Electrochemical high-flux testing method based on photolithographic mask and micro liquid tank and device

A photolithographic mask and testing device technology, which is applied in the direction of measuring devices, test sample preparation, scientific instruments, etc., can solve problems such as liquid leakage, oxygen diffusion, high ohmic resistance, etc., achieve precise control of reaction area, improve reaction Area ratio, effect of eliminating crevice corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

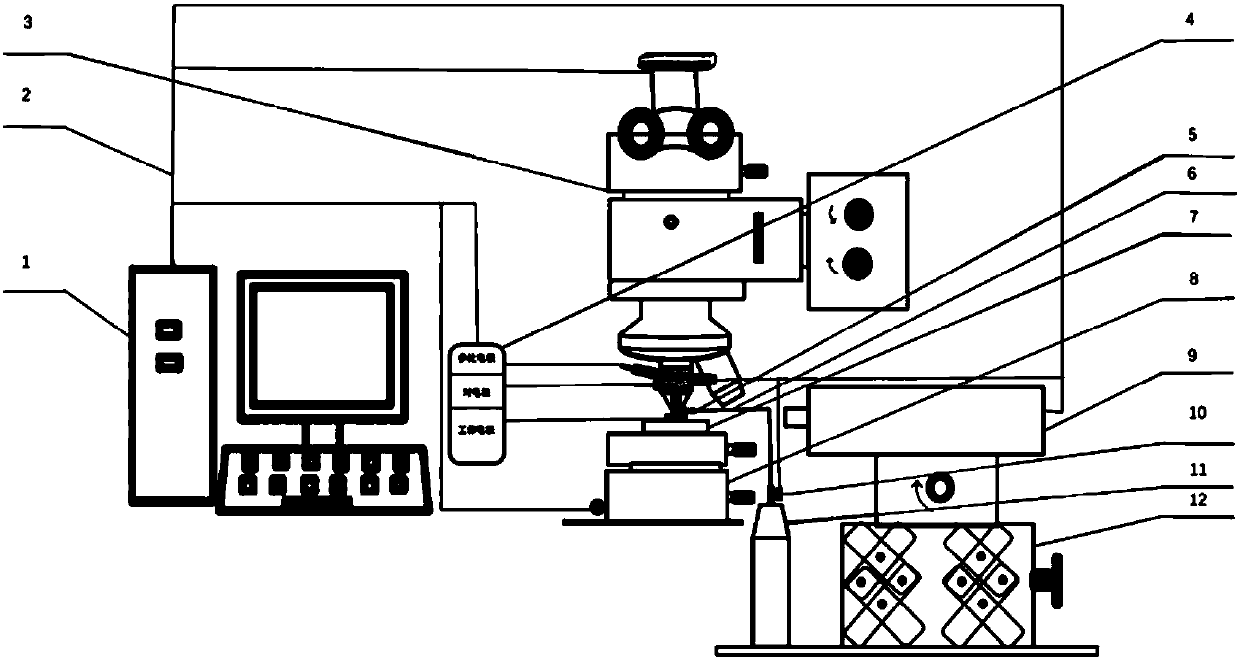

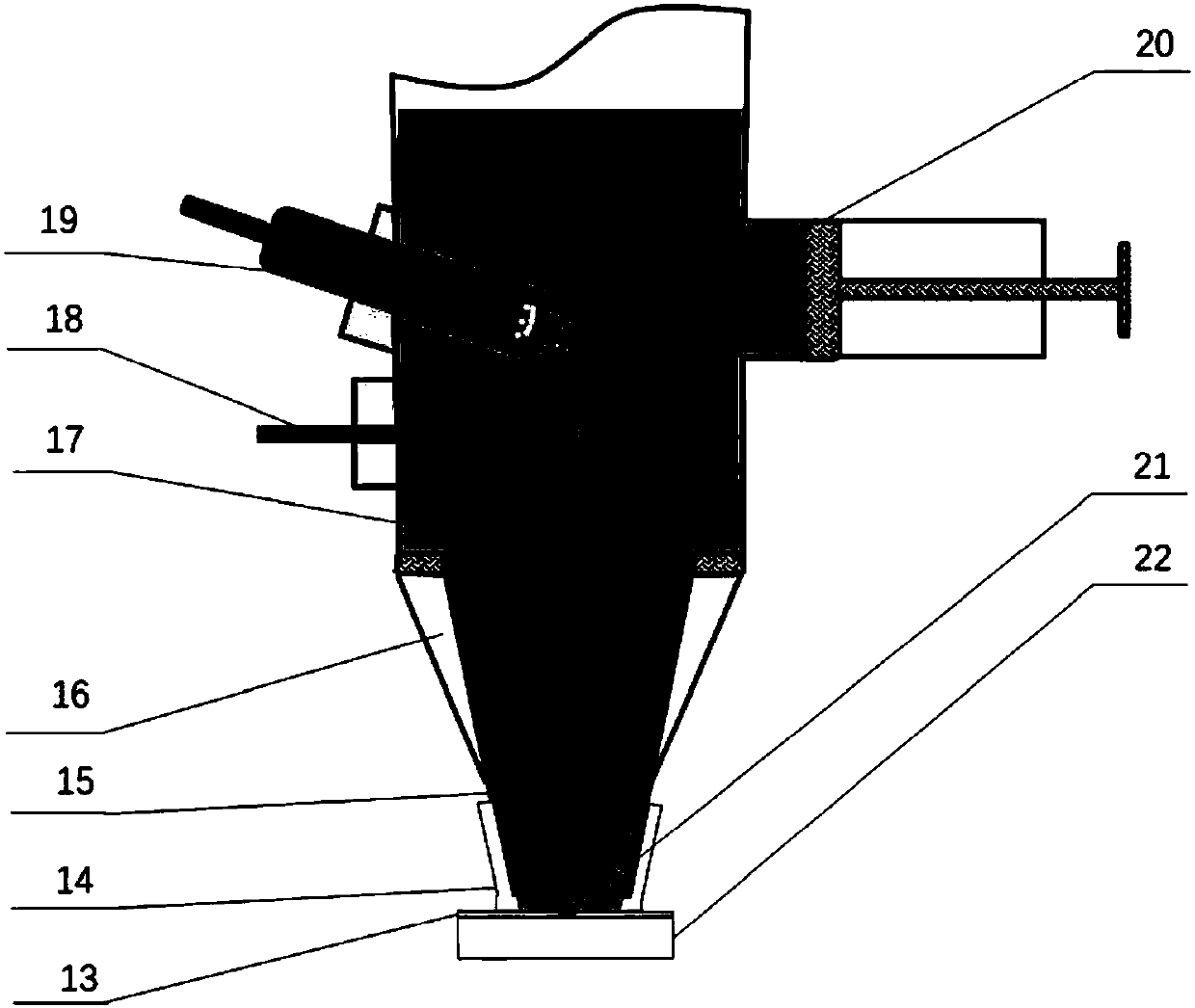

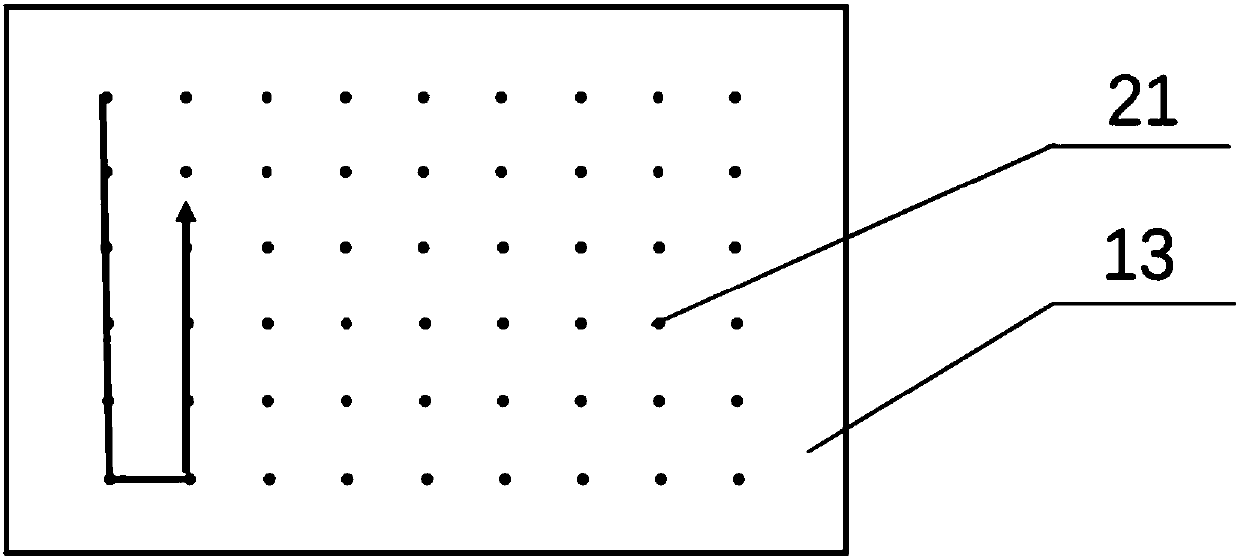

[0046] Utilizing photolithographic mask technology to perform array photolithographic mask pinholes on the surface of metal samples is a relatively mature commercial standardized operation, which will not be described in the present invention. In this embodiment, a method based on photolithographic mask and microscopic The electrochemical high-throughput test device of the liquid pool (see the appendix Figure 1-3 ), using photolithographic mask technology combined with the device described in this embodiment, so that only the microtube 15 can be replaced to carry out the electrochemical test of the multi-size exposed area of the metal sample 22. Photoresist 13 is evenly coated on the surface of the metal sample 22 by photolithographic mask technology, and the photolithographic mask small holes 21 are arrayed. The size of the photolithographic mask small holes can be selected according to needs, even the same metal sample The surface array has photolithographic mask holes of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com