Gumming machine for belt pulley scrubbing ring

A technology of gluing machines and pulleys, which is applied in coatings and devices for coating liquid on the surface, etc. It can solve the problems of difficult handling of frosting rings, uneven gluing, slow gluing speed, etc., and achieve fast gluing speed , Realize the effect of automation and uniform glue layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

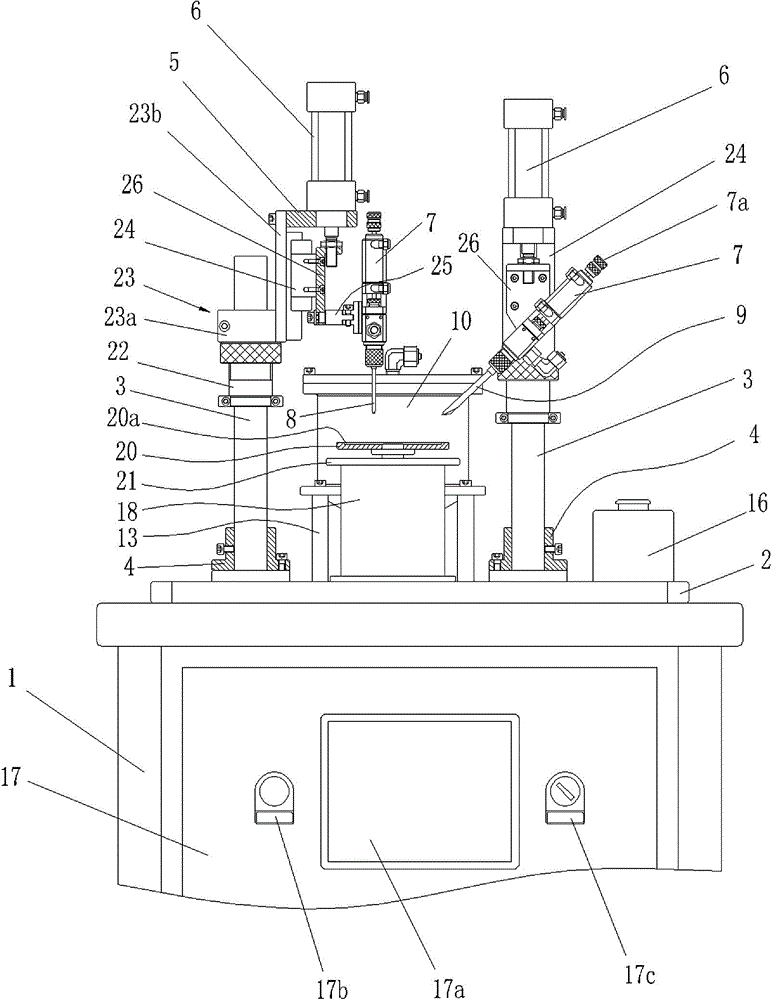

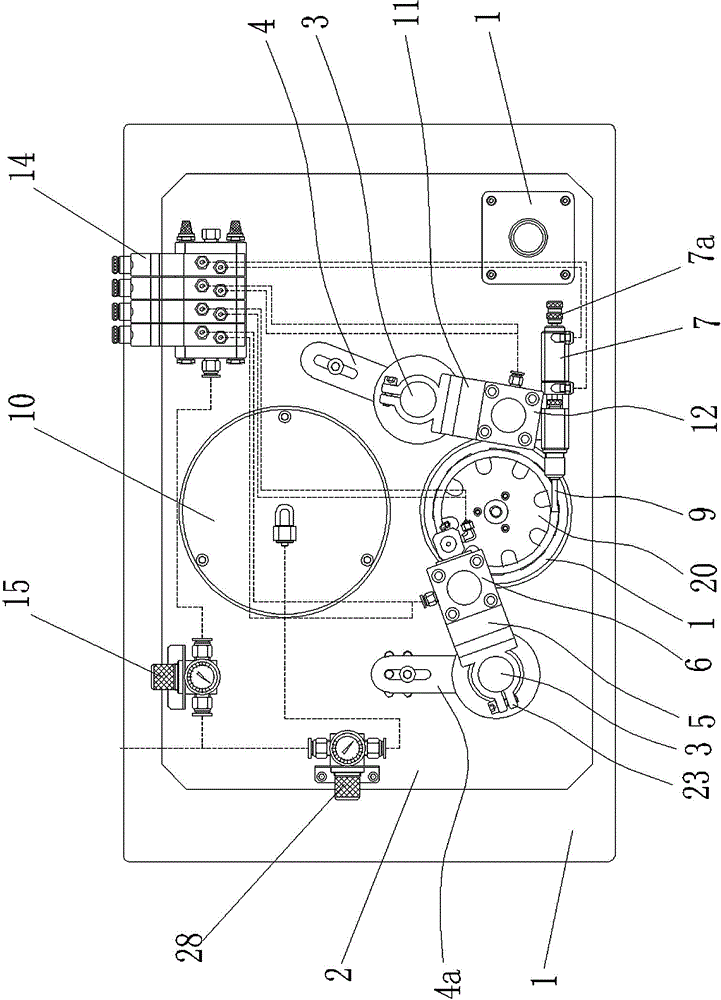

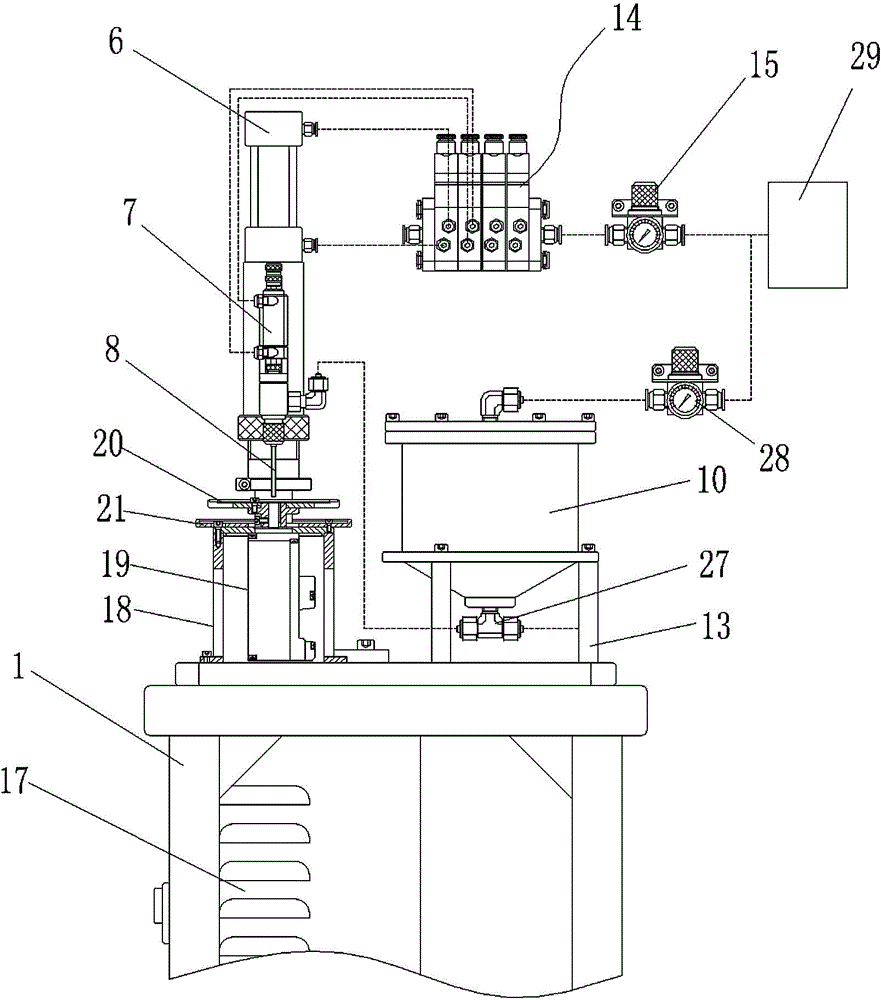

[0024] Such as figure 1 , figure 2 and image 3 As shown, a kind of gluing machine for belt pulley grinding ring provided by the present invention is characterized in that comprising:

[0025] Frame 1, the frame 1 is a side cuboid cabinet, four corners at the bottom of the cabinet are respectively provided with a leg, a control cabinet 17 is connected in the frame 1, and the underside of the frame 1 is respectively provided with A touch control panel 17a, a power indicator light 17b and a power switch 17c connected to the control cabinet 17 are connected. On the top of the frame 1, a fixed base plate 2 is connected by screws, and two columns 3, a motor 19, a rubber material cylinder 10, a solenoid valve 14, a cylinder pressure regulating valve 15, and a rubber cylinder pressure regulating valve are respectively connected on the fixed base plate 2. Valve 28 and activation switch 16.

[0026] The bottom of the column 3 is provided with a flange base, and the bottom of each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com