Method for operating a centrifugal separator

一种离心分离器、运行方法的技术,应用在离心分离器的运行领域,能够解决转动能量失去等问题,达到排除烦扰、排除干扰和负担的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

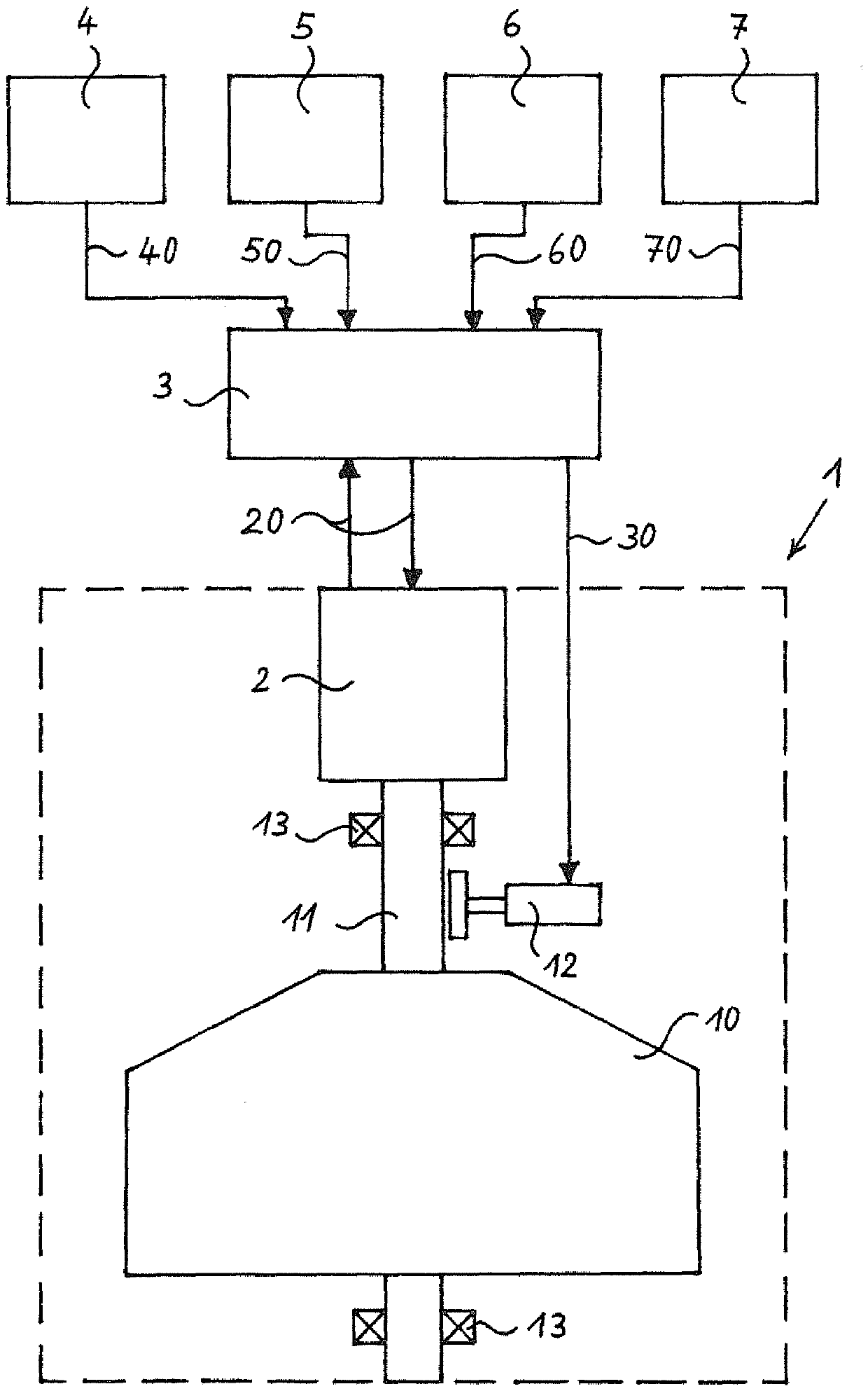

[0030] figure 1 Below it is shown schematically a centrifugal separator 1 with a rotor 10 , which is embodied as a disk separator by way of example. The rotor 10 is mounted rotatably by means of a rotor shaft 11 and two rotor bearings 13 in a separator housing, not specifically shown here. By means of a drive mechanism 2 connected to the rotor shaft 11, such as an electric motor, the rotor 10 can be rotated during the operation of the centrifugal separator 1, thereby separating microparticles of the second medium from the first medium flowing through the rotor 10 by means of centrifugal force. Drops or granules, as known per se.

[0031] Furthermore, the exemplary embodiment of the centrifugal separator 1 shown here comprises a braking mechanism 12 which, if required, applies a braking force to the rotor shaft 11 and thus also to the rotor 10 by means of friction. Alternatively, the braking mechanism 12 can also be an electrical braking mechanism, optionally with energy reco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com