Spare power automatic switching device and method for three-segment bus two-segment switch

A technology of bus section and backup auto-initialization, which is applied in the direction of circuit devices, electrical components, emergency power supply arrangement, etc., can solve the problems of lower reliability and complex auto-initialization logic, and achieve the effect of preventing malfunction or refusal to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

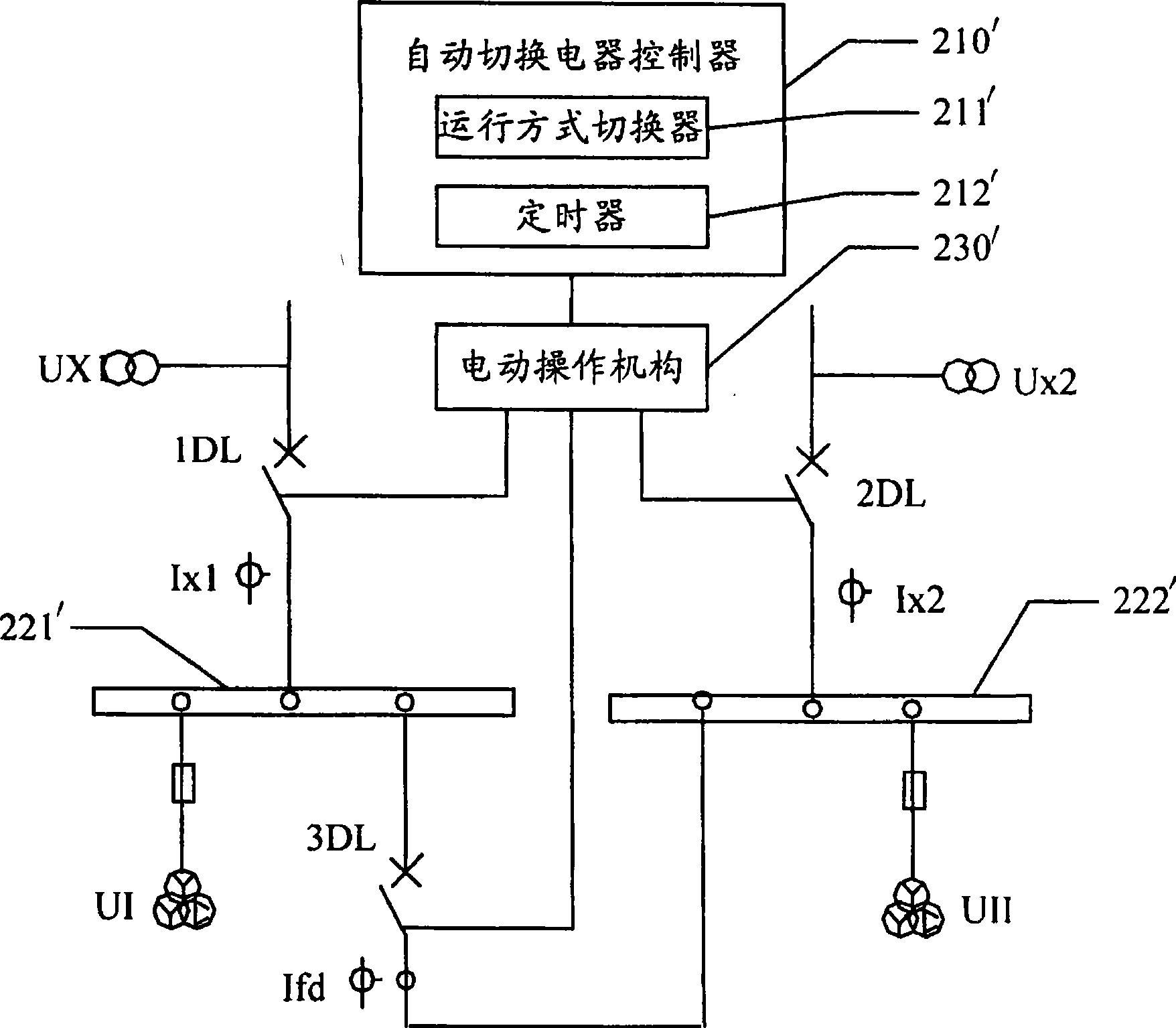

Method used

Image

Examples

Embodiment 1

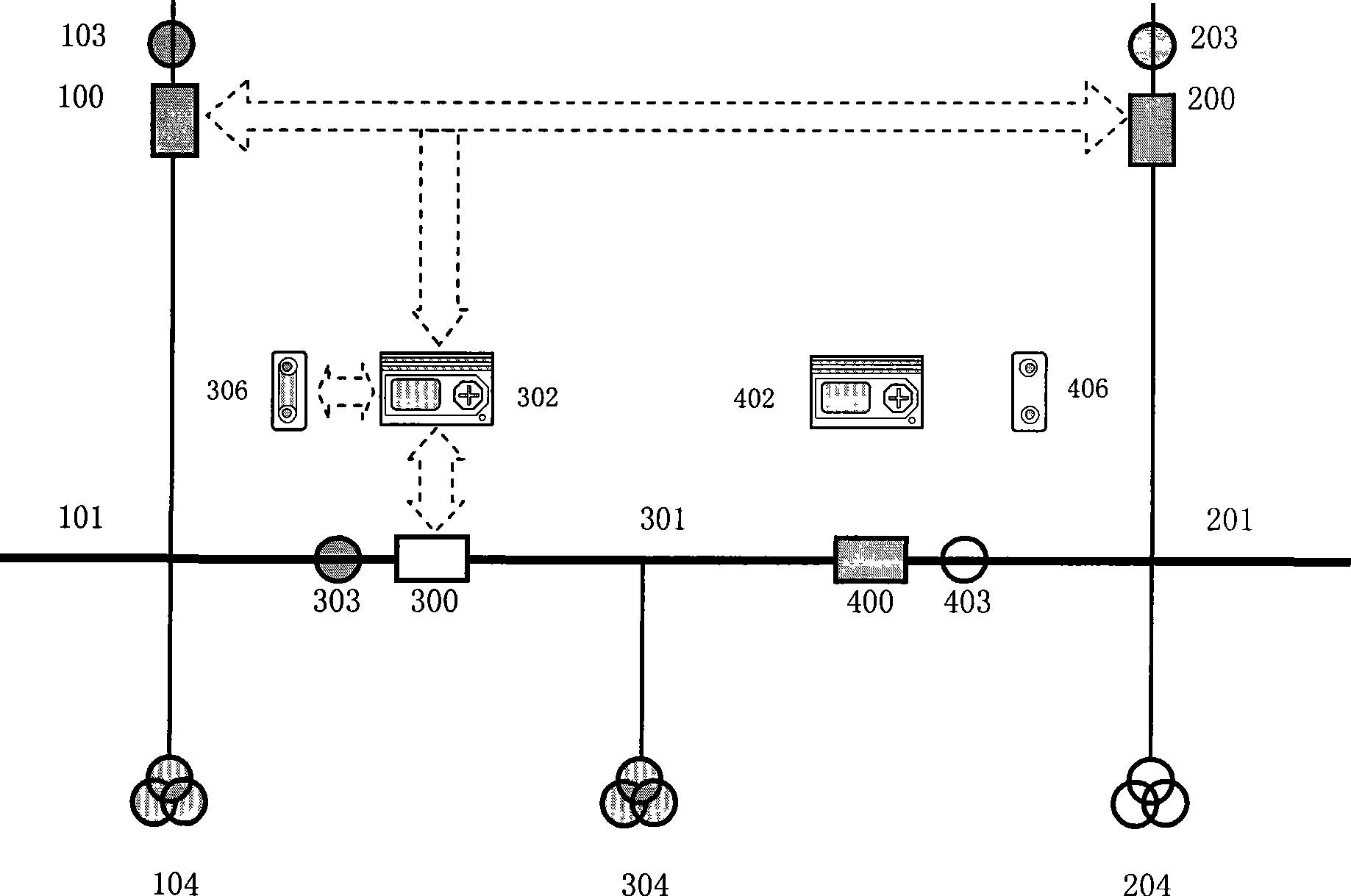

[0130] Operation mode: the first incoming circuit breaker 100 supplies power to the first bus section 101 alone, and the second incoming circuit breaker 200 supplies power to the second and third bus sections 201 and 301 at the same time (such as image 3 shown).

[0131] Its first section circuit breaker is in the "hot standby" position and its second section circuit breaker is in the "running" position.

[0132] The first and second backup power automatic input controllers respectively adopt the following methods: Figure 5 , Image 6 The wiring method; and adopt Figure 7 , 8 The logical relationship shown.

[0133] Put the first throwing / retracting plate 306 on, and take off the second throwing / retracting plate 406.

[0134] When a no-current or no-voltage fault occurs in the second bus section 201, the first start-up condition judging circuit of the first standby power supply controller 302 is started, and the second incoming circuit breaker 200 is judged to be not o...

Embodiment 2

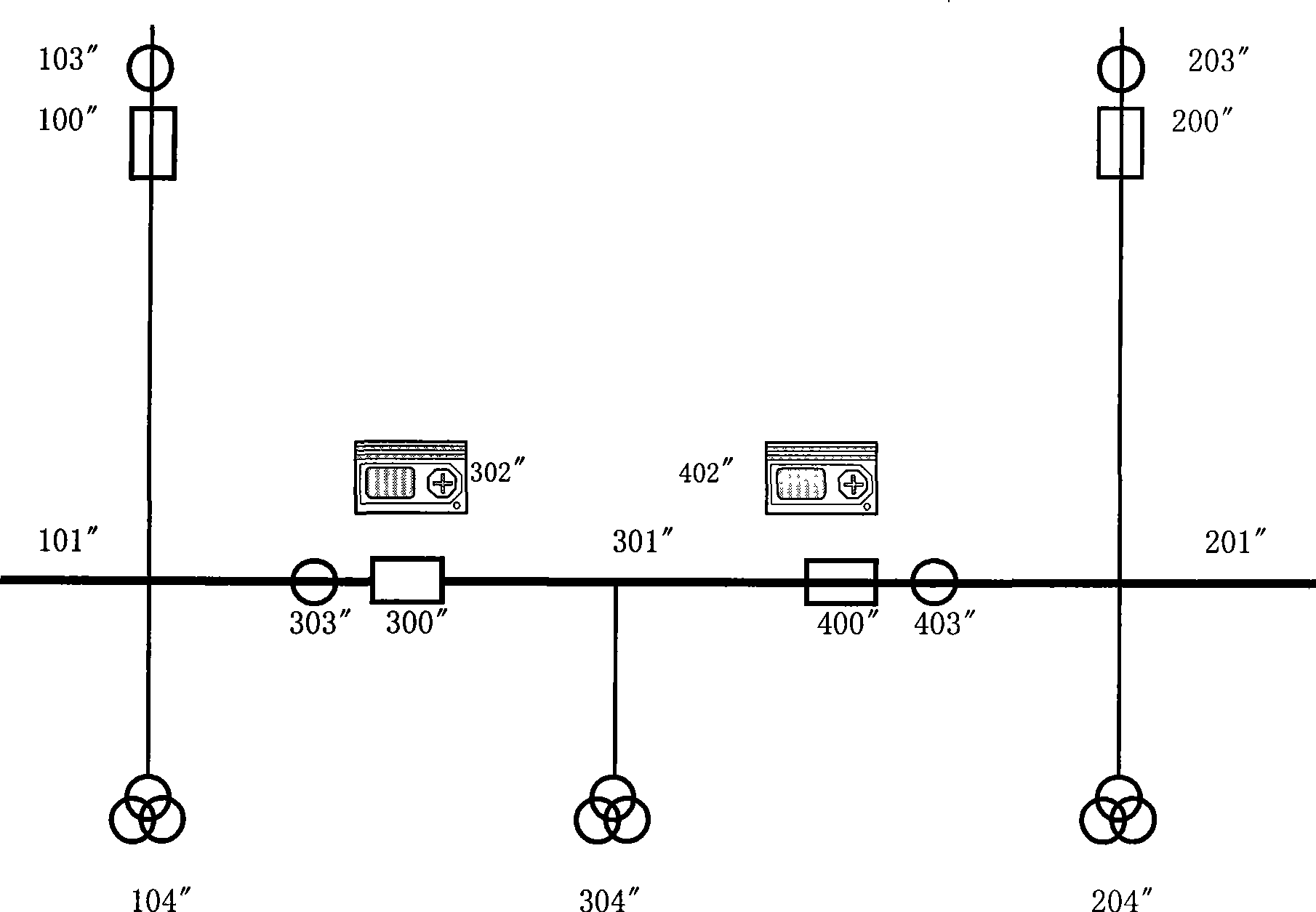

[0139] Operation mode: the first incoming circuit breaker 100 supplies power to the first and third bus sections 101 and 301 at the same time, and the second incoming circuit breaker 200 supplies power to the second bus section 201 alone (such as Figure 4 shown).

[0140] Its first section circuit breaker is in the "RUN" position and its second section circuit breaker is in the "Hot Standby" position.

[0141] The first and second backup power automatic input controllers respectively adopt the following methods: Figure 5 , Image 6 The wiring method; and adopt Figure 7 , 8 The logical relationship shown.

[0142] The first throwing / retracting plate 306 is taken off, and the second throwing / retracting plate 406 is put on.

[0143] When a no-current or no-voltage fault occurs in the second bus section 201, the first start-up condition judging circuit of the second backup power supply is automatically put into the controller 402 to start, after judging that the second inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com