Driving method of stirring motor in the flocculation treatment process and washing machine

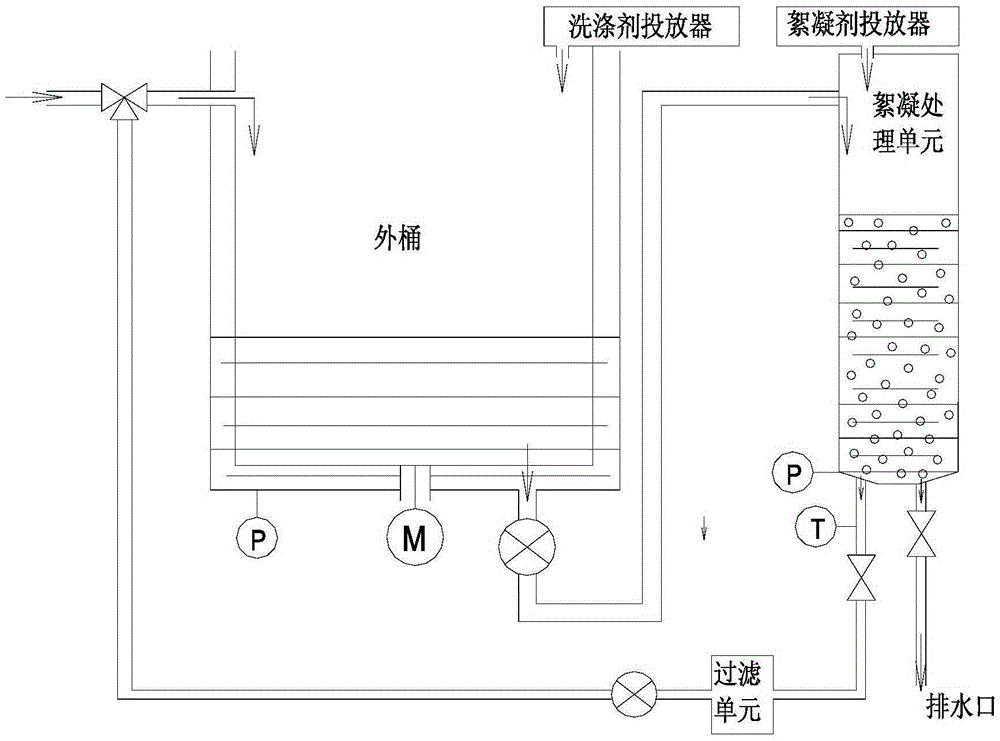

A technology of treatment process and stirring motor, which is applied in the control device of washing machine, washing device, textile and paper making, etc., can solve the problems of clothes pollution in the washing tub, influence of flocculation efficiency, water return, etc. The effect of suitable promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] In this embodiment, the set value Vi is a set range from V1 to V2; when the detected value V is less than the set value V1, increase the input power of the motor until the detected value V reaches (V1+V2) / 2 ; When the detected value V is greater than the set value V2, reduce the input power of the motor until the detected value V reaches (V1+V2) / 2. Preferably, V2-V1=10rpm, so as to make the setting range reasonable, improve the control precision and reduce the misjudgment rate.

[0048] By setting the setting value as a range interval, a buffer space is provided for the adjustment of the motor, and on the premise of ensuring the accuracy of the speed control, it is avoided that the motor adjusts the frequency too fast and reduces the service life.

[0049] In this embodiment, when the washing machine starts to perform the flocculation process and the agitation mechanism starts to rotate, the input power W of the motor is the maximum value Wmax, so that the rotation spee...

Embodiment 2

[0063] This embodiment introduces a flocculation control method of a flocculation washing machine. In different time periods of the flocculation process, corresponding to different set values Vi, to change the input power W of the motor, so that the stirring mechanism can V rotates. In this embodiment, during the flocculation process of the washing machine, the motor is controlled to work at the corresponding speed V according to the driving method described in the above embodiment, so as to change the speed of the stirring mechanism during the flocculation process and achieve the purpose of precise control of the flocculation process.

[0064] In this embodiment, in the flocculation process of the washing machine, according to the existing sequence of time periods, different corresponding motor speed setting values Vi are correspondingly matched, so as to realize that the stirring mechanism operates at different speeds in different time periods during the flocculation proc...

Embodiment 3

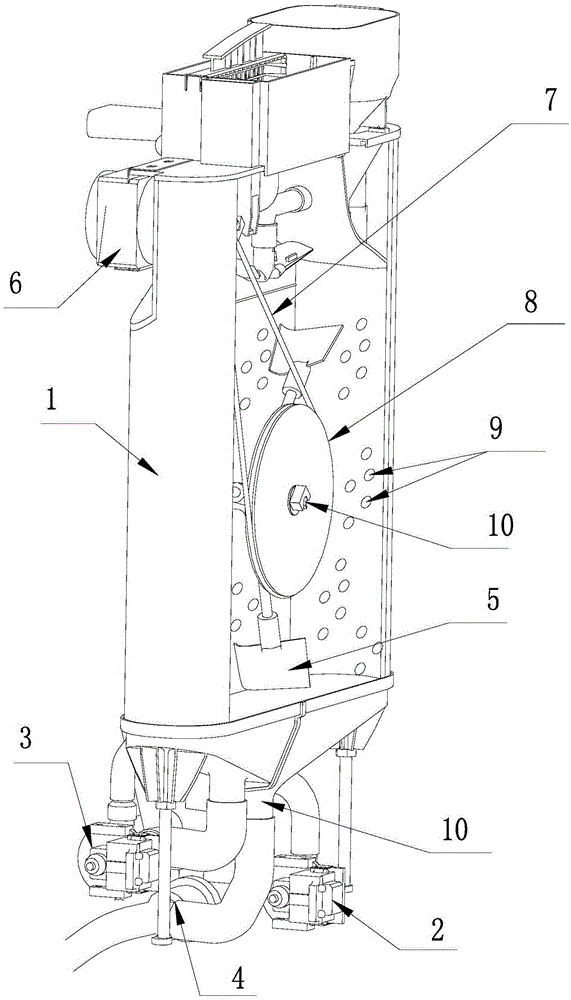

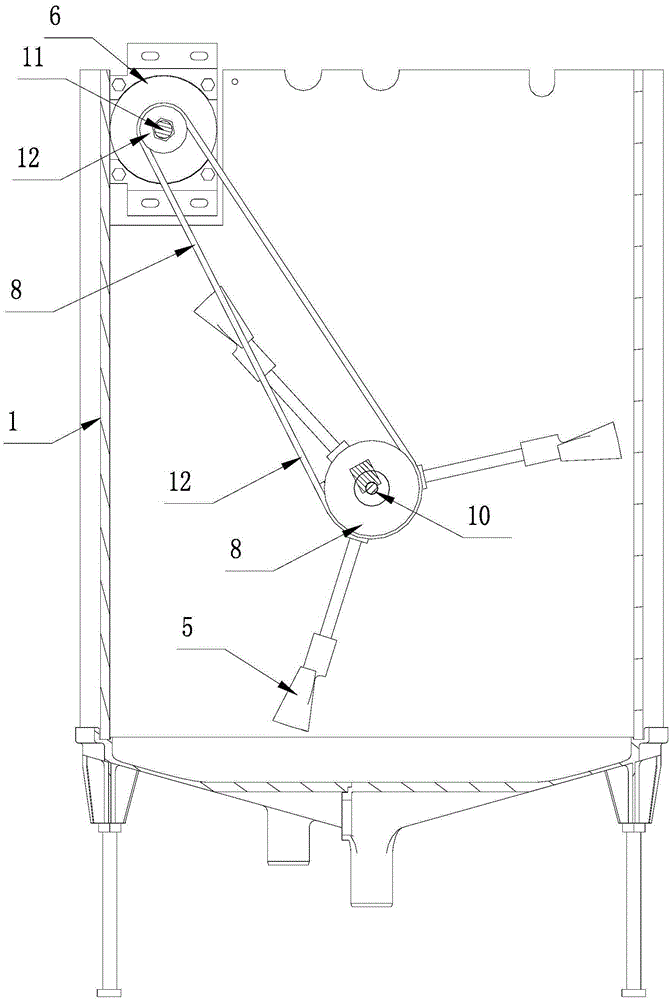

[0070] This embodiment introduces a stirring mechanism of a flocculation washing machine. The washing machine includes a flocculation bucket 1 for flocculation treatment of washing water; Flocculate the water in bucket 1.

[0071] Such as figure 2 with 3 As shown, in this embodiment, the stirring mechanism in the flocculation bucket 1 includes a stirrer driven by the motor 6 to rotate; the stirrer includes a rotating shaft 10, and the rotating shaft 10 is connected with a plurality of stirring blades rotating around the rotating shaft 10 5. The rotating shaft 10 is provided with a pulley 8, which is connected to the output end of the motor 6 through the belt 7, so that the motor 6 is driven by the belt to drive the stirring blade 5 to rotate around the rotating shaft 10.

[0072] In this embodiment, the motor 6 is fixedly installed on the outside of the side wall of the flocculation bucket 1, and the motor 6 is set beyond the liquid level of the flocculation bucket 1. The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com