Product analysis method and system and device and medium

A product analysis and product technology, applied in the field of intelligent manufacturing and artificial intelligence, can solve the problems of large influence of parameter elimination process threshold setting, difficult association rules, complex influence relationship, etc., to achieve strong flexibility and scalability, auxiliary adjustment and optimization , the effect of strong interpretability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

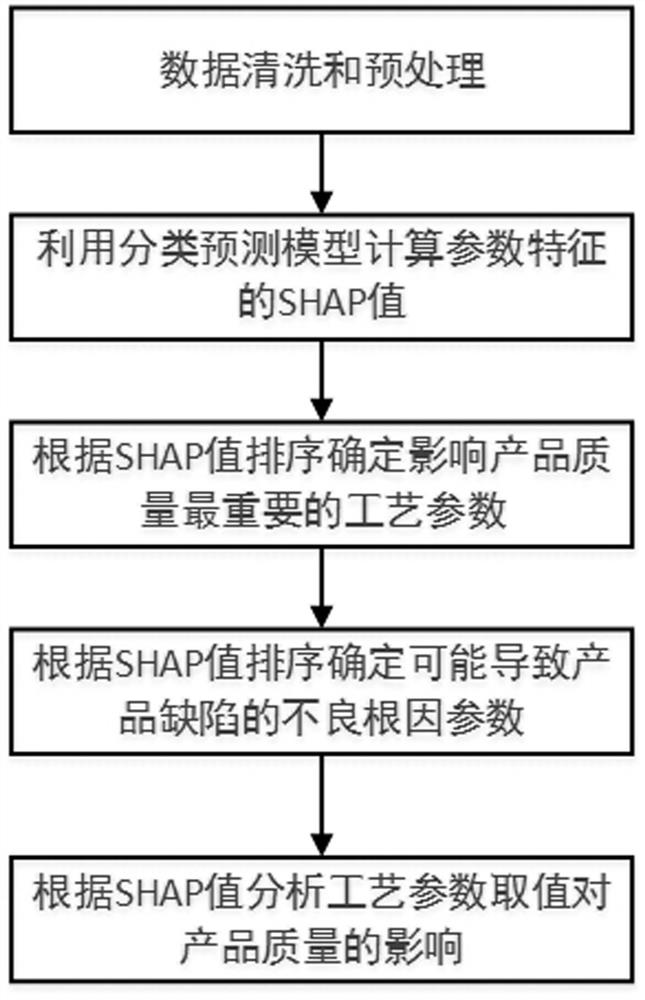

Image

Examples

Embodiment 1

[0095] where SHAP is an additivity explanatory model inspired by the Shapley value. Shapley value originated from

[0108] Before data analysis, all must be preprocessed. It should be noted that the production and processing data in the industrial manufacturing field,

[0110] (1) Delete and record the process parameters that are highly correlated with each other.

[0112] Therefore, the correlations among all process parameters were first calculated. For two process parameters whose correlation exceeds the preset value

[0114] Preferably, the present invention adopts the Pearson correlation coefficient to calculate the correlation of the numerical process parameters.

[0115] (2) Use multiple independent type selection variables to replace the original single type selection parameter.

[0124]

[0127]

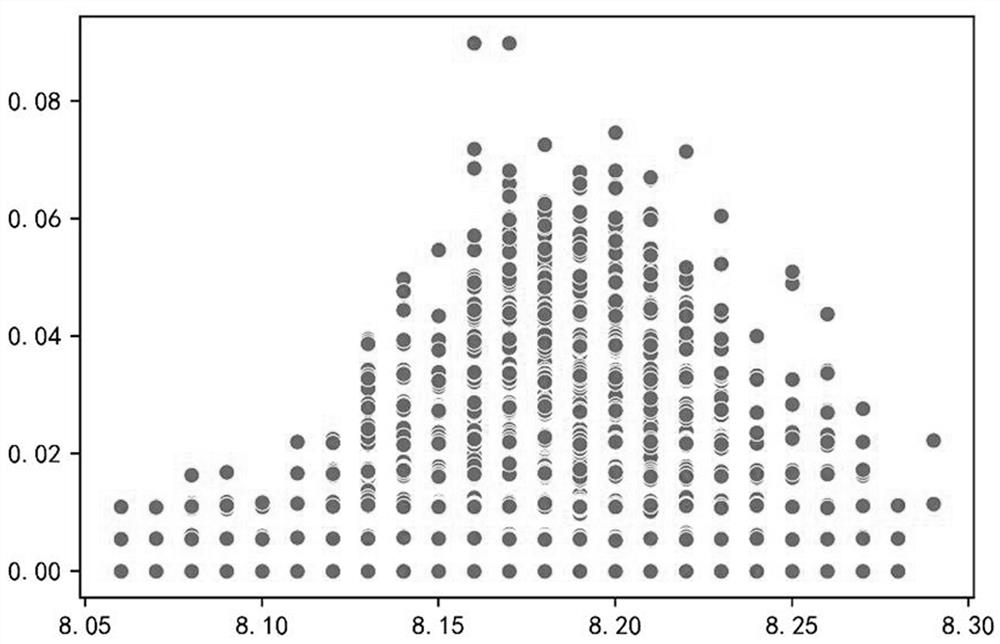

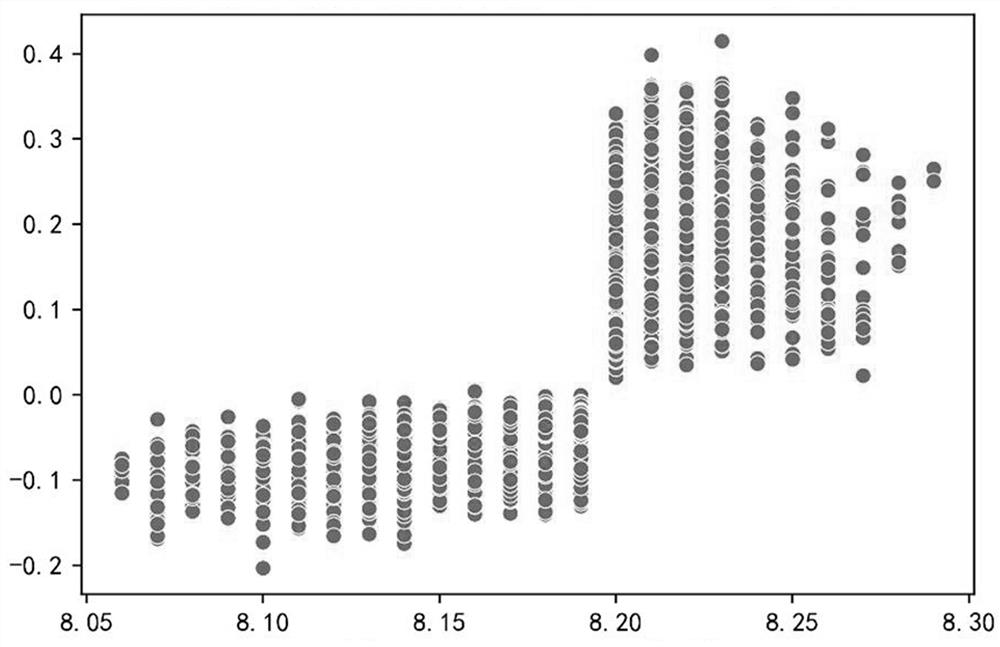

[0146] The SHAP value reflects the direction in which the feature affects the model output ("enhancing the output" or "reducing the output") and the effect of

Embodiment 2

[0150] It should be understood that the specific embodiments described herein are only used to explain the present invention, and are not used to limit the present invention.

[0153] In the traditional regression analysis method, the number of bad samples is large enough and the processing status of different processing equipment

[0154] The present invention is described below for the analysis of some unfavorable real data in the production of a certain type of glass panel.

[0157] The failure detection data of the glass panel records the product number of the glass panel, the type of failure, and the severity of the failure.

[0158] At the same time, in the original processing data of the product, only the processing records of the product that retains the quality inspection data are screened.

[0159] Obviously, in other embodiments, the product quality grades can be divided into other multiple grade categories, and can also be repeated

[0161] According to the product numb...

Embodiment 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com