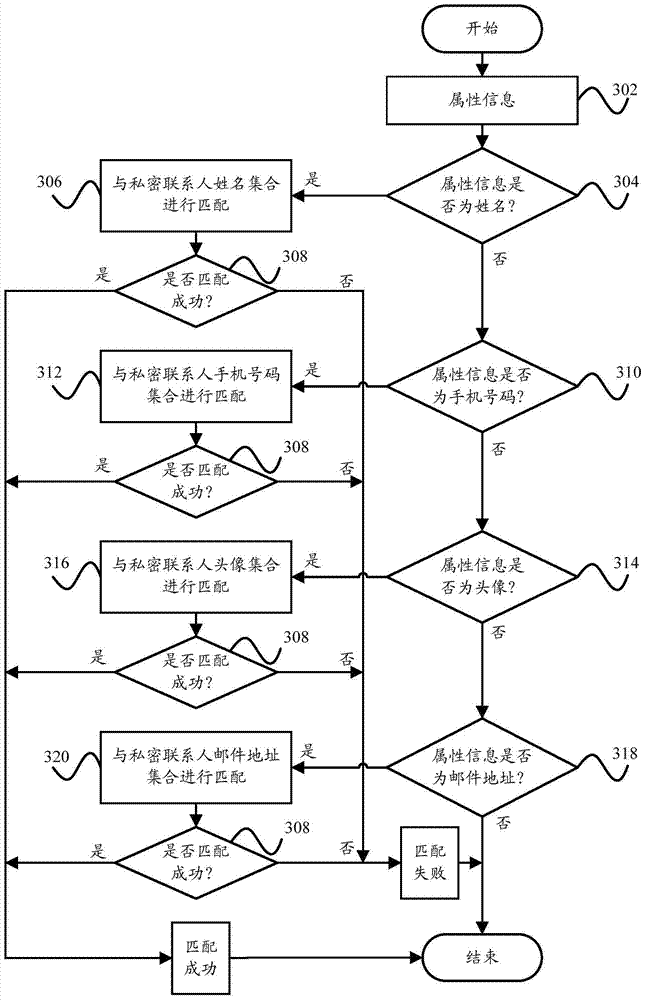

Information processing method and device

InactiveCN104270525AFast auto switchImprove experienceEavesdropping prevention circuitsInformation processingComputer hardware

The invention provides an information processing method and device. The information processing method includes the steps that when a terminal located in a current system receives input information, the current system obtains attribute information inside the information and judges whether the attribute information is matched with pre-stored data, which are stored in the current system, of a target system or not; when the attribute information is matched with the pre-stored data, the terminal is switched to the target system from the current system to process the information, wherein the security level of the target system is higher than that of the current system. According to the technical scheme, rapid and automatic switching can be achieved between the common system and the security system, and the user experience is improved.

Owner:COOLPAD SOFTWARE TECH (SHENZHEN) CO LTD

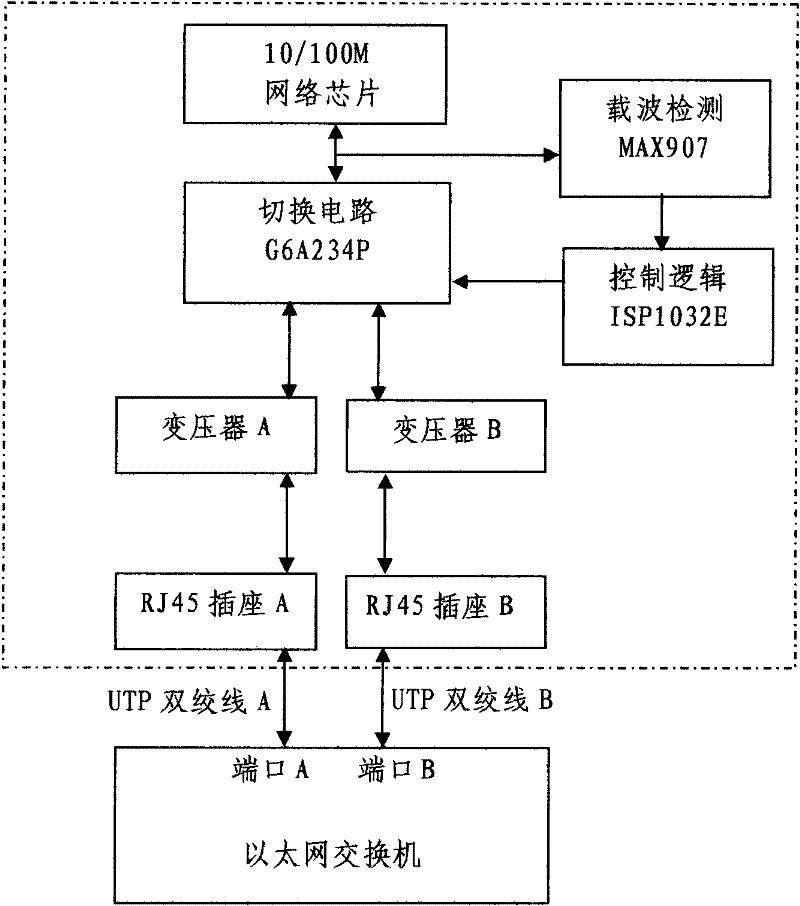

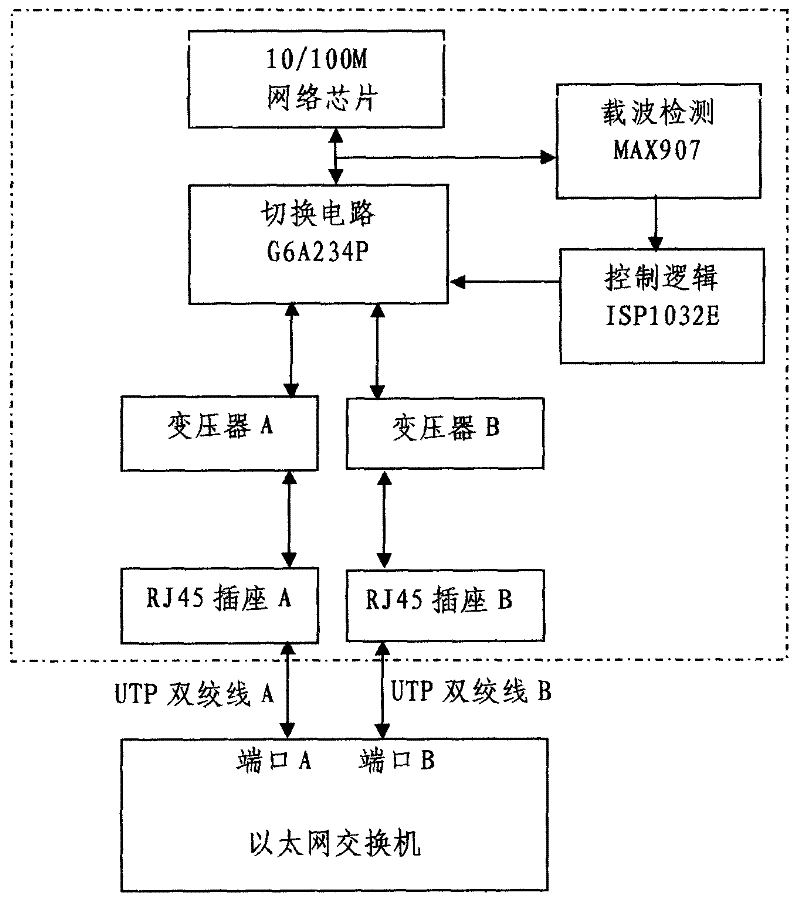

10/100M Ethernet double interface switching method based upon carrier detect and device thereof

InactiveCN101753284ALow costImprove reliabilityError preventionData switching by path configurationCarrier signalEmbedded system

The invention relates to a 10 / 100M Ethernet double interface switching method based upon carrier detect and a device thereof. According to the principle of automatic negotiation mechanism, the method detects the working state of the link by hardware method in no association with application software and operating system, and all hardware completes automatic switching between double redundant network interfaces and link. By using all hardware method, the invention monitors the working states of network card and network link, wherein the network link is switched to a standby network link in the case that the working state is in error. The invention implements quick automatic switching between two network links without interferences from the application software and the operating system and implements double link redundancy design with low cost, thereby improving the reliability of network transmission. The invention can be applied to all military and civil fields with the requirement of high network transmission reliability.

Owner:NO 709 RES INST OF CHINA SHIPBUILDING IND CORP

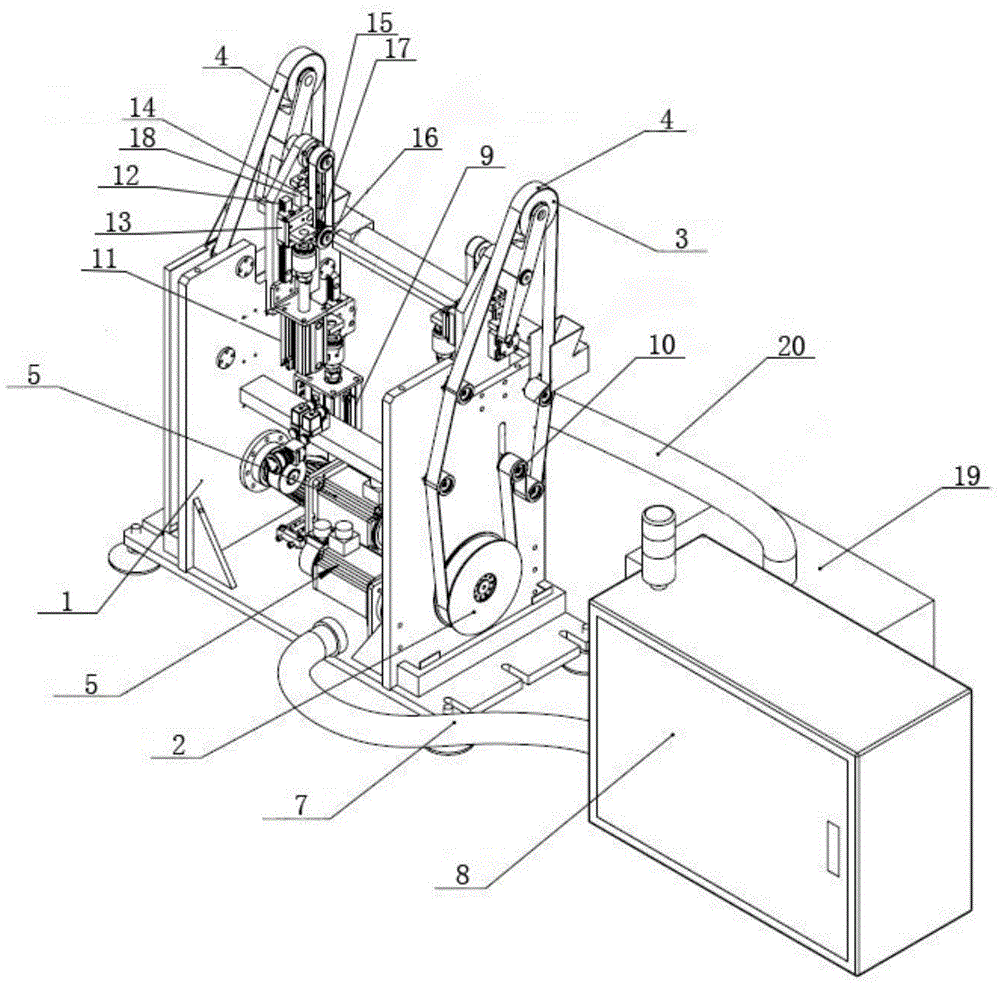

Abrasive belt machine

ActiveCN104816221AGuaranteed balanceQuick changeBelt grinding machinesGrinding/polishing safety devicesProgrammable logic controllerEngineering

The invention discloses an abrasive belt machine. The abrasive belt machine comprises a frame, driving wheels, contact wheels, abrasive belts and servo motors; the driving wheels, the contact wheels, the abrasive belts and the servo motors are symmetrically arranged on the frame; each servo motor is connected with the corresponding driving wheel; each abrasive belt is arranged on the corresponding driving wheel and contact wheel in a sleeving mode; each contact wheel is driven by the corresponding driving wheel to run; each abrasive belt is driven by the corresponding contact wheel to run; one side of each contact wheel is provided with a contact wheel pressure control mechanism; one side of each abrasive belt is provided with an abrasive belt tension control mechanism; one side of the abrasive belt machine is connected with a PLC (Programmable Logic Controller) control box. According to the abrasive belt machine, the double-head double contact wheels can be rapidly replaced or automatically switched for different curved surfaces during use conveniently; the abrasive belt tension control mechanisms are controlled by a precision pressure reducing valve, the tension of the abrasive belts can be automatically adjusted when the resistance is produced so as to enable the tension to be stabilized within a set value, and accordingly the smooth operation of the abrasive belts is ensured and the service life of the abrasive belts is extended; the abrasive belt machine is provided with the contact wheel pressure control mechanisms, the contact wheels are rubber coating wheels, and accordingly the full contact of the complex curved surfaces can be implemented during polishing, the elasticity is achieved, and workpieces are not easy to damage.

Owner:SHANGHAI DIJIA MACHINERY EQUIP CO LTD

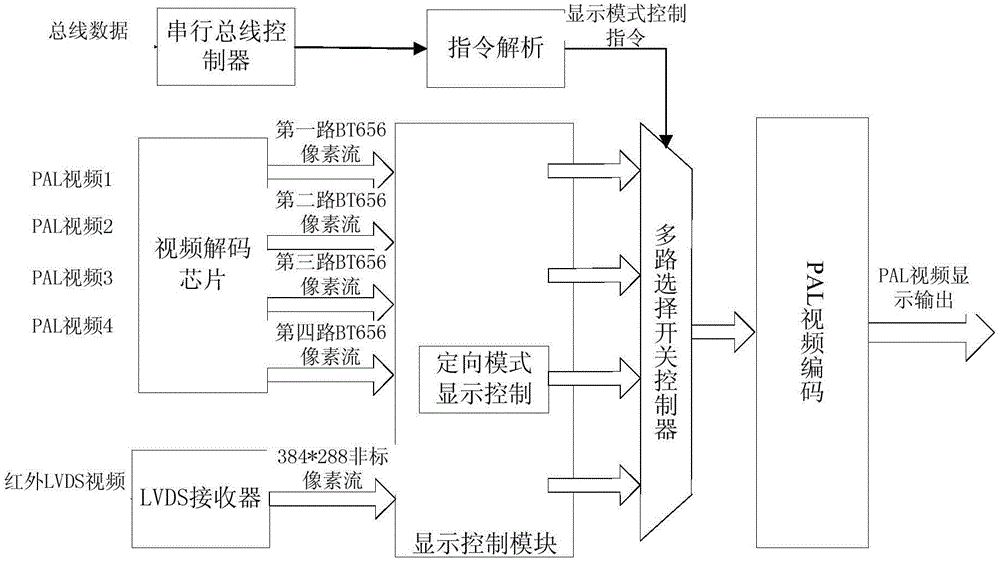

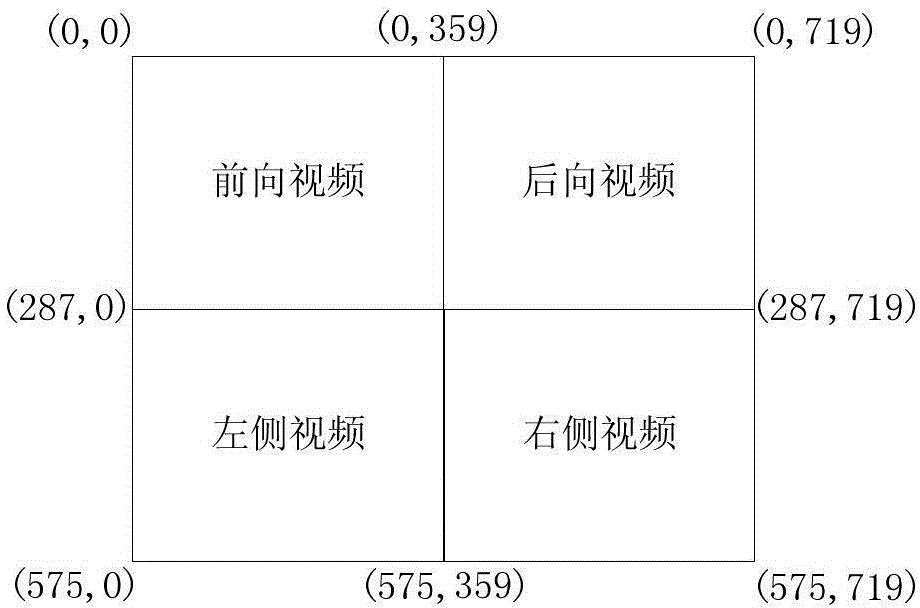

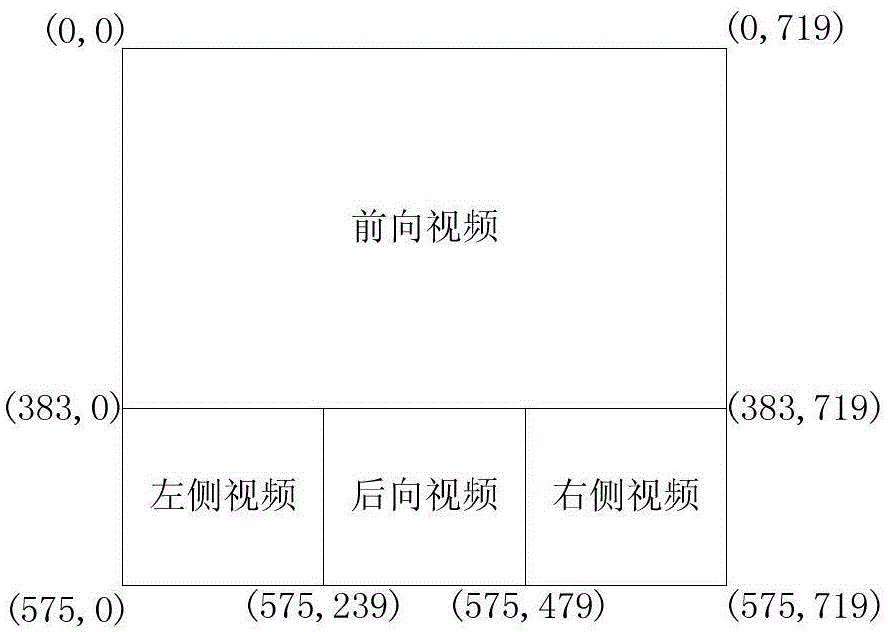

Low-latency omni-directional navigation video multi-mode display control method

ActiveCN105721789ALower latencyFast auto switchTelevision system detailsColor television detailsDigital videoOmni directional

A low-latency omni-directional navigation video multi-mode display control method comprises the following steps: (1) carrying out video decoding on four PAL cameras carried by a reconnaissance robot through a multi-path video decoding chip to get four video data flows in accordance with the BT.656 protocol, converting an LVDS differential signal of a non-standard infrared spectral camera mounted at the front end of the robot into a 384*288 50HZ single-end digital video signal through an LVDS receiving chip, receiving a control instruction sent by an operation end through a serial communication bus, and analyzing the instruction format; (2) displaying videos in different video display modes according to the analyzed instruction format; and (3) encoding a BT.656 video processed in different video display nodes through a PAL video encoding chip, and generating a PAL analog output video. According to the invention, the battlefield situation can be acquired and controlled in an all-round manner.

Owner:AVIC NO 631 RES INST

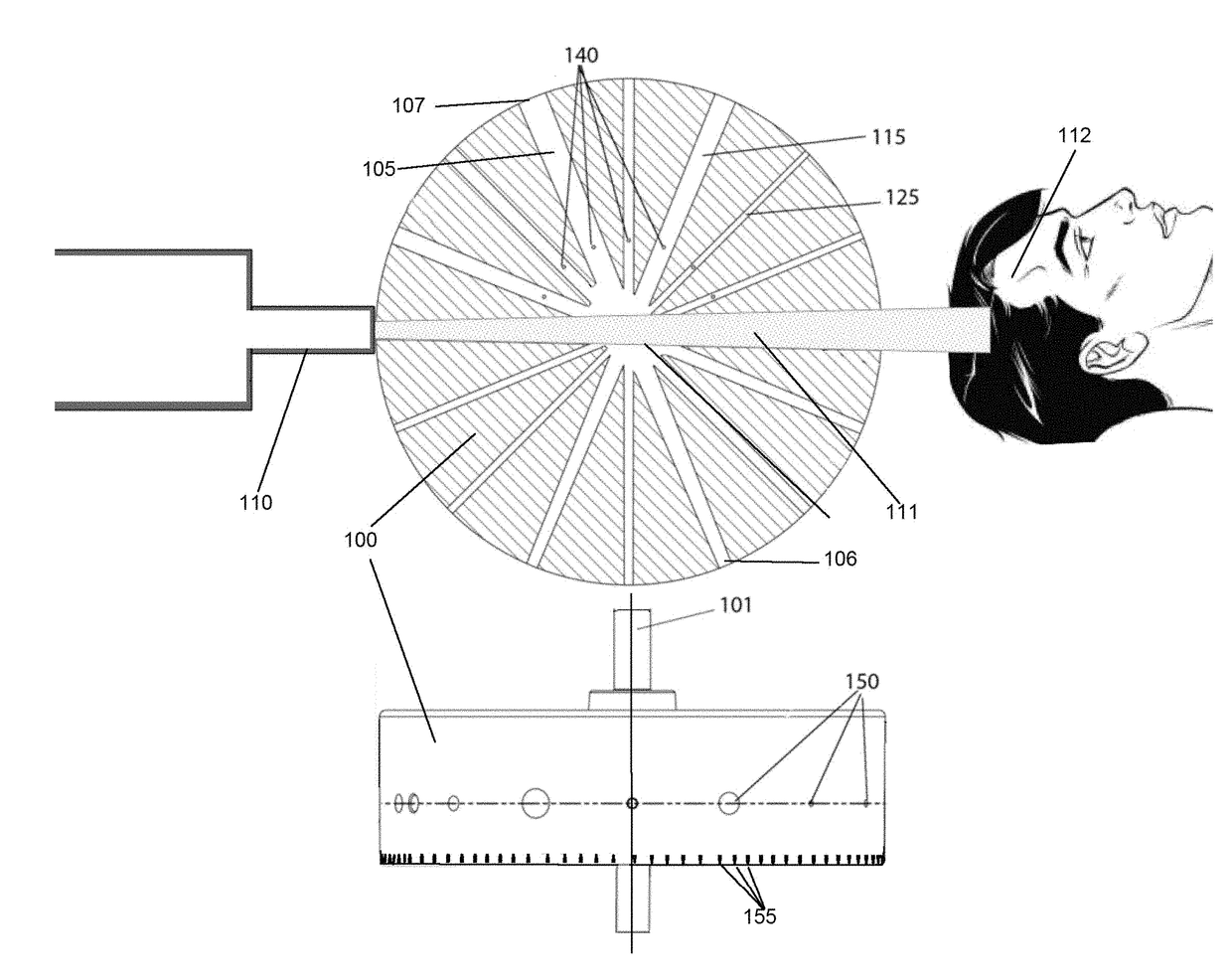

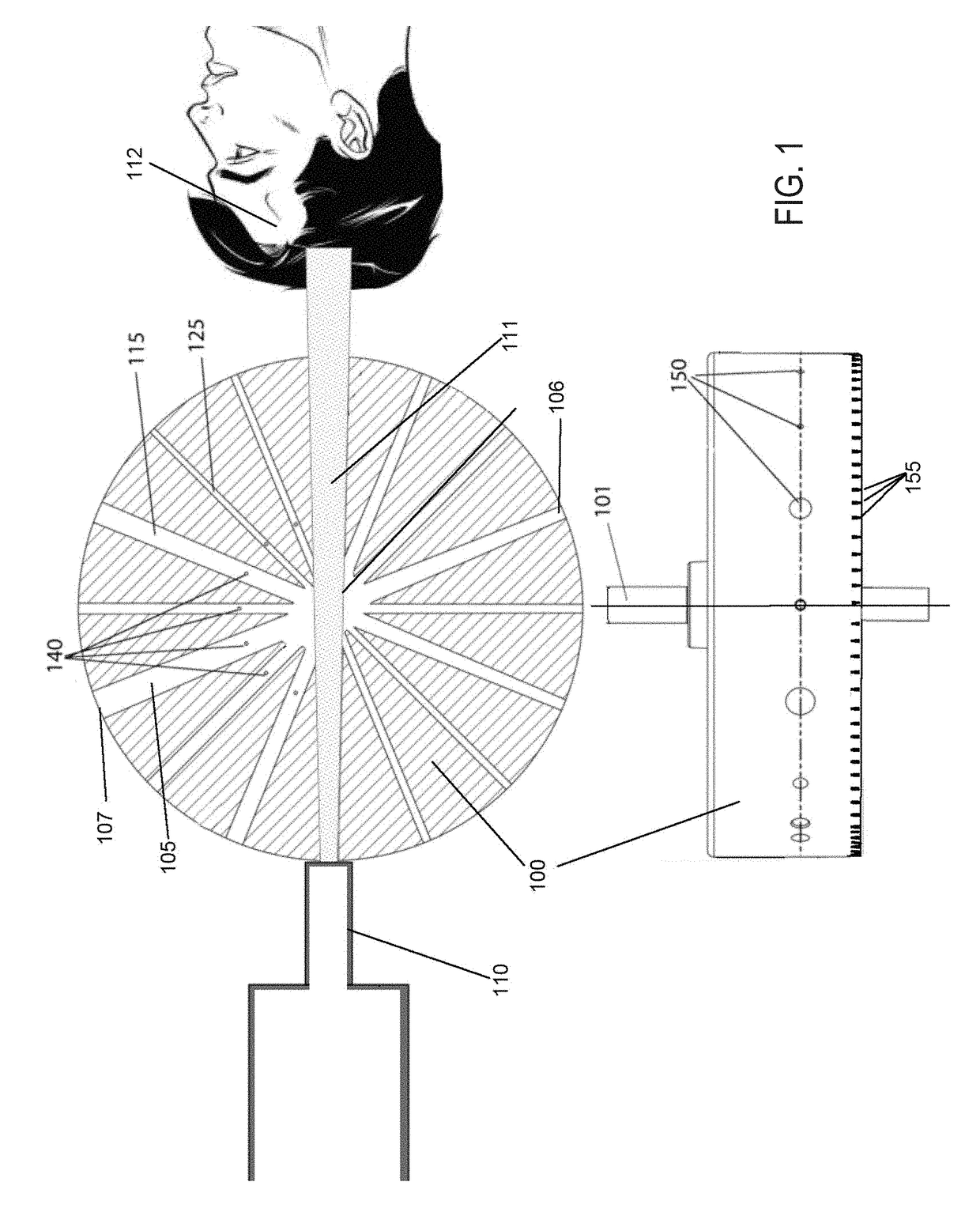

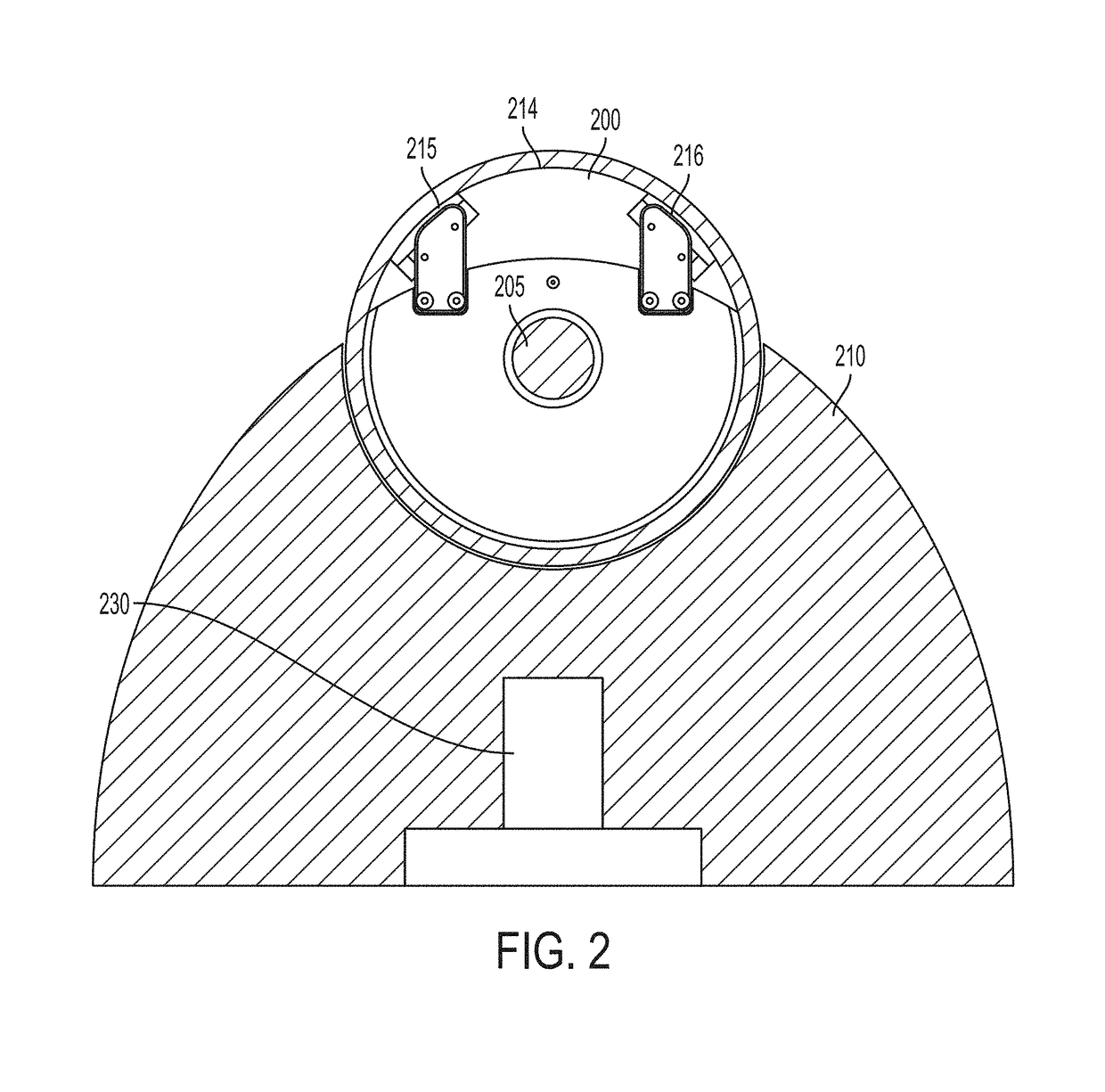

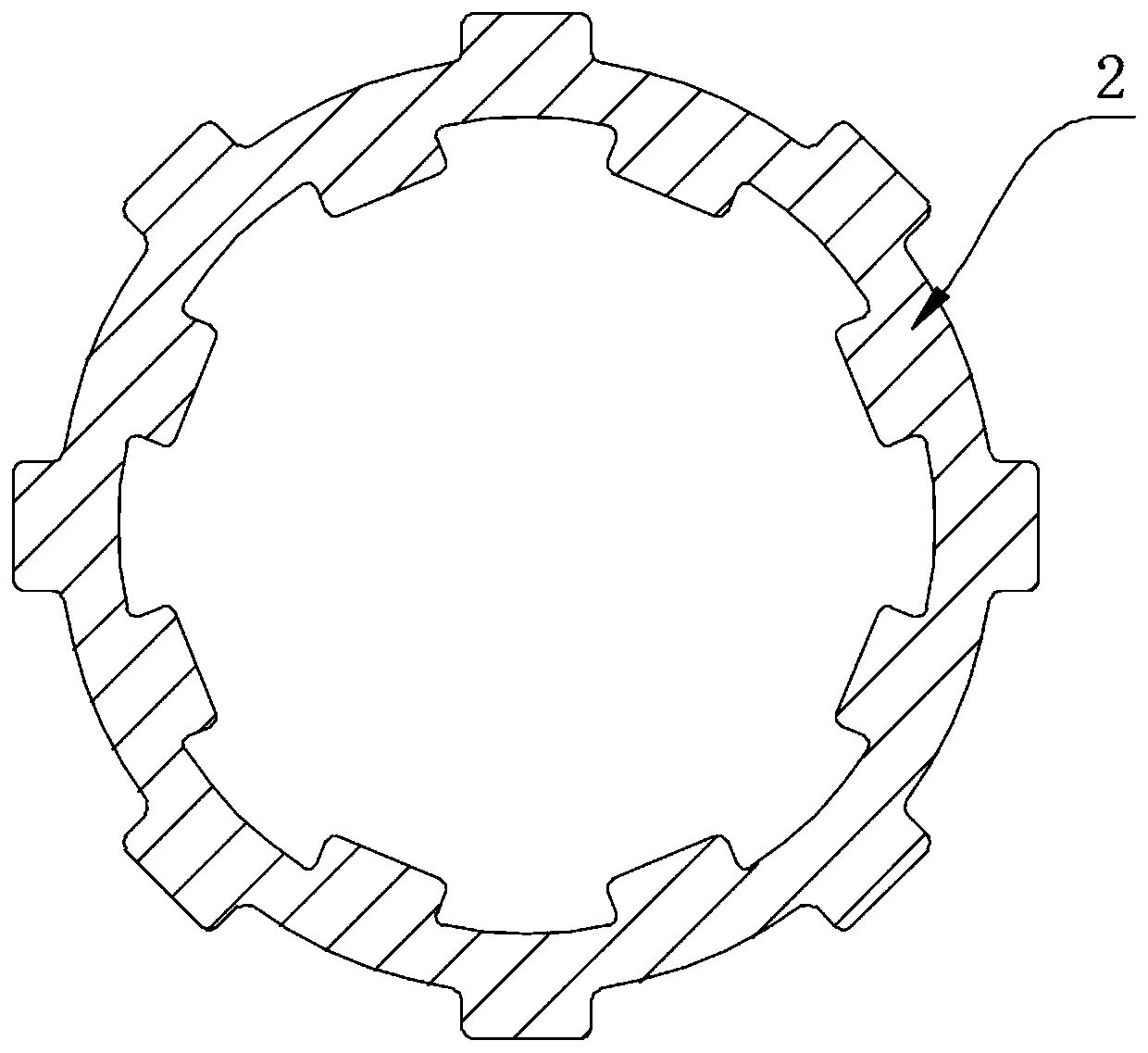

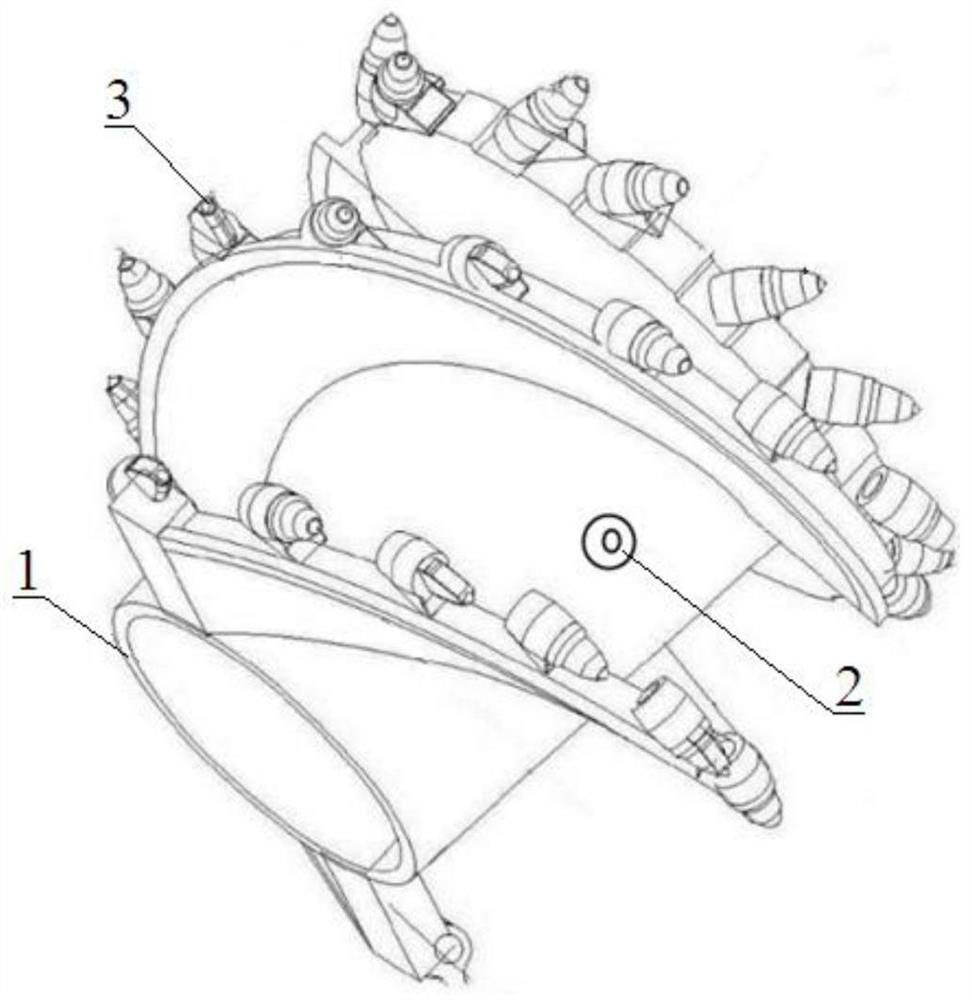

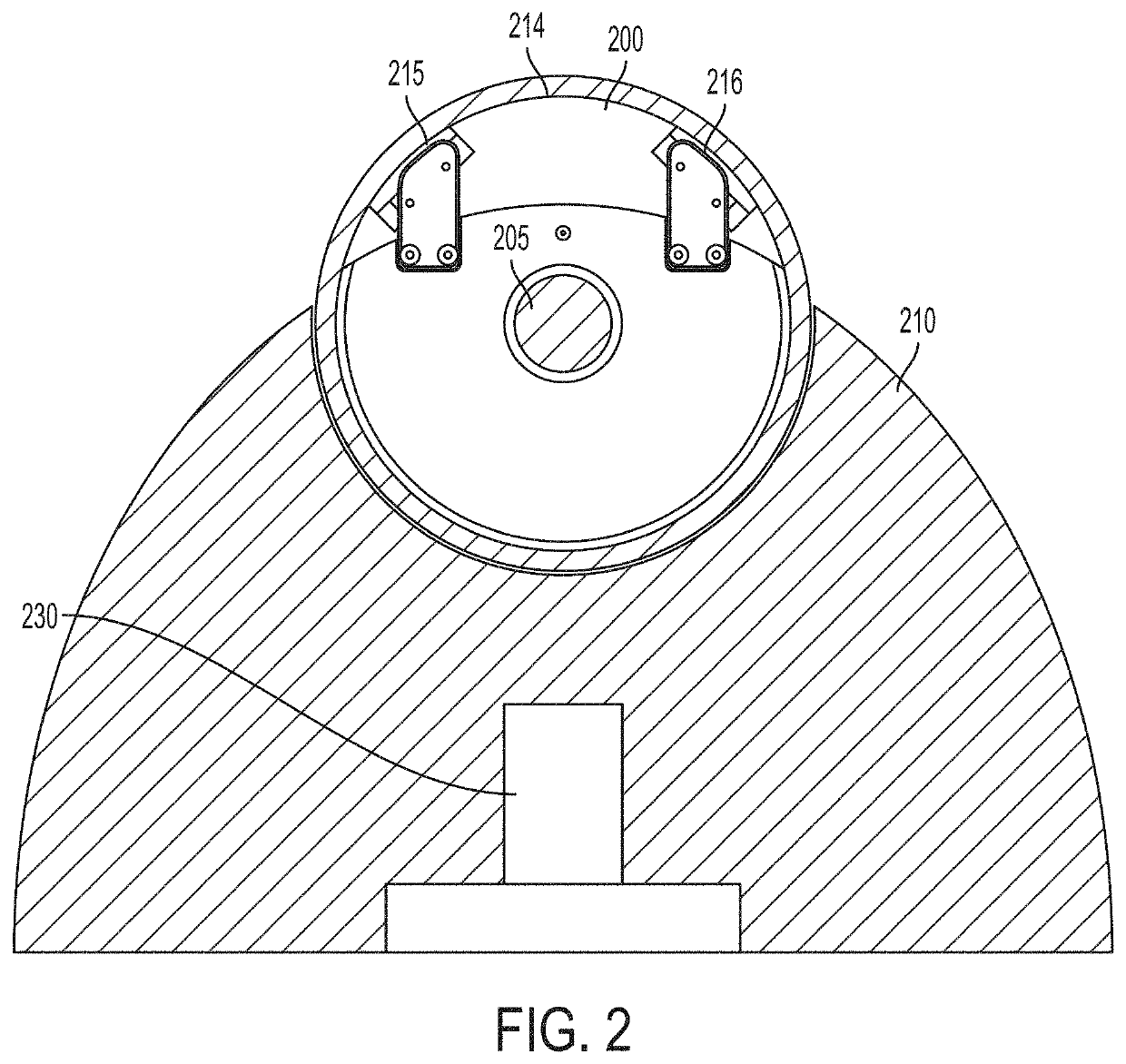

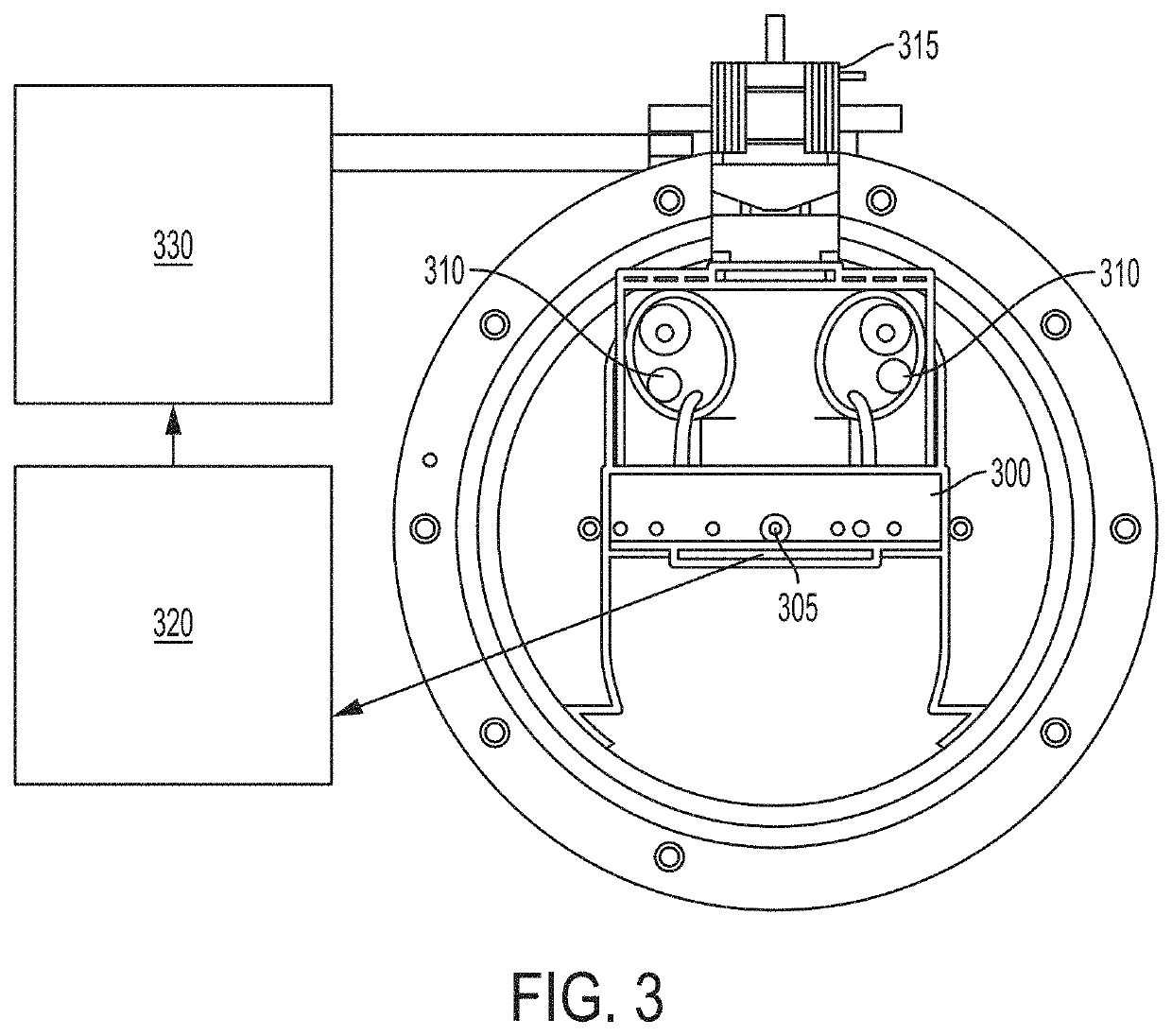

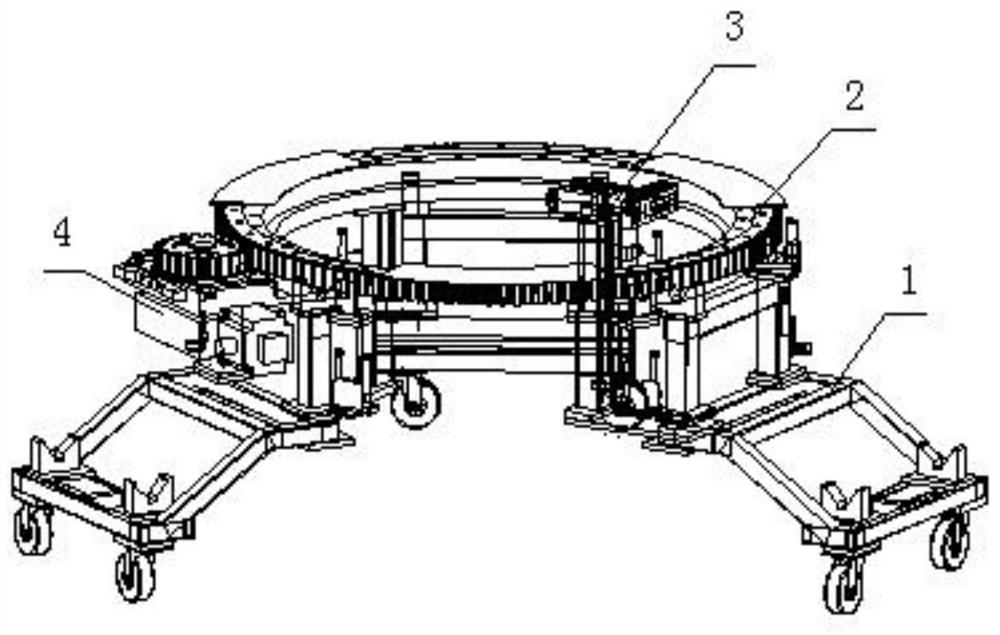

Revolving radiation collimator

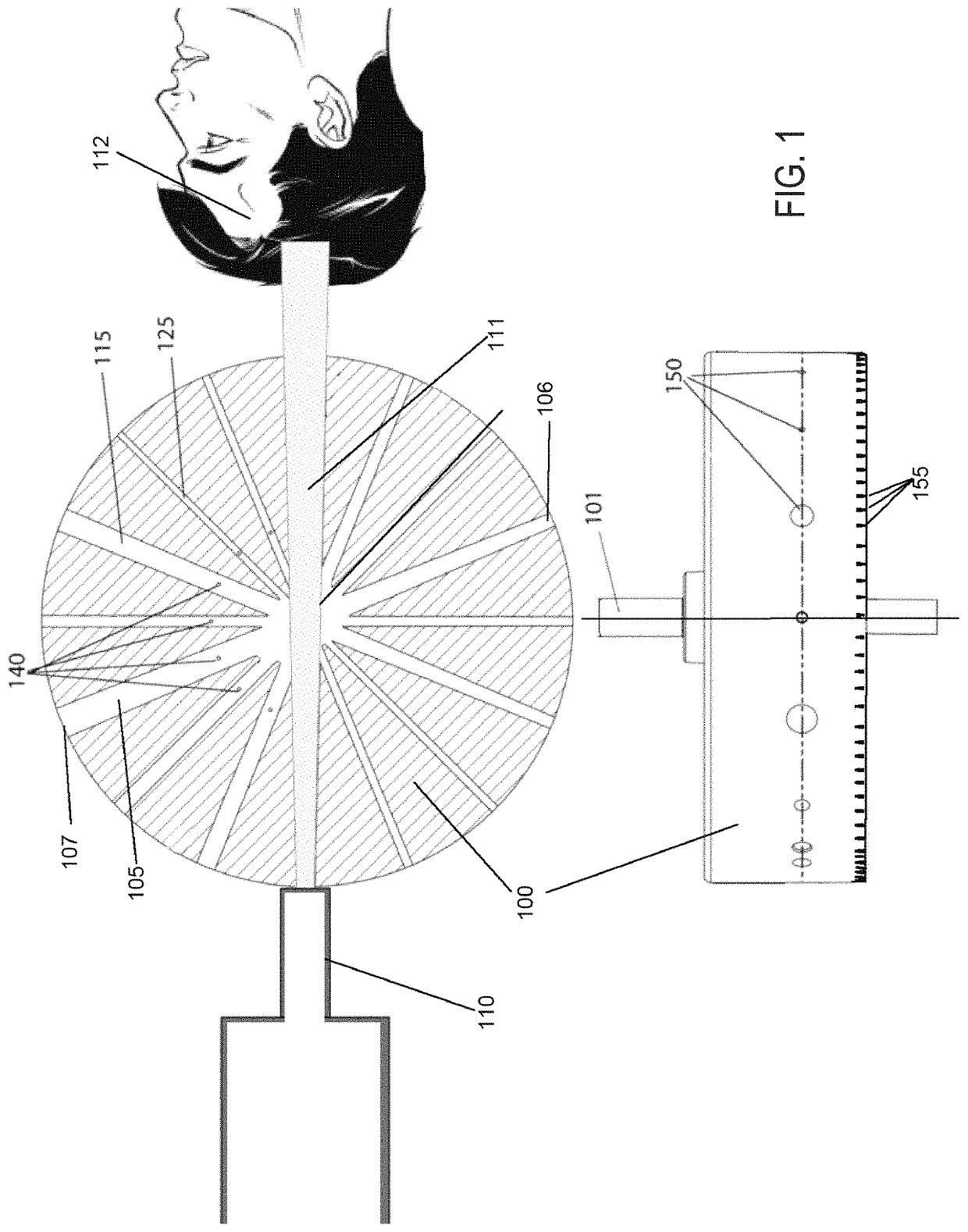

ActiveUS20180318607A1Quick changeLow costHandling using diaphragms/collimetersUsing optical meansCollimator devicesControl system

Devices, systems and method that allow for delivery of therapeutic radiation beams of differing sizes or shapes during a radiation treatment are provided herein. Such devices can include a rotatable collimator body having multiple collimator channels of differing size or shape defined therein, the channels extending through the collimator body substantially perpendicular to the axis of rotation. The collimator body can include markers thereon to facilitate detection of an alignment position by a sensor of a control system to allow the collimator body to be rapidly and accurately moved between alignment positions to facilitate delivery of differing therapy beams during a treatment.

Owner:ZAP SURGICAL SYST INC

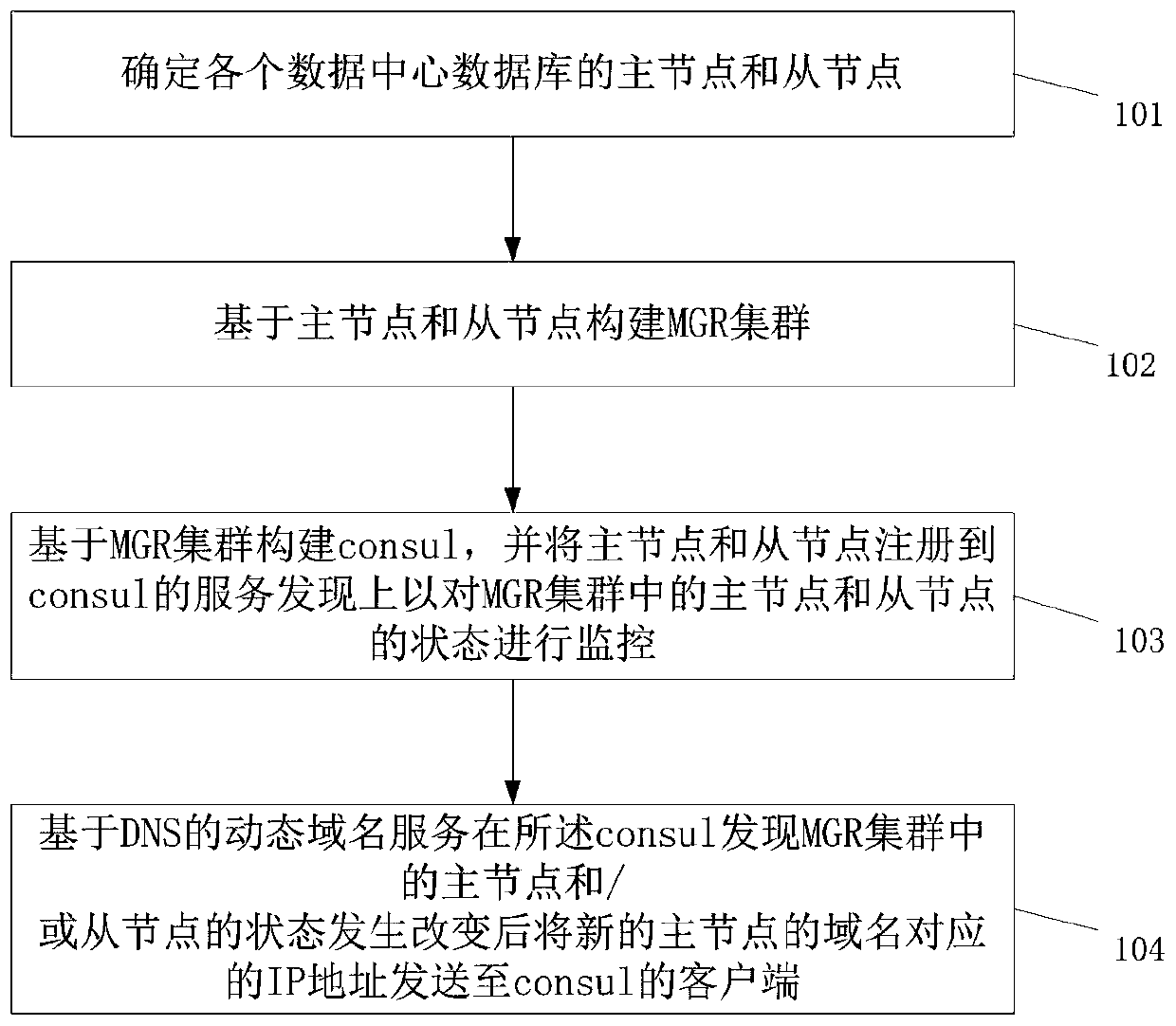

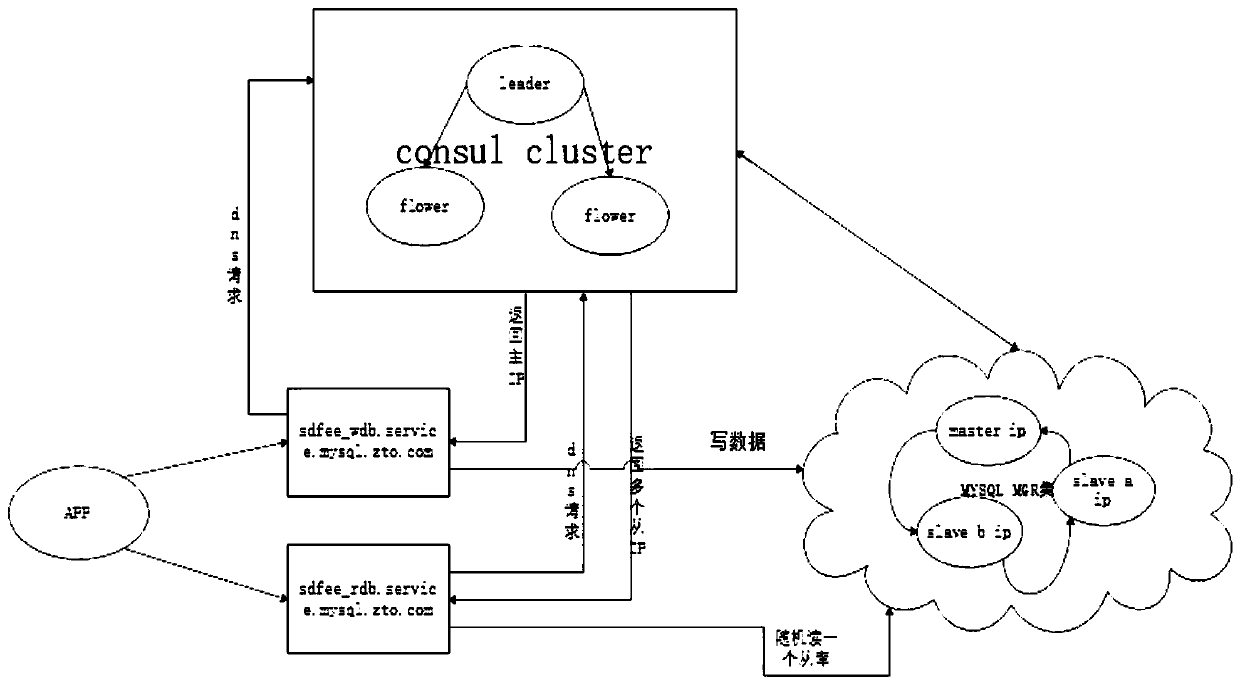

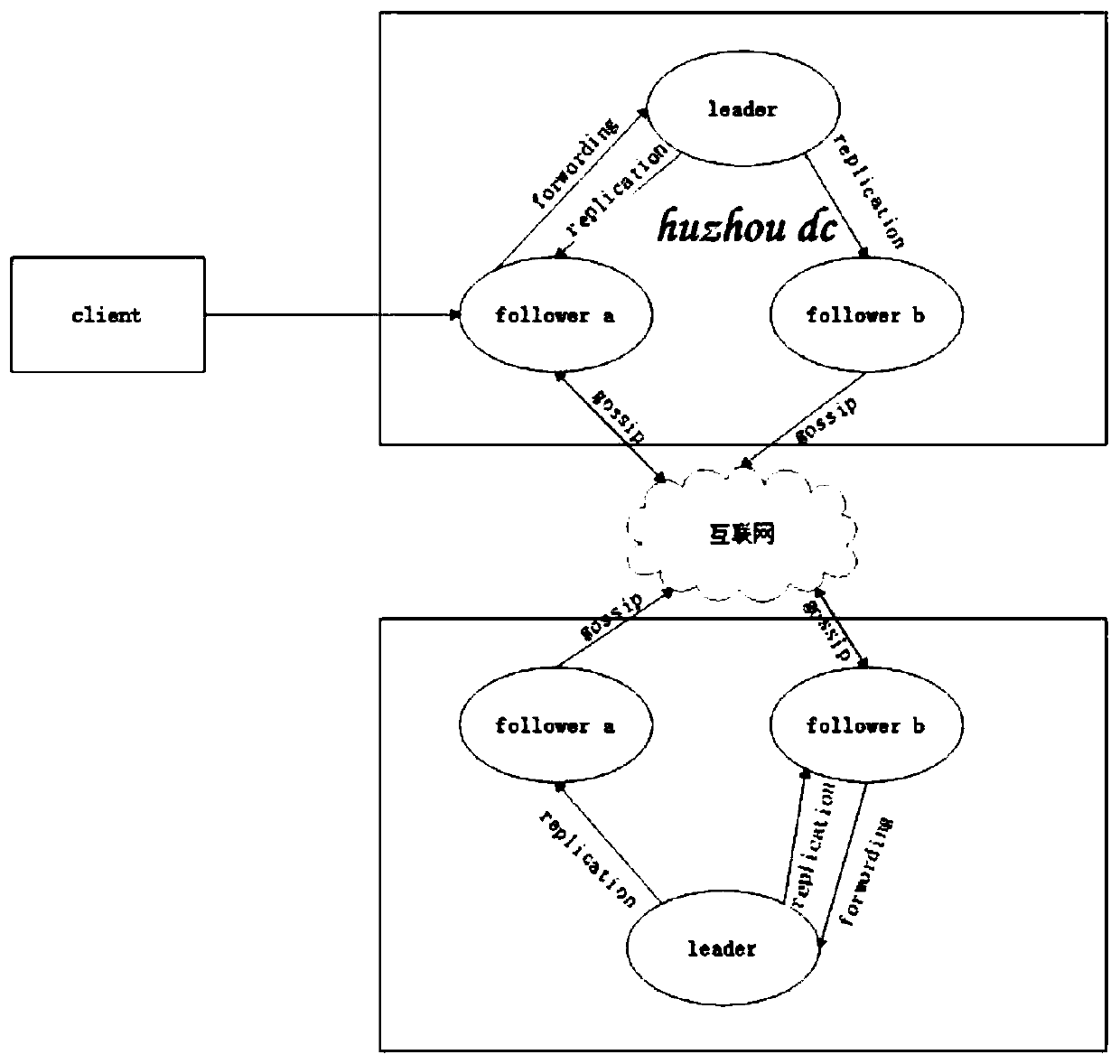

Database high availability method, device, system and storage medium

ActiveCN111581284AGuaranteed reliabilityFast auto switchRelational databasesDatabase distribution/replicationDomain nameIp address

The invention relates to a database high availability method, a device, a system and a storage medium. Master nodes and slave nodes in a data center database form an MGR cluster, MySQL can automatically discover a master library crash in an MGR mode, a new master node is generated through a master selection mechanism to provide read-write service for the outside, and automatic master-slave switching and fault recovery capacity are achieved; and the relationship between the nodes is maintained in combination with the consul in the micro-service framework to realize the synchronization and strong consistency of the data between the nodes, and the domain name of the switched main node is analyzed in combination with the dynamic domain name server to obtain the corresponding IP address, so that the reliability and rapidness of automatic switching are ensured.

Owner:SHANGHAI ZHONGTONGJI NETWORK TECH CO LTD

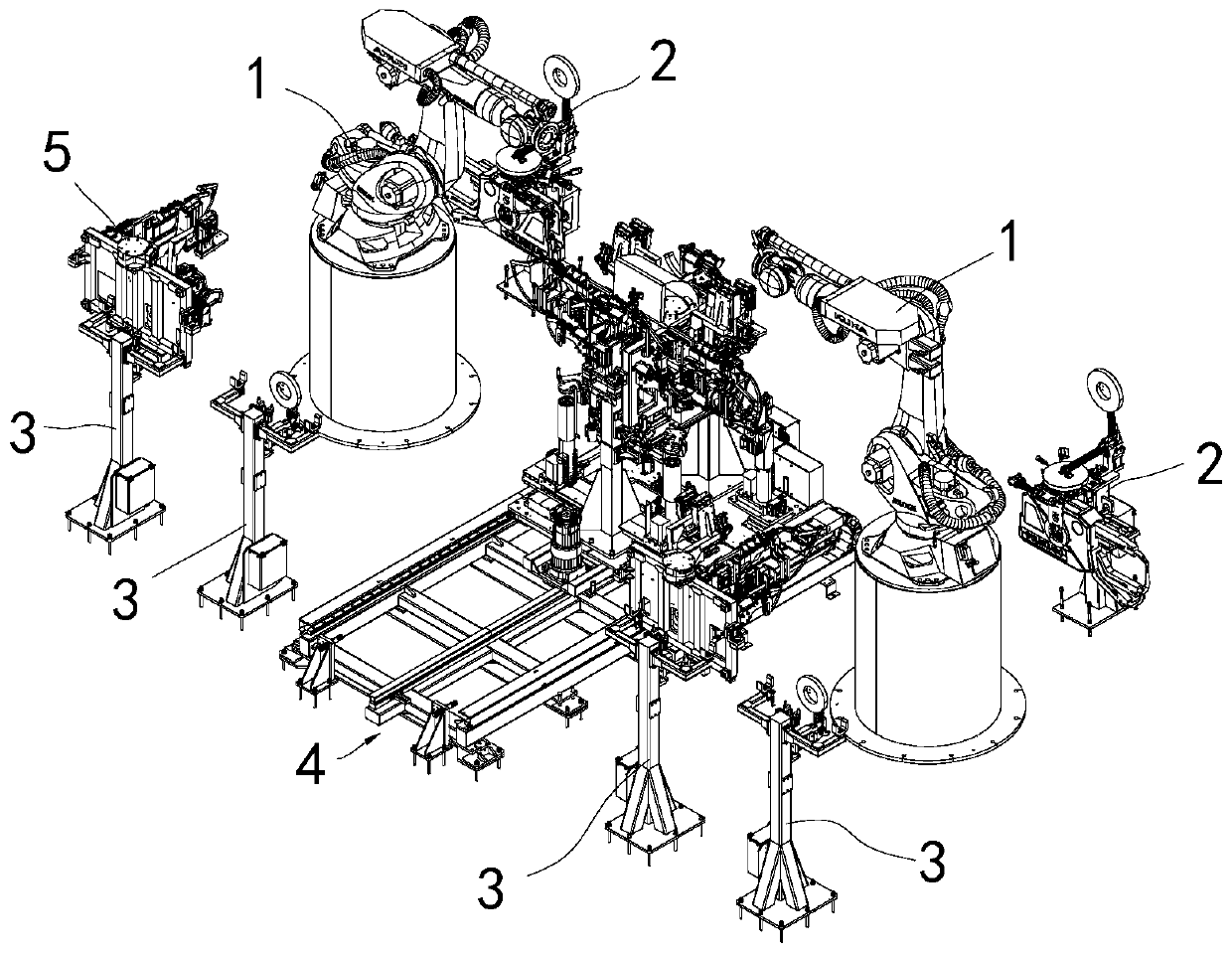

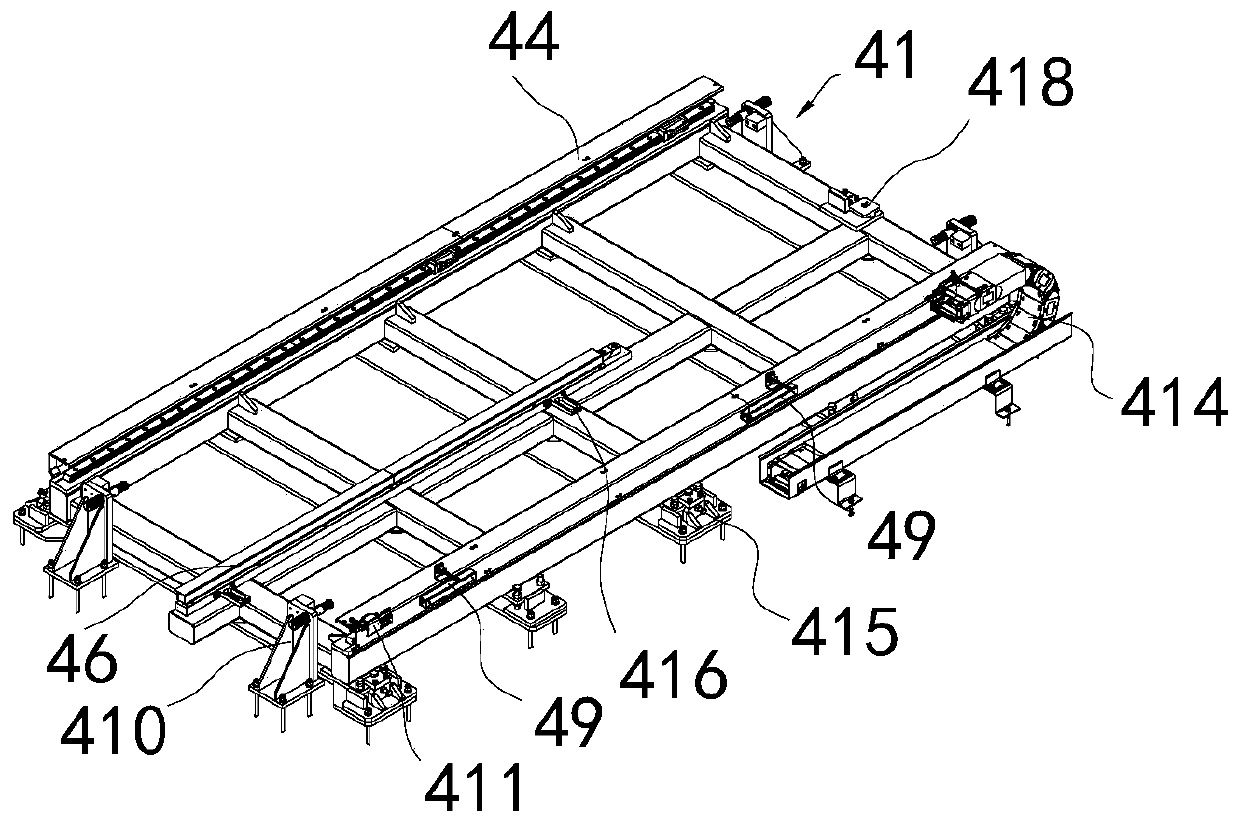

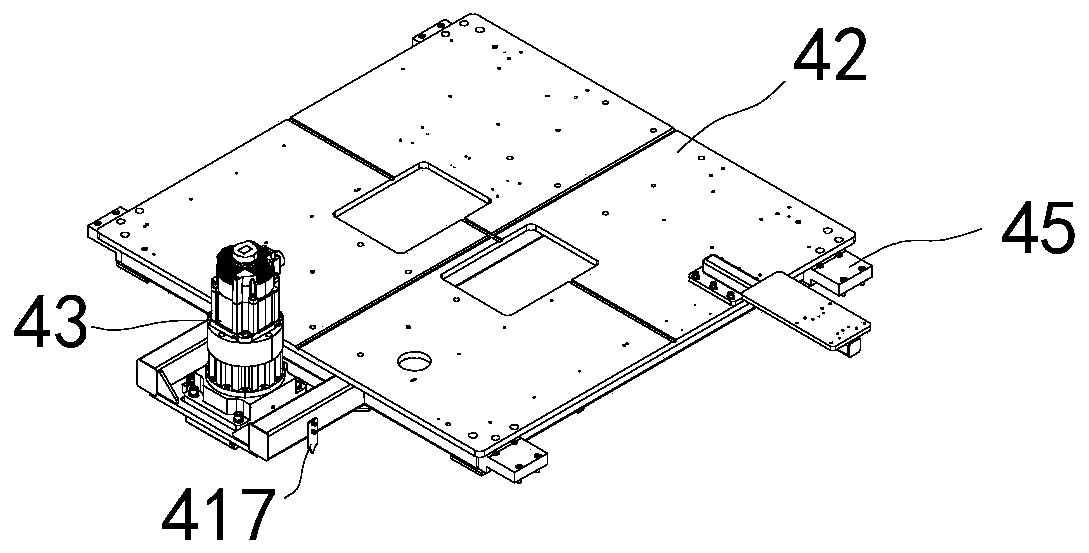

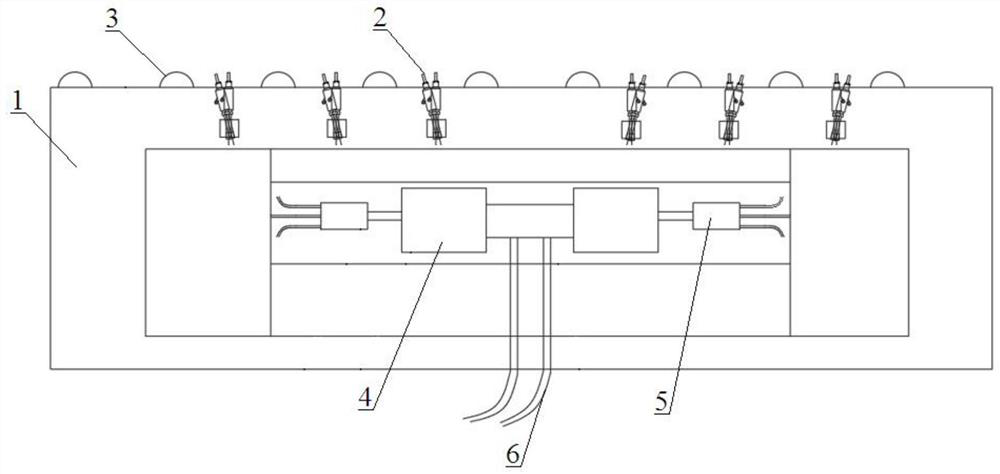

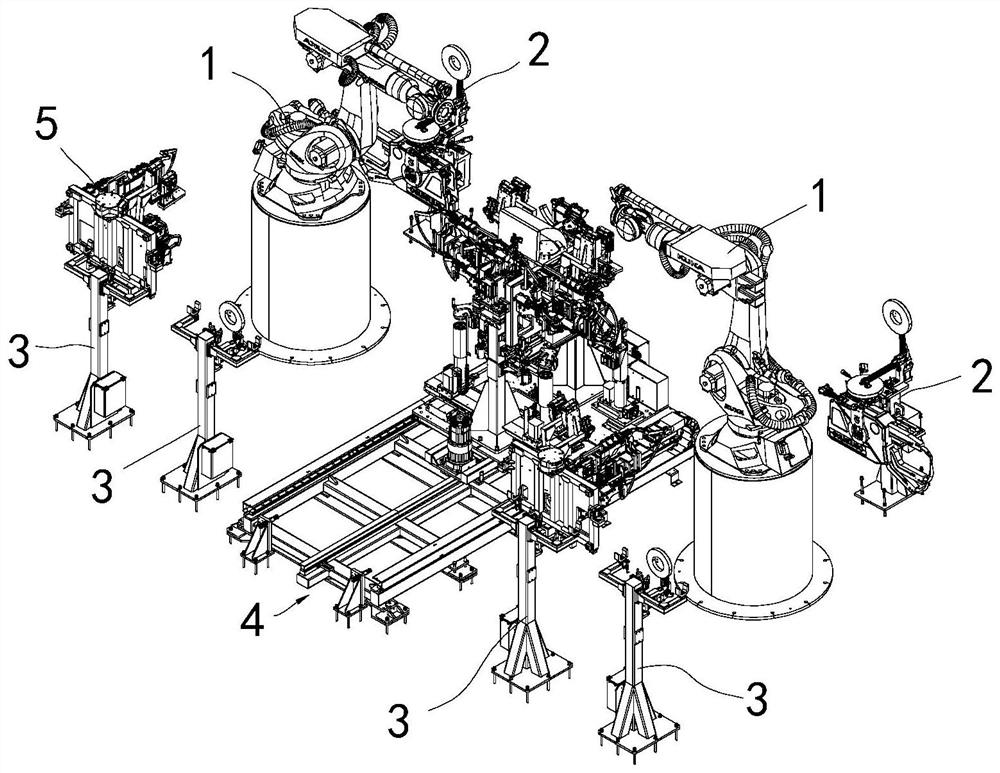

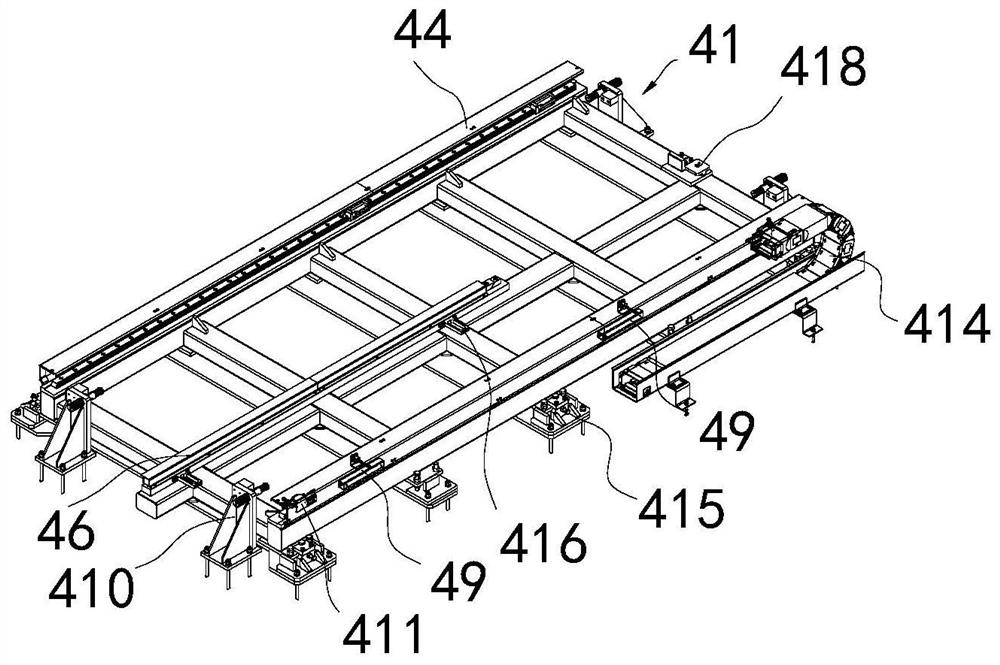

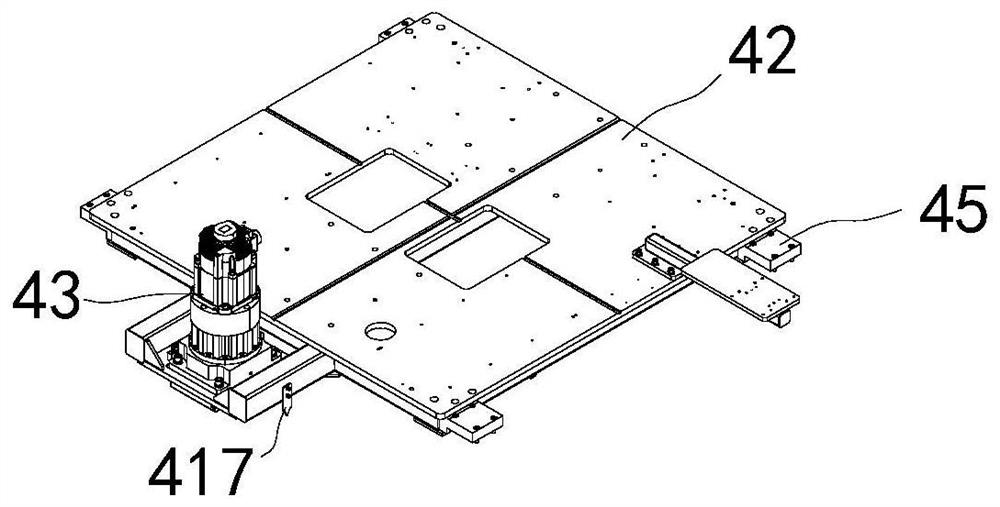

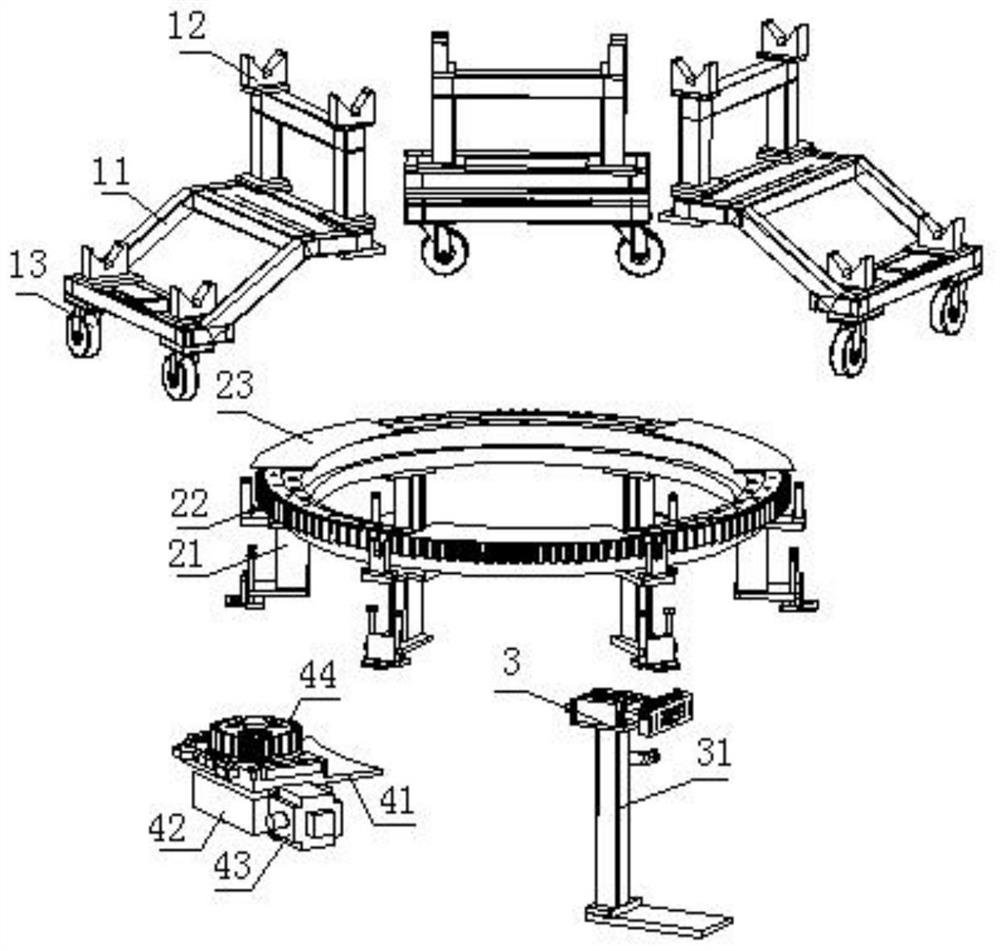

Multi-vehicle frock clamp switching system

ActiveCN109877493AQuick switchFast auto switchWelding/cutting auxillary devicesAuxillary welding devicesProduction lineEngineering

The invention discloses a multi-vehicle frock clamp switching system. The frock clamp system is applied to the field of automobile automatic production and manufacturing. The frock clamp switching system comprises a welding post, wherein the welding post is provided with a robot, a welding gun placing assembly and a plurality of clamp placing assemblies, the car body part is used for taking and placing the working posts, the conveying device is capable of operating between the welding post and the car body part taking and placing post, the robot can taking and placing a welding gun on the welding gun placing assembly, the robot can pick up the frock clamp on the conveying device and place the frock clamp on the clamp placing assembly, and the frock clamp on the other clamp placing assemblyis picked up and placed on the conveying device. The frock clamp capable of realizing rapid switching of different vehicle types, the structure is simple, the operation is stable, the safety and reliability are achieved, the equipment utilization rate can be improved, and the manufacturing cost of the production line can be reduced, the occupied area of equipment is reduced, the rapid and automatic switching of the vehicle types can be realized, the switching time is saved, so that the production line is developed towards flexible, intelligent, high-yield and low-cost directions.

Owner:MINO AUTOMOTIVE EQUIP SHANGHAI CO LTD

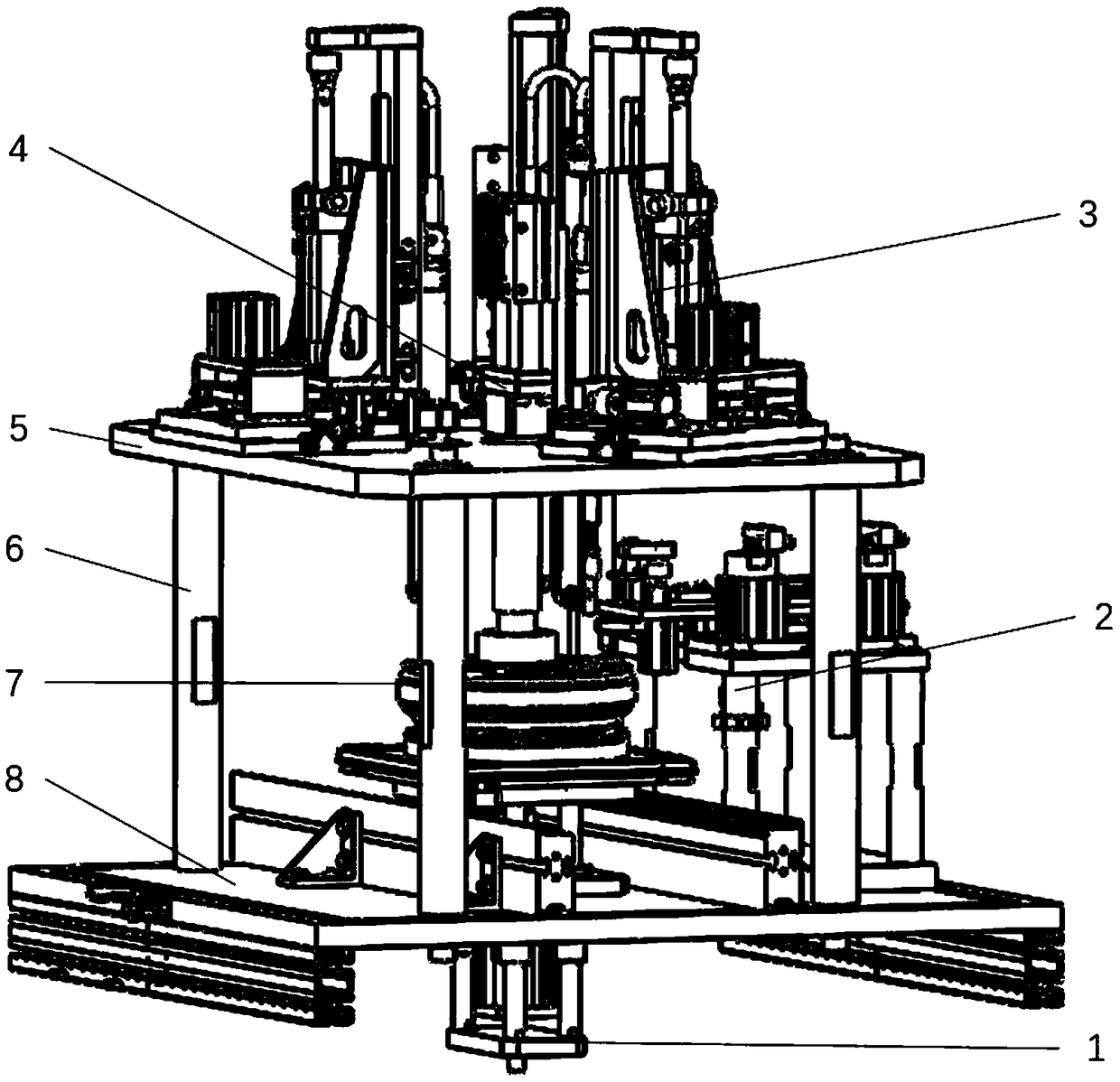

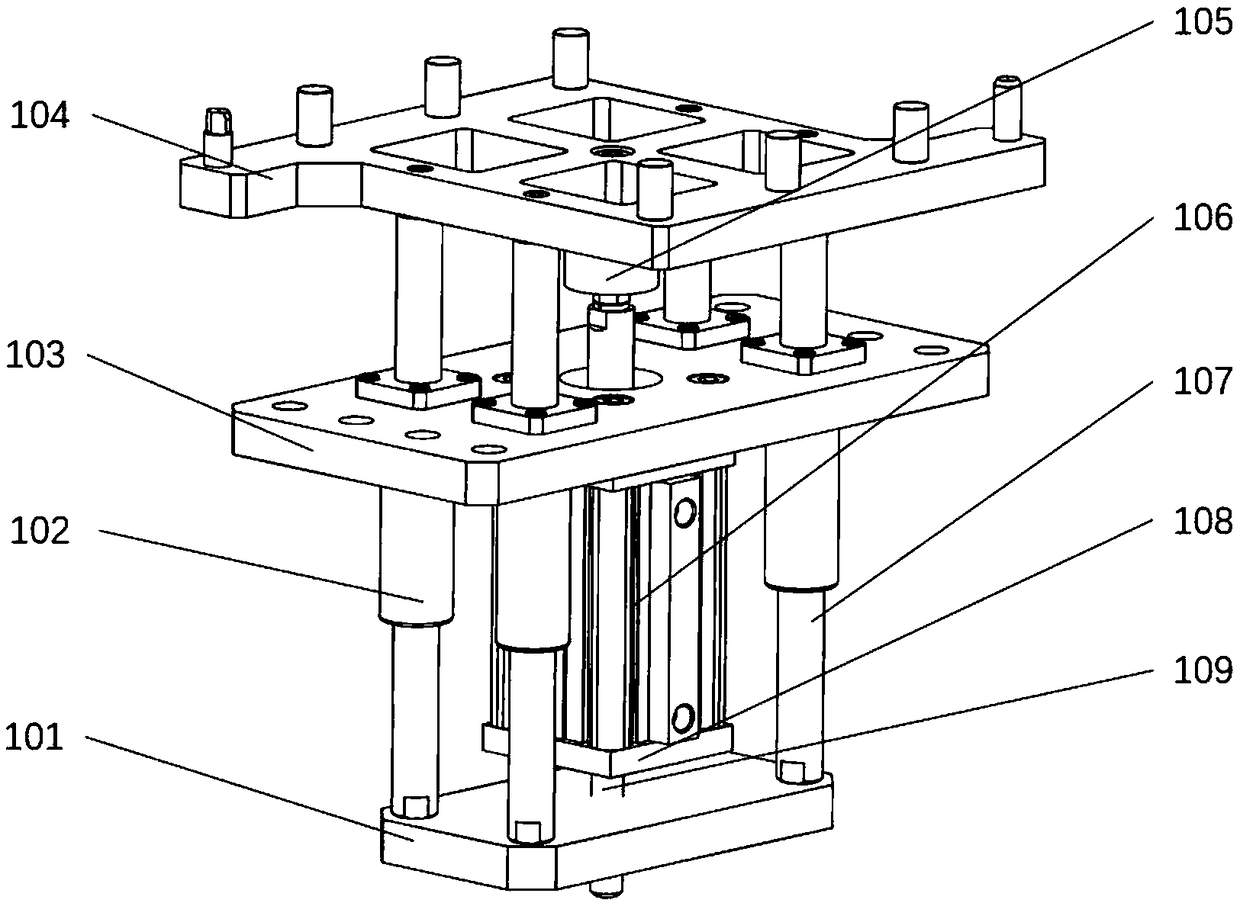

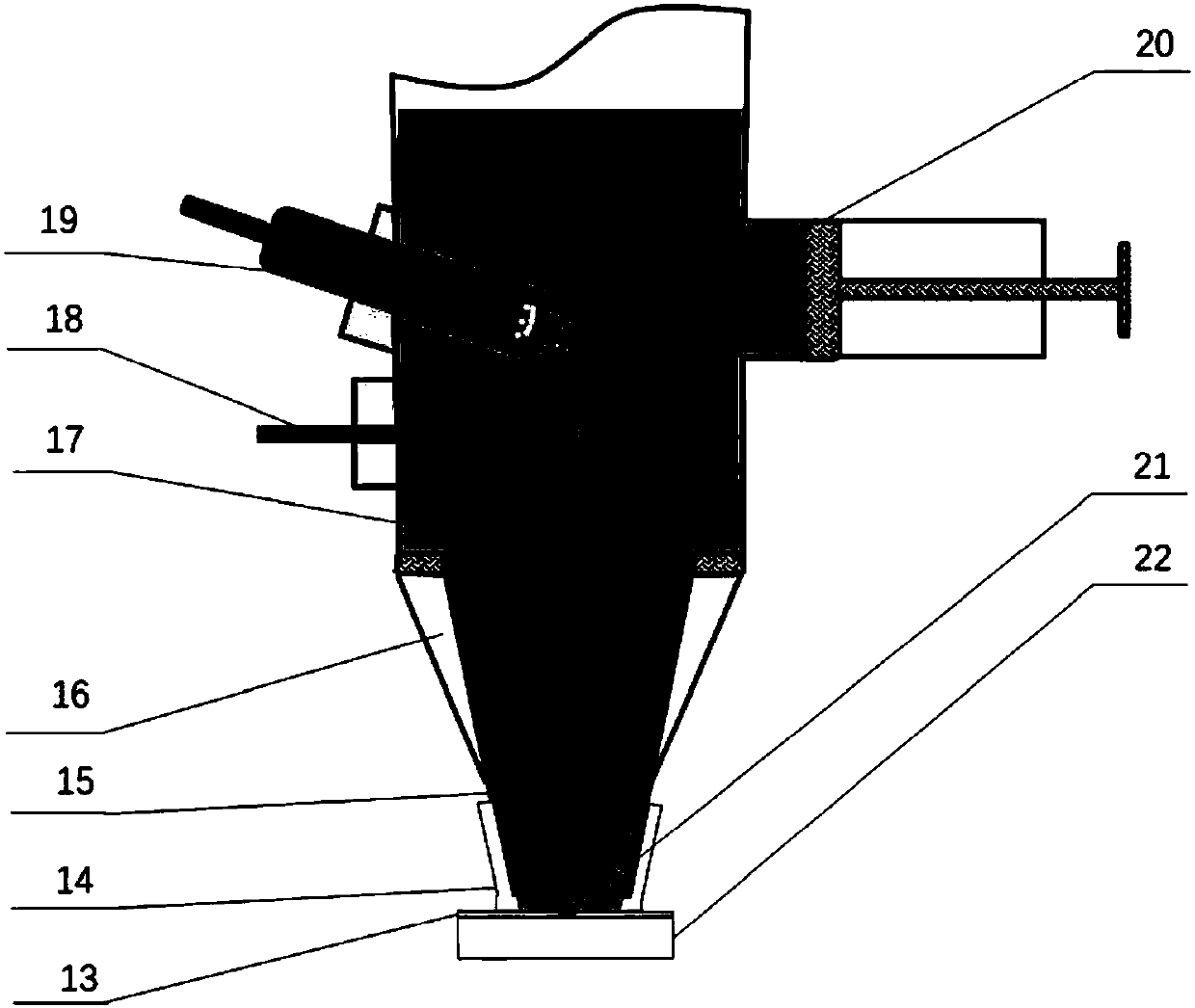

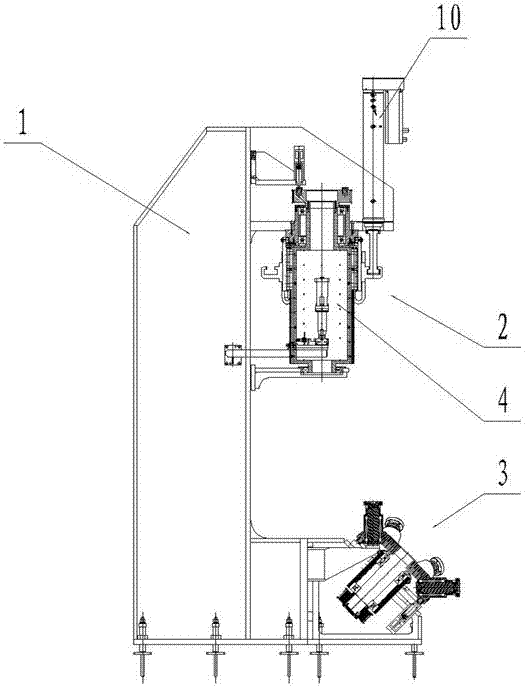

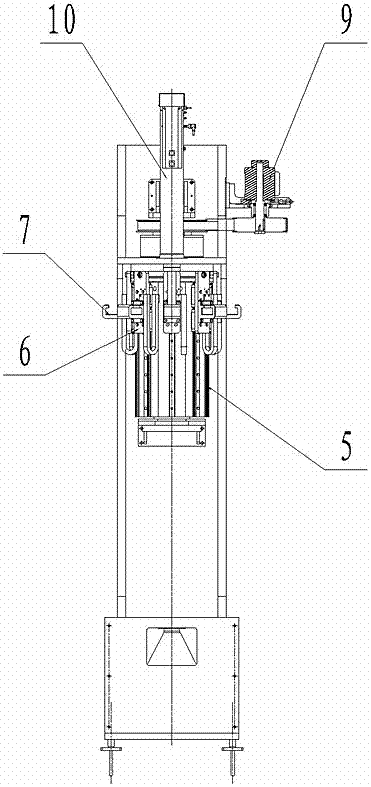

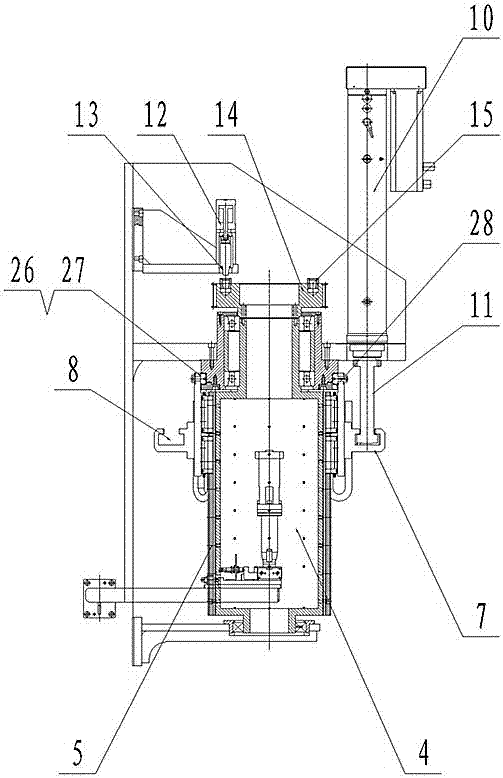

Automatic detecting device of three-reference-circle screw hole of hydraulic torque converter

PendingCN108955468AThe lifting process is stablePrecise angular positioningMachine part testingMechanical diameter measurementsProduction lineControl theory

The invention provides an automatic detecting device of a three-reference-circle screw hole of a hydraulic torque converter. The automatic detecting device comprises a mounting bottom plate; a supporting mechanism, a lifting mechanism and a positioning mechanism are arranged on the mounting bottom plate; and the supporting mechanism is arranged between the mounting bottom plate and a detecting mechanism mounting plate. A detecting mechanism and a compressing mechanism are arranged on the detecting mechanism mounting plate. A workpiece hydraulic torque converter is arranged on the supporting mechanism. According to the invention, the hydraulic torque converter can be lifted stably and accurate angular positioning can be carried out on the hydraulic torque converter; simultaneous detection of different-reference-circle screw holes of the hydraulic torque converter is realized; quick and automatic switching is realized for different reference circles; and mixing-production line productionof same kinds of products with different types is realized while the efficiency is improved, the cost is saved, and the stability is improved.

Owner:安徽华元智控科技有限公司

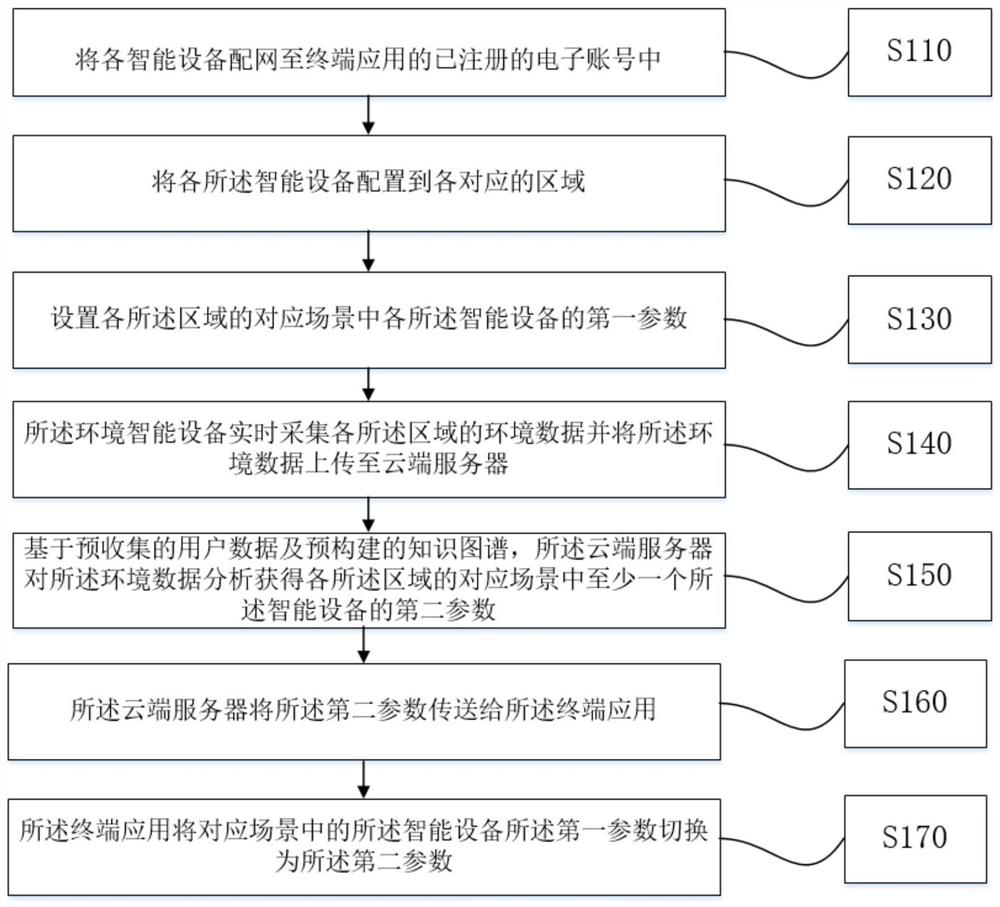

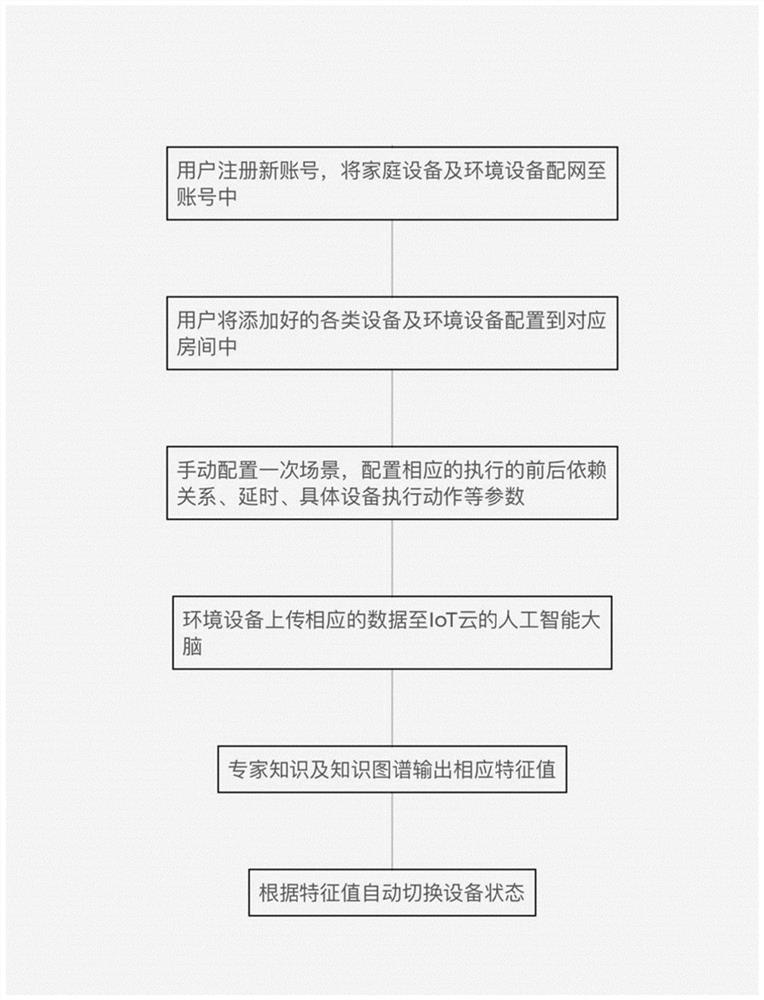

Intelligent equipment control method and device, storage medium and electronic equipment

InactiveCN112782990AReduce low-value operationsFast auto switchComputer controlTotal factory controlComputer hardwareAmbient data

The invention discloses an intelligent device control method and device, a storage medium and electronic equipment. The method comprises the following steps: distributing each intelligent device to a registered electronic account of a terminal application; configuring each intelligent device to each corresponding area; setting a first parameter of each intelligent device in the corresponding scene of each area; enabling the environment intelligent equipment to collect environment data and upload the environment data to the cloud server; on the basis of pre-collected user data and a pre-constructed knowledge graph, enabling the cloud server to analyz the environment data to obtain a second parameter of at least one intelligent device in a corresponding scene of each region; enabling the cloud server to transmit the second parameter to the terminal application; and after the terminal application obtains the second parameter, switching the first parameter of the intelligent equipment in the corresponding scene into the second parameter. According to the method, the parameters of the intelligent equipment in the corresponding scene can be quickly and automatically switched, so that the low-value operation of the user is reduced, and the user can really enjoy the intelligent life.

Owner:GREE ELECTRIC APPLIANCES INC +1

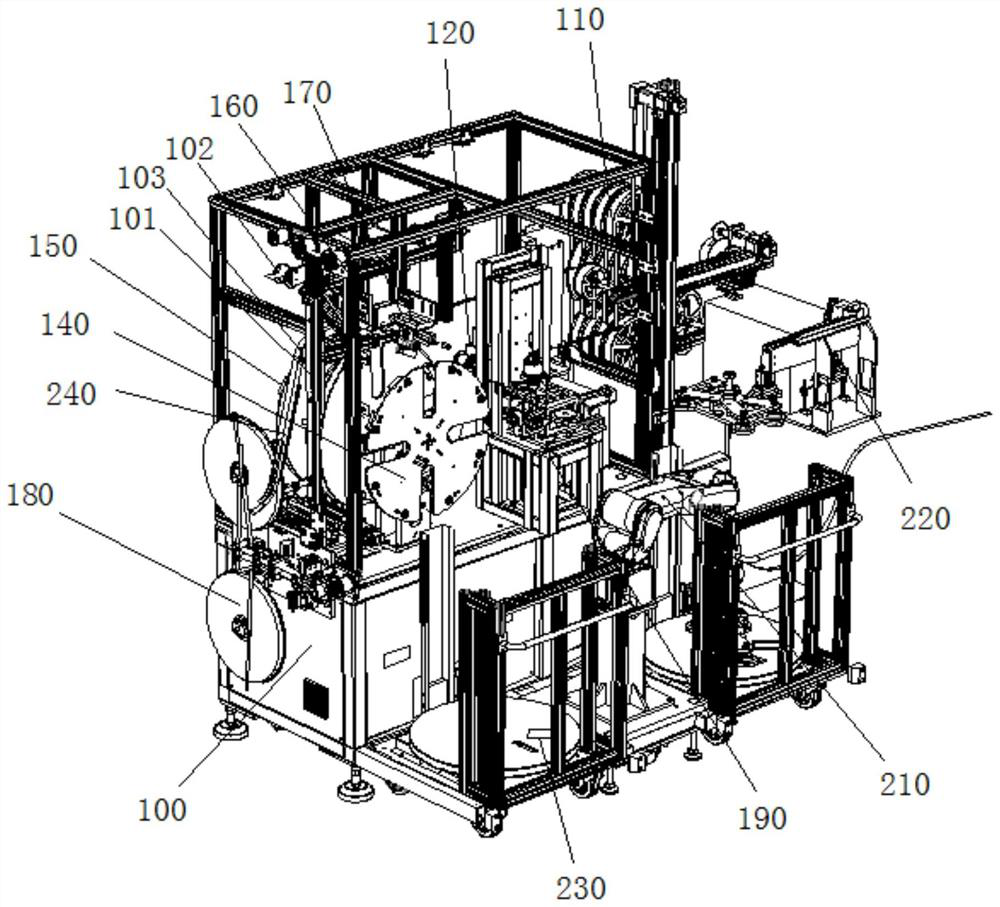

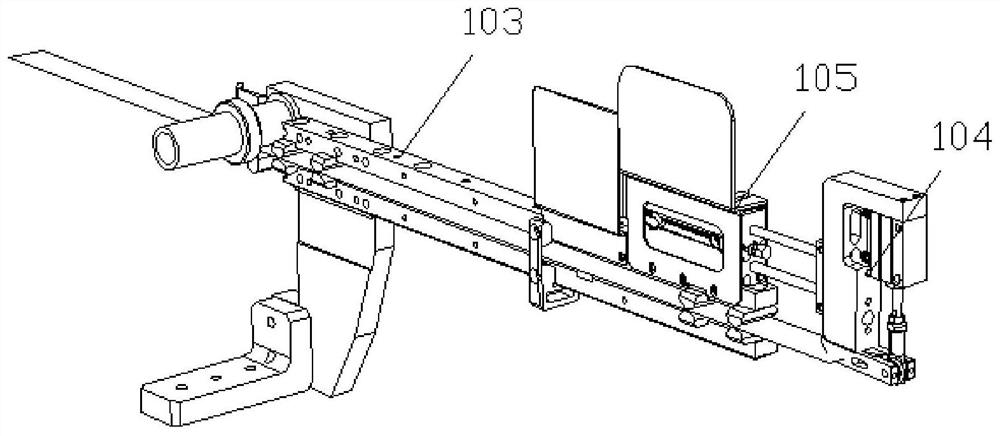

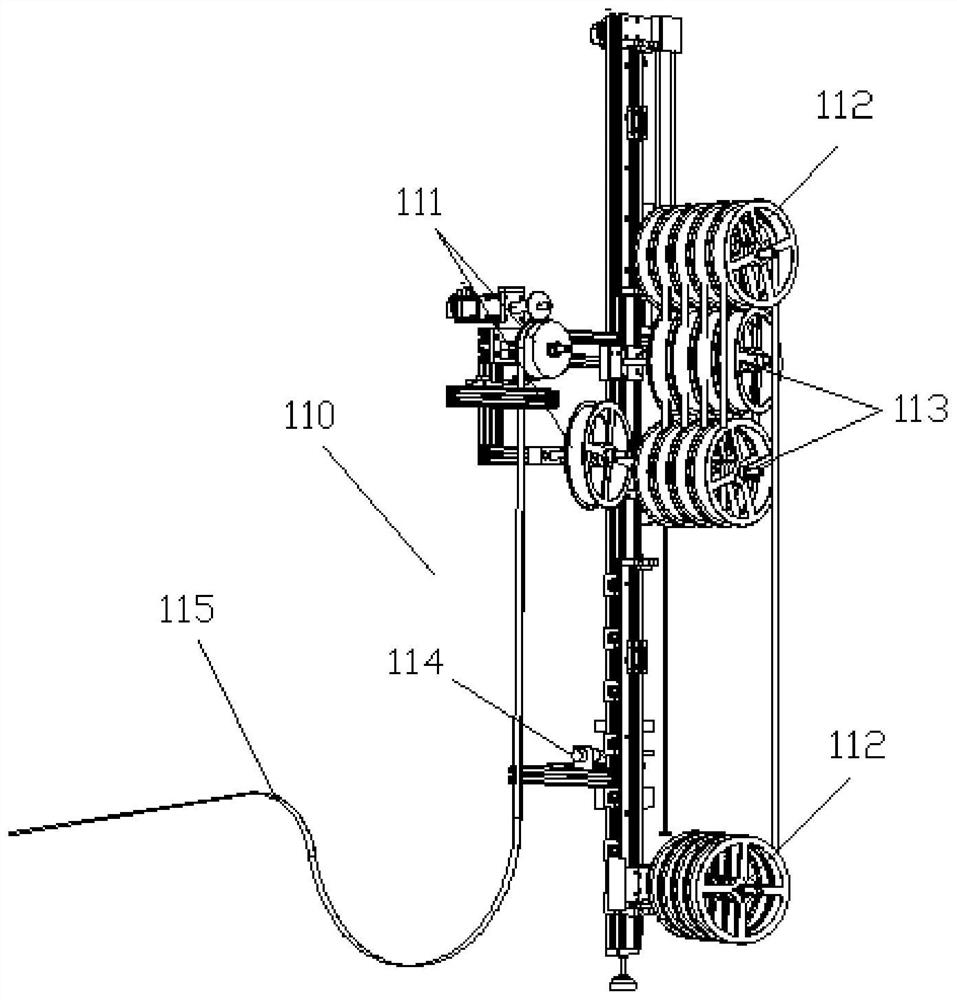

Automatic winding machine for stamping material tape, and operation method thereof

PendingCN113371488AFast auto switchQuick switchLiquid surface applicatorsMetal-working feeding devicesWinding machineAdhesive belt

The invention relates to an automatic winding machine for a stamping material tape, and an operation method thereof. The automatic winding machine for the stamping material tape comprises a buffer tower, a material tape feeding mechanism, a cutting mechanism, a rotary disc winding mechanism, a driven disc mechanism, an adhesive dispensing mechanism, a shearing mechanism, a paper tape feeding mechanism, an adhesive tape pasting mechanism, a manipulator carrying mechanism, a labeling mechanism and an appearance sampling mechanism, wherein the material tape passes through the buffer tower and the material tape feeding mechanism and then enters the rotary disc winding mechanism, the paper tape feeding mechanism feeds a paper tape into the rotary disc winding mechanism, the rotary disc winding mechanism winds the material tape and the paper tape together on a paper disc, the adhesive dispensing mechanism dispenses adhesive on the paper tape, the cutting mechanism cuts off the material tape, the shearing mechanism shears off the paper tape, and the driven disc mechanism sucks the paper disc; and the adhesive tape pasting mechanism pasts an adhesive tape to the paper disc, the manipulator carrying mechanism is used for loading and unloading for the paper disc, the labeling mechanism pasts a label to the paper disc, and the appearance sampling mechanism samples the material tape. The automatic winding machine for the stamping material tape is high in automation degree, and the material receiving efficiency, precision and stability are improved.

Owner:JIANGSU JUSTECH PRECISION IND CO LTD

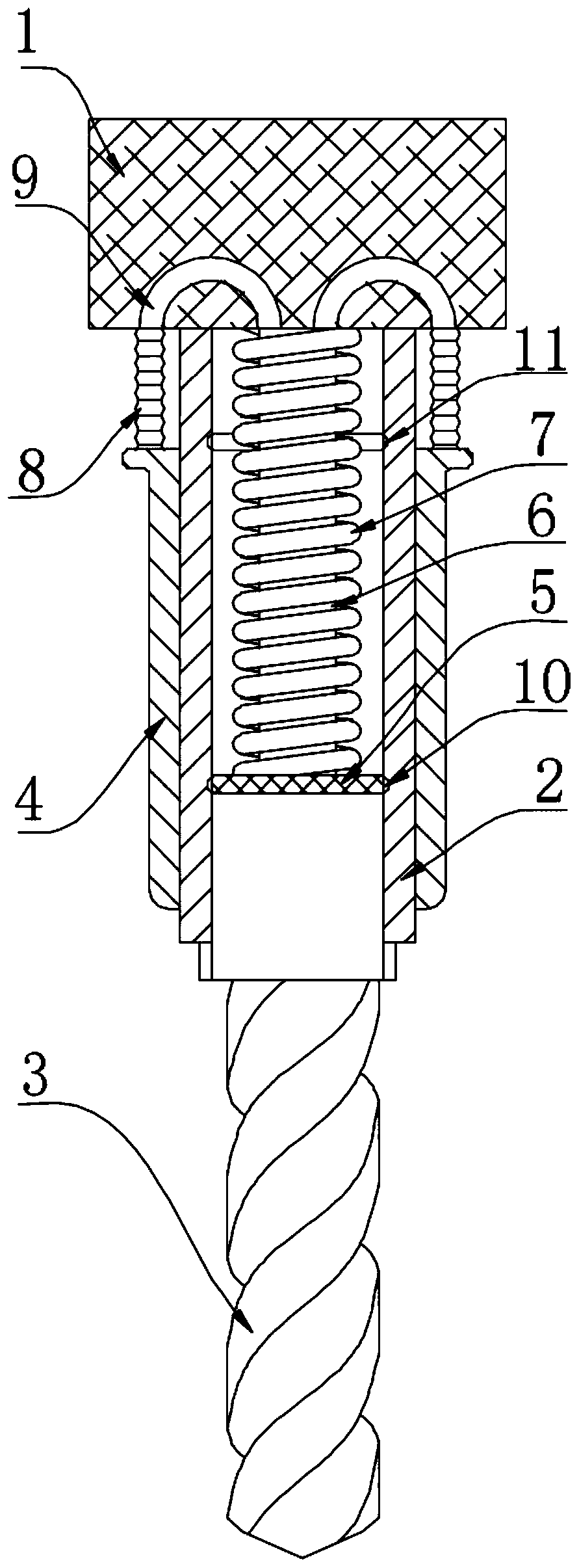

Integrated drilling and grinding dual-purpose tool for manufacturing precision machinery

ActiveCN110560752AEasy to operate for knife settingRealize the purpose of comprehensive setting on one tool holderTransportation and packagingTrepanning drillsEngineeringTool holder

The invention discloses an integrated drilling and grinding dual-purpose tool for manufacturing precision machinery. The integrated drilling and grinding dual-purpose tool for manufacturing precisionmachinery comprises a tool holder, wherein a double-sided spline ring is fixed on the lower wall of the tool holder; a drill bit is sleeved with the double-sided spline ring in a sliding mode in the up-down direction; an annular grinding head sleeves the double-sided spline ring; a conductive block is fixed at one end, close to the tool holder, of the drill bit; the conductive block and the tool holder are jointly and fixedly connected with a flexible inner pipe body; the grinding head and the tool holder are jointly and fixedly connected with a plurality of flexible outer pipe bodies; the tool holder is internally provided with communication cavities of which the number is the same as the number of the outer pipe bodies; and each communication cavity communicates with the outer pipe bodyat the corresponding position. The integrated drilling and grinding dual-purpose tool for manufacturing precision machinery has the advantages that the double-sided spline ring with splines on the inner wall and the outer wall is arranged, so that the drill bit and the grinding head synchronously rotate along with the double-sided spline ring when the double-sided spline ring rotates, the drill bit and the grinding head slide along the axial direction of the double-sided spline ring, and the purpose of comprehensively arranging the drill bit and the grinding head on one tool holder is achieved.

Owner:深圳市新昌晶鑫金属制品有限公司

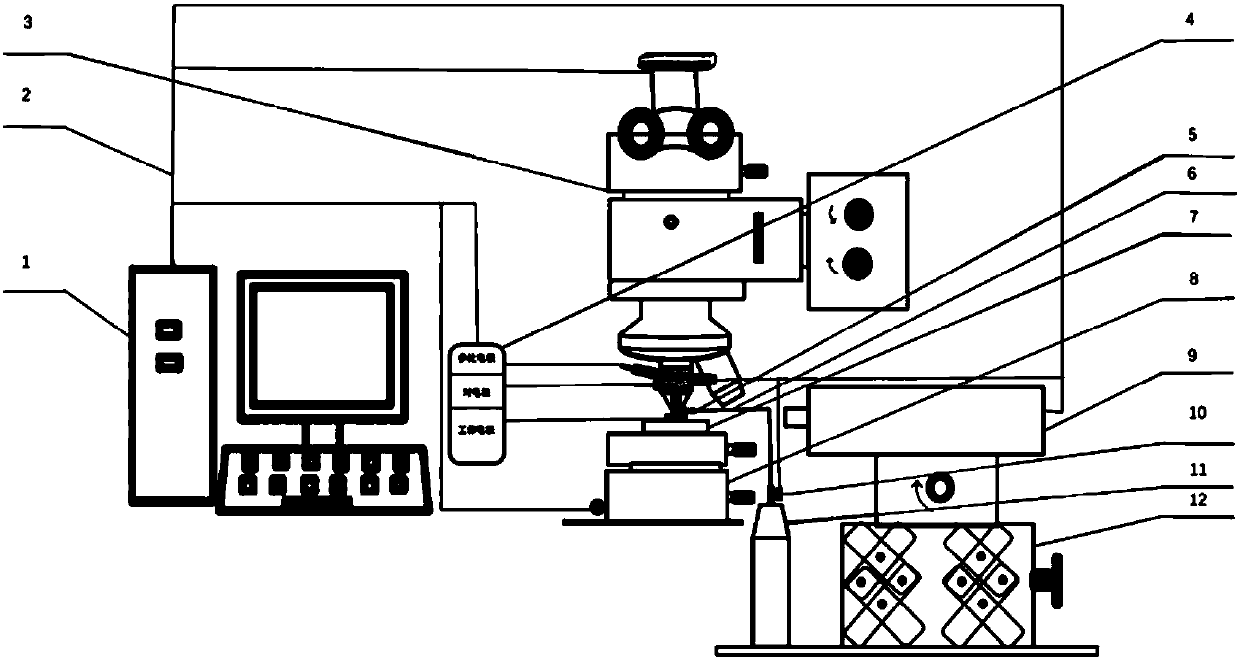

Electrochemical high-flux testing method based on photolithographic mask and micro liquid tank and device

ActiveCN107941687AAchieve accurate positioningAchieve precise positioningWeather/light/corrosion resistancePreparing sample for investigationElectrical resistance and conductanceControl system

The invention discloses an electrochemical high-flux testing method based on a photolithographic mask and a micro liquid tank and a device and relates to the technical field of metal corrosion, microcell electrochemistry and systematic data accumulation application. The device comprises a micro liquid tank testing system, a testing liquid updating system, a high-precision XYZ three-dimensional moving platform, a microscopic monitoring system, an electrochemical testing system, a storage and control system and a connection system, wherein the connection system is used for controlling instructions and testing data to be effectively transmitted among the systems. Due to modular design, the device is high in expandability; with the combination of a photolithographic mask technique and the micro liquid tank testing system, and a high-flux idea, the reaction area of a working electrode is precisely controlled, a high solution amount / working electrode reaction area ratio is achieved, influence of reaction products is reduced, seam corrosion is eliminated, risks of liquid leakage, blocking and oxygen diffusion are reduced, relatively low solution resistance is achieved, mask graphs and micro-tube sizes can be selected according to demands, high-flux and automatic measurement on microcell electrochemistry are achieved, and the measurement and analysis efficiency are improved.

Owner:UNIV OF SCI & TECH BEIJING

Operating method and electronic system

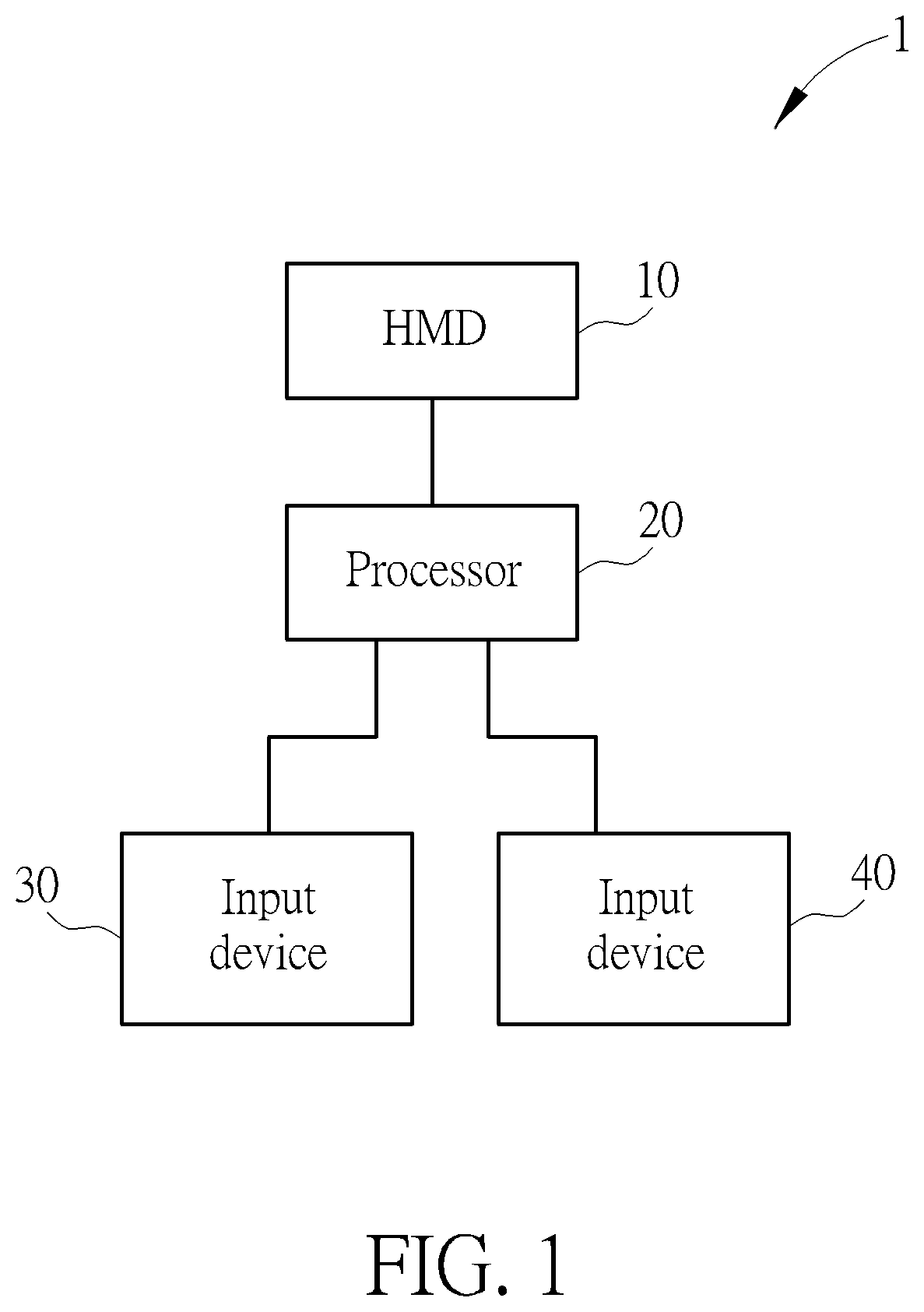

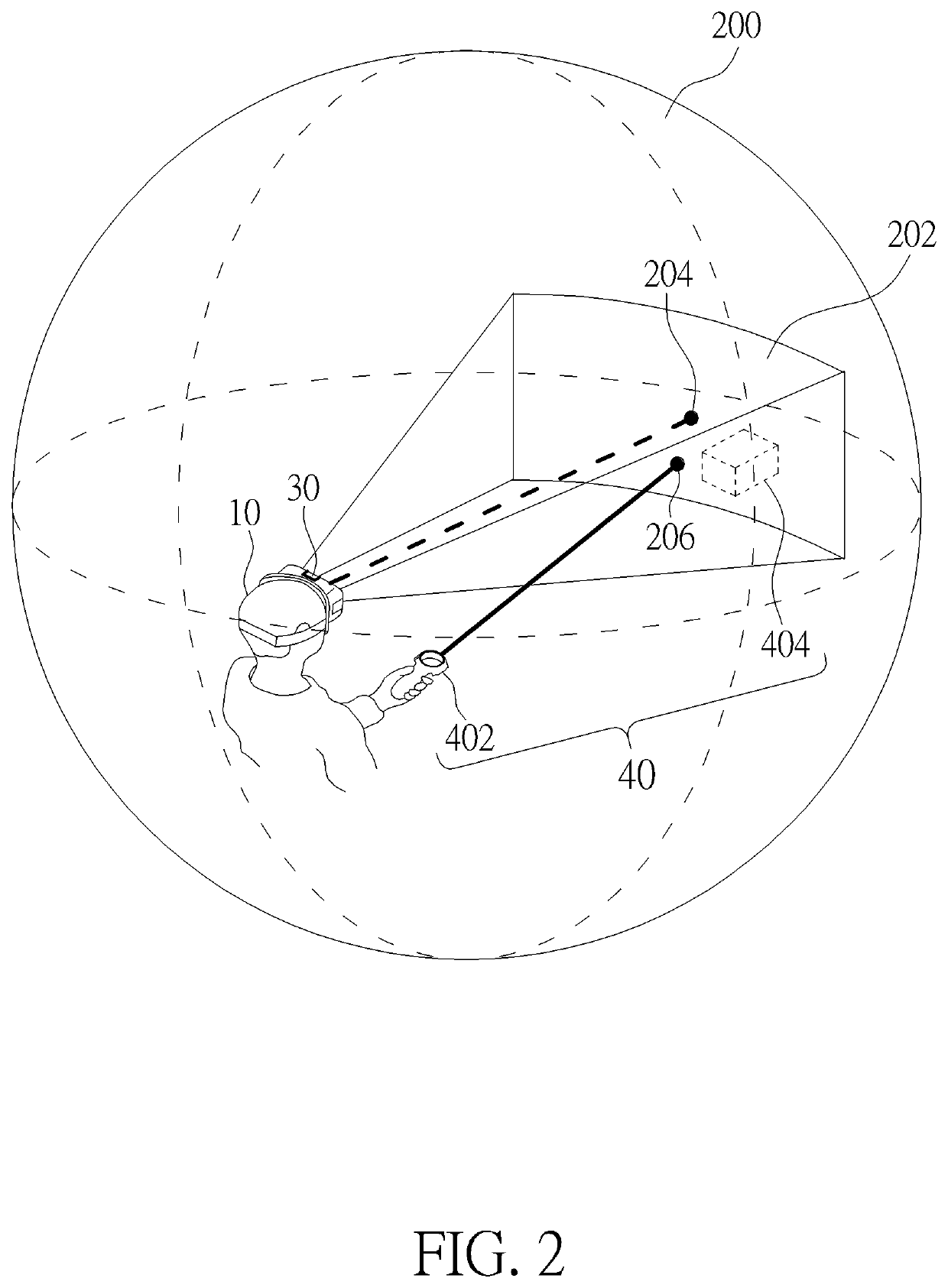

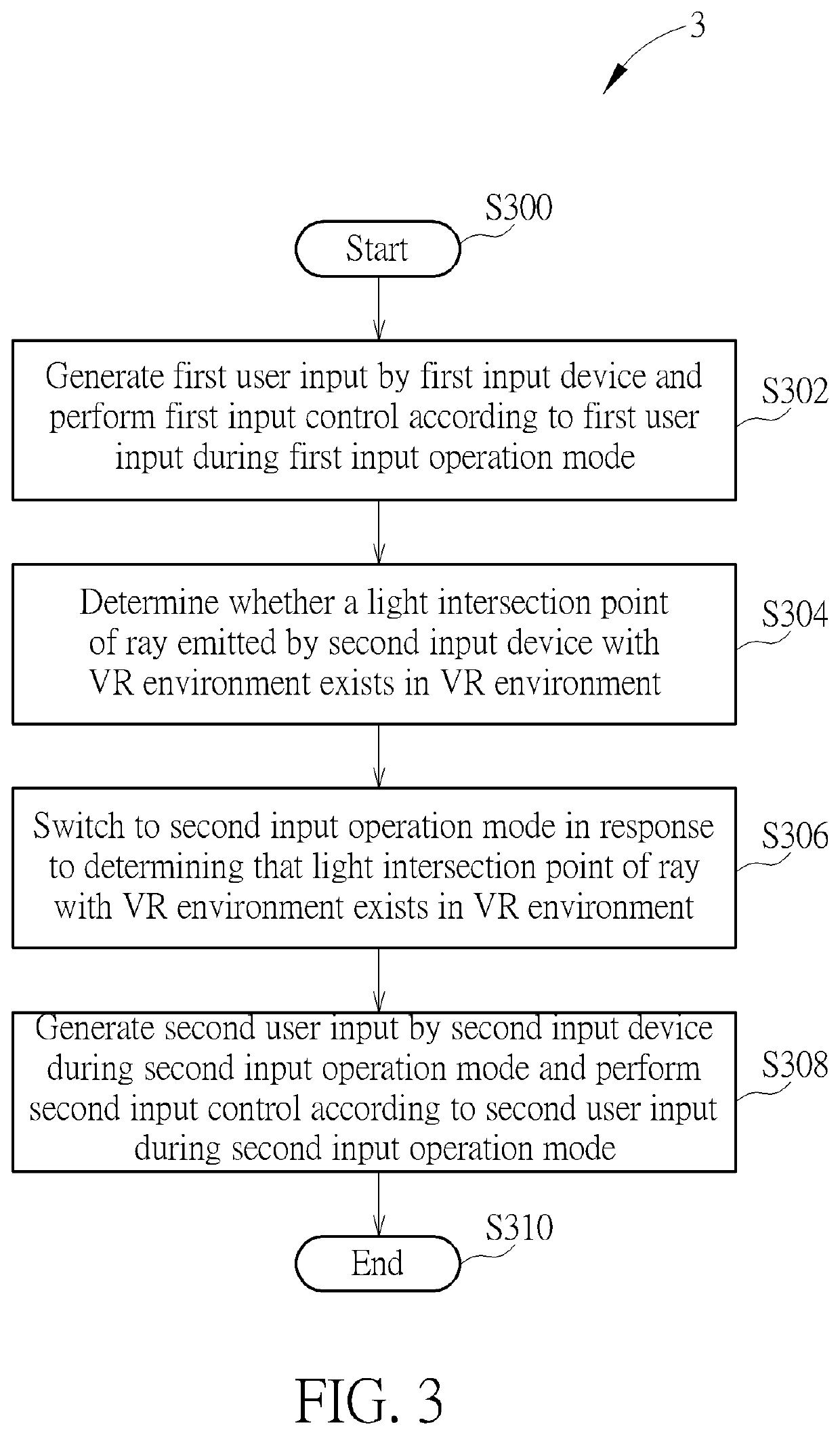

ActiveUS11467403B2Fast auto switchInput/output for user-computer interactionNon-electrical signal transmission systemsElectronic systemsInput control

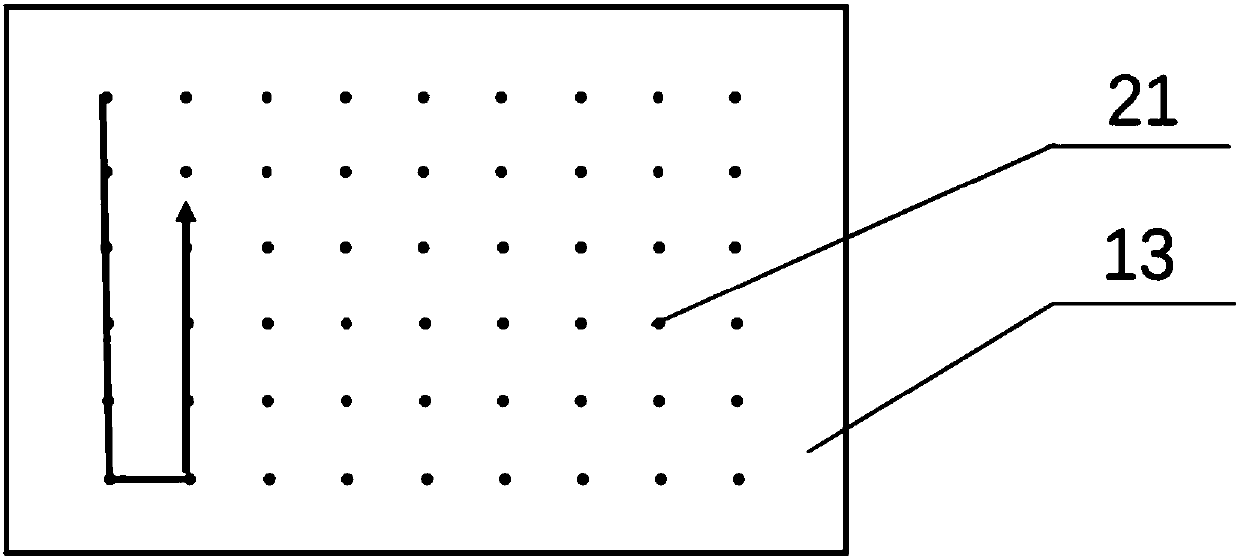

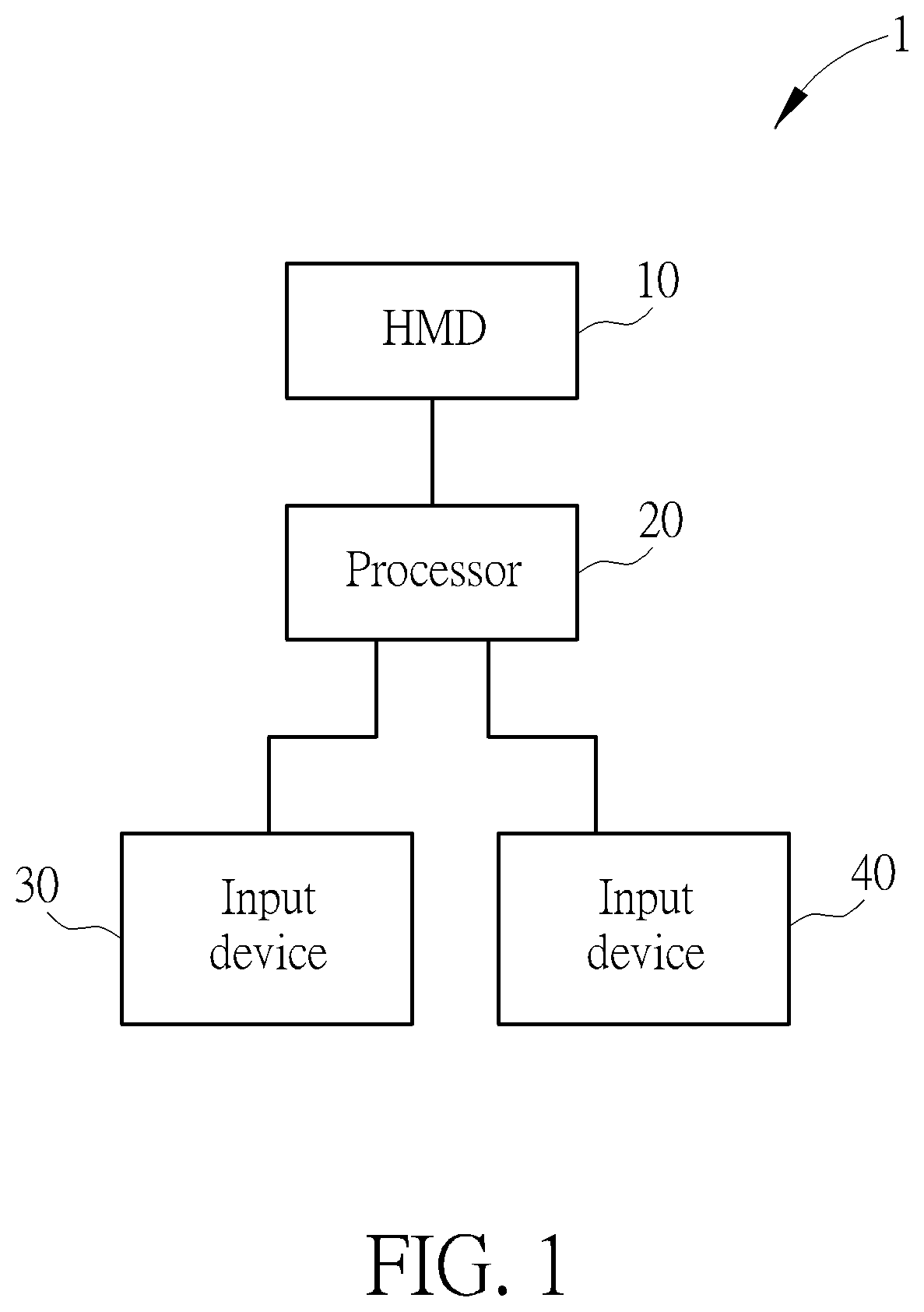

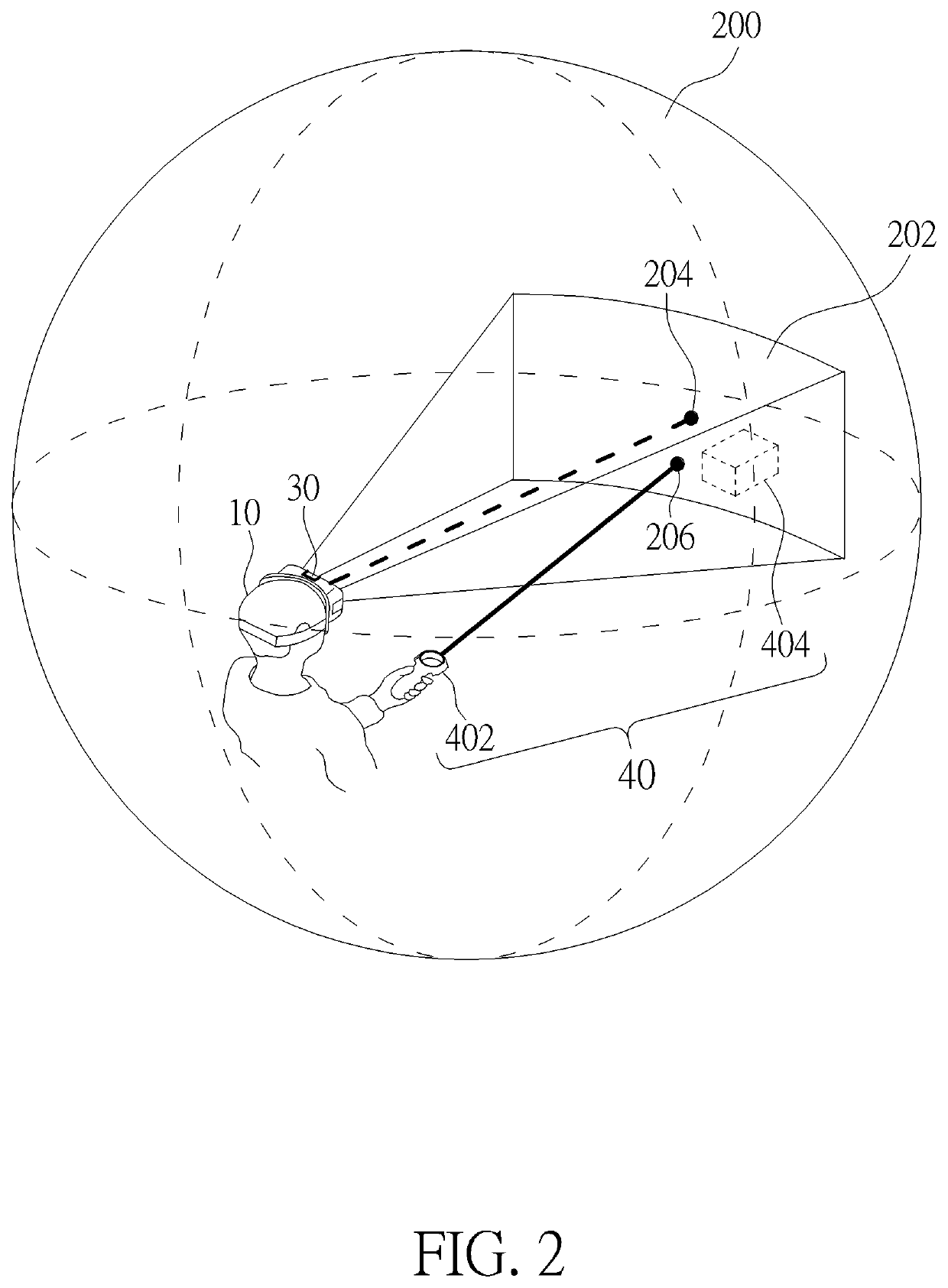

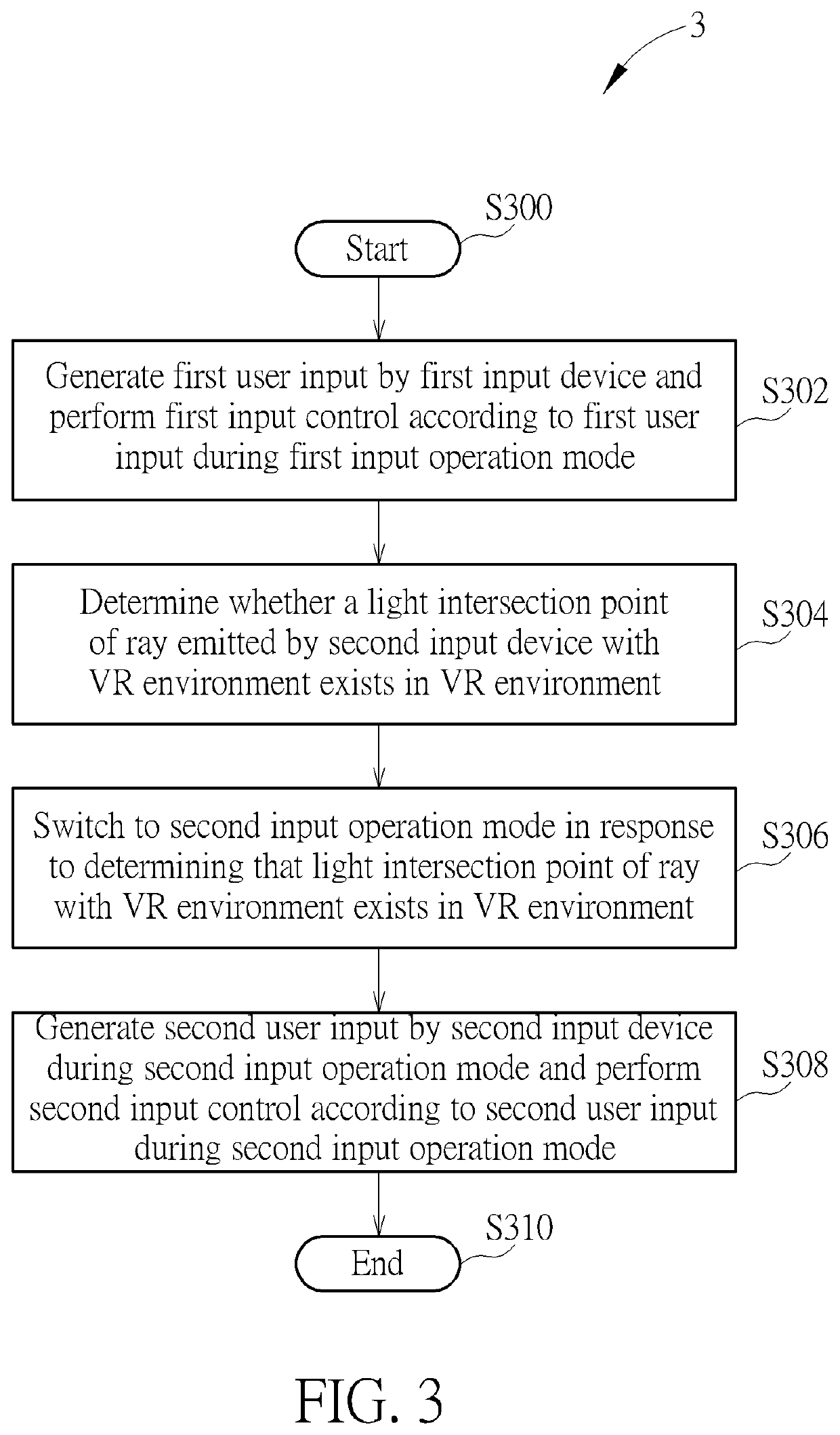

An operating method of an electronic system is provided. The operating method of the electronic system includes generating a first user input by a first input device and performing a first input control according to the first user input during a first input operation mode, determining whether a light intersection point of a ray emitted by a second input device with a virtual reality (VR) environment exists in the VR environment, switching to a second input operation mode in response to determining that the light intersection point of the ray with the VR environment exists in the VR environment and generating a second user input by the second input device and performing a second input control according to the second user input during the second input operation mode.

Owner:HTC CORP

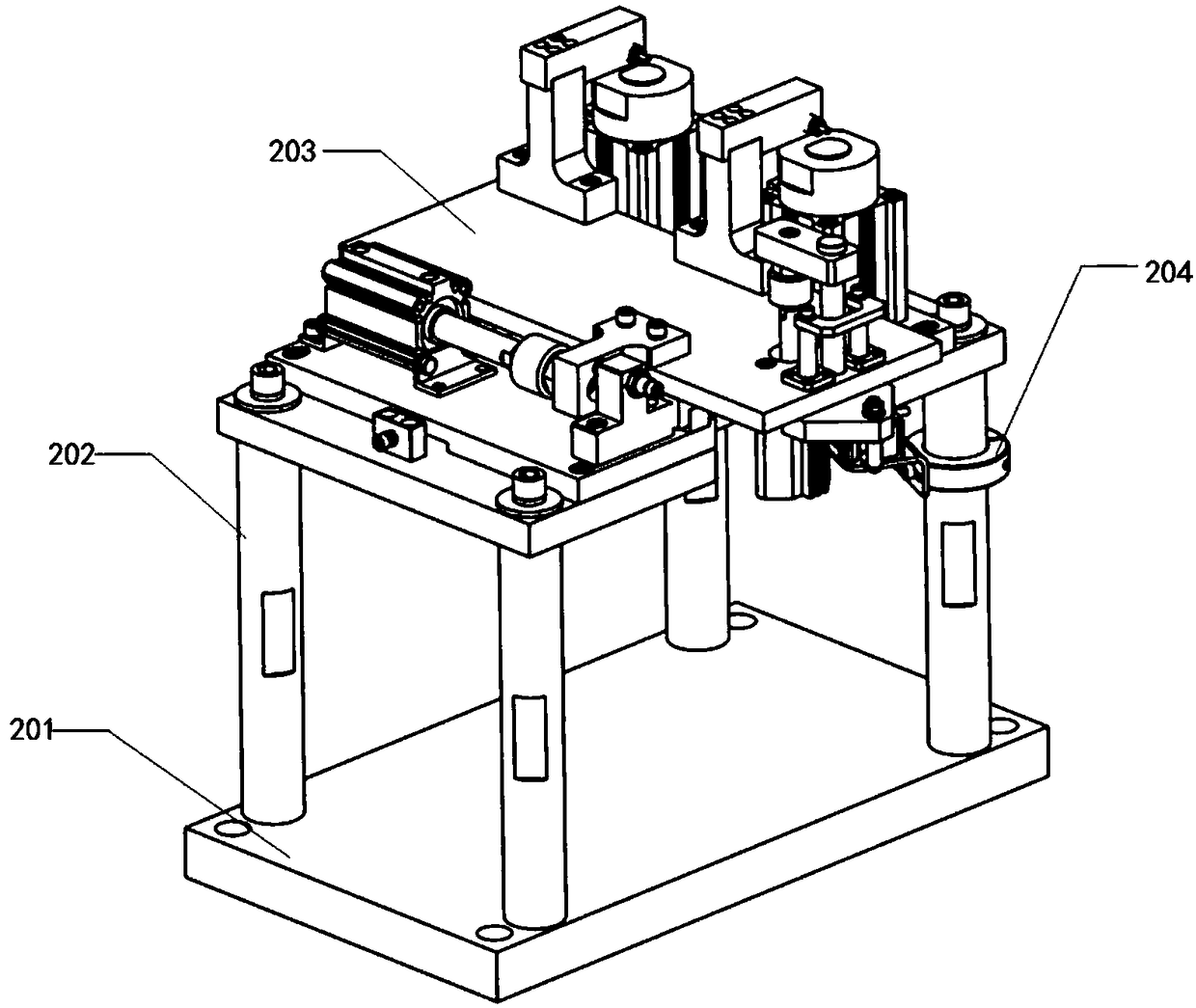

Intelligent flexible assembly unit

ActiveCN106938387ASimple structureIngenious designMetal working apparatusOperational costsEngineering

The invention discloses an intelligent flexible assembly unit simple in structure, ingenious in design and reasonable in layout. The device with a special assembly mechanism and a special reverse leaning mechanism is designed for the problem that the function of a traditional full-automatic assembly device is simplex. Multiple slide bases are arranged on the assembly mechanism of the intelligent flexible assembly unit. When a certain slide base is driven by a drum to move to a work station, the slide base can be driven by a work cylinder to move downwards. Meanwhile, a rotary table capable of rotating is arranged in the reverse leaning mechanism of the intelligent flexible assembly unit, and multiple reverse leaning tables are arranged on the rotary table. When the reverse leaning tables rotate to the work station, pressing heads at the bottom ends of the slide bases are right matched with the reverse leaning tables. In this way, rapid and automatic switching between the different pressing heads and the reverse leaning tables can be achieved, multiple purposes can be achieved through one machine, the operation cost of enterprises is greatly saved, the work efficiency is improved, and therefore it can be said that the intelligent flexible assembly unit has various beneficial effects, is particularly suitable for being applied and popularized in the field and is quite wide in market prospect.

Owner:豪森润博智能装备常州有限公司

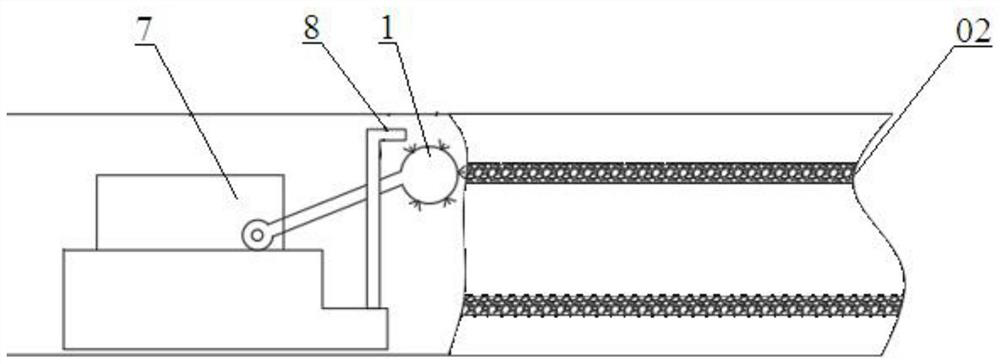

Water jet assisted bolter miner and tunneling method

ActiveCN113266351AHigh hardnessSmooth tunnelingSlitting machinesCutting machinesDust controlWater flow

The invention provides a water jet assisted bolter miner and a tunneling method. The bolter miner comprises a cutting roller and a water jet injection assembly, the water jet injection assembly comprises at least one spray head movably arranged on the surface of the cutting roller, the spray head comprises a cutting nozzle, a dust removal nozzle and a nozzle switching assembly arranged between the cutting nozzle and the dust removal nozzle, the nozzle switching assembly comprises a plugging piece and an elastic piece, and the plugging piece reciprocates between the two nozzles under the combined action of water flow and the elastic piece, so that water is sprayed out of the cutting nozzle to form clustered jet flow or sprayed out of the dust removal nozzle to form diffused jet flow. During tunneling operation, the tunneling anchor machine switches the operation mode of the spray head by controlling the pressure of the output flow of a pump station; in the high-pressure small-flow mode, the cluster jet flow cuts a gangue layer to form a groove; and in the low-pressure large-flow mode, the cutting roller rotates to crush rocks, and the diffused jet flow cools cutting teeth and remove dust during construction, so that shutdown tool changing and complex nozzle switching operation can be avoided, and the working efficiency is improved.

Owner:CHINA RAILWAY CONSTR HEAVY IND

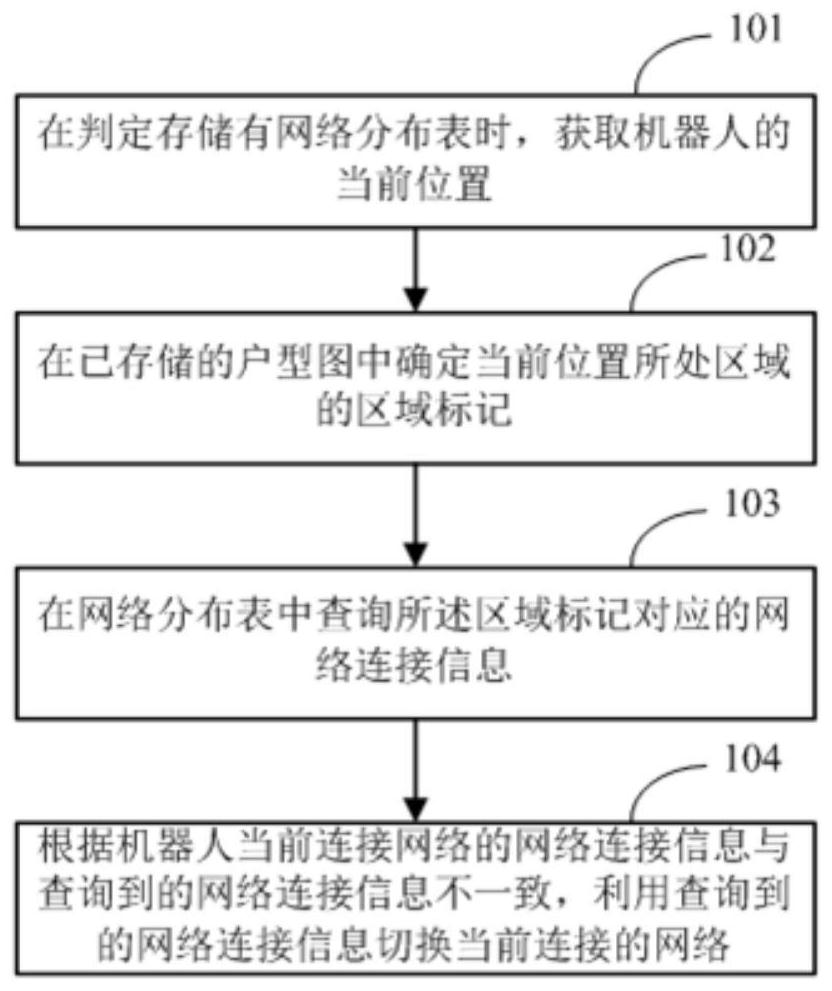

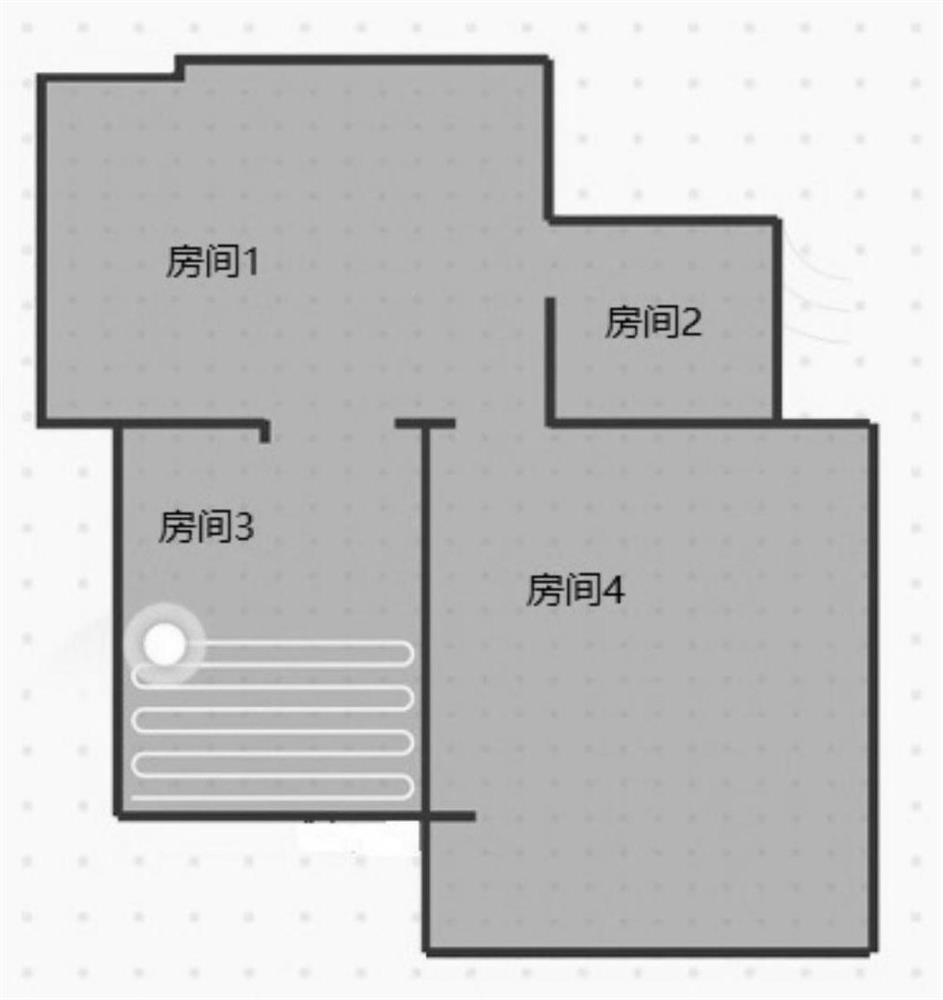

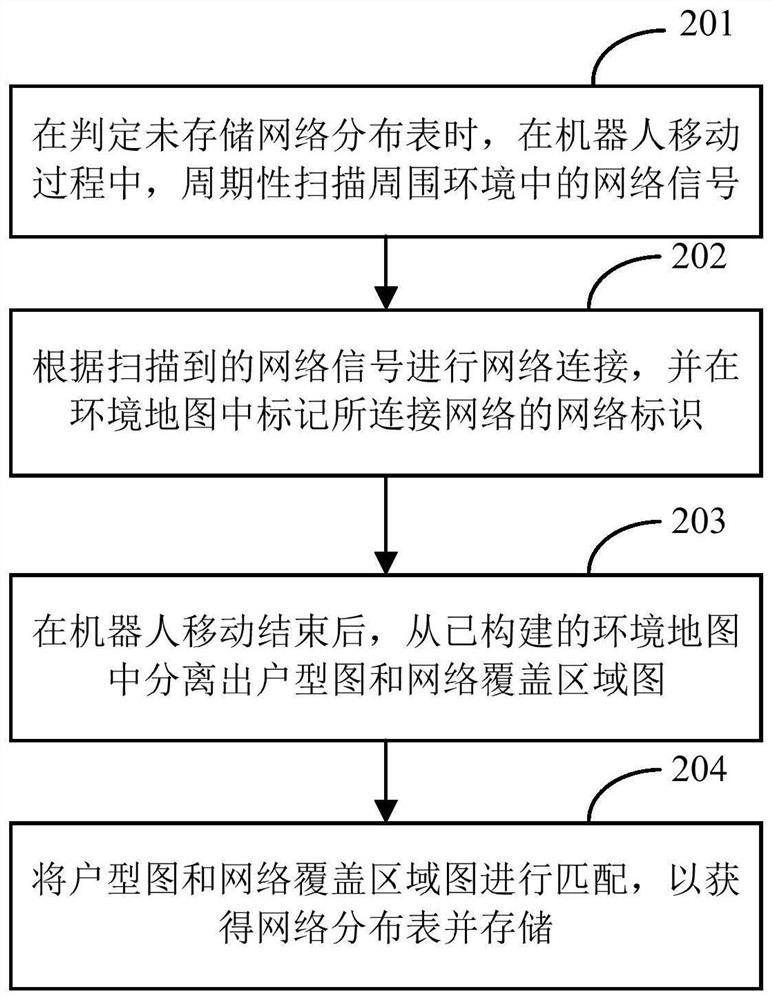

Robot network switching method and device and storage medium

PendingCN113645566AReduce calculation loadFast auto switchLocation information based serviceNetwork connectionSimulation

The invention discloses a robot network switching method and device and a storage medium, and the method comprises the steps: determining a region mark of a region where the current position of a robot is located in a stored house type image when a network distribution table is stored; querying network connection information corresponding to the region marks in a network distribution table; and switching the currently connected network by using the queried network connection information according to the inconsistency between the network connection information of the currently connected network of the robot and the queried network connection information. The area where the current position of the robot is located can be obtained at any time through the existing house type diagram, the network connection information of the area where the robot is located can be obtained by searching the network distribution table, and then the network connected with the robot can be rapidly and automatically switched through the network connection information. According to the scheme, the robot does not need to continuously and periodically scan each network signal for network switching, the calculation load of the robot can be reduced, and the robot can use more calculation resources for navigation path calculation.

Owner:MIDEA ROBOZONE TECH CO LTD

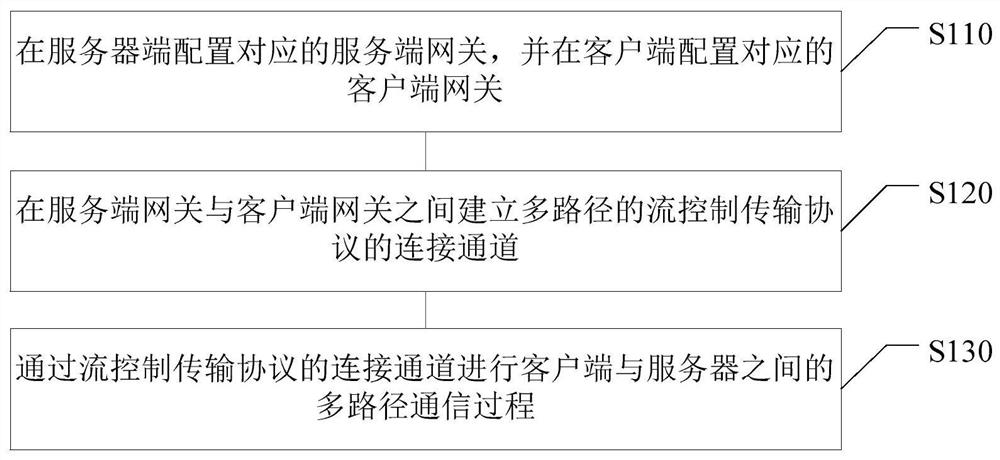

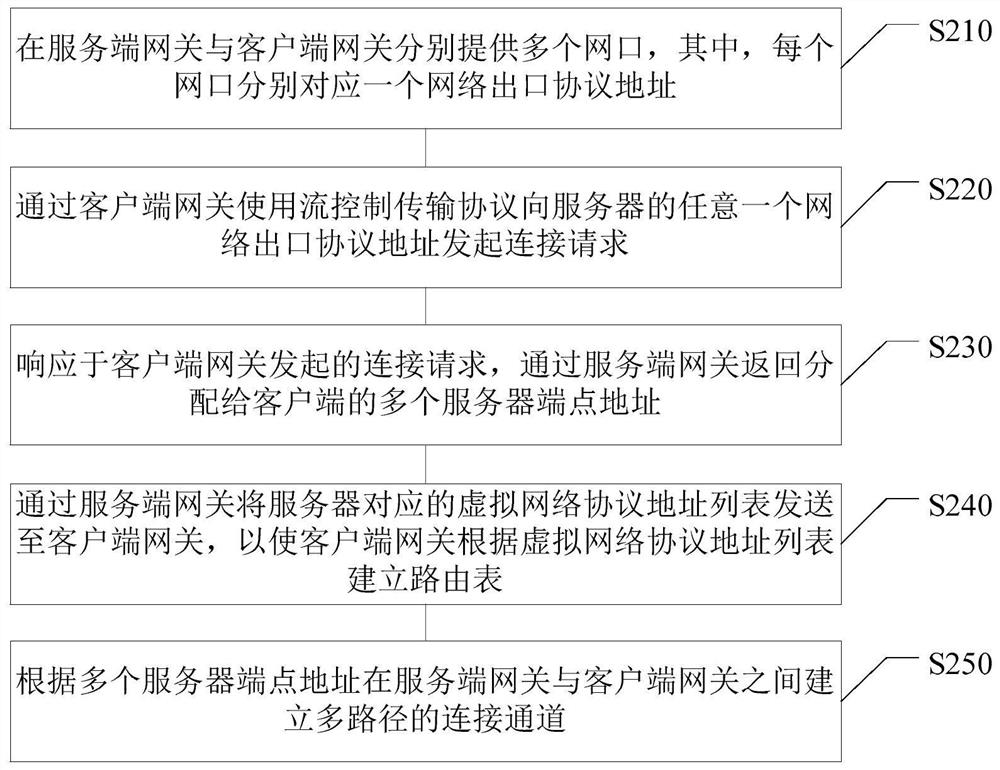

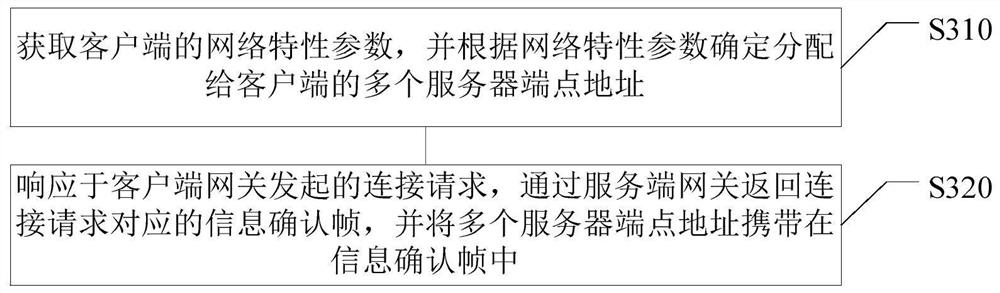

Multipath communication method and device, electronic equipment and computer readable medium

ActiveCN113726648ASimple and lightweight architectureQuickly and automatically switch pathsData switching networksTelecommunicationsServer-side

The invention relates to a multipath communication method and device, electronic equipment and a computer readable medium, and belongs to the technical field of communication. The method comprises the following steps: configuring a corresponding server gateway at a server, and configuring a corresponding client gateway at a client; establishing a connection channel of a multi-path flow control transmission protocol between the server gateway and the client gateway; and performing a multi-path communication process between the client and the server through the connection channel of the flow control transmission protocol. According to the method and the device, the corresponding lightweight gateway devices are respectively configured at the server side and the client side, and the multipath connection channel is established through the server side gateway and the client side gateway, so that the multipath communication process based on the flow control transmission protocol between the client side and the server can be realized.

Owner:CHINA TELECOM CORP LTD

Operating method and electronic system

ActiveUS20220057634A1Fast auto switchInput/output for user-computer interactionNon-electrical signal transmission systemsElectronic systemsInput control

An operating method of an electronic system is provided. The operating method of the electronic system includes generating a first user input by a first input device and performing a first input control according to the first user input during a first input operation mode, determining whether a light intersection point of a ray emitted by a second input device with a virtual reality (VR) environment exists in the VR environment, switching to a second input operation mode in response to determining that the light intersection point of the ray with the VR environment exists in the VR environment and generating a second user input by the second input device and performing a second input control according to the second user input during the second input operation mode.

Owner:HTC CORP

Revolving radiation collimator

ActiveUS11058892B2Fast auto switchQuick changeHandling using diaphragms/collimetersUsing optical meansCollimator devicesControl system

Devices, systems and method that allow for delivery of therapeutic radiation beams of differing sizes or shapes during a radiation treatment are provided herein. Such devices can include a rotatable collimator body having multiple collimator channels of differing size or shape defined therein, the channels extending through the collimator body substantially perpendicular to the axis of rotation. The collimator body can include markers thereon to facilitate detection of an alignment position by a sensor of a control system to allow the collimator body to be rapidly and accurately moved between alignment positions to facilitate delivery of differing therapy beams during a treatment.

Owner:ZAP SURGICAL SYST INC

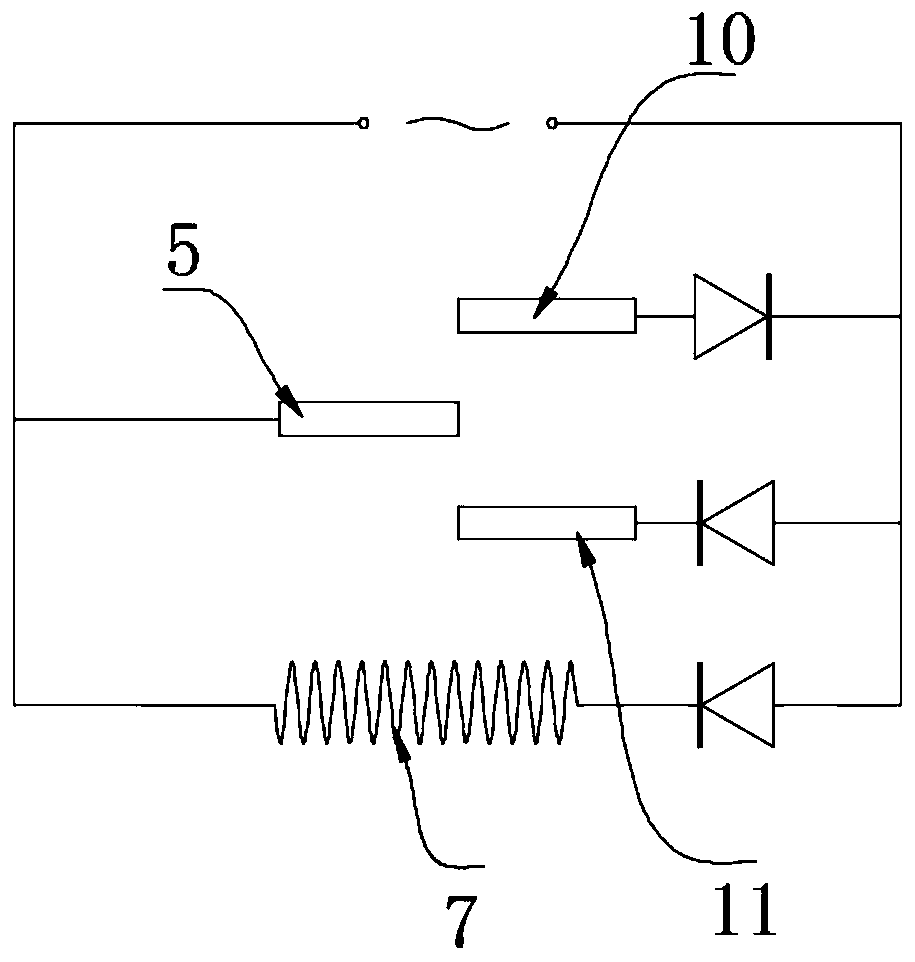

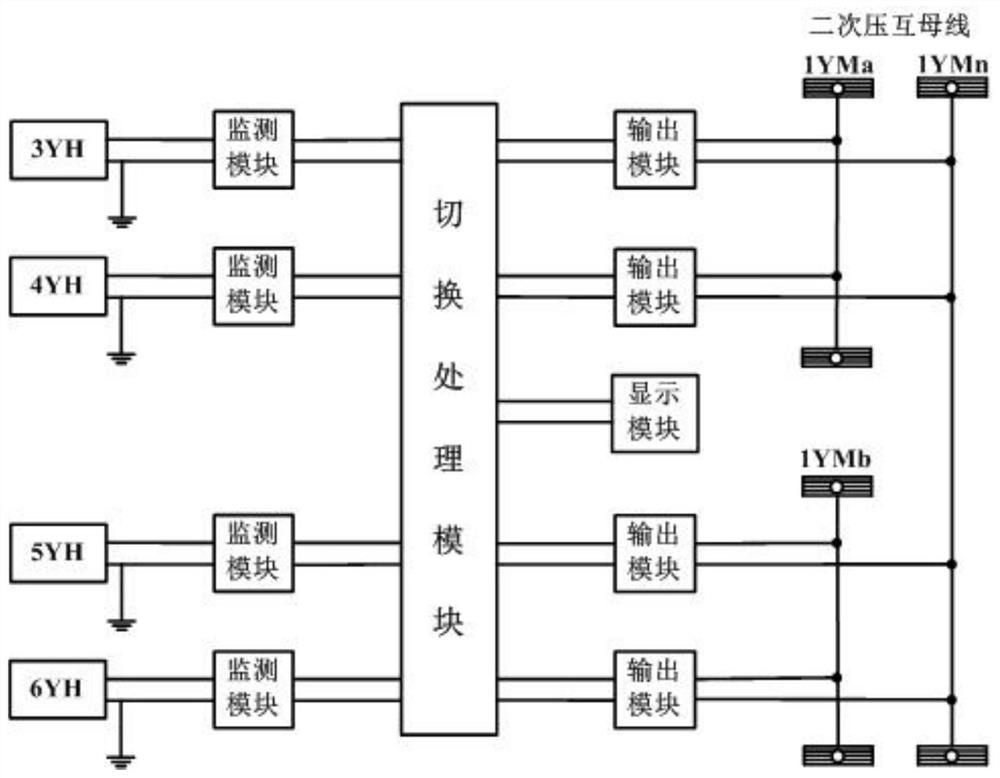

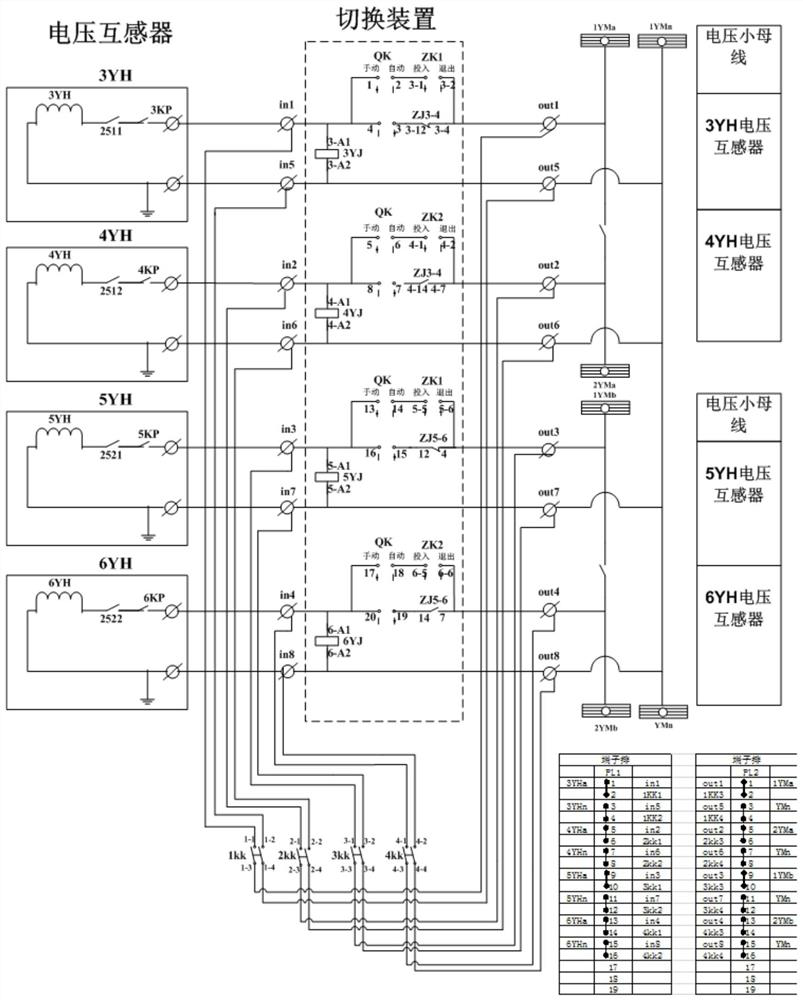

Secondary voltage loop automatic switching system and automatic switching method

ActiveCN112600291AFast auto switchVersatileCurrent/voltage measurementPower network operation systems integrationAutomatic controlTransformer

The invention belongs to the technical field of automatic control, and particularly relates to a secondary voltage loop automatic switching system and an automatic switching method. The secondary voltage loop automatic switching system comprises a voltage transformer, a monitoring module, a switching module and an output circuit, wherein the input end of the voltage transformer is connected with asecondary voltage loop bus, the output end of the voltage transformer is connected with the input end of the monitoring module, the output end of the monitoring module is connected with the input endof the switching module, and the output end of the switching module is connected with the input end of the output circuit. According to the invention, the switching module adopted by the system can be timely, effectively and automatically switched to the standby circuit when the secondary voltage loop breaks down, so that the switching action is fast, the effectiveness and timeliness are improved, and economic losses caused by faults are avoided.

Owner:XIAN RAILWAY BUREAU SCI & TECH INST

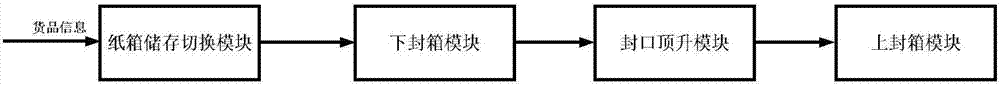

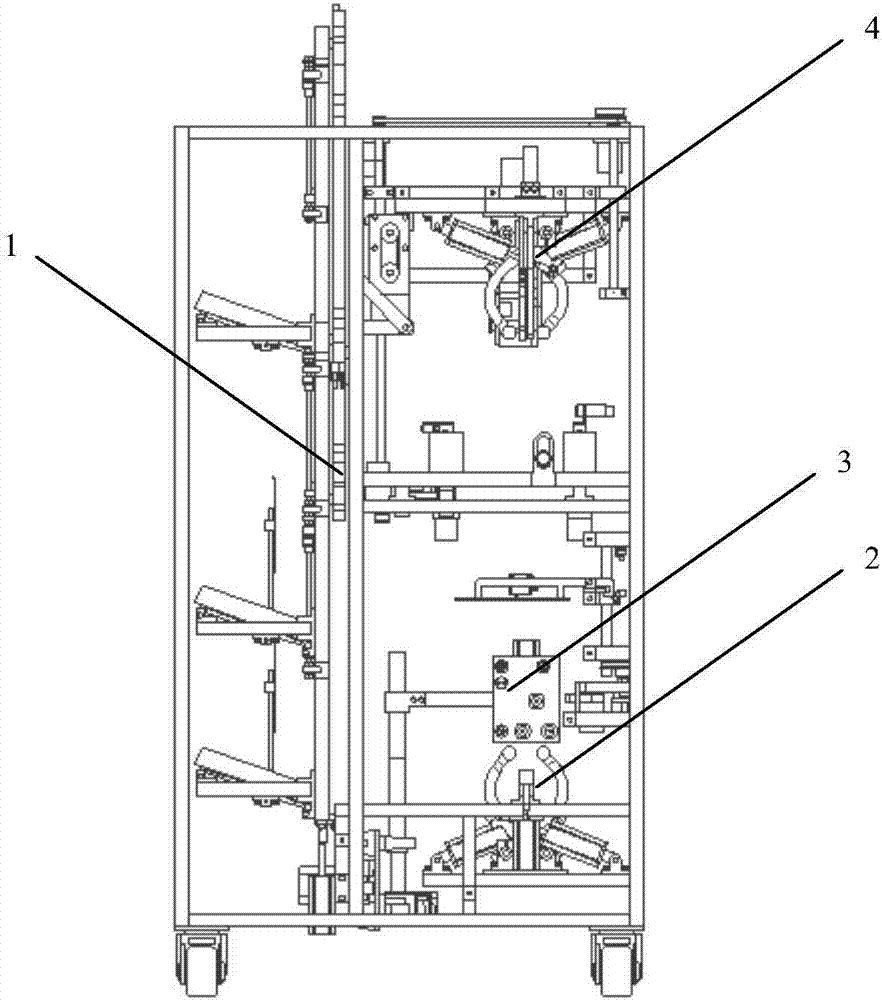

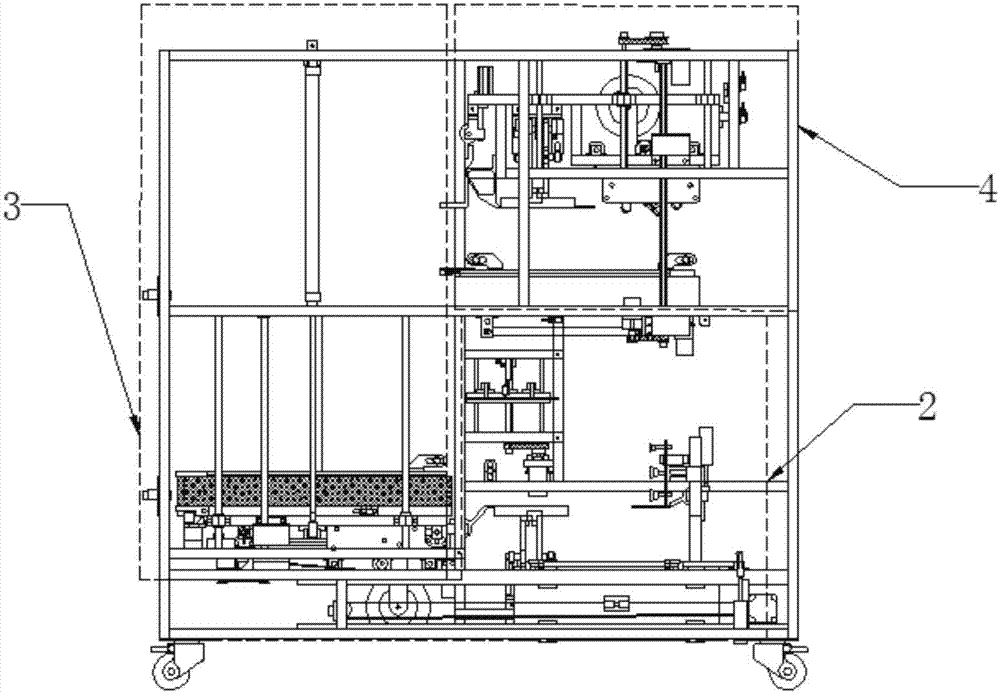

Automatic packaging machine

ActiveCN106965978AFast auto switchQuick box formingWrapper twisting/gatheringButt jointLocking mechanism

The present invention relates to an automatic packaging machine. The automatic packaging machine comprises a rack, a carton storage and switching module, a lower carton-sealing module, a sealing and jacking module and an upper carton-sealing module. The carton storage and switching module is disposed at one side of the rack and is in butt joint with the lower carton-sealing module. The lower carton-sealing module and the sealing and jacking module are arranged at the bottom part of the other side of the rack, and the upper carton-sealing module is arranged above the lower carton-sealing module. The carton storage and switching module is used for switching cartons of different specifications. The lower carton-sealing module is used for sucking the cartons and sealing the lower parts of the cartons. The sealing and jacking module is used for delivering the cartons. The upper carton-sealing module is used for sealing the upper parts of the cartons. According to the automatic packaging machine provided by the invention, required packing boxes are switched by using a turret-type rotating switching mechanism, accurate feeding of the packing boxes is realized through coordination of a positioning and locking mechanism and the sensor technology, and thus cartons of standard sizes are obtained by folding. By a mechanical and electronic integration manner, actions such as rapid and automatic switching of cartons of different specifications, rapid carton-fetching and shaping, automatic lower cover sealing and automatic upper cover sealing are realized, thereby realizing rapid, flexible and automatic packing.

Owner:浙江机电职业技术学院

Information processing method and information processing device

InactiveCN104270525BFast auto switchImprove experienceEavesdropping prevention circuitsInformation processingComputer hardware

The present invention proposes an information processing method and an information processing device, wherein the information processing method includes: when the terminal in the current system receives input information, the current system acquires the attribute information of the target system, and judge whether the attribute information matches the pre-stored data about the target system stored in the current system; when the attribute information matches the pre-stored data, the Switching to the target system to process the information, wherein the target system has a higher security level than the current system. Through the technical solution of the present invention, rapid and automatic switching between the common system and the security system can be realized, and user experience can be improved.

Owner:COOLPAD SOFTWARE TECH (SHENZHEN) CO LTD

Spare power automatic switching device and method for three-segment bus two-segment switch

InactiveCN101369739BFast auto switchAvoid misuseEmergency power supply arrangementsBusbarStandby power

A three-busbar two-section switch standby self-casting apparatus, belonging to power distribution field, includes two power supply lead-in circuit breakers, three busbar segments and two section breakers. Two standby self-casting devices being mounted on the position of the two section breakers; the standby self-casting device being equipped with a current detection loop, a voltage detection loopand a control circuit; the current detection loop using the signal of a two-path lead-in current transformer as ''non stream'' criterion, and using the current signal of the corresponding section breaker as ''over current'' criterion; while the voltage detection loop using the voltage signals of the two busbar segments, neighboring the corresponding section breaker, as ''pressure / non-pressure'' criterion. The standby power supply self-casting device includes a electrification discrimination circuit, a first and a second startup condition judgment circuit, a standby self-casting motion circuitand a rear acceleration motion circuit. The invention also discloses standby self-casting method for the apparatus. The apparatus implements power supply rapid automatic switching when the lead-in isfailure under different running modes of the three-section busbar, and ensures the power supply reliability under accidents status.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

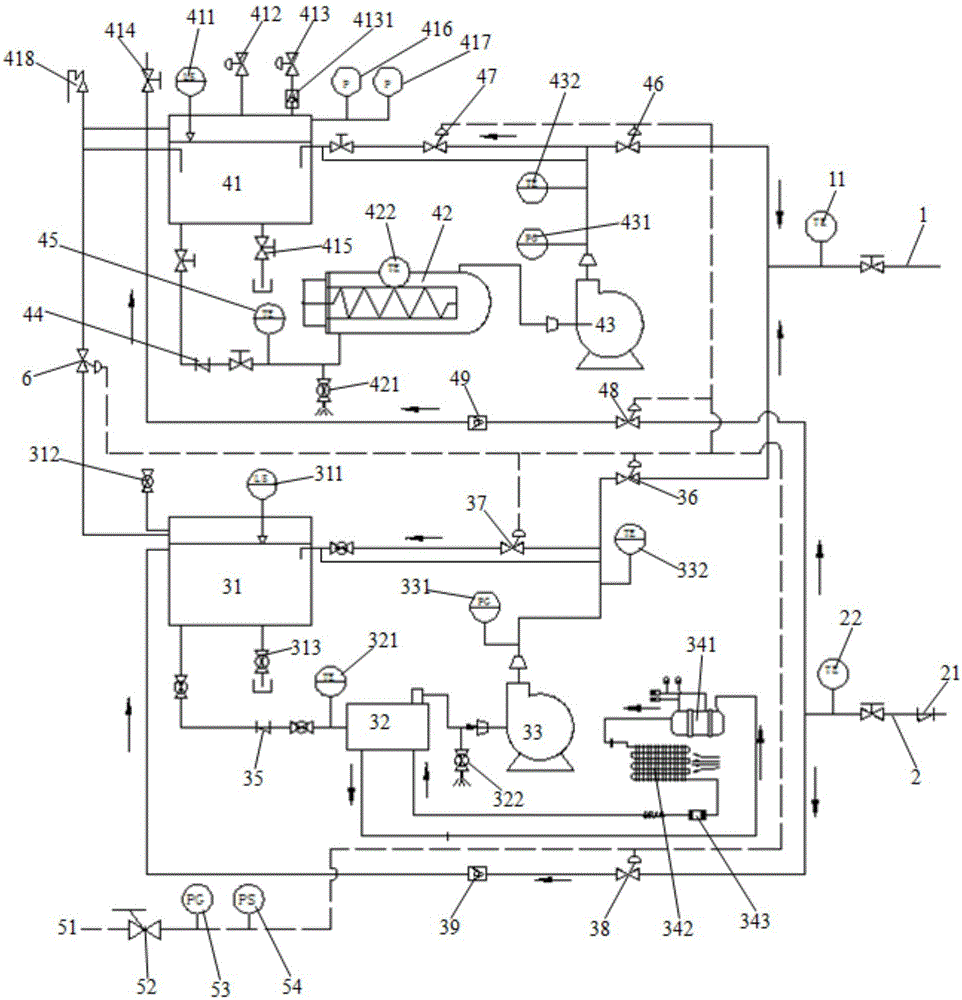

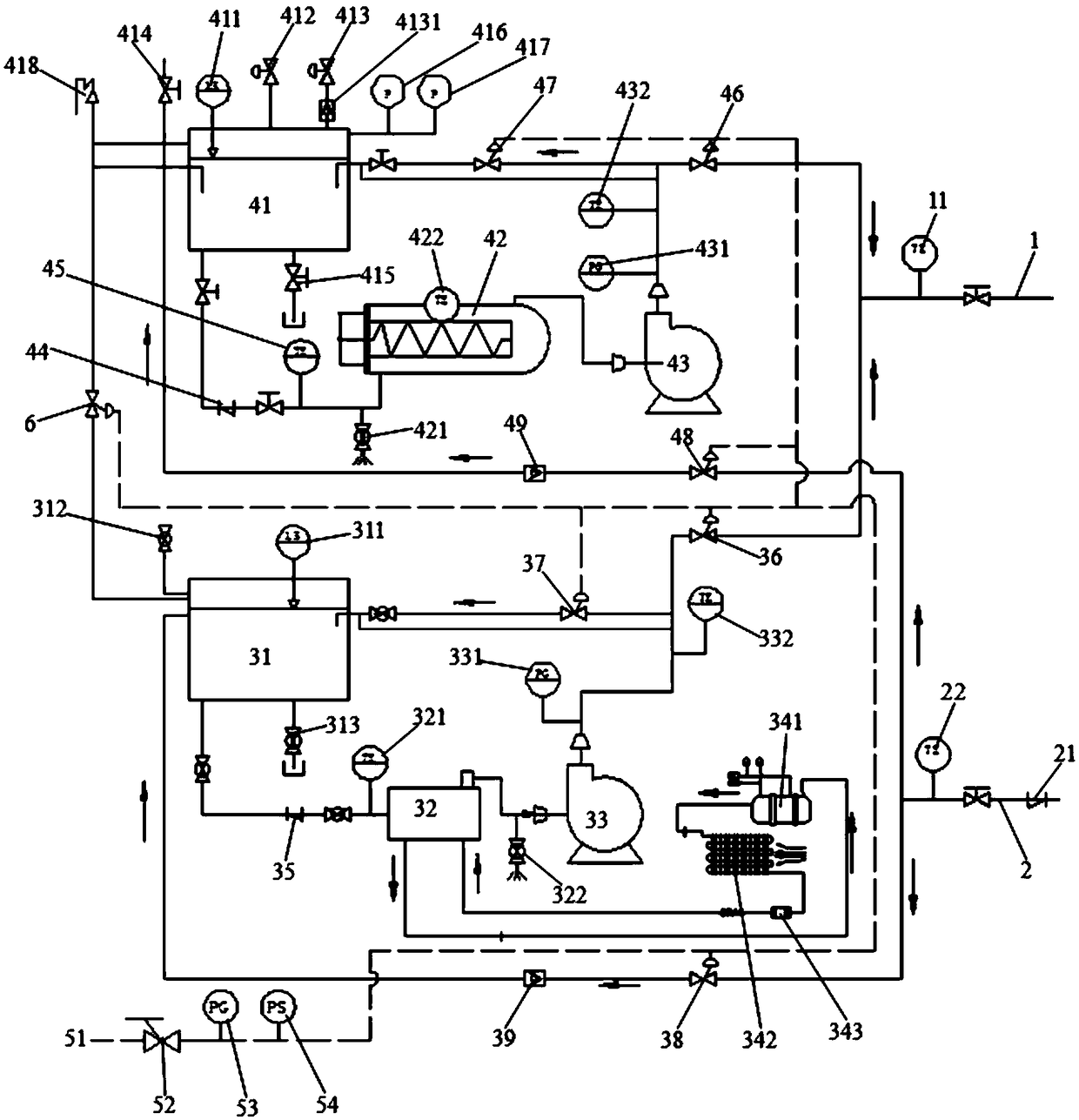

Quick-cooling and quick-heating fast automatic switching temperature control system

ActiveCN105955337ARealize automatic switching between each otherImprove cooling efficiencyTemperature control using electric meansTemperature controlPneumatic valve

The invention discloses a quick-cooling and quick-heating fast automatic switching temperature control system, which comprises an oil outlet pipeline, an oil return pipeline, a cooling circulation system and a heating circulation system, wherein the cooling circulation system and the heating circulation system are each communicated with the oil outlet pipeline and the oil return pipeline, a first pneumatic valve is arranged on a pipeline which communicates the cooling circulation system and the oil return pipeline, a second pneumatic valve is arranged on a pipeline which communicates the cooling circulation system and the oil outlet pipeline, a fourth pneumatic valve is arranged on a pipeline which communicates the heating circulation system and the oil return pipeline, and a fifth pneumatic valve is arranged on a pipeline which communicates the heating circulation system and the oil outlet pipeline. The quick-cooling and quick-heating fast automatic switching temperature control system can realize mutual automatic switching of the cooling system and the heating system quickly, can raise the temperature from 30 DEG C to 280 DEG C within 3 min by heating, and can reduce the temperature from 280 DEG C to 30 DEG C within 5 min.

Owner:深圳市奥德机械有限公司

Multi-model tooling and fixture switching system

ActiveCN109877493BQuick switchFast auto switchWelding/cutting auxillary devicesAuxillary welding devicesProduction lineIndustrial engineering

Owner:MINO AUTOMOTIVE EQUIP SHANGHAI CO LTD

Quick cooling and quick heating fast automatic switching temperature control system

ActiveCN105955337BRealize automatic switching between each otherImprove cooling efficiencyTemperature control using electric meansTemperature controlPneumatic valve

Owner:深圳市奥德机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com