Reliable and efficient carrying mechanical arm used for wafer cassette

A technology of manipulators and wafer boxes, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of overturning wafer boxes, seldom mentioning, and breaking wafers, so as to ensure safety and improve work Efficiency and reliability, effects of eliminating the influence of positional deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

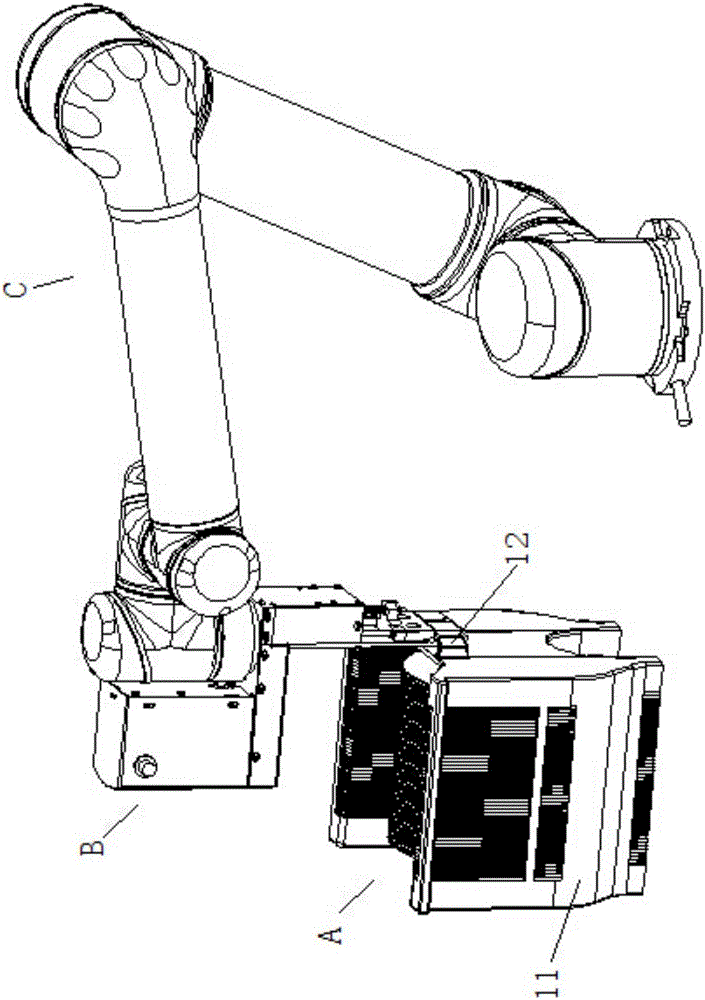

[0043] see Figure 1 to Figure 9 , as shown in the legend, a manipulator for reliable and efficient handling of wafer boxes. Wafer box A is positioned on the stage, and manipulator B is driven by robotic arm C to grab and transport wafer box A.

[0044] The wafer box A includes a box body 11 and a handle 12 , the handle 12 is generally U-shaped when viewed from above, and the two free ends of the handle 12 are respectively connected to the outer surfaces of the box body 11 .

[0045] Manipulator B includes:

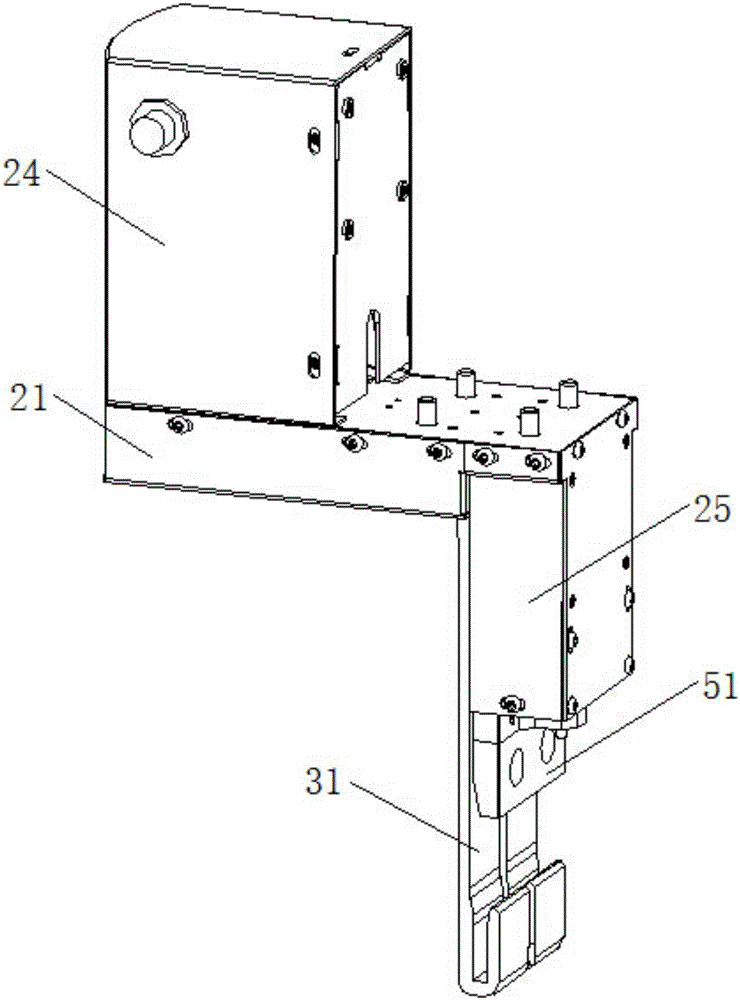

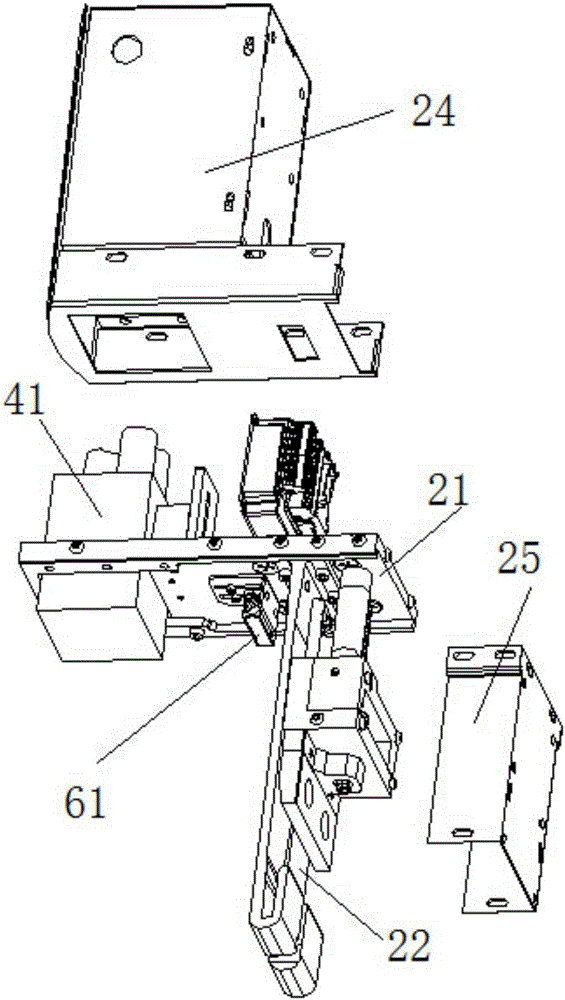

[0046] The mounting plate 21 is connected to the end of the mechanical arm C;

[0047] The hand claw 31 is generally J-shaped in side view, and the upper end of the non-hook part of the hand claw 31 is connected to the mounting plate 21;

[0048] Visual sensor 41, the visual sensor 41 is arranged on the non-hook side of the gripper 31 and communicates with the transport controller, the visual sensor 41 is assembled on the mounting plate 21, and the transport controller ...

Embodiment approach

[0053] In one embodiment:

[0054] The non-hook part of the gripper 31 is provided with a release groove 32 penetrating to the free end of the hook of the gripper 31, and the two groove walls at the lower port of the release groove 32 are generally in a figure-eight shape in front view. Two guide slopes 33 are respectively processed on the opposite surface of the free end of the crotch hook of the claw 31 and the non-crotch part of the claw opposite thereto.

[0055] The contact part with the wafer box is required to be polished smoothly, so if there is not an obvious positional deviation between the grabbing point of the wafer box and the positioning point of the robot arm, it can guide the claws to smoothly insert into the slot of the wafer box handle inward and hook the outer edge of the handle.

[0056] In one embodiment:

[0057] The locking driving unit includes a motor 531 and a reducer 532. The motor 531 is provided with an encoder 533 and its output end is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com