Automatic winding machine for stamping material tape, and operation method thereof

A technology of winding machine and winding mechanism, which is applied in the direction of labeling machine, thin material processing, winding strips, etc., and can solve the problems of heavy burden on operators, waste of production capacity of stamping machines, and many personnel operating procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

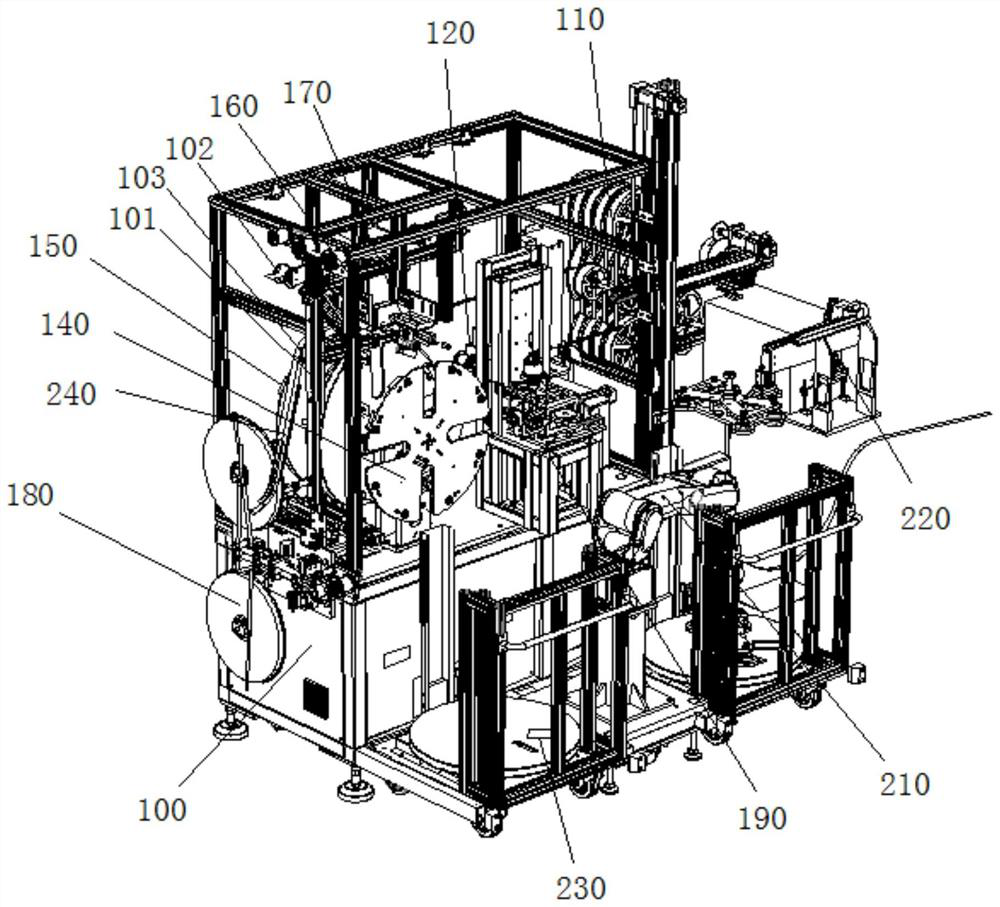

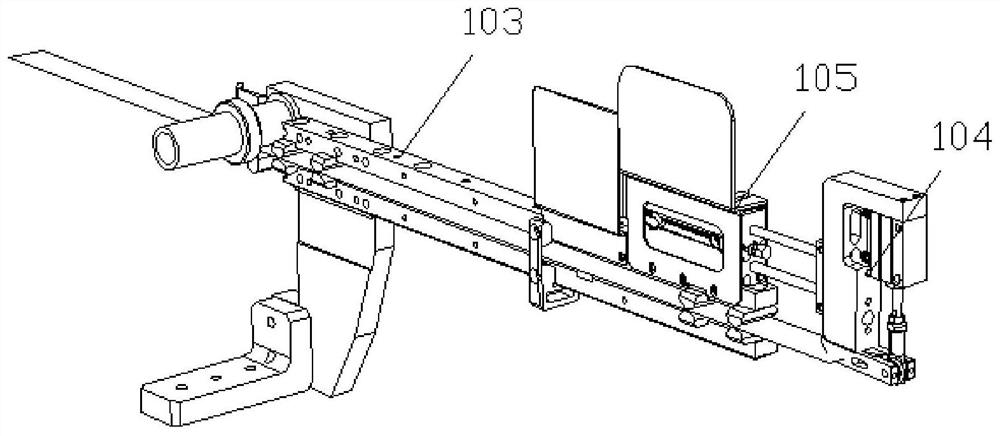

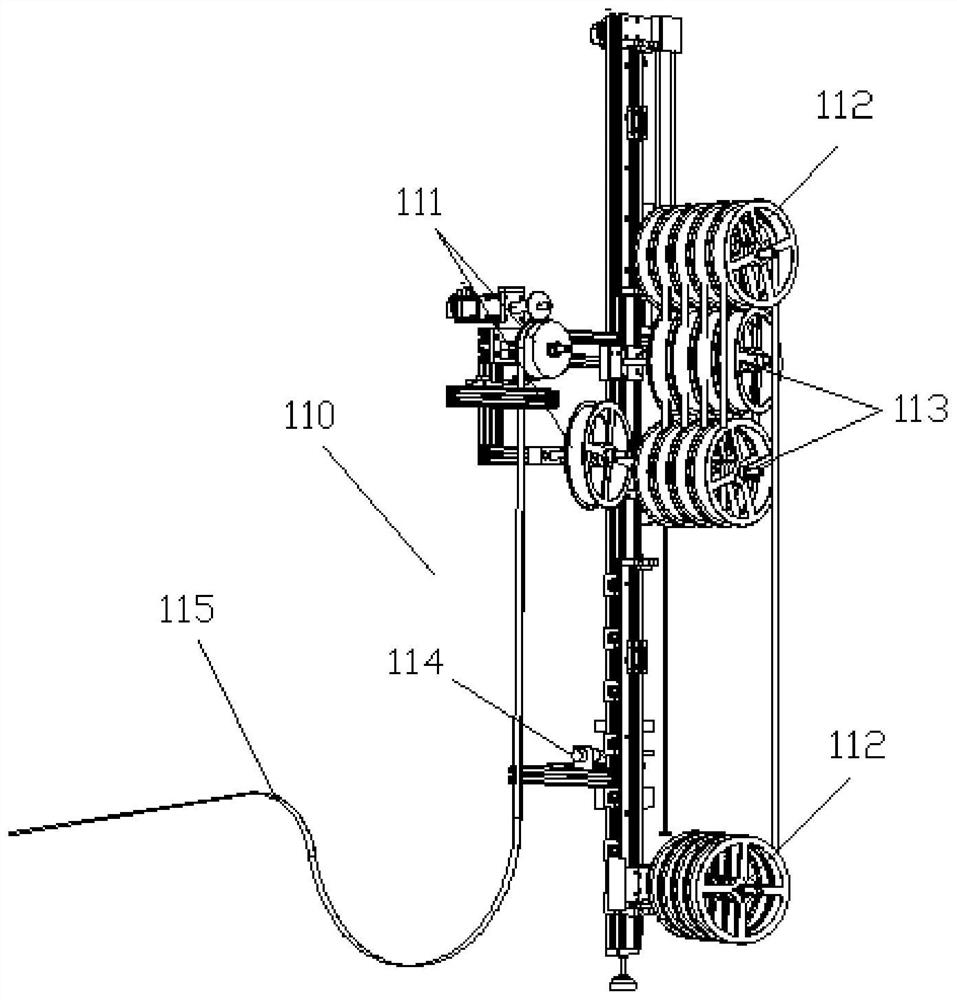

[0059] Example: such as Figure 1-19 As shown, a stamping strip automatic winding machine includes a frame 100 and a buffer tower 110 located on the frame, a strip feeding mechanism 120, a cutting mechanism 130, a turntable winding mechanism 140, and a driven disk mechanism 150, glue dispensing mechanism 160, shearing mechanism 170, paper tape feeding mechanism 180, tape sticking mechanism 190, manipulator handling mechanism 210, labeling mechanism 220 and appearance sampling mechanism 240, the material belt 115 passes through the buffer tower 110 after being discharged from the punching machine , enter the tape feeding mechanism 120 through the buffer tower 110, the tape feeding mechanism 120 sends the tape 115 into the turntable winding mechanism 140, and the paper tape feeding mechanism 180 sends the paper tape 186 into the turntable winding mechanism 140, The turntable winding mechanism 140 winds the tape 115 and the paper tape 186 together on the paper tray 232, the glue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com