Patents

Literature

30results about How to "Eliminate human influence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

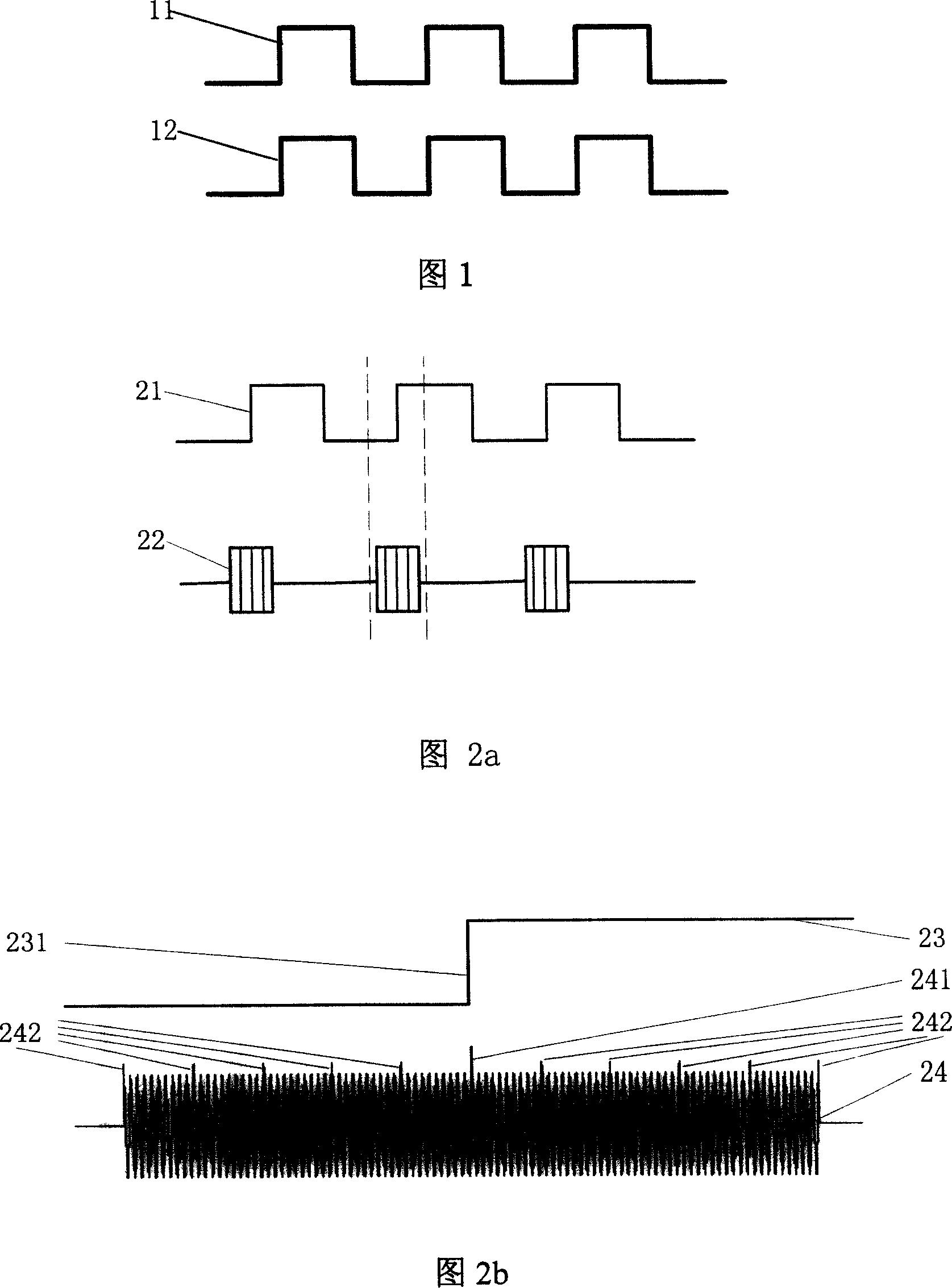

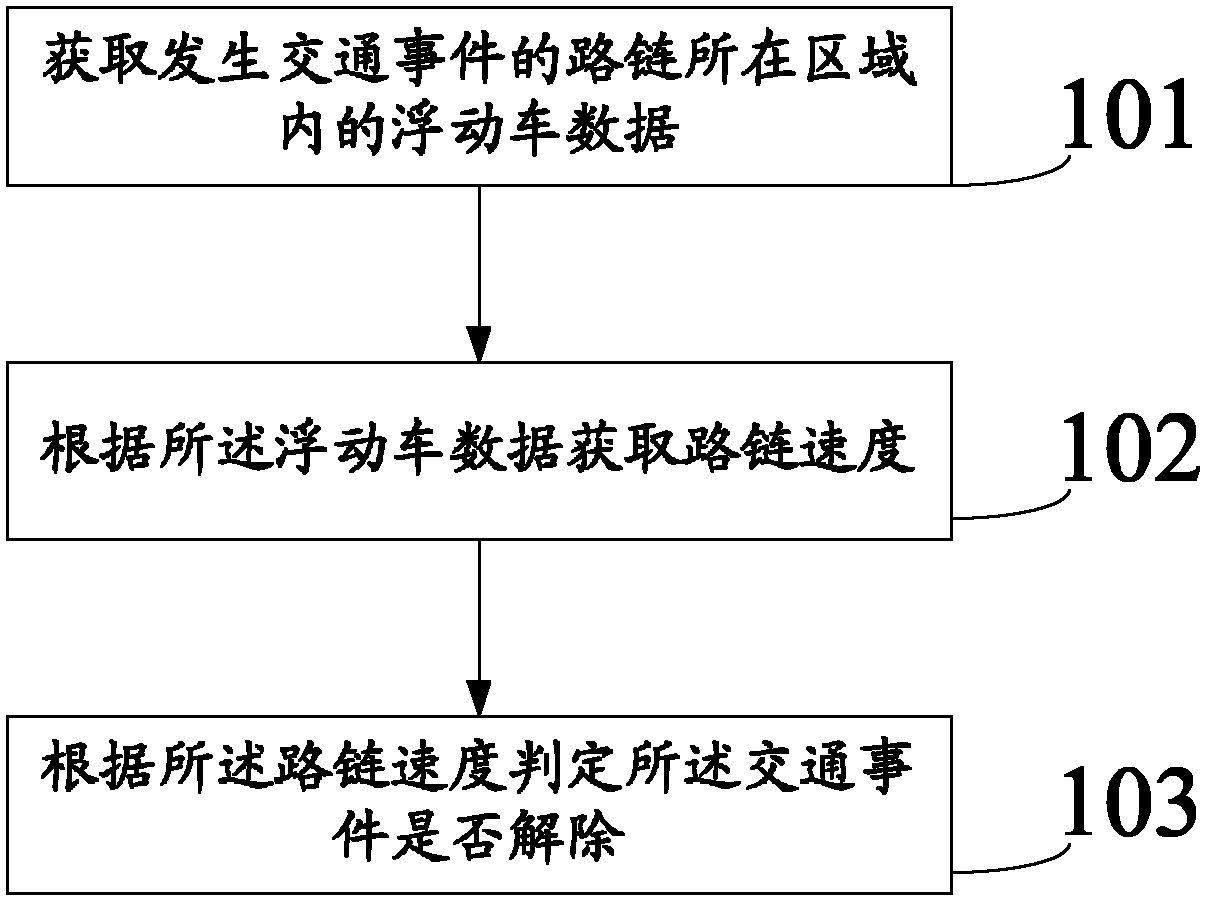

Digital TV video and audio synchronous testing signal and measuring method thereof

ActiveCN101022560AAvoid parallax effectsThe measurement results are correct and reliablePulse modulation television signal transmissionDigital videoStream data

A method for measuring synchronism of audio / video on digital TV includes generating image and sound data according to requirement of test signal audio / video waveform, generating audio / video basic stream data by compressing code and forming composite TS stream signal data, selecting test device corresponding to tested device and using detection device to fetch out measurement result correctly. The test signal applied in said method is also disclosed.

Owner:MUDAN SHIYUAN ELECTRONICS BEIJING

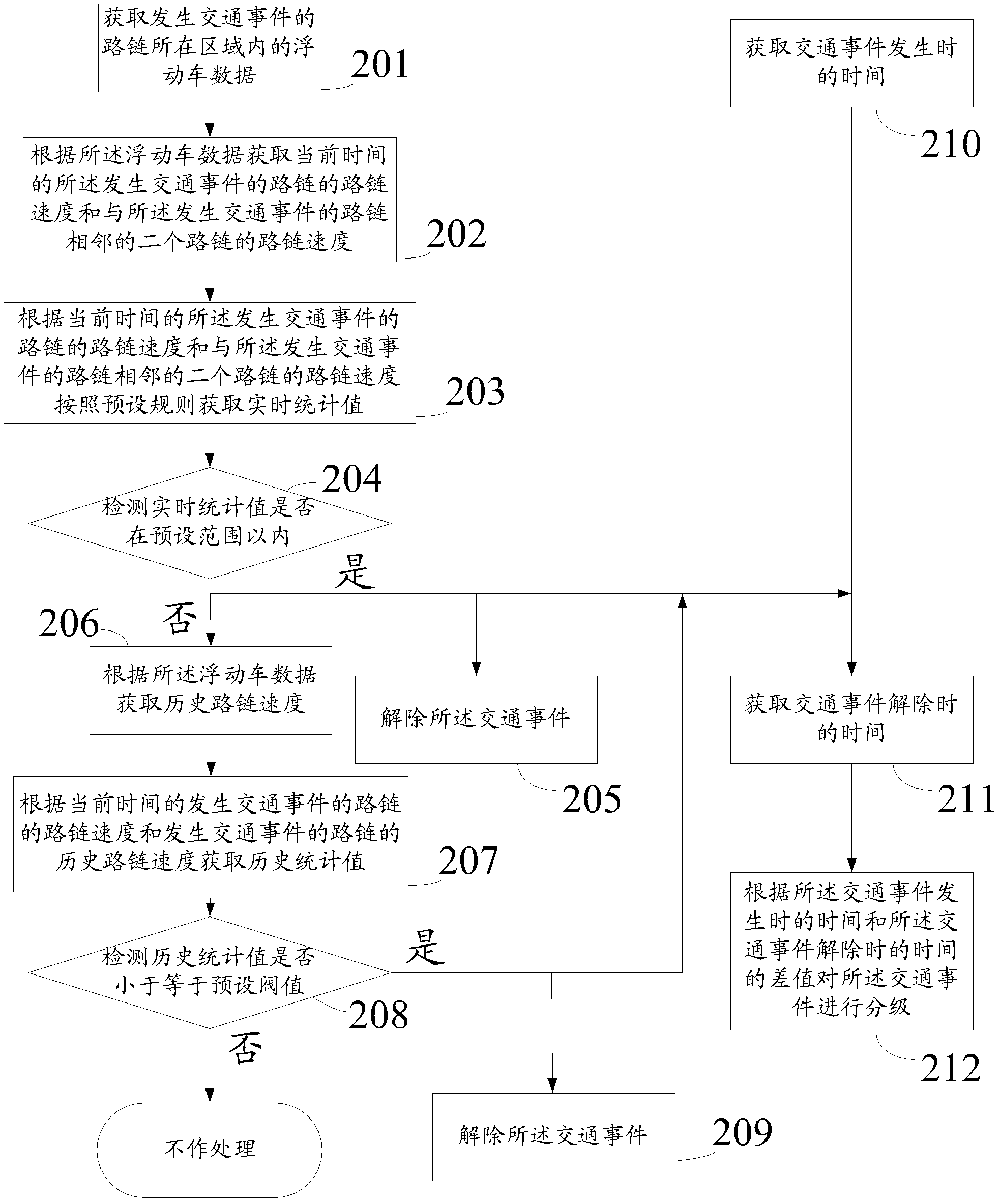

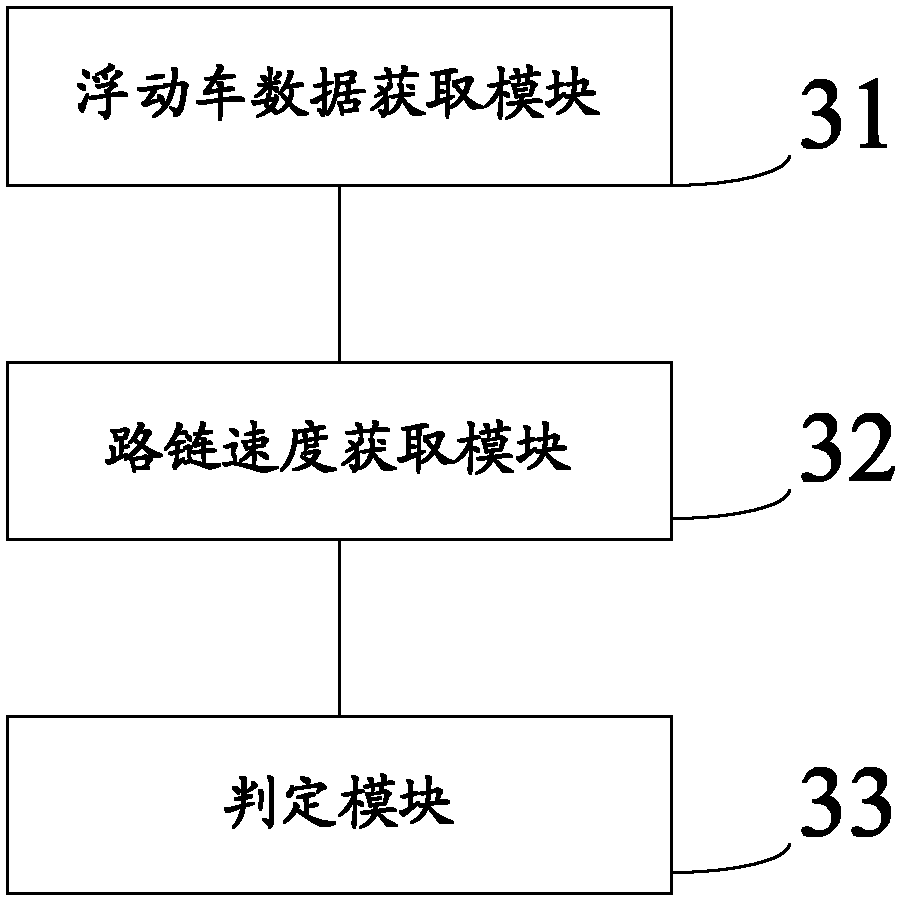

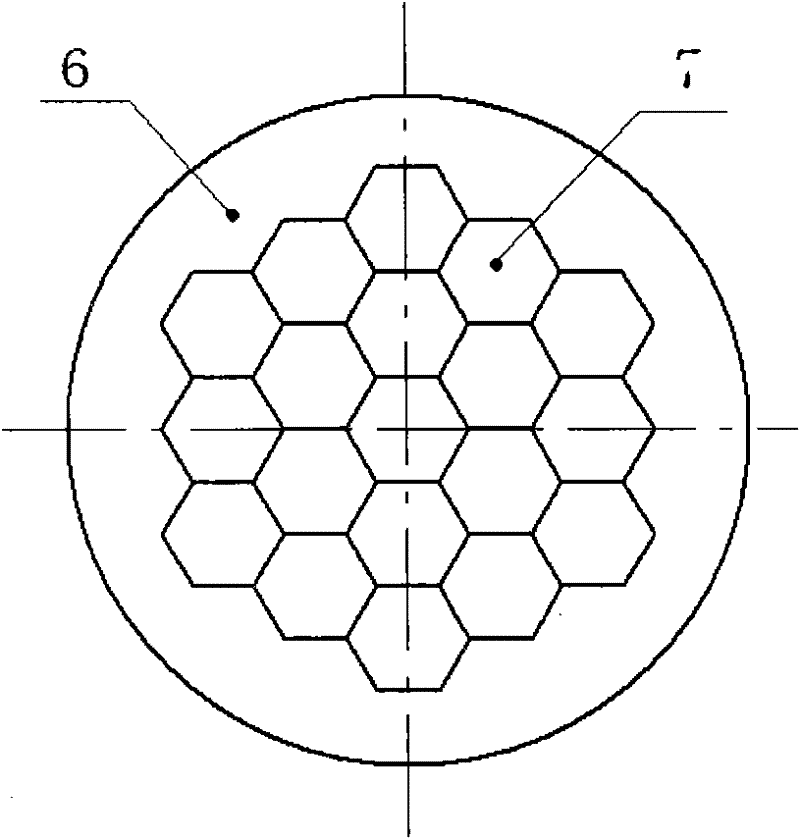

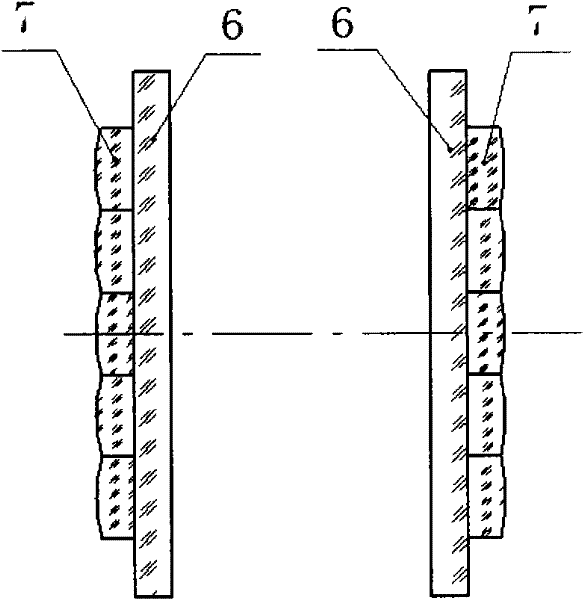

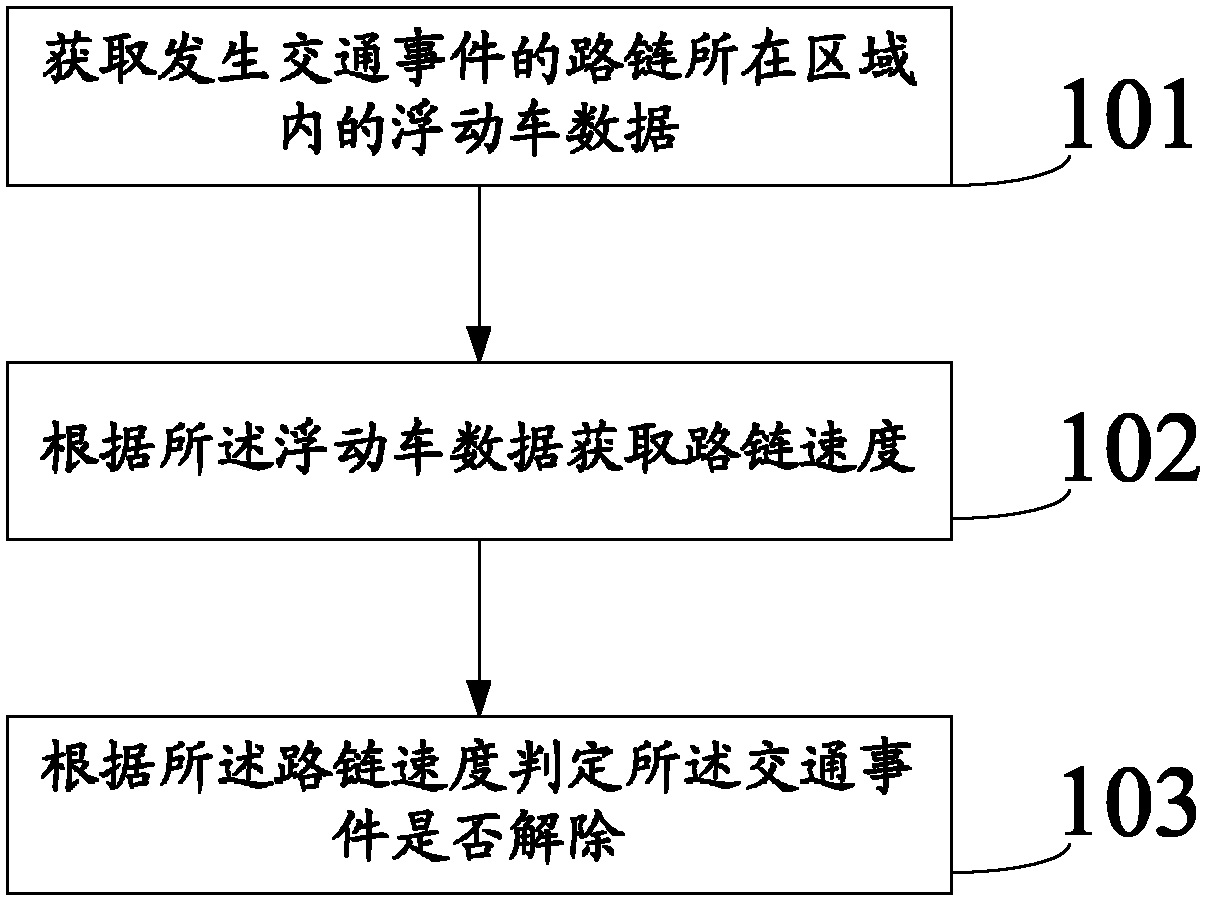

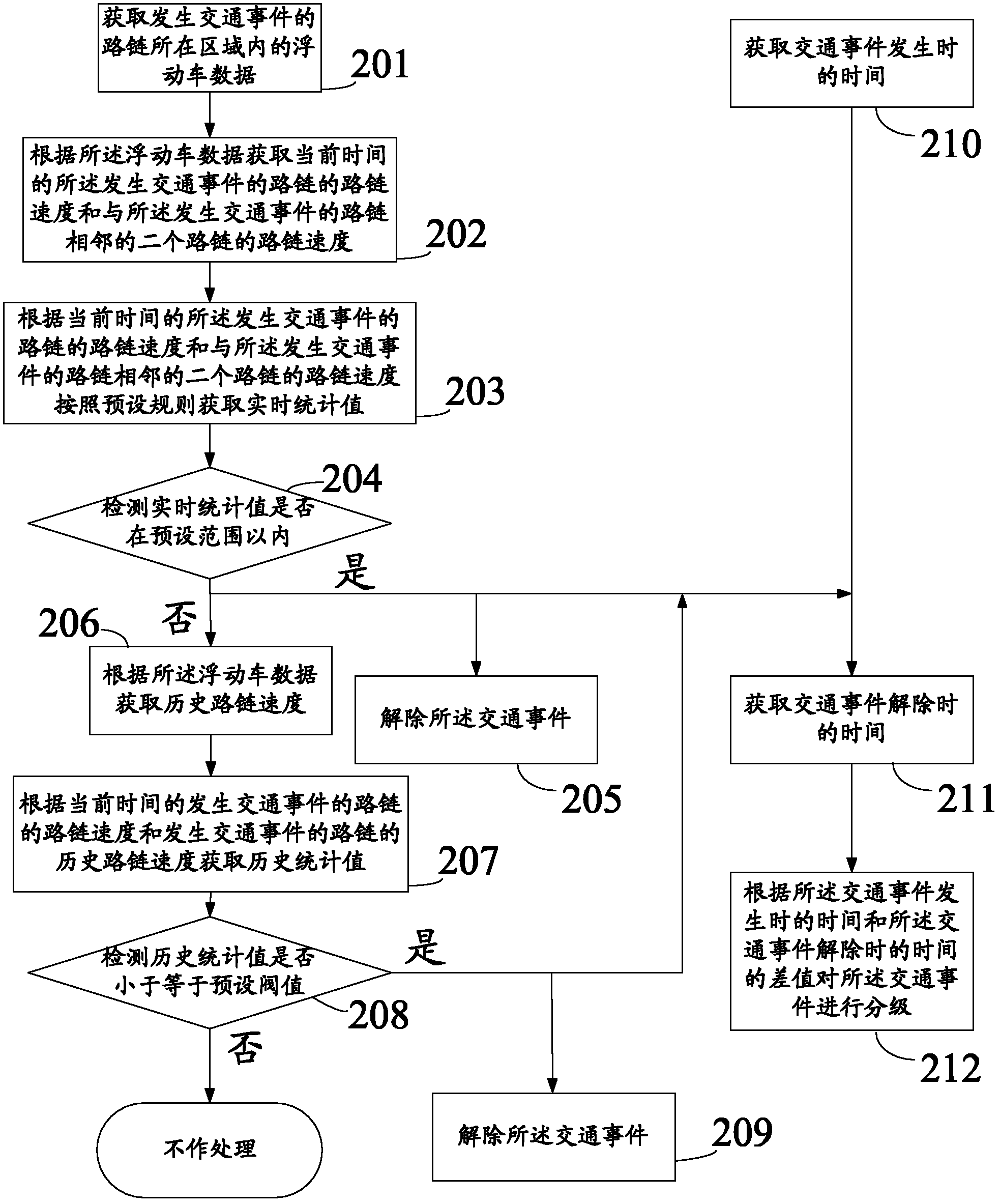

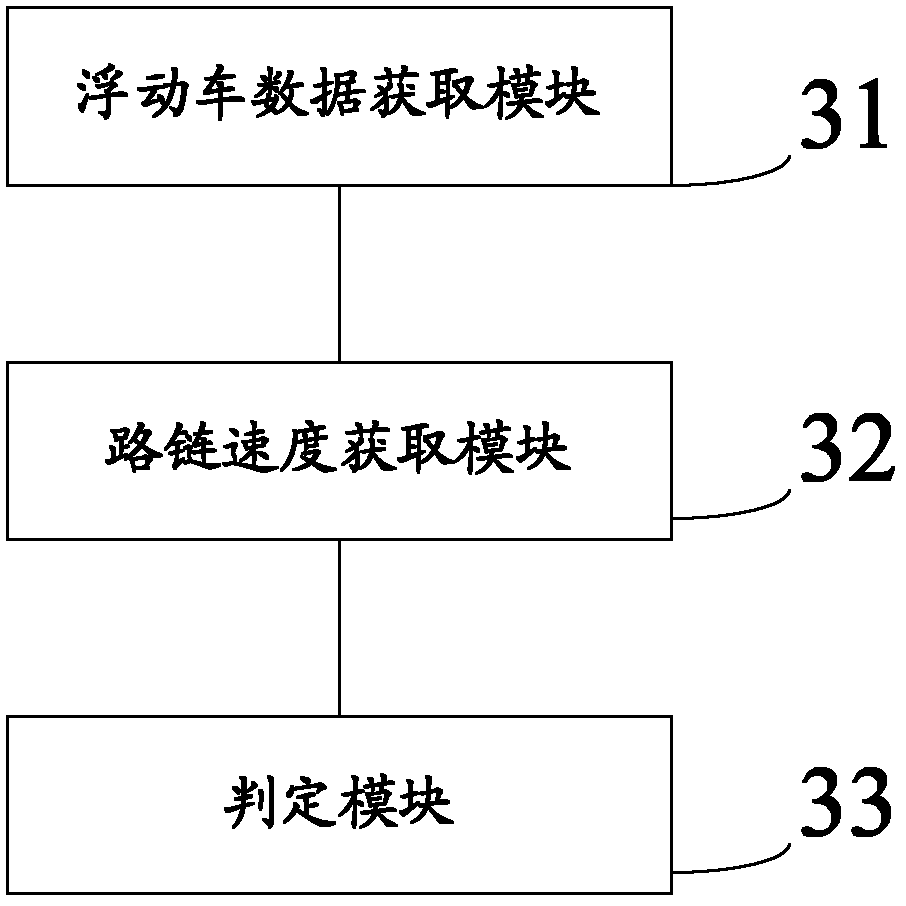

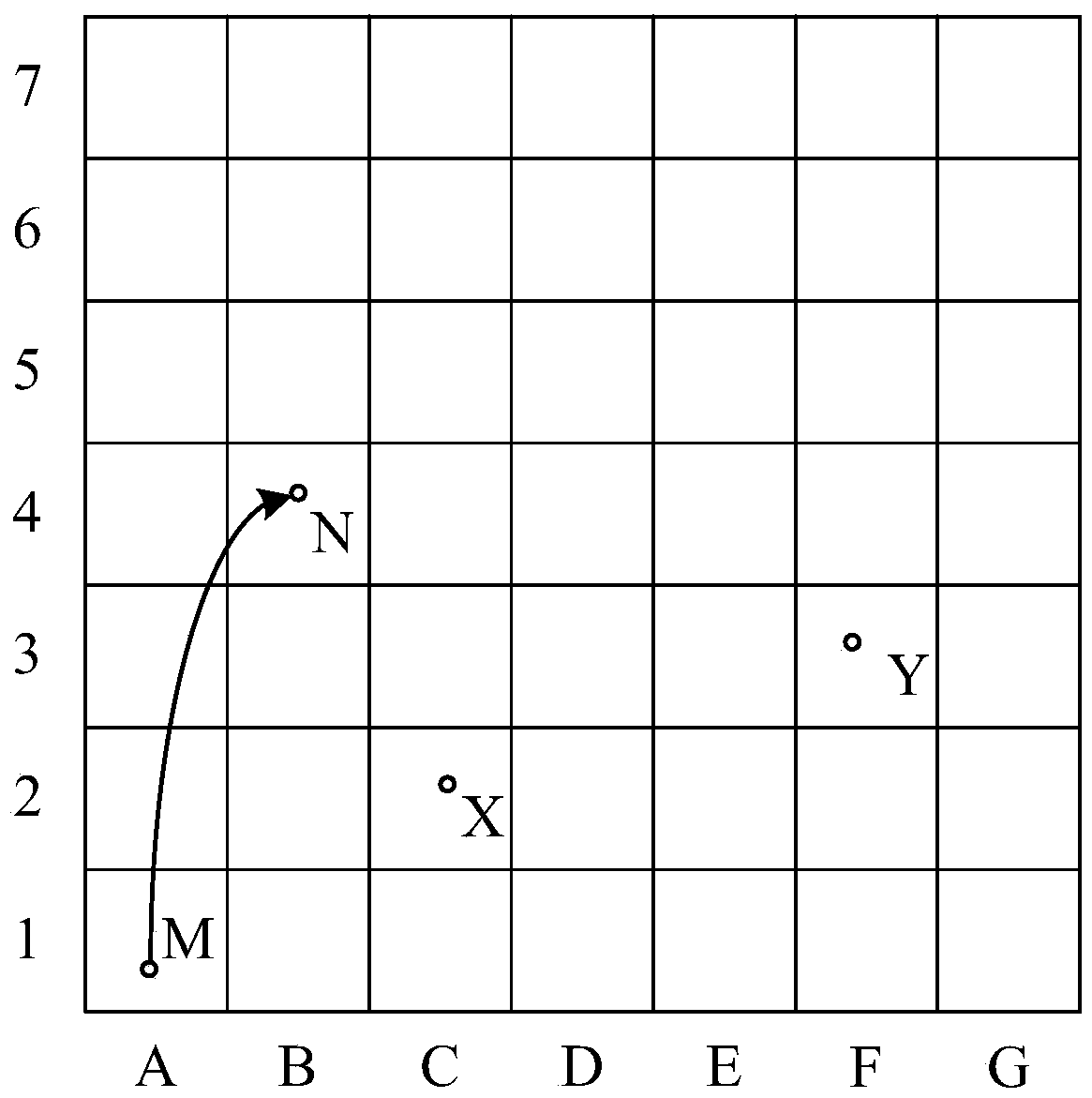

Method and device for judging release of traffic incident

ActiveCN102622883AImprove accuracyEliminate human influenceDetection of traffic movementTraffic systemReal-time computing

The embodiment of the invention discloses a method and device for judging release of a traffic incident, relating to the field of intelligent traffic systems. Whether the traffic incident is released is automatically judged according to a quantized specific value obtained according to floating car data, and subjective deviation caused in a manual judgment process is avoided, thus the accuracy of judging the release of the traffic incident is improved. The method provided by the invention comprises the steps of: obtaining the floating car data in an area where a road link generating the traffic incident occurs; obtaining a speed of the road link according to the floating car data, wherein the speed of the road link is a traffic flow speed on a road corresponding to the road link; and judging wherein the traffic incident is released or not according to the speed of the road link. The invention is suitable for judging the release of the traffic incident.

Owner:CENNAVI TECH

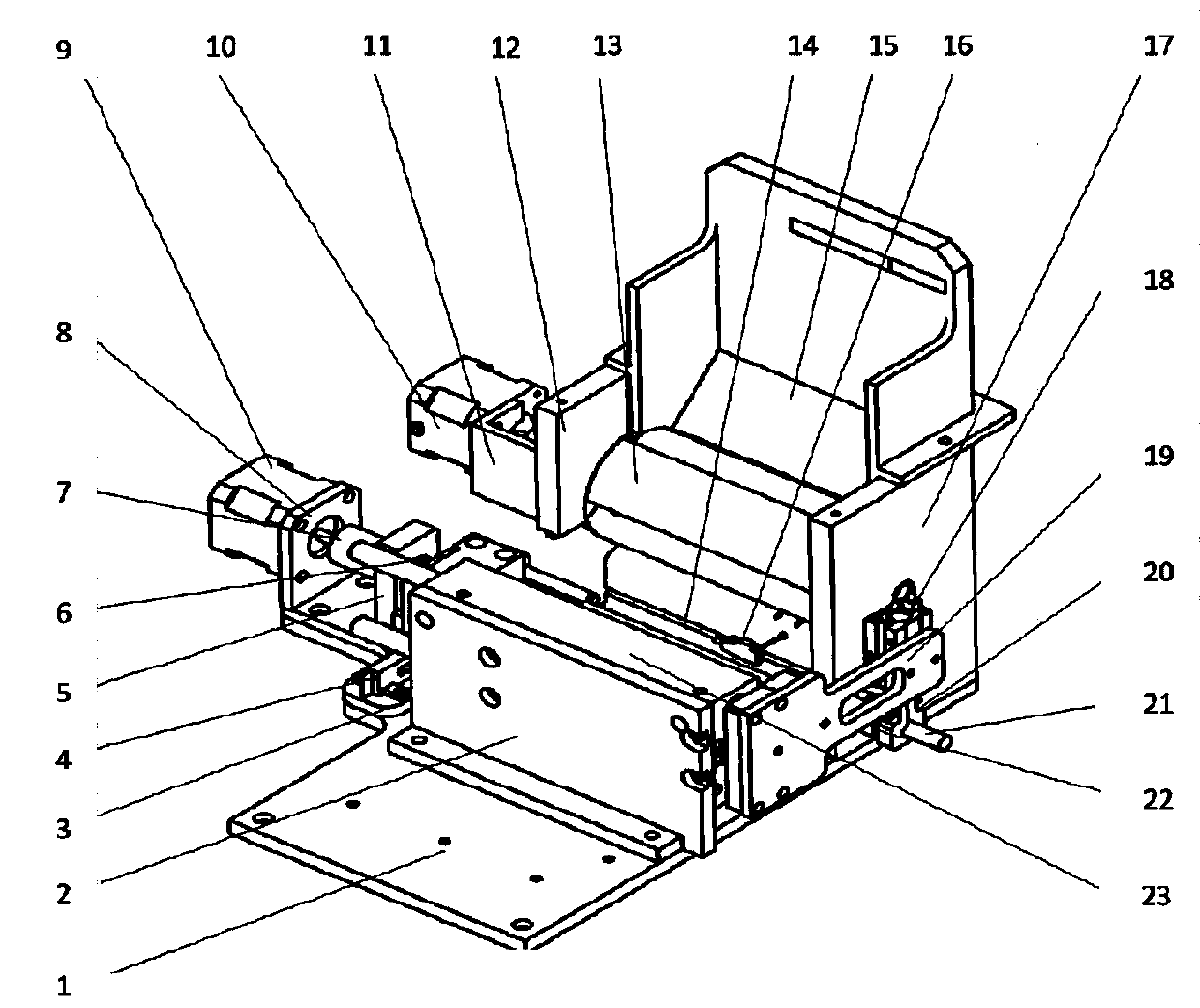

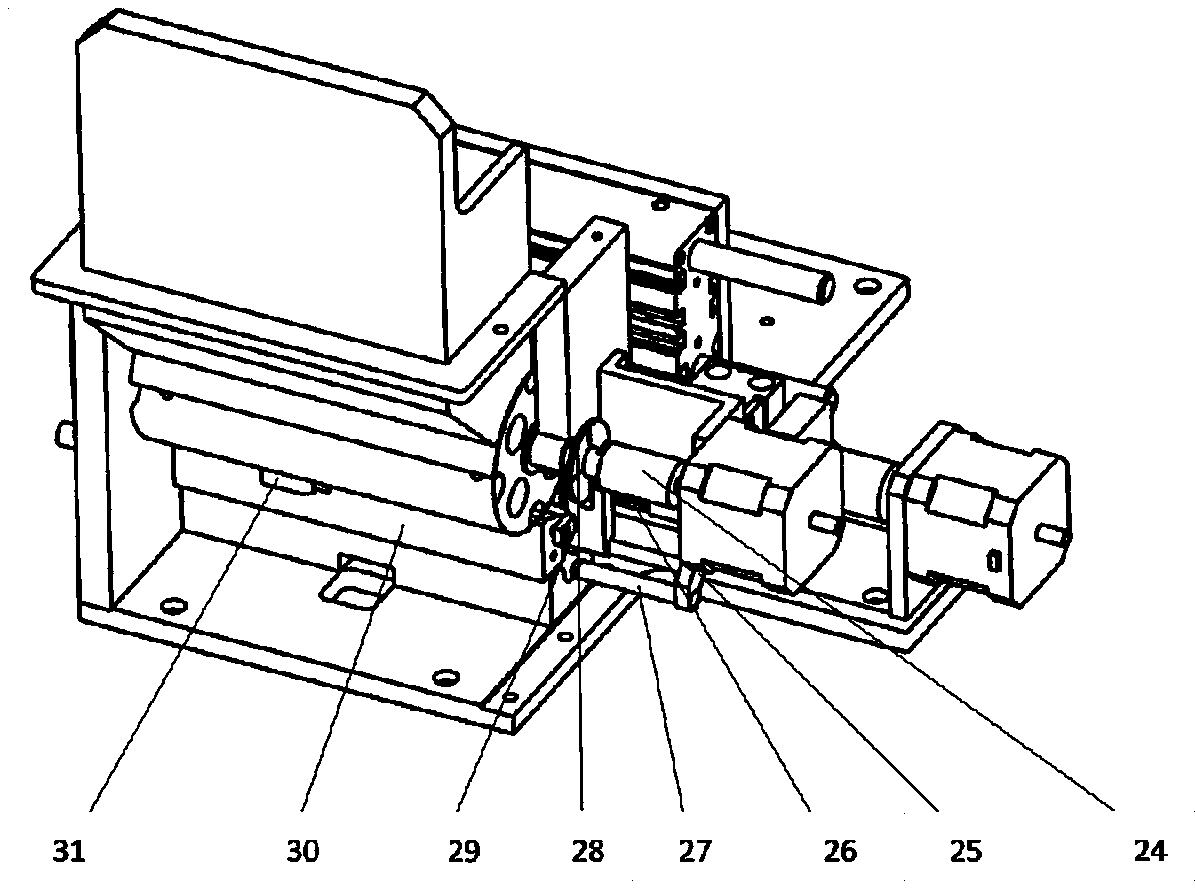

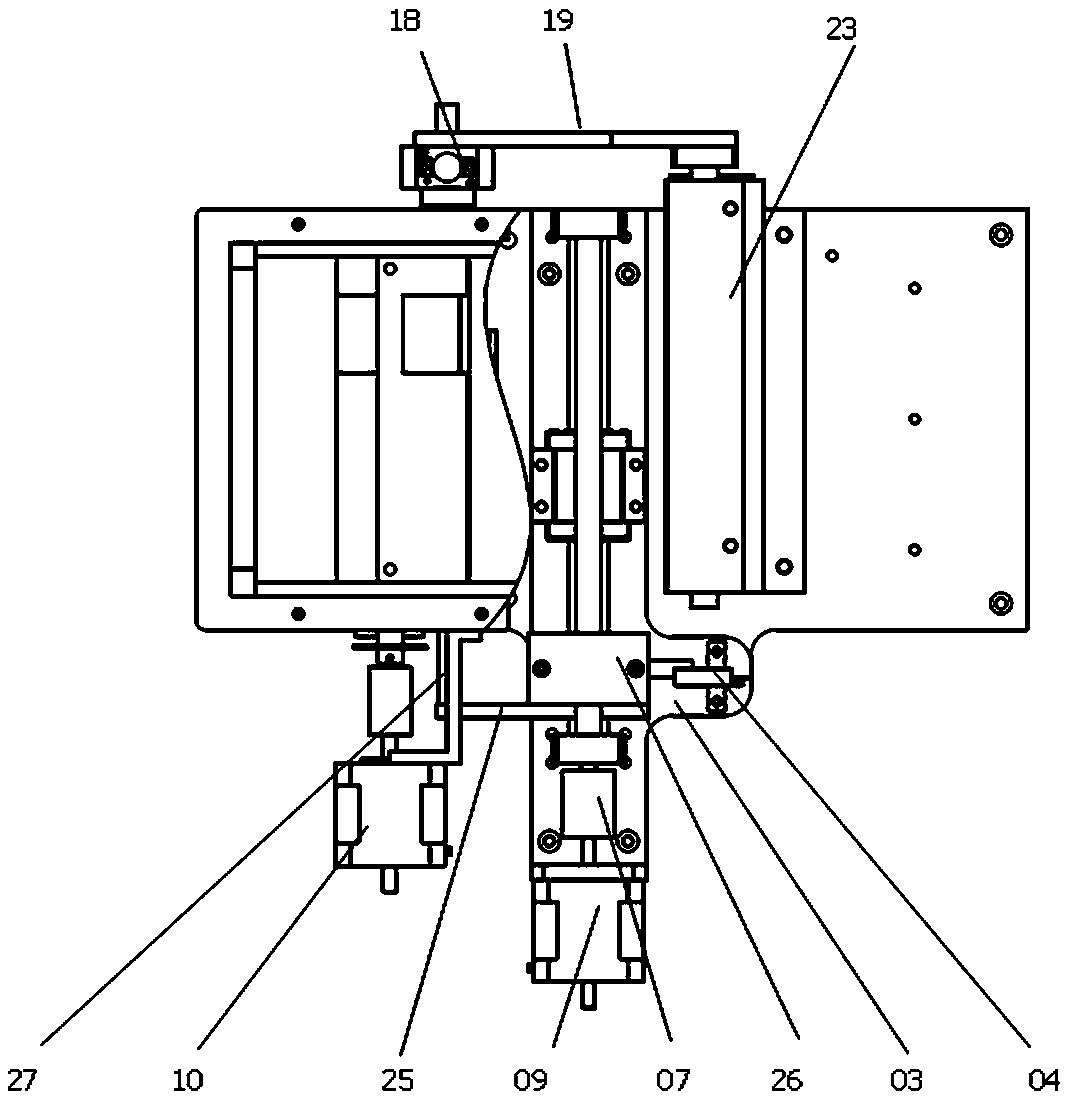

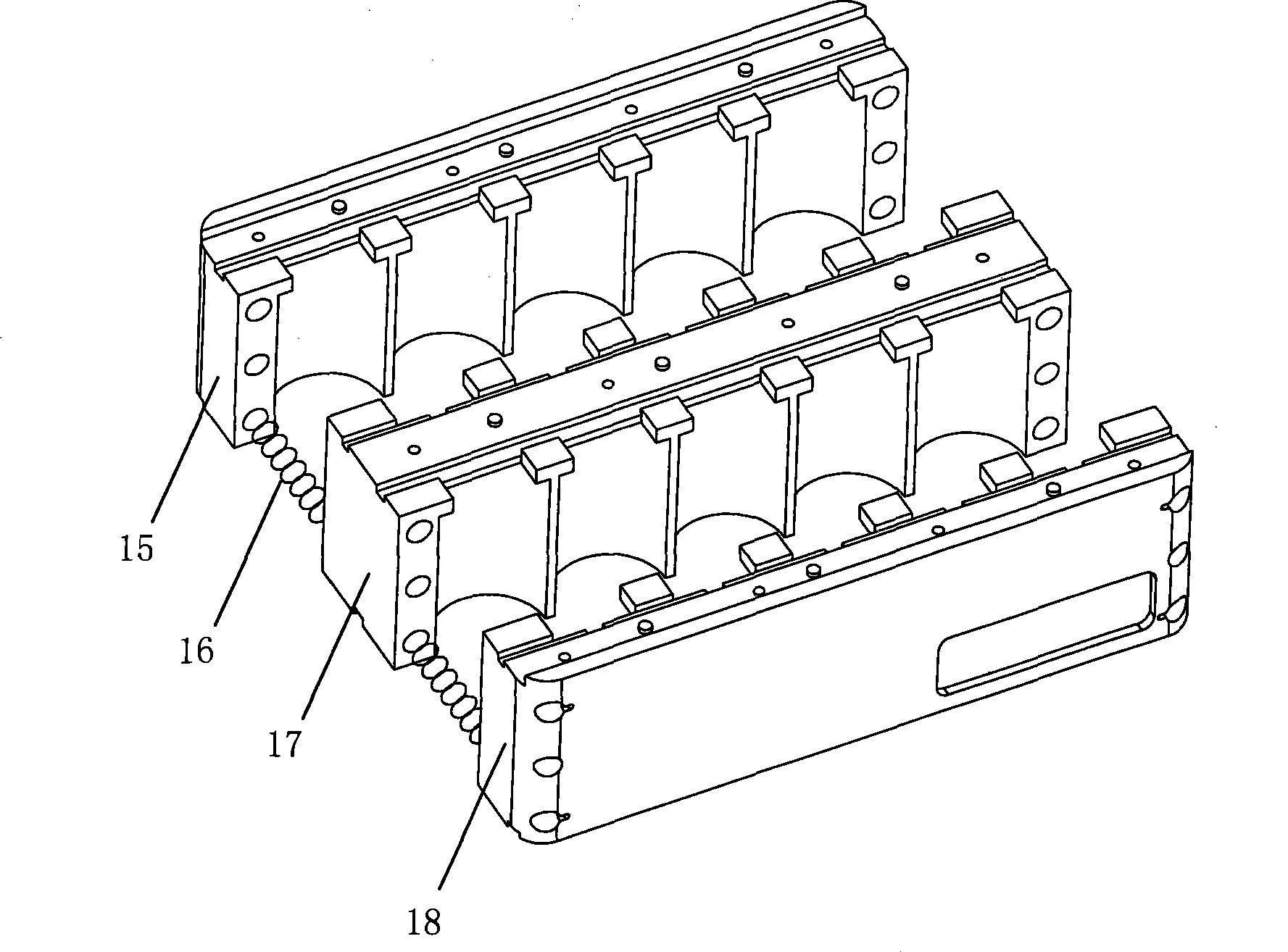

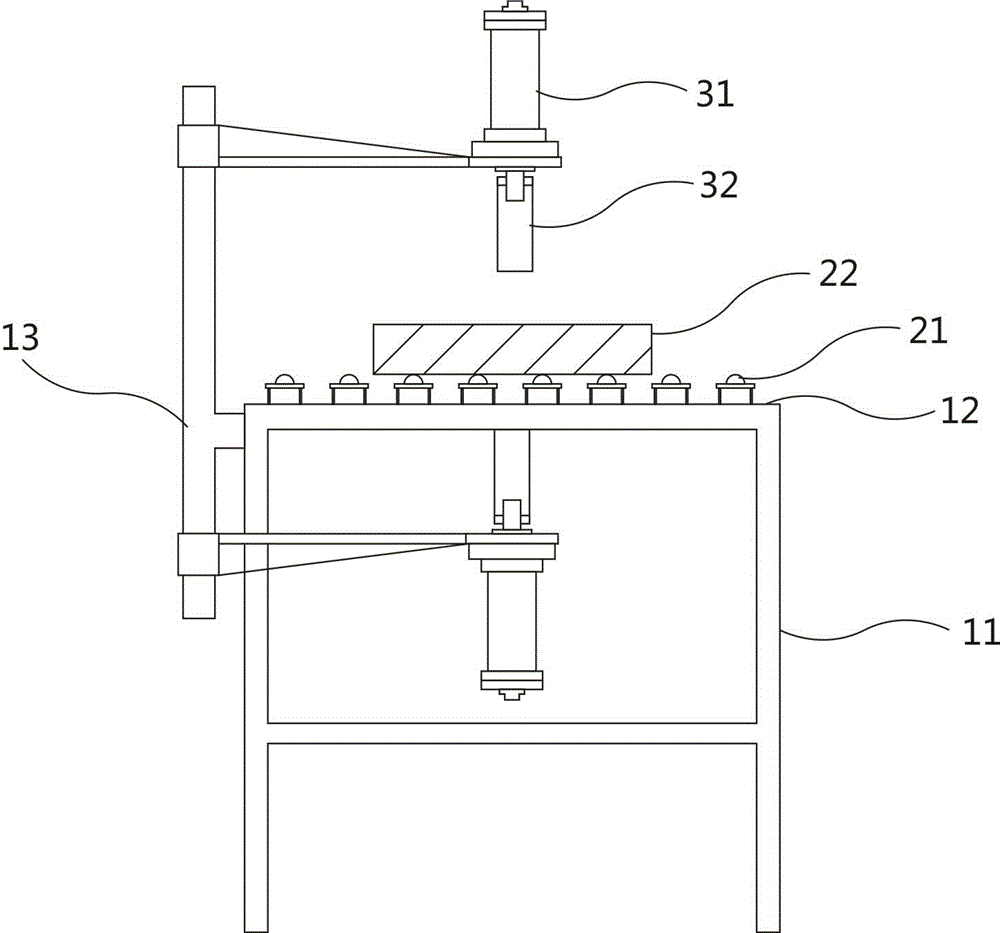

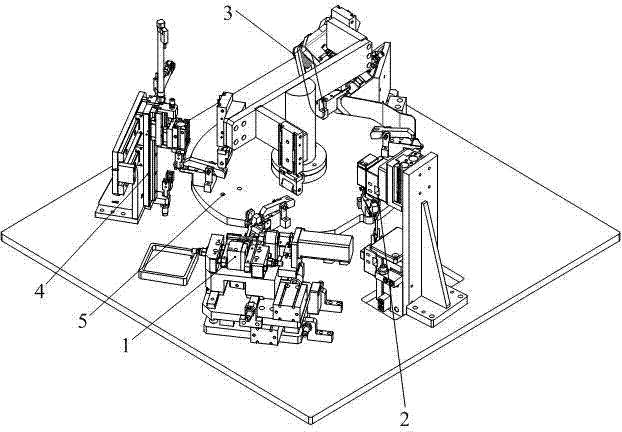

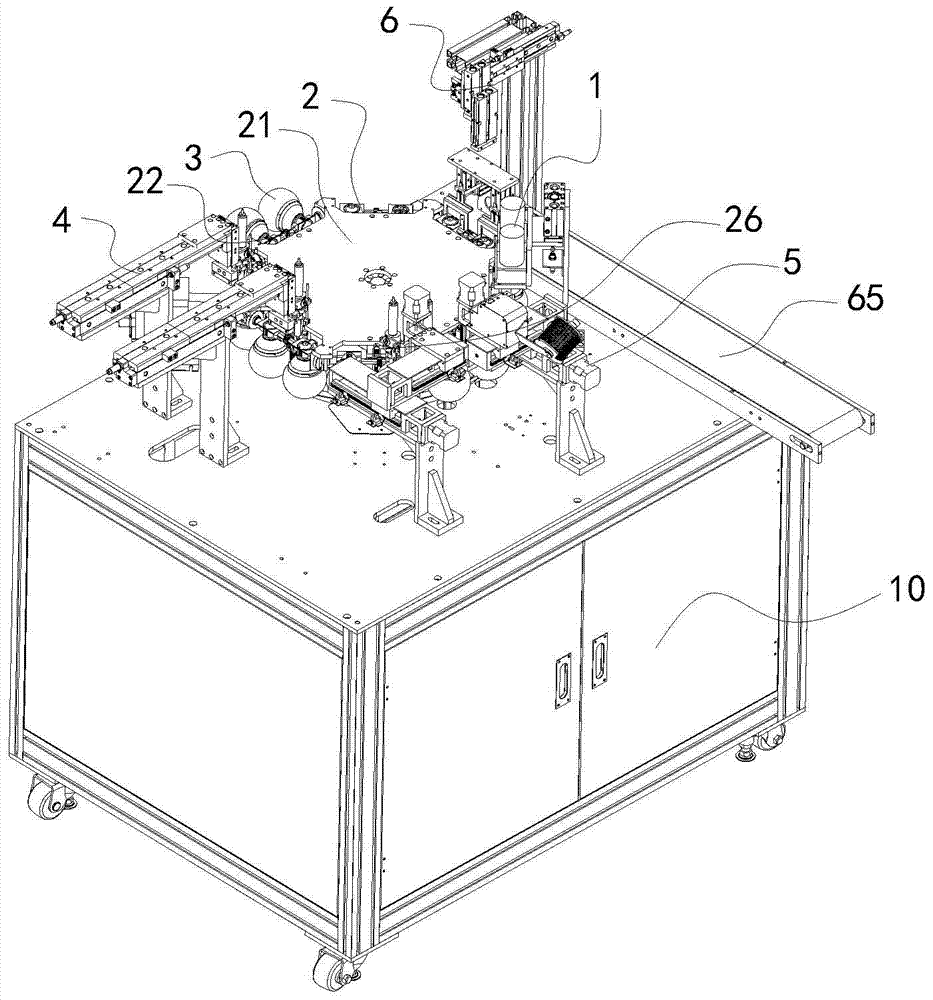

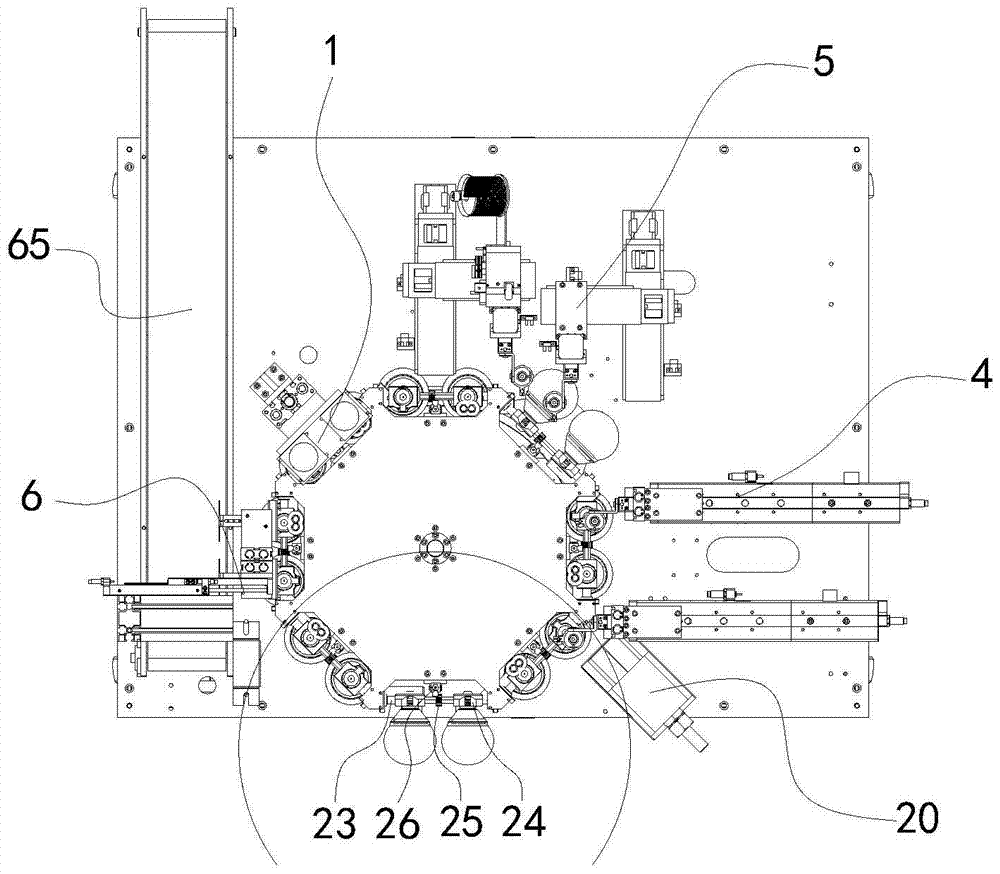

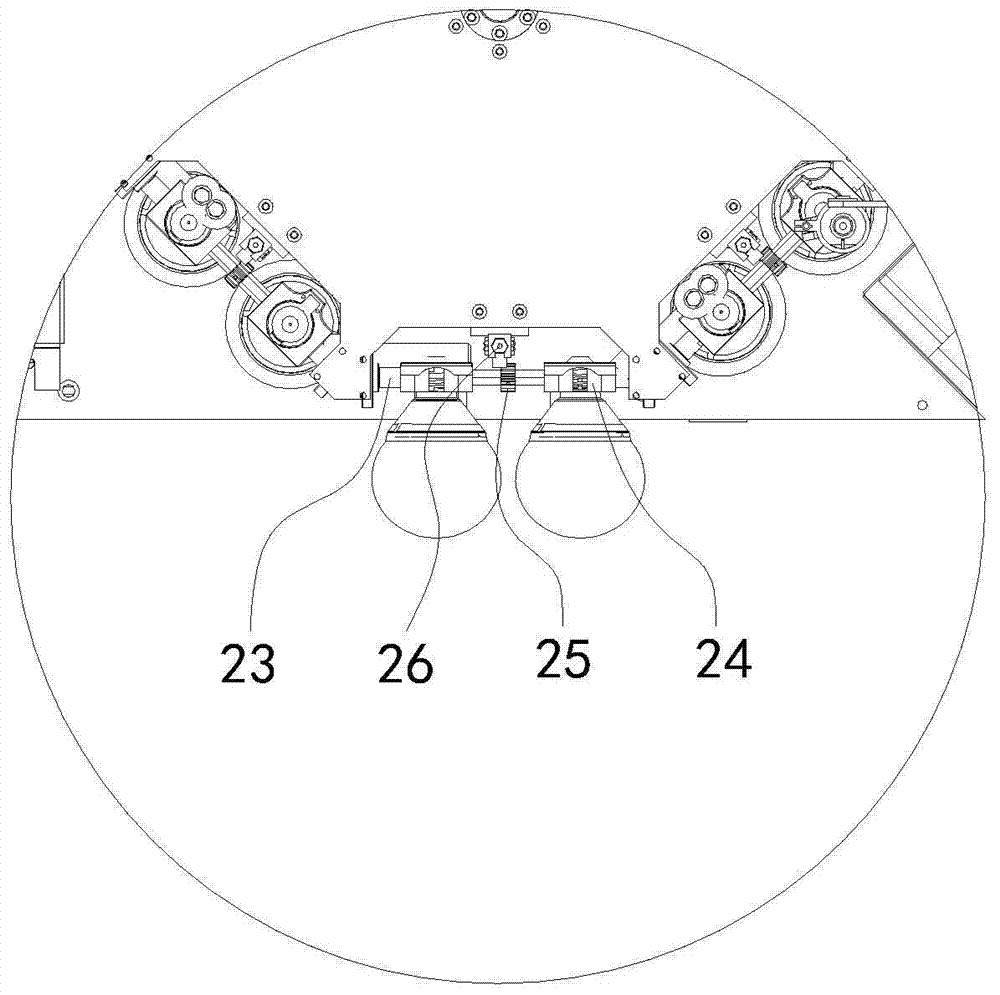

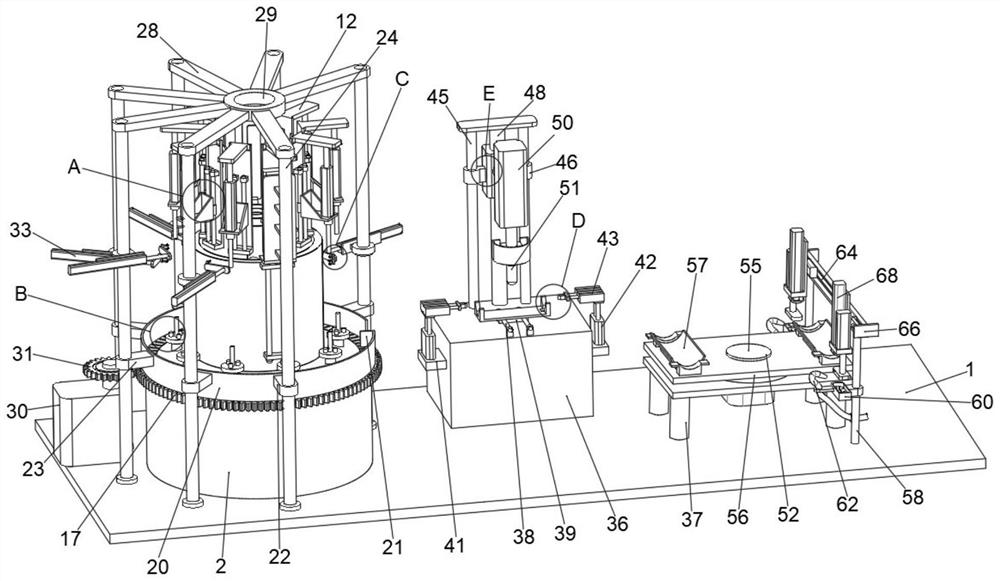

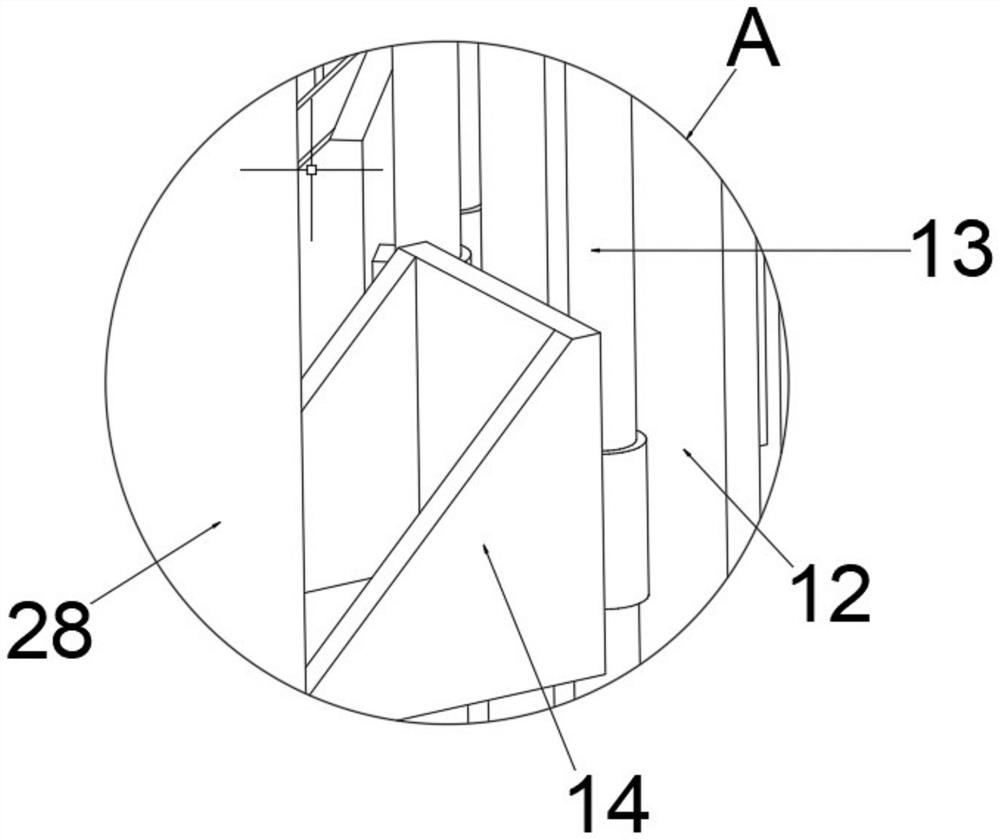

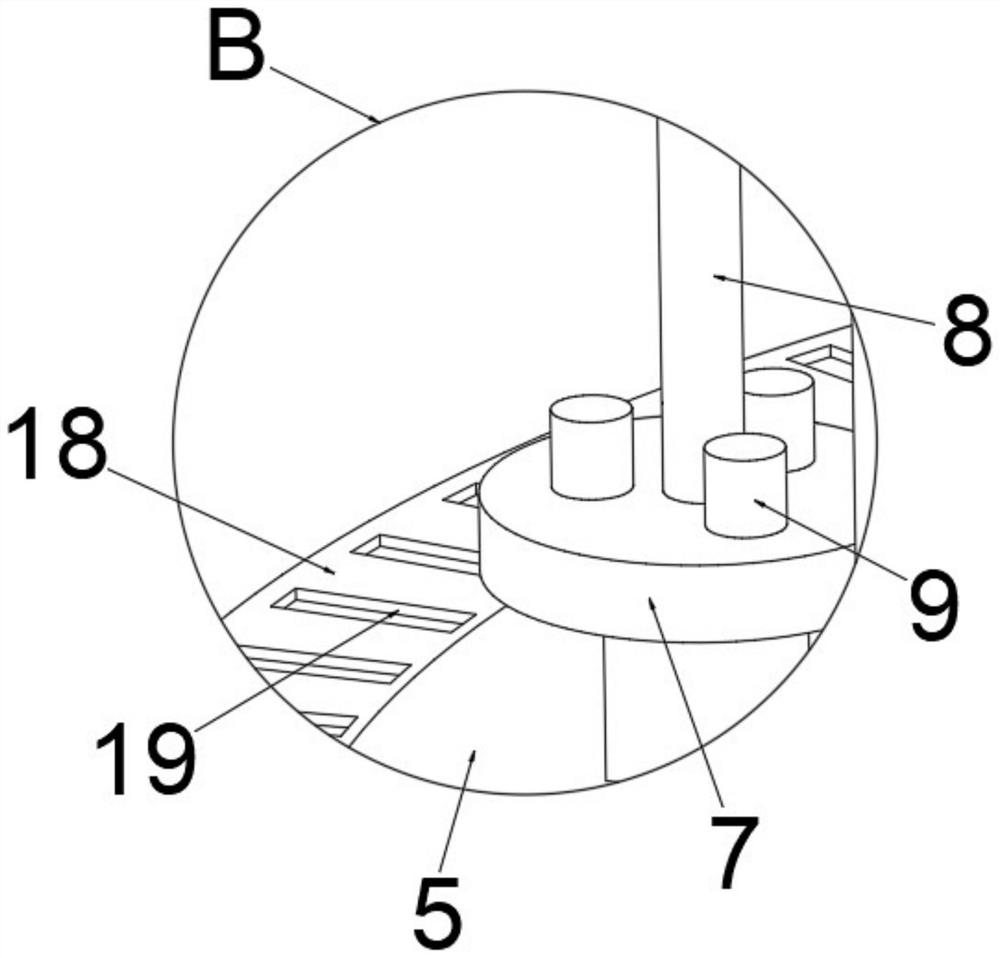

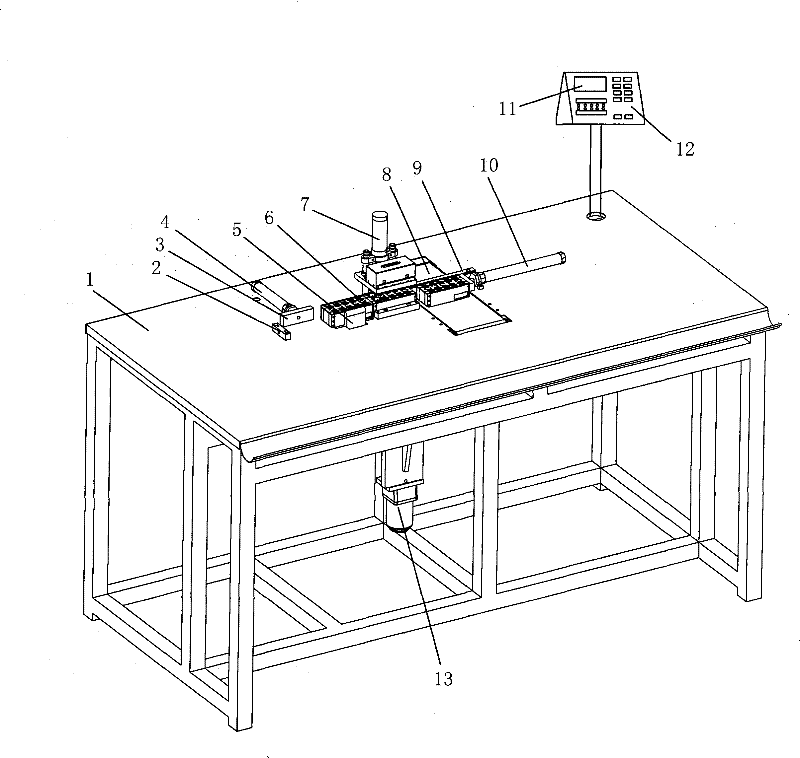

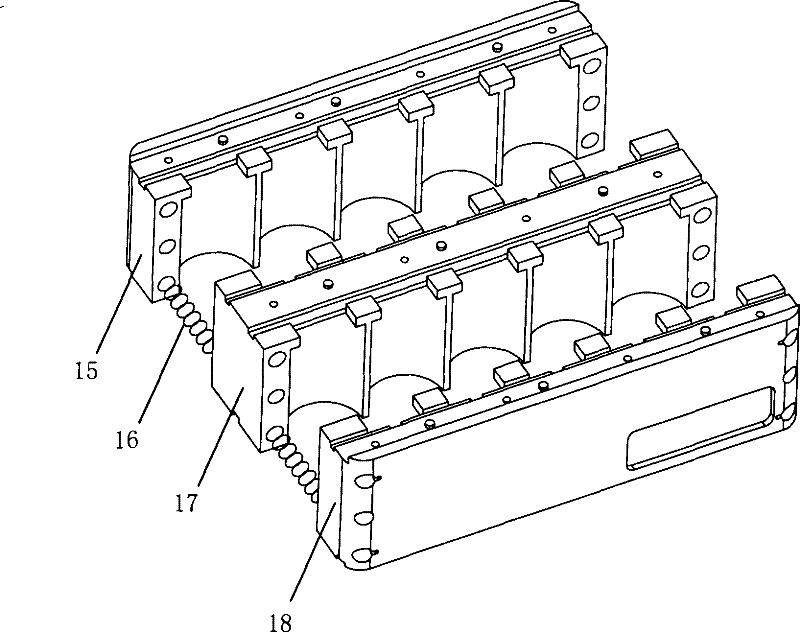

Automatic sampling device for detecting quality of cigarettes

PendingCN108037303AEnables continuous sample testingEliminate human influenceMaterial analysisManufacturing computing systemsElectric machineryEngineering

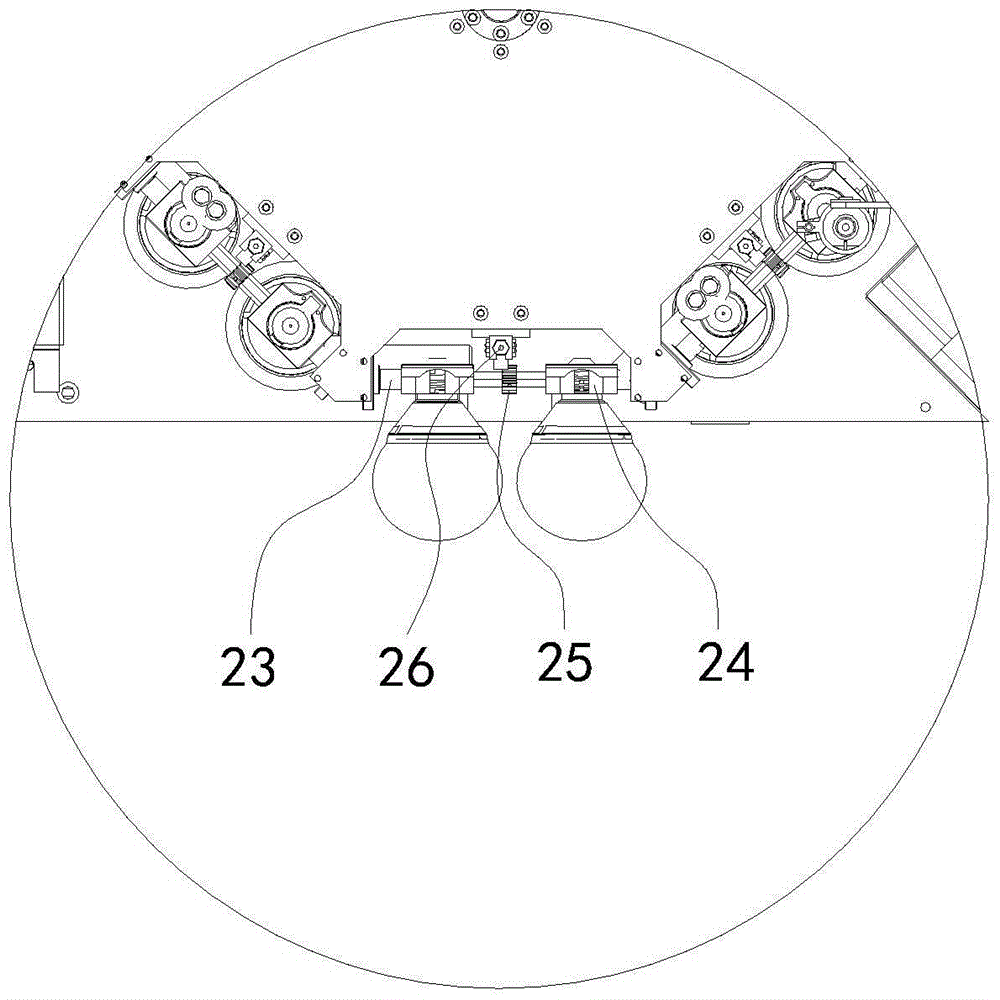

The invention discloses an automatic sampling device for detecting the quality of cigarettes. The automatic sampling device is characterized by comprising a cigarette feeding module and a cigarette pushing module which are arranged on a base (1), wherein the cigarette feeding module comprises a cigarette collecting box (15), a sampling roller (13) arranged at the bottom of the cigarette collectingbox, a roller motor (10), and a cigarette sliding chute (14) which is formed in the cigarette feeding base and is positioned below the sampling roller; the cigarette pushing module comprises a cigarette pushing motor (9), a cigarette pushing lead screw platform (26), a push rod (27), as well as a transverse air cylinder (23) which is arranged in parallel to the cigarette pushing lead screw platform (26) side by side; a clamping jaw air cylinder (18) and a cigarette feeding clamping jaw (20) are arranged at the front end of the transverse air cylinder by a clamping jaw mounting base (19). Theworking process of the device is that automatic mounting of cigarette samples is realized by corresponding actions of the cigarette feeding module and the cigarette pushing module, human influence inthe process of manually mounting the cigarette samples to the tested position is eliminated, and automation of cigarette sampling is realized, so that the working efficiency is improved.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +2

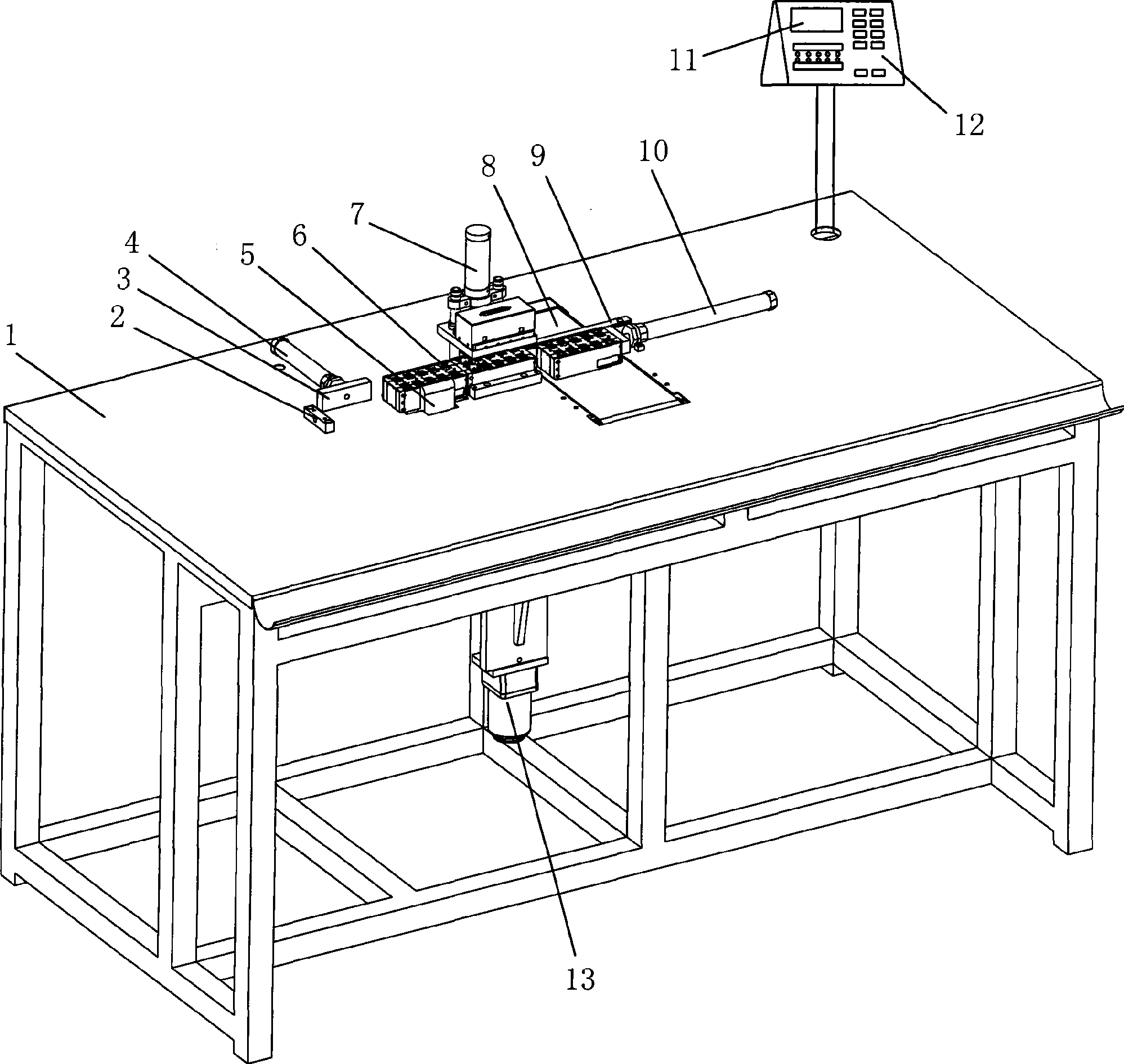

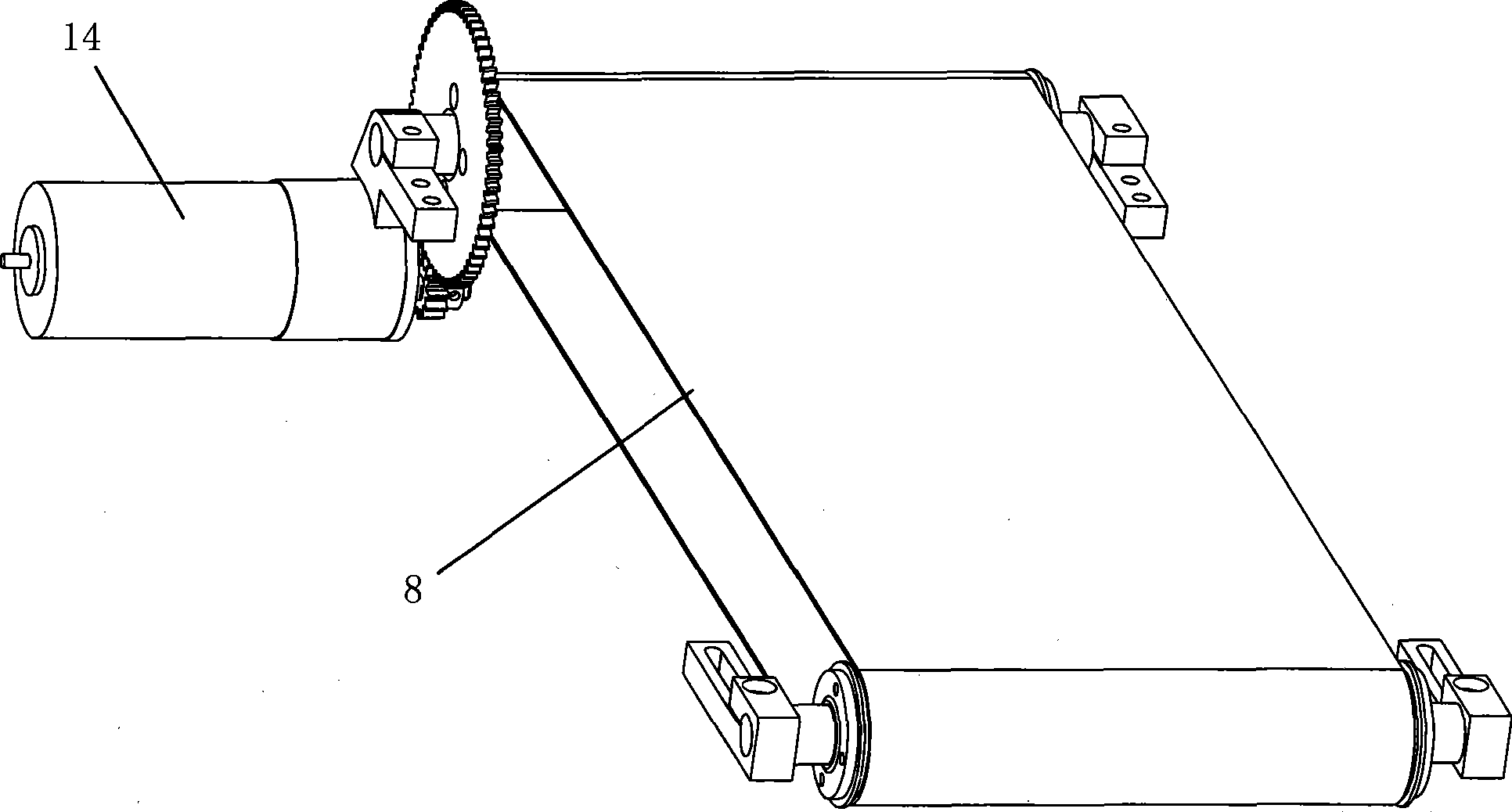

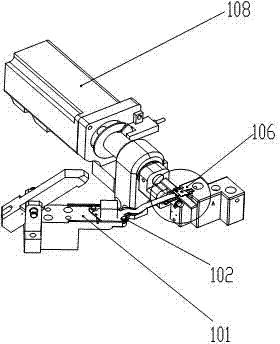

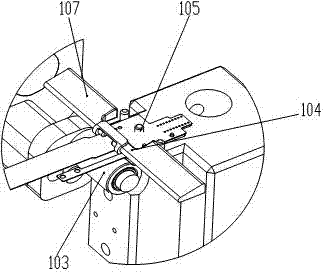

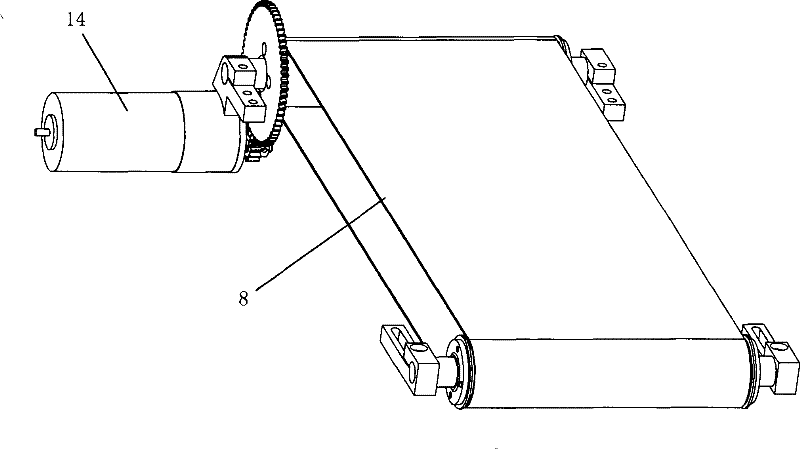

Machine for automatically testing and sorting code devices

InactiveCN101474618ASolve the problem of difficult product quality inspectionImprove consistencySortingInstrumentsDisplay deviceEngineering

The invention relates to an automatic testing and sorting machine of encoders, belonging to the field of encoder quality detecting device. The quality detection of existing encoders is carried out manually. The invention comprises a bench panel, a display, an operation panel and a movable mold core; the bench panel is designed with a mold entering device, a testing device, a sorting device and a mold stripping device in sequence; the chassis is internally designed with a principle shaft rotating mechanism and a test control circuit board; the testing device is connected with the principle shaft rotating mechanism; the display, the operation panel, the mold entering device, the testing device, the sorting device, the mold stripping device and the principle shaft rotating mechanism are respectively connected with the test control circuit board; the mold entering device comprises a mold pushing cylinder, a mold core baffle, a conveyer belt and a motor; the testing device comprises upper and lower probe cylinders and a probe box; the sorting device comprises a reject gate component, a splitting mold cylinder A, a splitting mold cylinder B, a splitting mold draw plate A, a splitting mold draw plate B, a stuck material sensor and a reject gate driver. The automatic testing and sorting machine can carry out automatic test on the encoders and sort the unqualified products out.

Owner:SOUNDWELL ELECTRONICS PROD GUANGDONG

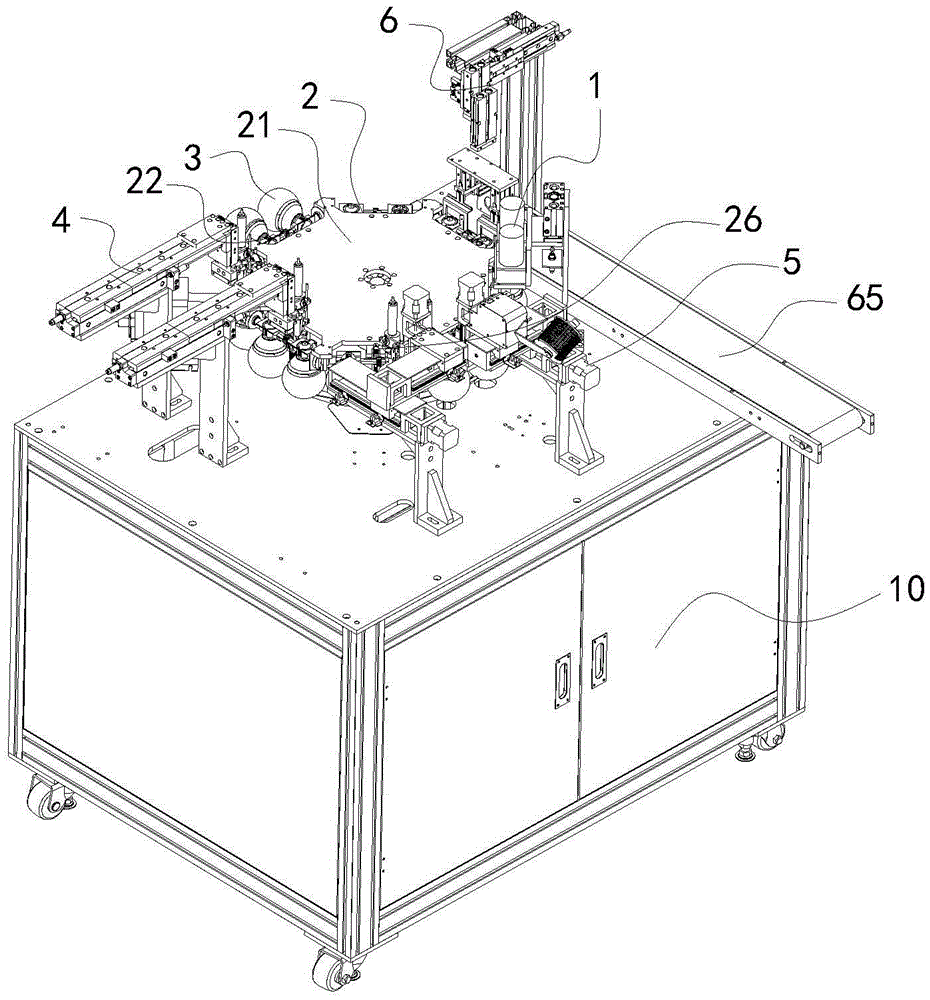

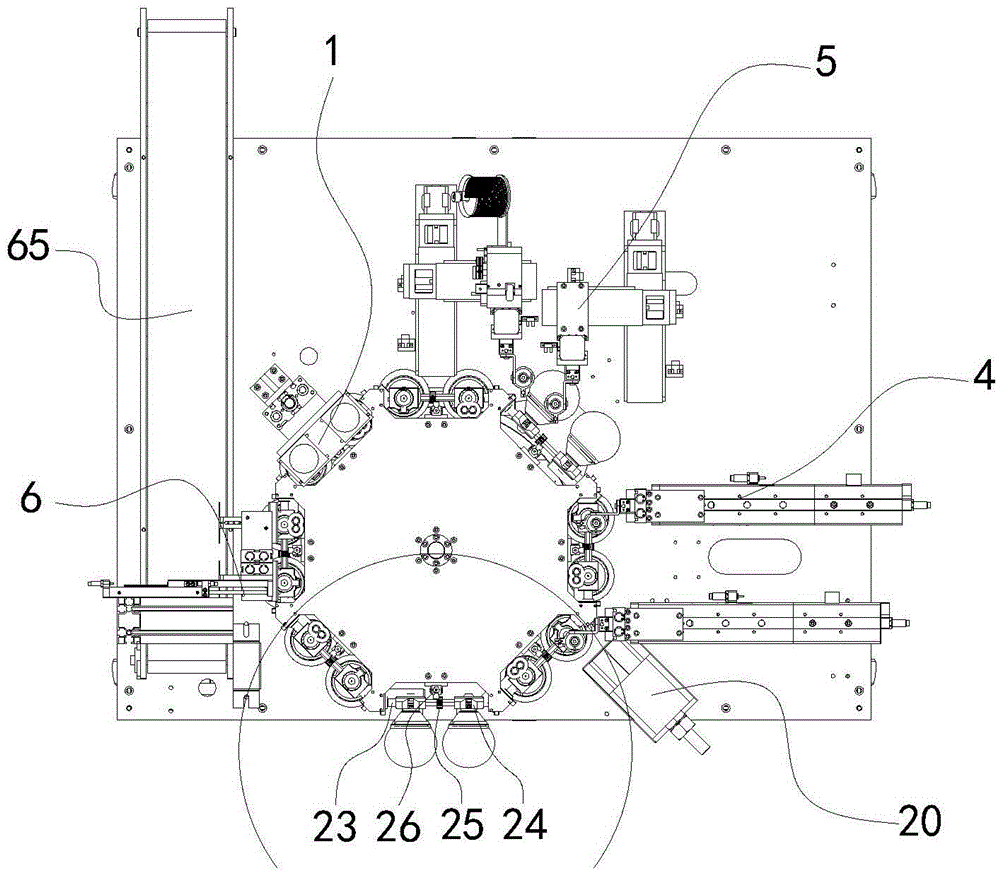

LED bulb lamp welding system

ActiveCN105478949AGuaranteed cooling effectRealize automatic weldingMetal working apparatusSoldering auxillary devicesWeldingEngineering

The invention discloses an LED bulb lamp welding system which comprises a rack. A rotary disc mechanism is arranged on the rack. The rotary disc mechanism comprises a disc and a rotary disc motor driving the disc to rotate. A plurality of material positions are arranged on the disc in the circumferential direction, and rotating clamping head mechanisms used for fixing bulb lamps are arranged on the material positions respectively. The outer side of the disc is provided with a side face welding mechanism, a top welding mechanism, a rosin removing mechanism and a discharging mechanism in sequence. The rotary disc motor drives the disc to rotate. The rotating clamping head mechanisms are used for clamping the LED bulb lamps to be welded. The feeding mechanism conducts feeding. The side face welding mechanism is used for welding the side faces of the LED bulb lamps. The top welding mechanism is used for welding the tops of the LED bulb lamps. The rosin removing mechanism is used for removing rosin on the tops of the LED bulb lamps. The discharging mechanism is used for performing discharging after rosin is removed, and automatic welding and rosin removing of the LED bulb lamps are achieved.

Owner:SUZHOU JINGSHUO AUTOMATION EQUIP CO LTD

Digital TV video and audio synchronous measuring method

ActiveCN100546391CAvoid parallax effectsThe measurement results are correct and reliablePulse modulation television signal transmissionDuration periodDigital video

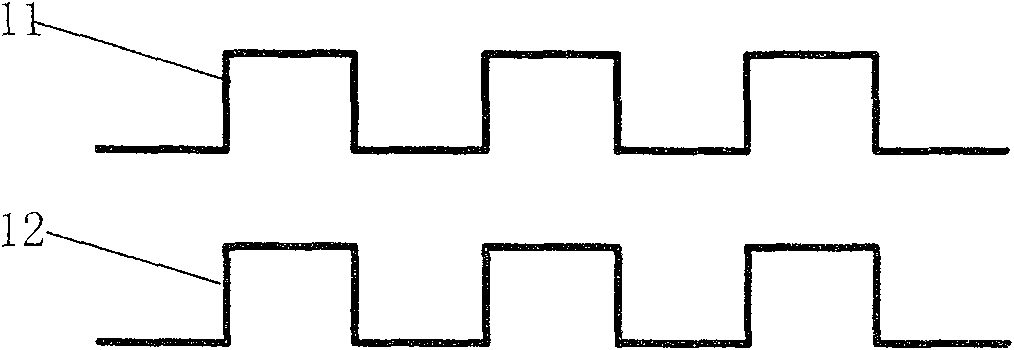

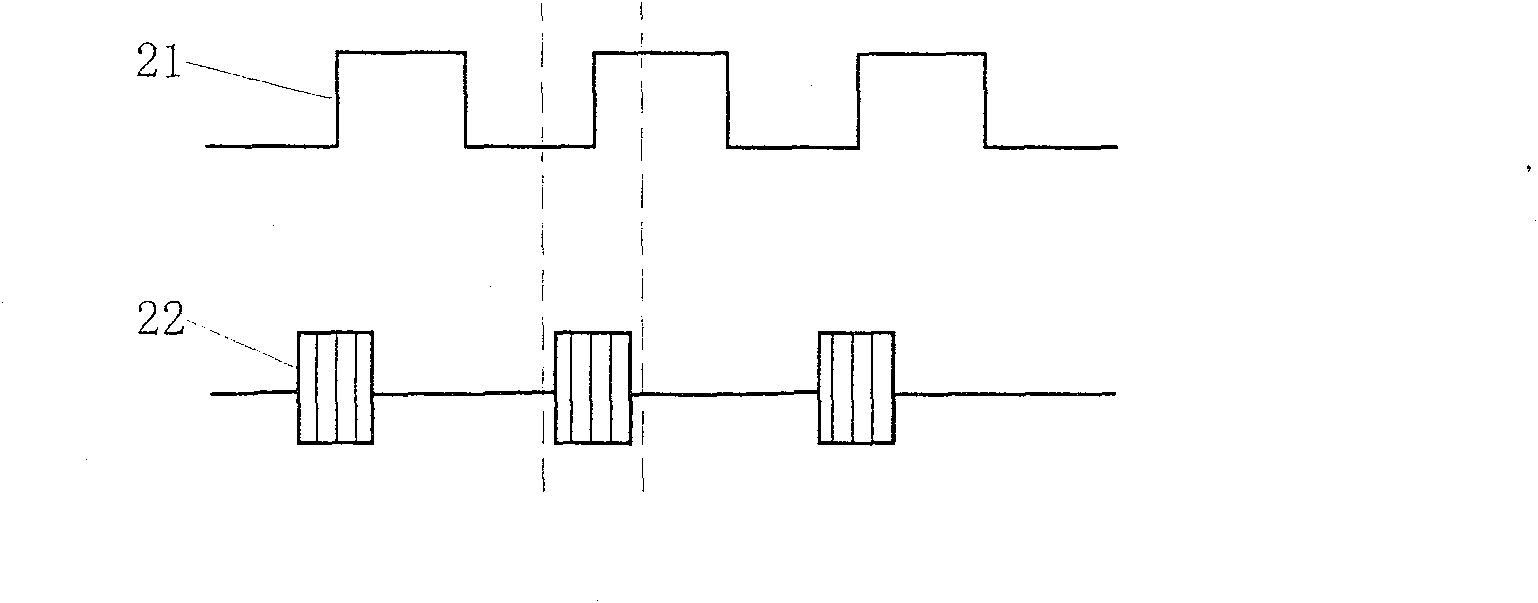

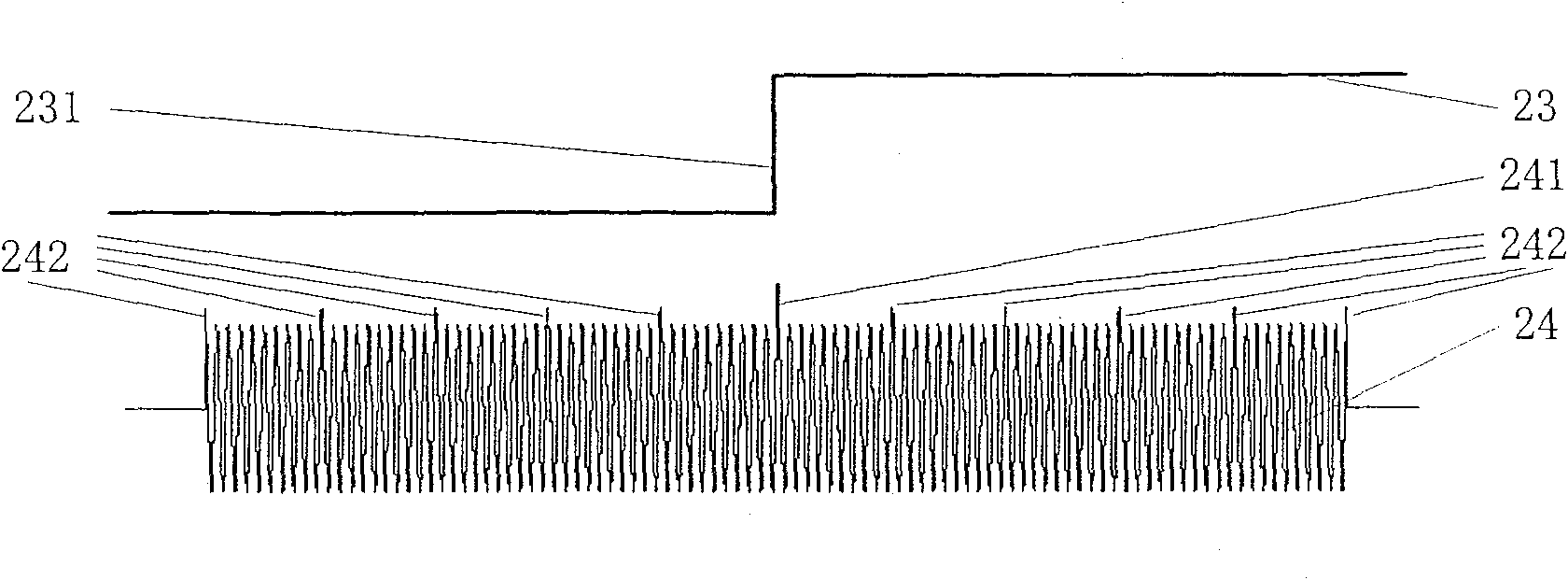

The invention relates to a video and audio synchronization test signal of a digital TV and a measuring method thereof, and belongs to the technical field of audio and video signal detection. The test signal is composed of a video signal and an audio signal. The waveform of the video signal is a rectangular curve, forming a cycle signal with full bright and full dark phase jumps; The video light and dark transitions have the same repetition period; the time difference between the video's rising edge and the midpoint of the audio duration is the test result of the video and audio synchronization. The measurement method is to first generate image and sound data according to the requirements of the video and audio waveform of the test signal; generate video and audio basic stream data through compression coding, and form composite TS stream signal data; select the corresponding test equipment for the tested equipment; The device reads the measurement correctly. The measurement result of the invention is correct and reliable, the precision of the detection equipment itself is not high, the measurement operation is simplified, and human error can also be avoided.

Owner:MUDAN SHIYUAN ELECTRONICS BEIJING

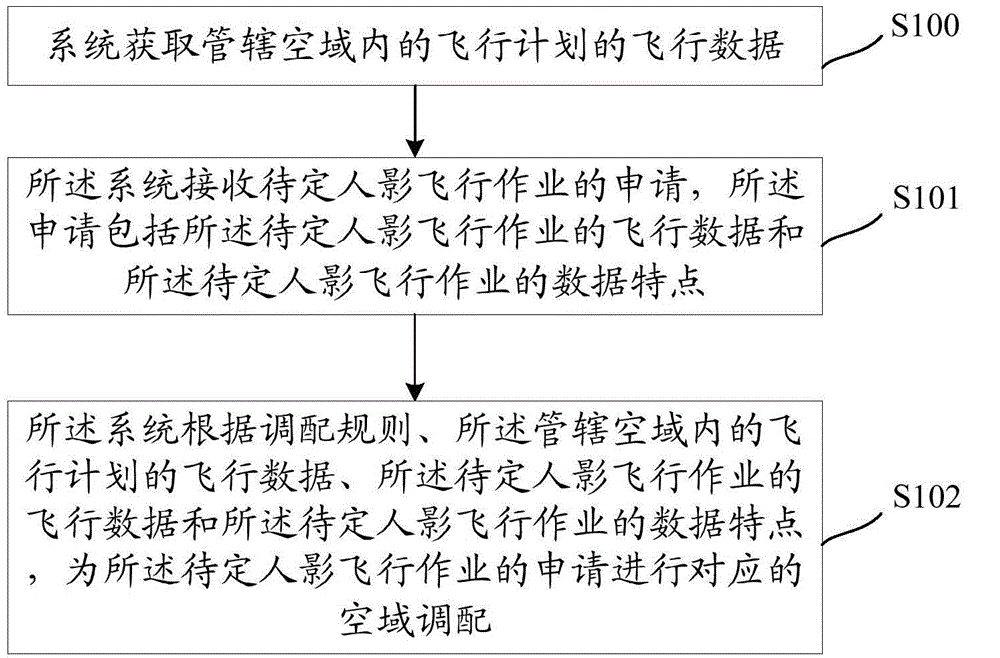

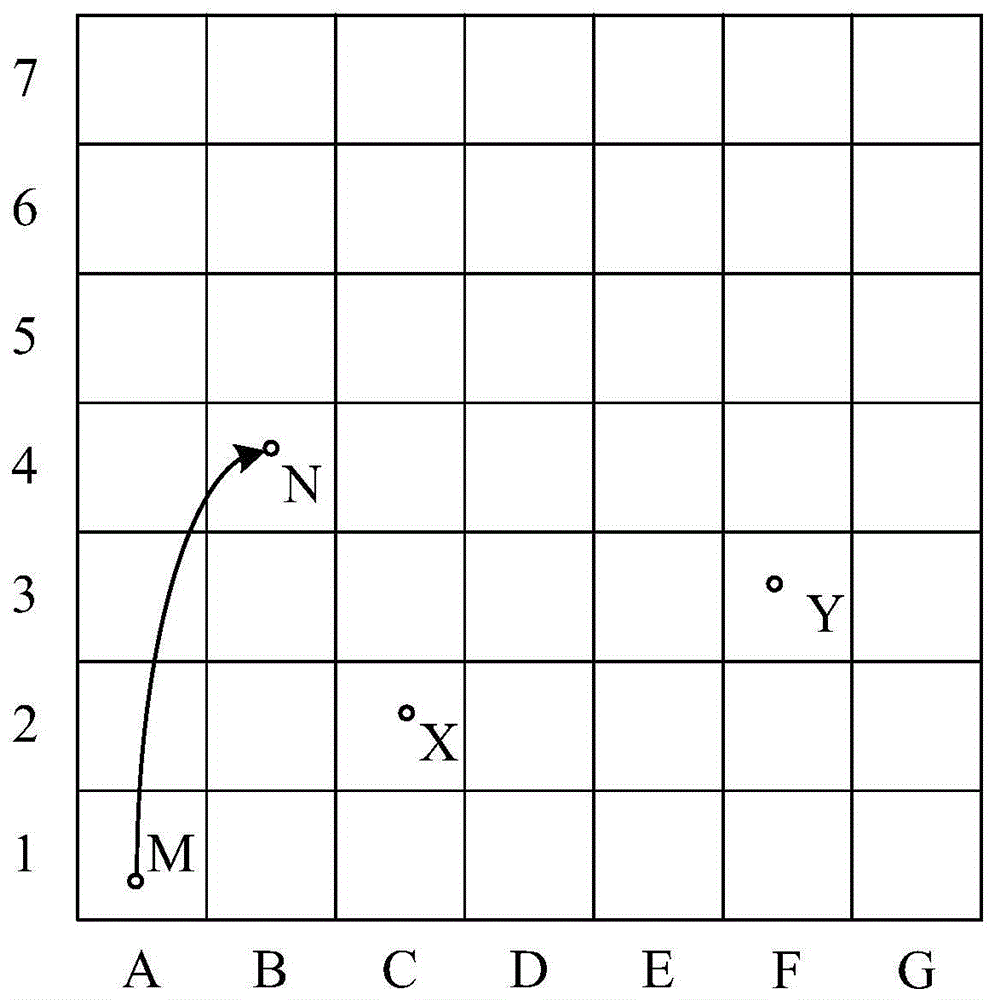

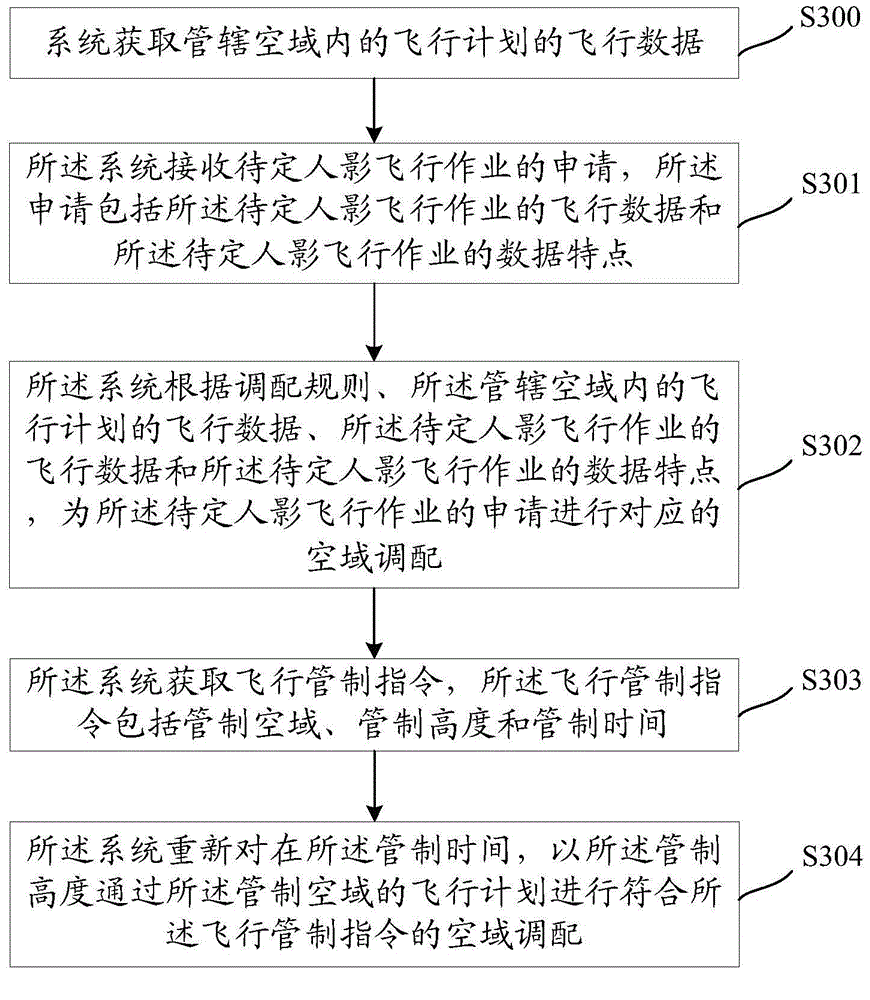

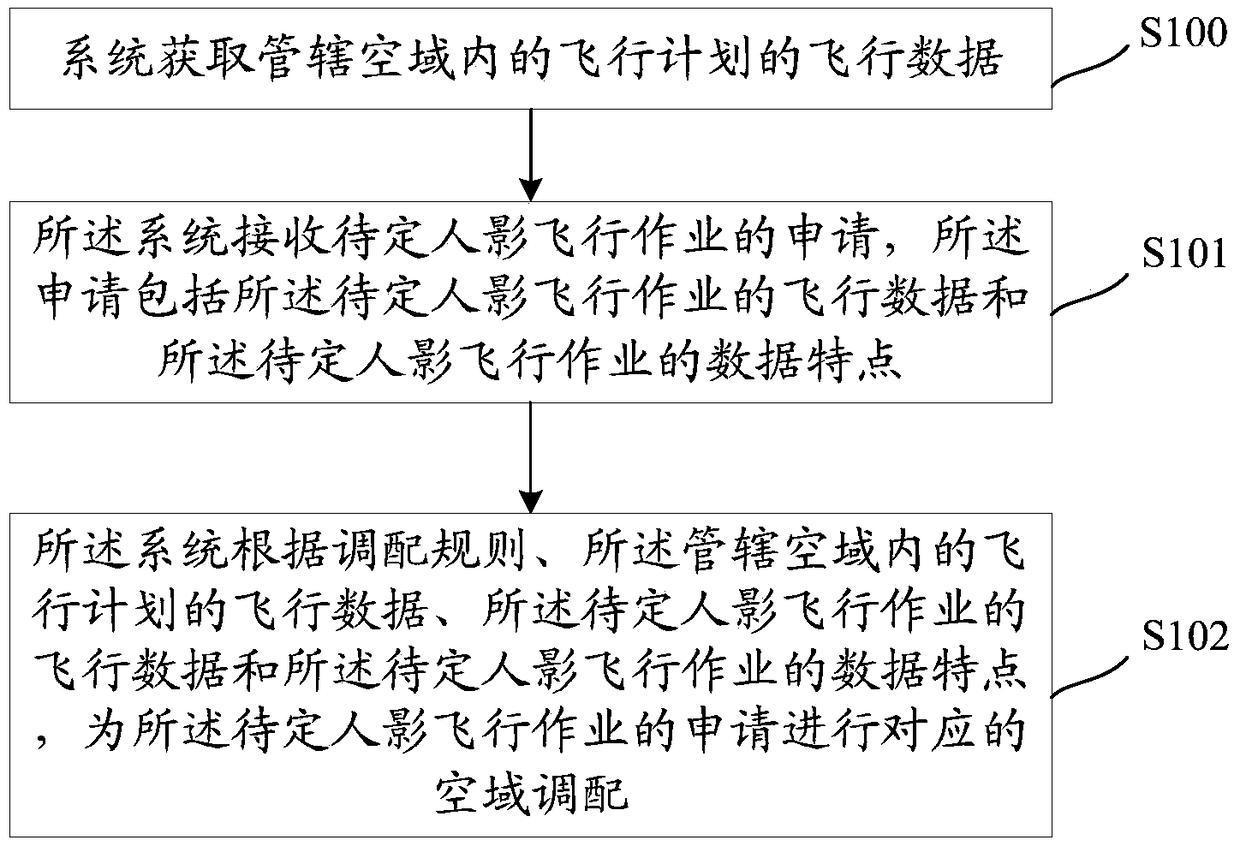

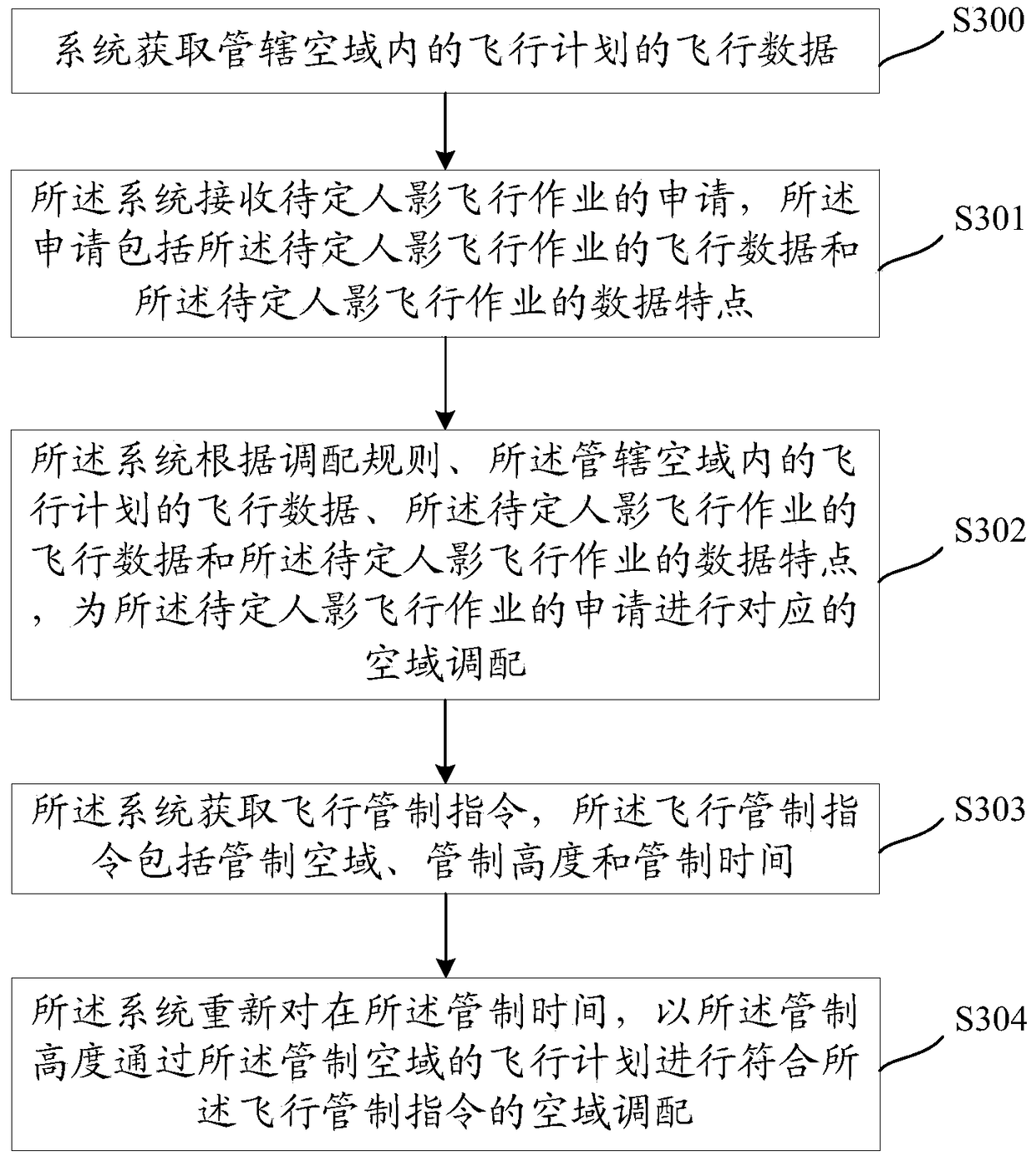

Flight plan data processing method and device

InactiveCN104463491ALearn about usageImprove allocation efficiencyFlight plan managementResourcesProgram planningComputerized system

The embodiment of the invention discloses a flight plan data processing method and device. A system acquires flight data of a flight plan in jurisdiction airspace, the system receives an application for undetermined figure flight operation, and the system carries out corresponding aerospace deployment on the application for the undetermined figure flight operation according to the deployment rule, the flight data of the flight plan in the jurisdiction airspace, the flight data of the undetermined figure flight operation and the data feature of the undetermined figure flight operation. Therefore, the system can comprehensively know the use condition of the jurisdiction airspace by acquiring the flight data of the flight plan in the jurisdiction airspace, when the application for any undetermined flight operation is received, the computer system can automatically carry out the corresponding aerospace deployment on the application for the undetermined figure flight operation fast and effectively, human influence in the aerospace deployment is removed, and therefore deployment efficiency and precision on the figure flight operation are improved.

Owner:BEIJING WEATHER MODIFICATION OFFICE +2

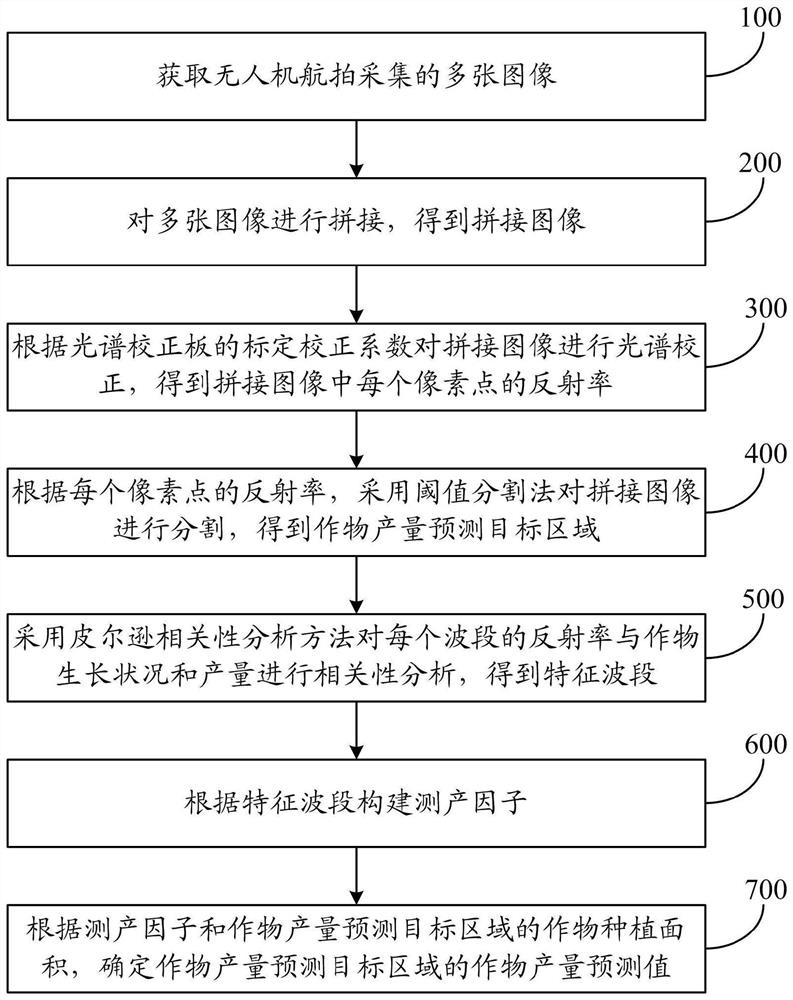

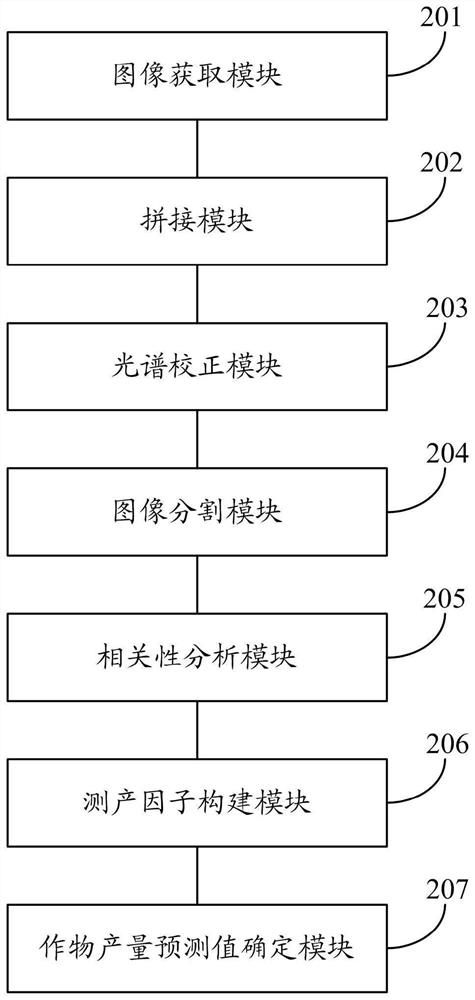

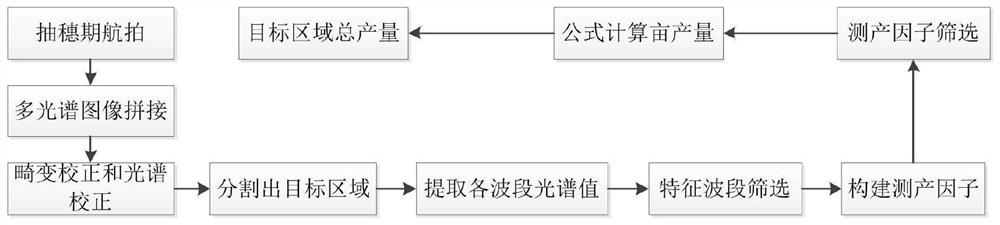

Crop yield prediction method and system based on unmanned aerial vehicle low-altitude remote sensing information

ActiveCN111815014AReduce labor intensityReduce operating costsImage enhancementImage analysisUncrewed vehicleAerial photography

The invention relates to a crop yield prediction method and system based on low-altitude remote sensing information of an unmanned aerial vehicle. The method comprises the following steps: acquiring aplurality of images acquired by aerial photography of an unmanned aerial vehicle; the unmanned aerial vehicle aerial photography adopts a multispectral camera to shoot a crop canopy to obtain reflection spectrum images of various different wave bands, and the multiple images are spliced to obtain a spliced image; performing spectral correction on the spliced image to obtain the reflectivity of each pixel point in the spliced image; segmenting the spliced image by adopting a threshold segmentation method to obtain a crop yield prediction target area; performing correlation analysis on the reflectivity of each waveband and the crop growth condition and yield by adopting a Pearson correlation analysis method to obtain a characteristic waveband; constructing a yield measurement factor according to the characteristic wave band; and determining a crop yield prediction value of the crop yield prediction target area according to the yield prediction factor and the crop planting area of the crop yield prediction target area. The crop yield prediction accuracy can be improved, and the labor intensity is reduced.

Owner:ZHEJIANG UNIV

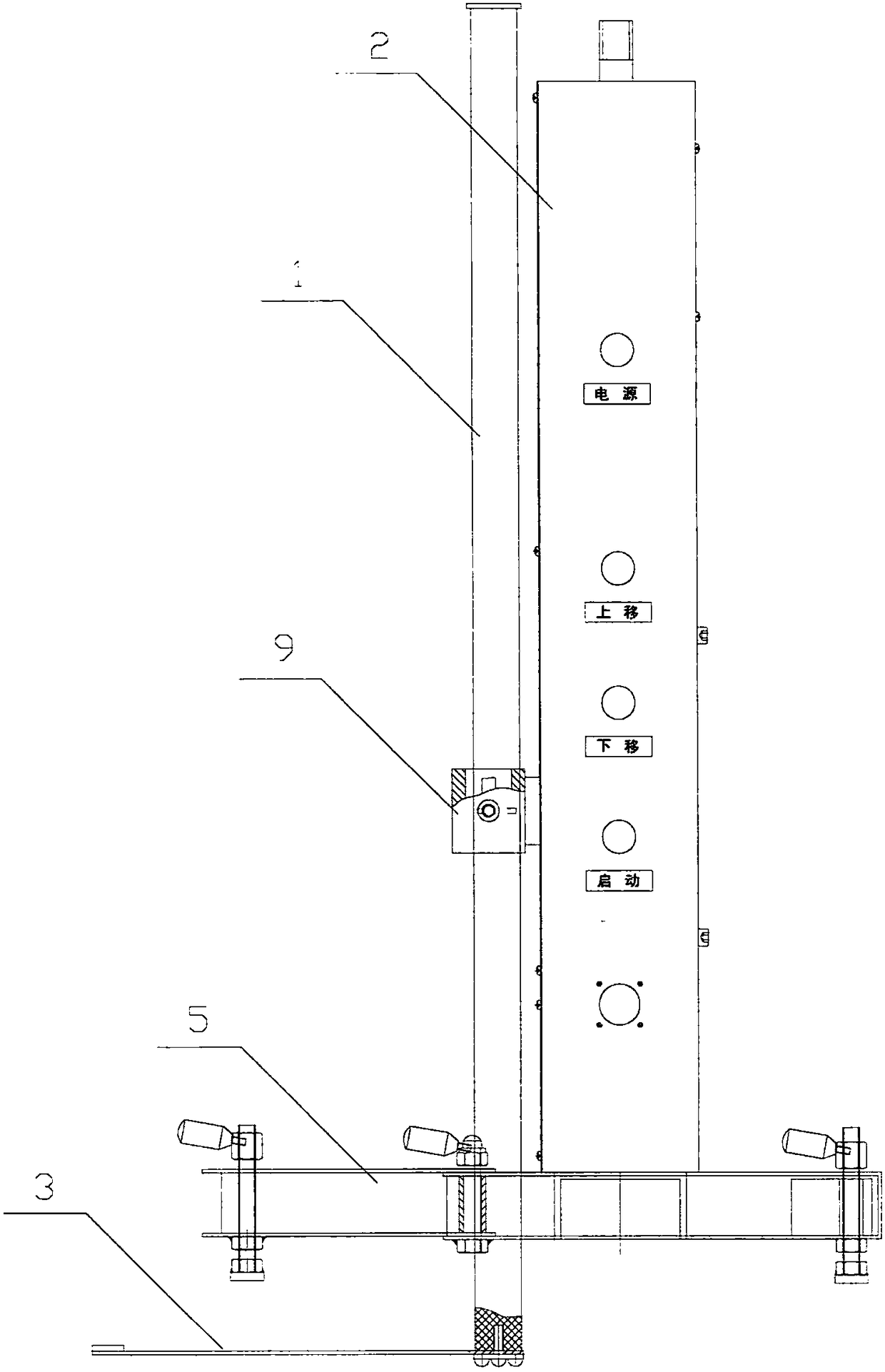

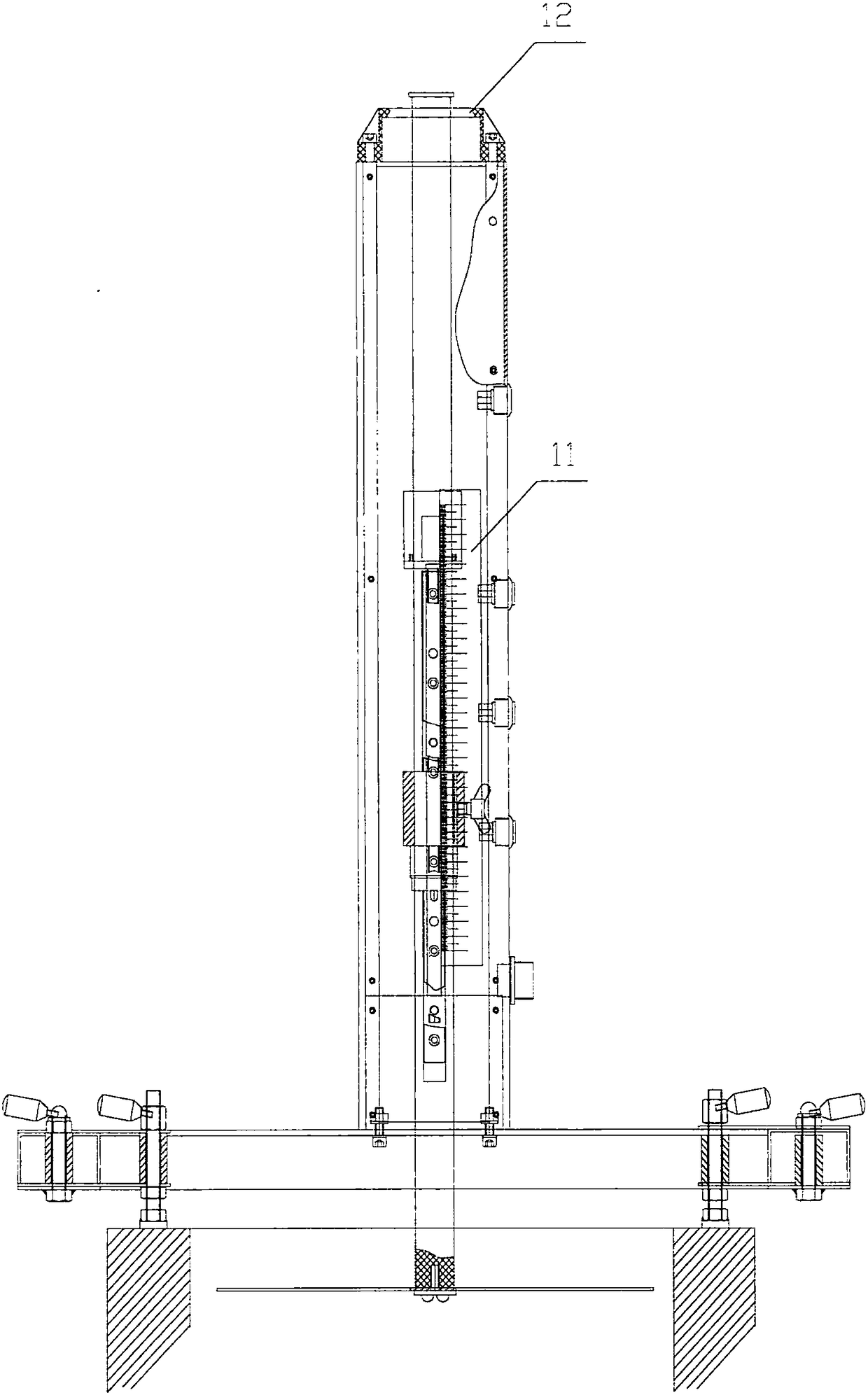

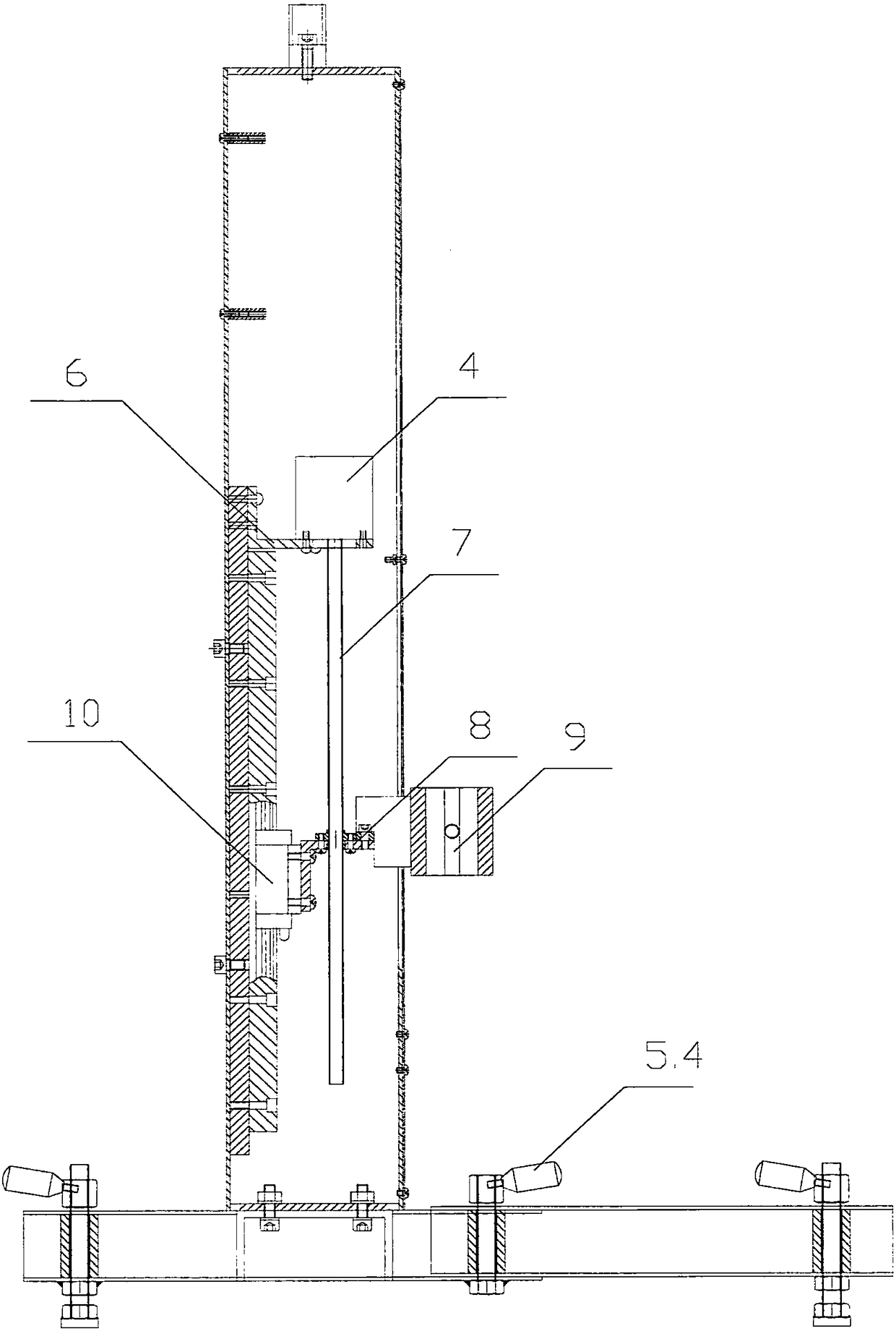

Novel automatic calibration device for eddy current liquid level meter

PendingCN108267198AGuaranteed uptimeImprove work efficiencyTesting/calibration apparatusEngineeringEddy current

The invention relates to an automatic calibration device for an eddy current liquid level meter. The automatic calibration device comprises a calibration rod, a fixed frame, a calibration plate and astepping motor, wherein the fixed frame is vertically mounted on a base and parallel to the calibration rod; the calibration plate is mounted at the bottom end of the calibration rod; the stepping motor is mounted at the upper part in the fixed frame; a vertical downward lead screw is connected onto an output end of the stepping motor; a lifting block in threaded connection is arranged on the leadscrew; a calibration rod clamp seat is connected with one side of the lifting block; the calibration rod is inserted and fixed in the calibration rod clamp seat; a scaleplate for calibration and measurement is vertically and fixedly mounted on the fixed frame. Under unified control of a liquid level secondary meter, one-key calibration as well as verification and re-check of calibration data is completed by the device, and calibration of an eddy current system is completed greatly and rapidly.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

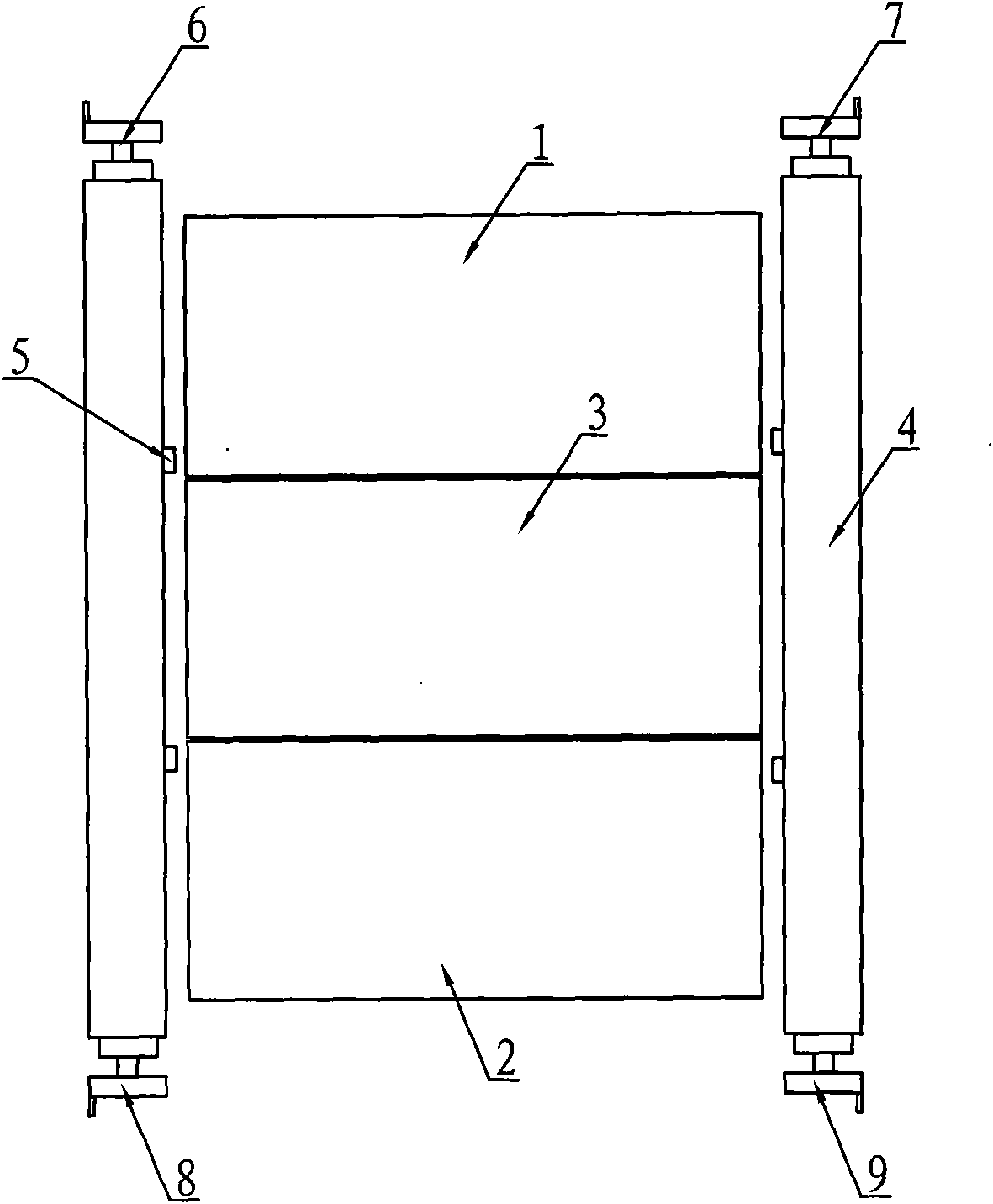

Green brick clamping device for ultrasonic detection

InactiveCN104833727APressure adjustable and controllableSame pressureMaterial analysis using sonic/ultrasonic/infrasonic wavesBrick clampEngineering

The invention discloses a green brick clamping device for ultrasonic detection. The green brick clamping device comprises a bracket, a table face, a support frame, balls, a sliding gate brick, two air cylinders and probe clamps; the table face is arranged on the bracket, a plurality of balls are arranged on the table face, the sliding gate brick is arranged on the balls, the support frame is fixedly installed at one side of the bracket, and the air cylinders are arranged right above and below the table face of the bracket of the support frame, the two air cylinders are opposite to each other, and the air cylinders are provided with the probe clamps. The green brick clamping device for the ultrasonic detection, disclosed by the invention, is convenient for detection.

Owner:武汉武钢维苏威高级陶瓷有限公司

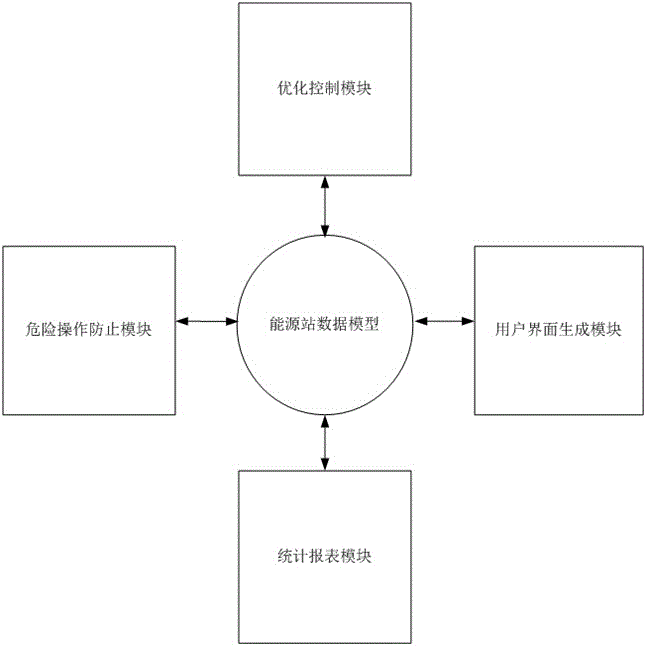

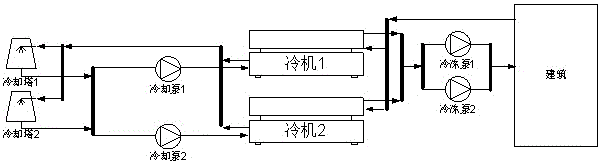

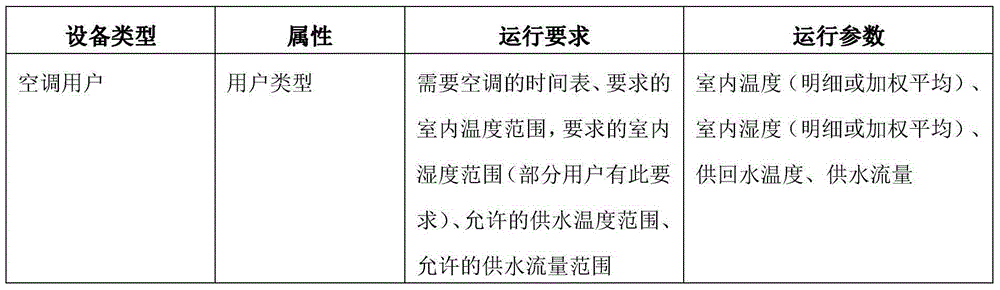

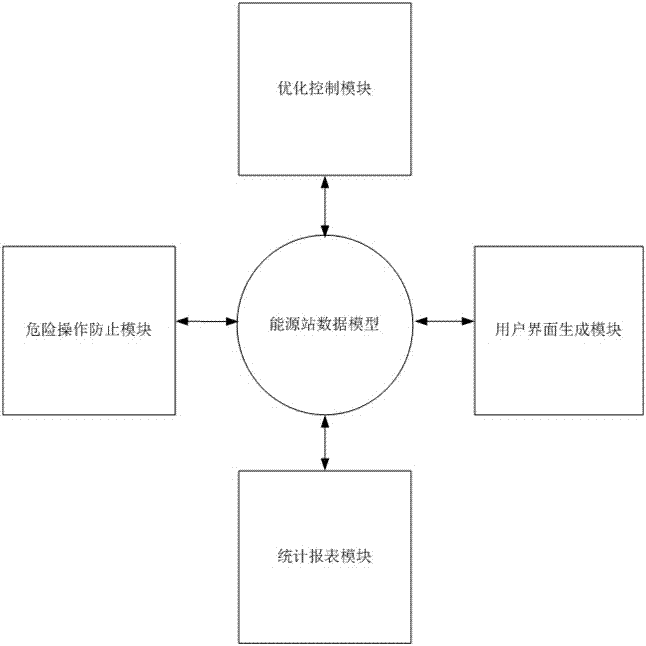

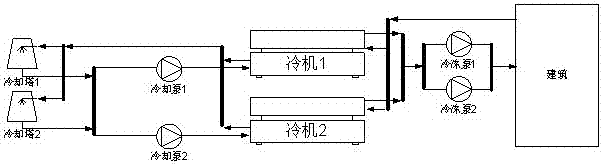

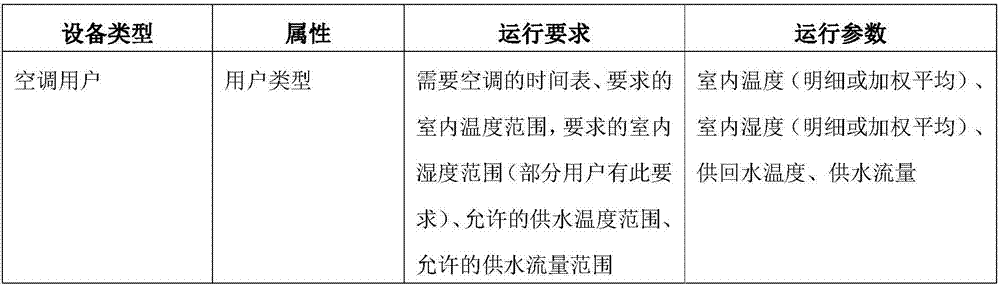

Energy station group control system configuration method

ActiveCN104898604AAvoid negligenceEliminate human influenceTotal factory controlProgramme total factory controlAdjacency relationData model

The invention provides an energy station group control system configuration method comprising the following steps: S1, establishing an energy station data model; S2, establishing an equipment adjacency relation matrix; S3, establishing a user interface generation module; S4, establishing an optimization control module; S5, establishing a dangerous operation prevention module; and S6, establishing a statistical statement module. By adopting the energy station group control system configuration method, most of the energy station group control system configuration work is completed by a computer, and manual negligence, prejudice and error are avoided. An engineer inputs a data model representing an energy station into a computer in accordance with the requirements of the invention, and the computer can use a software module provided by the invention to automatically complete optimization control, dangerous operation prevention, operation interface generation, data statistics and other work.

Owner:NANJING YOUZHU INTELLIGENT TECH

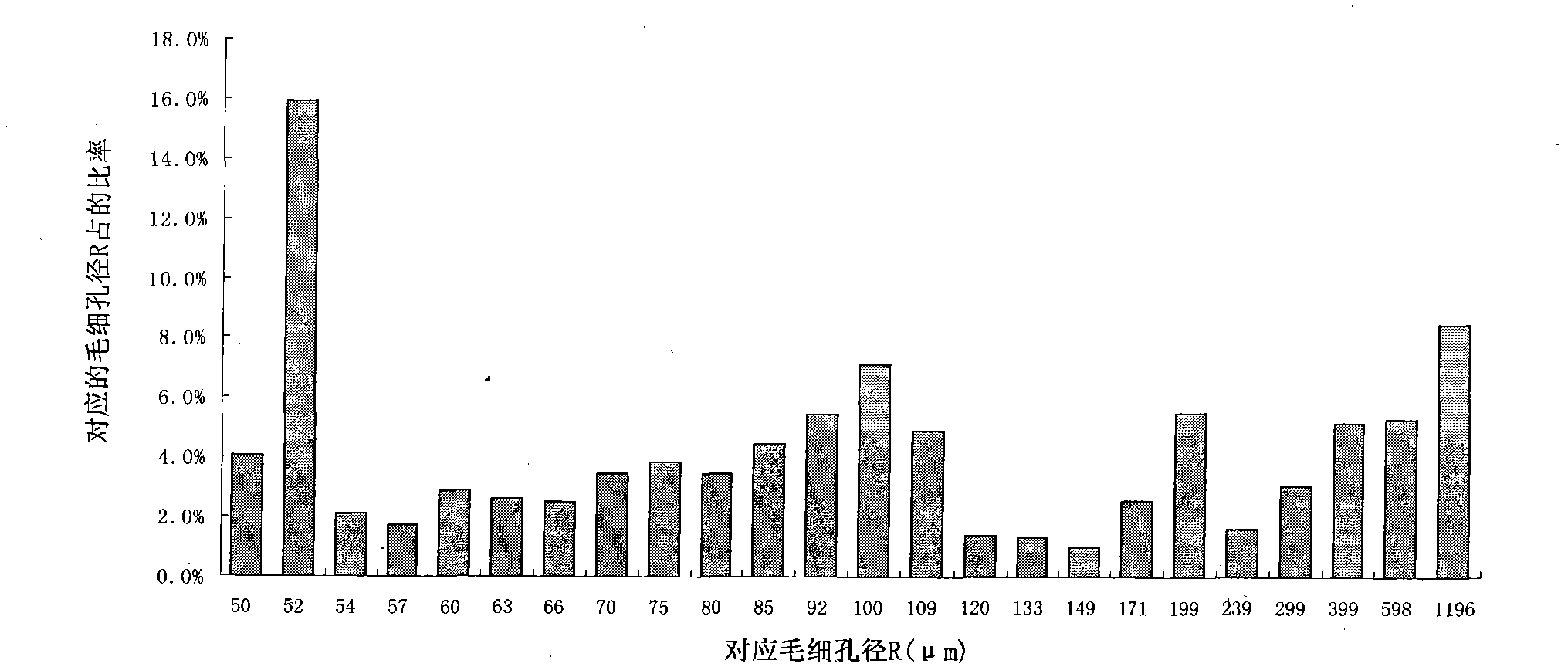

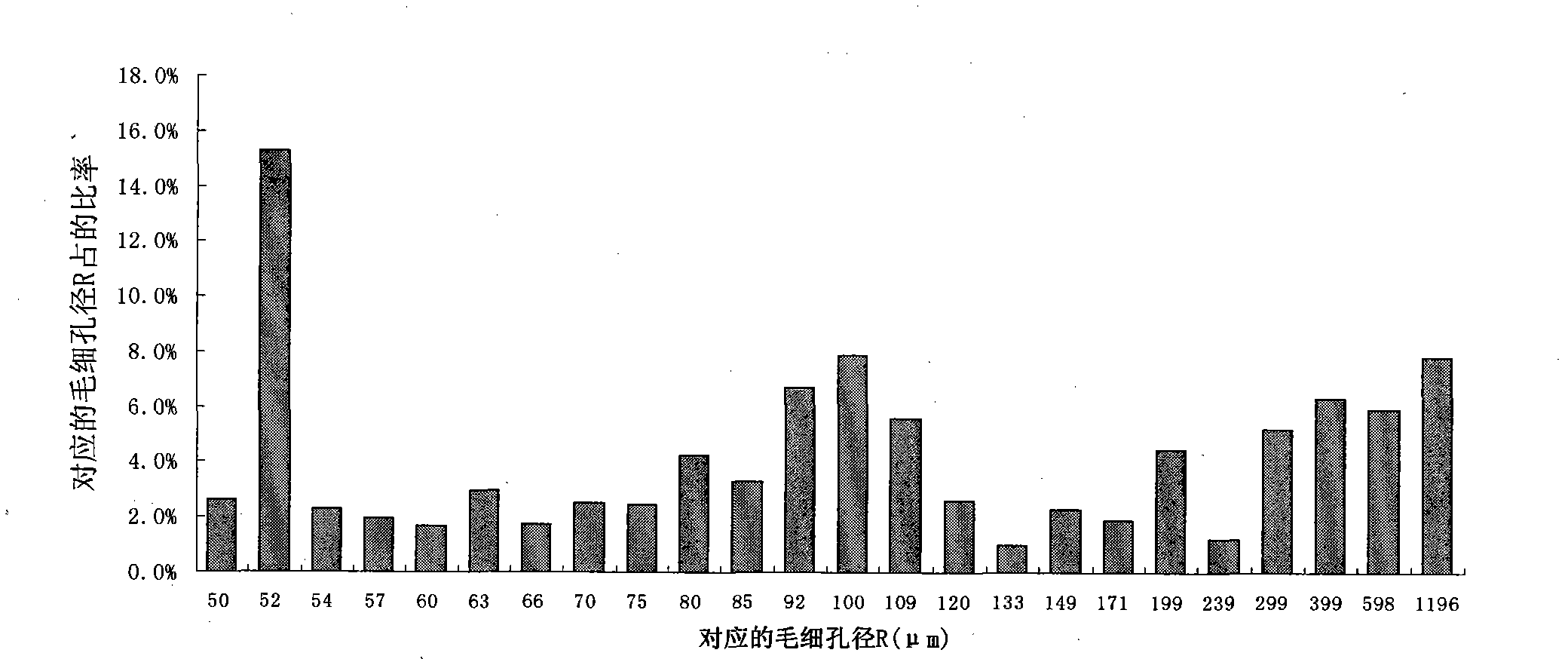

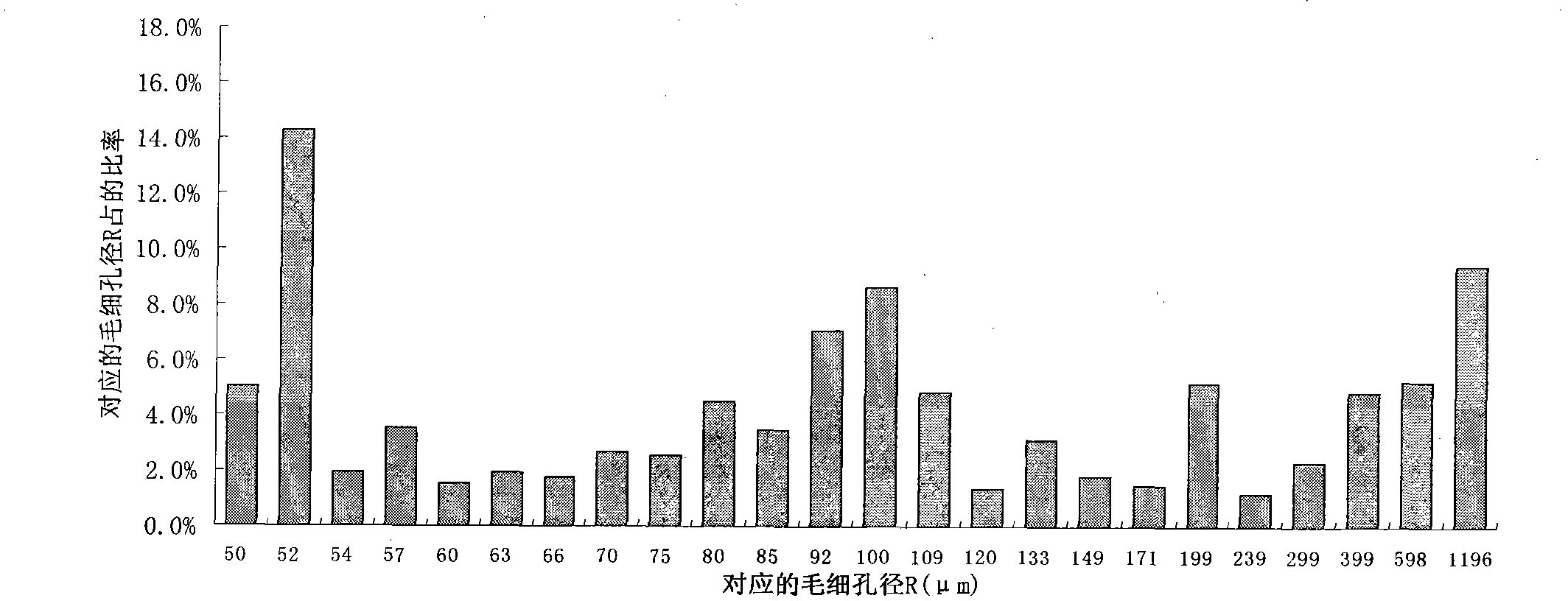

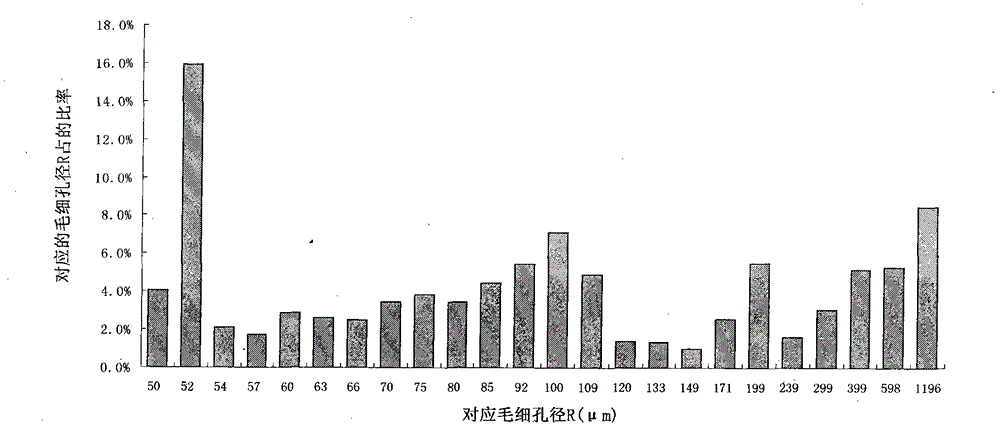

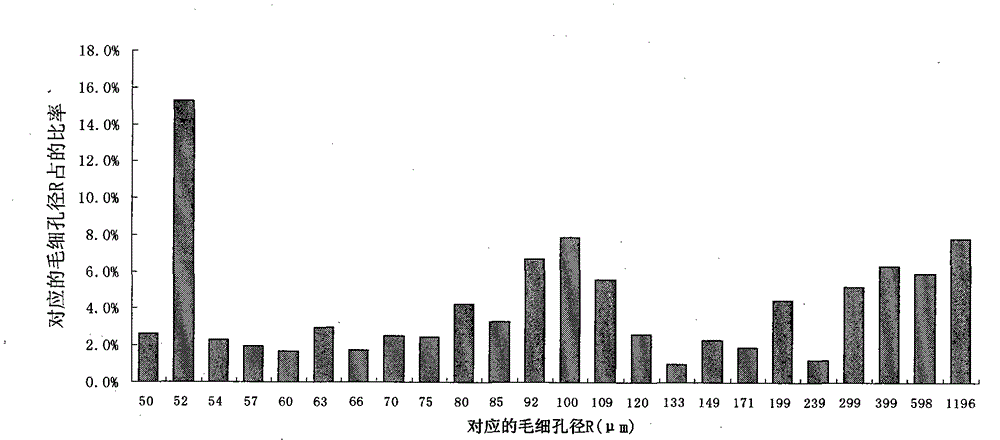

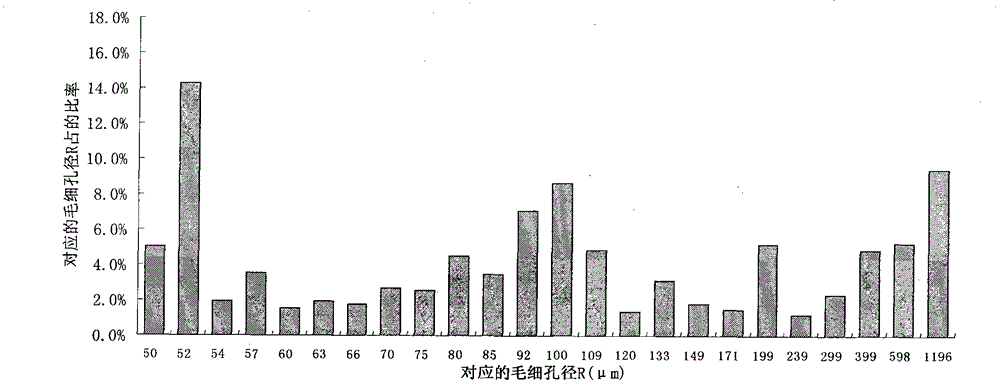

Fractional Gradient Wetting and Raffinate Combined Labeled Shearing Method for Fabric Pore Size Determination

InactiveCN102269689AEliminate data fluctuationsEliminate human influenceWeighing by removing componentPermeability/surface area analysisPhysicsEngineering

The invention discloses a fraction gradient soaking and raffinate merging indication scissoring method for fabric aperture determination, and relates to a method which belongs to the technical field of aperture dimension determination, and provides an accurate combination method aiming at a lining indication step and a fraction scissoring step in capillary aperture distribution determination of a flexible porous material. A fraction gradient soaking indication method is employed to ensure that a cloth sample maintains a same soaking state during the lining indication and cloth sample scissoring, so as to realize consistent tension force, least deformation and the most accurate lining indication. A raffinate merging method is employed to collect and weigh raffinate on a holder and a scissor together during the scissoring process, so as to reduce an liquid content weighing error. A fraction dimension correcting method is employed to correct a real weight of each scissored fraction into a standard weight, so as to eliminate an error caused by different dimensions of the scissored fractions. The three technologies are combined to substantially increase data precision and reappearance of a weight grading method for determining aperture distribution of the flexible material.

Owner:WUYI UNIV

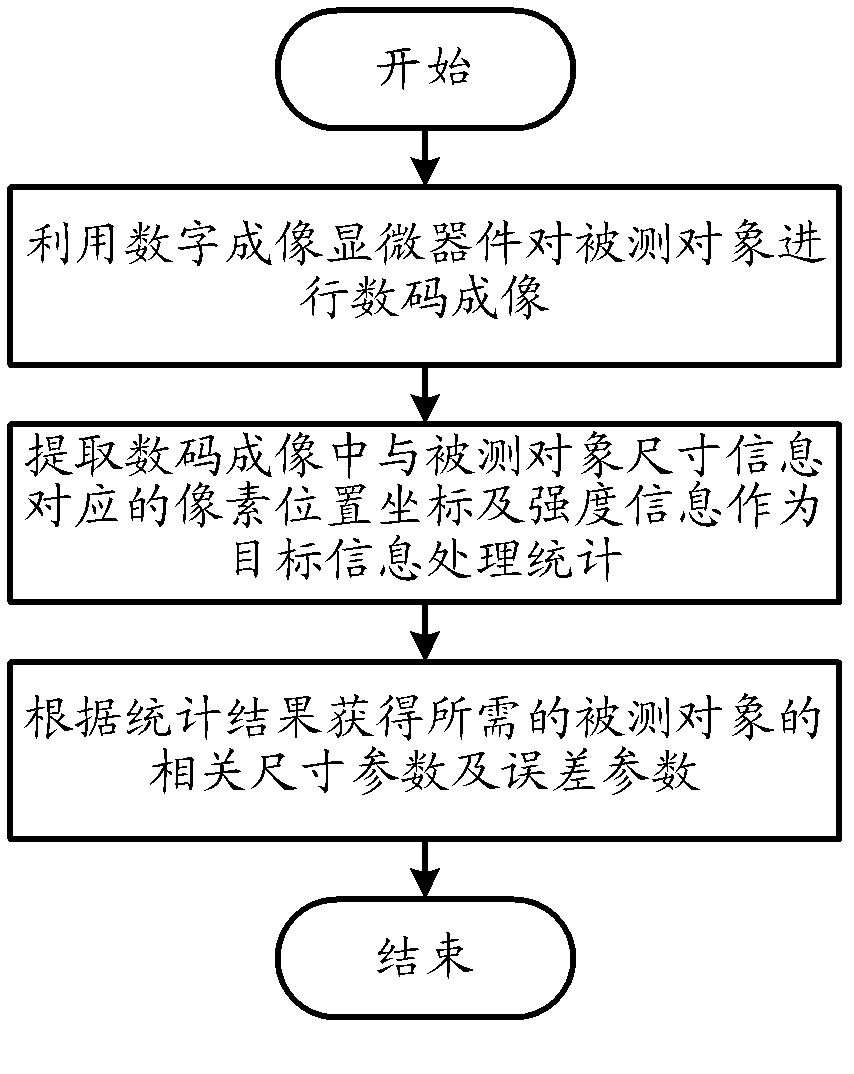

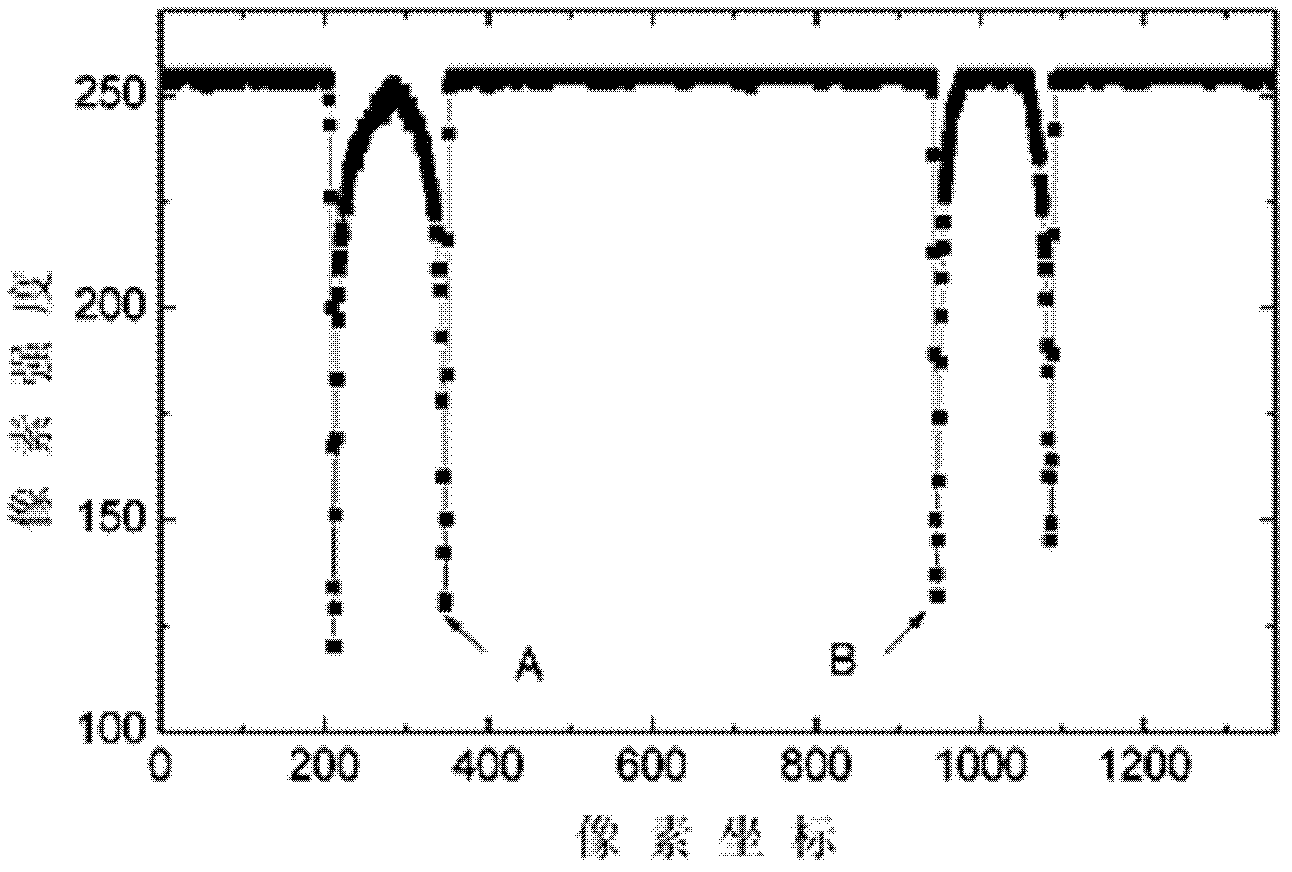

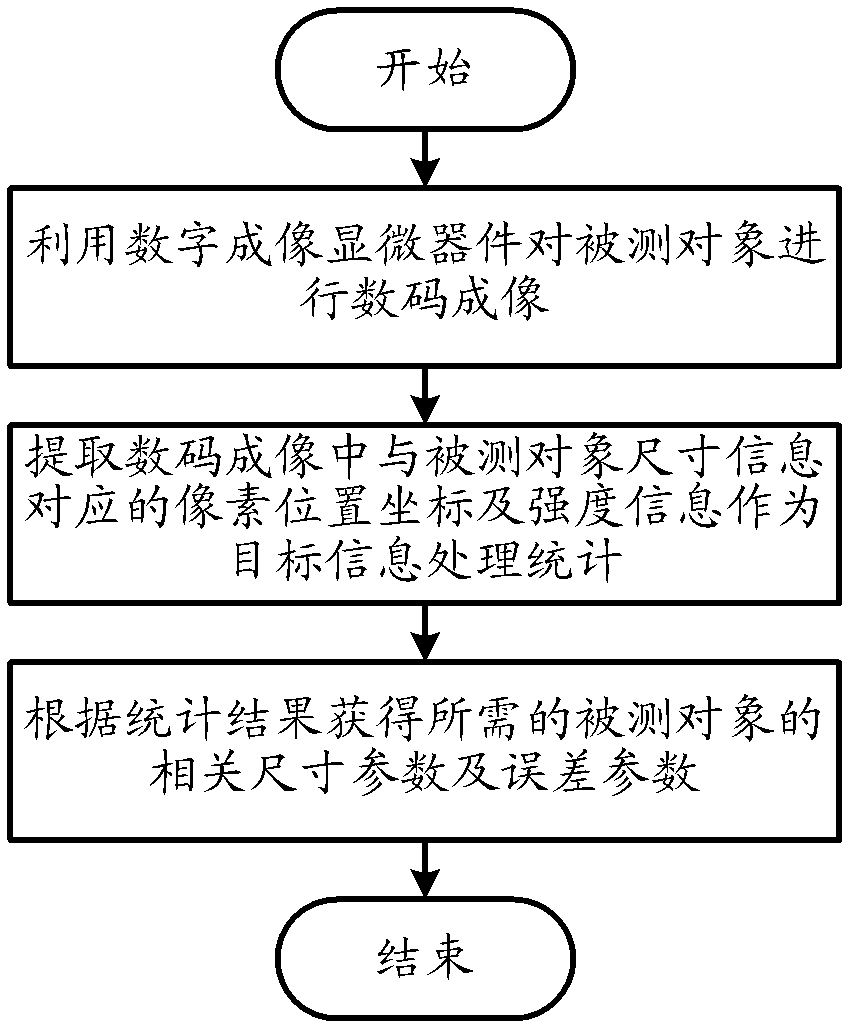

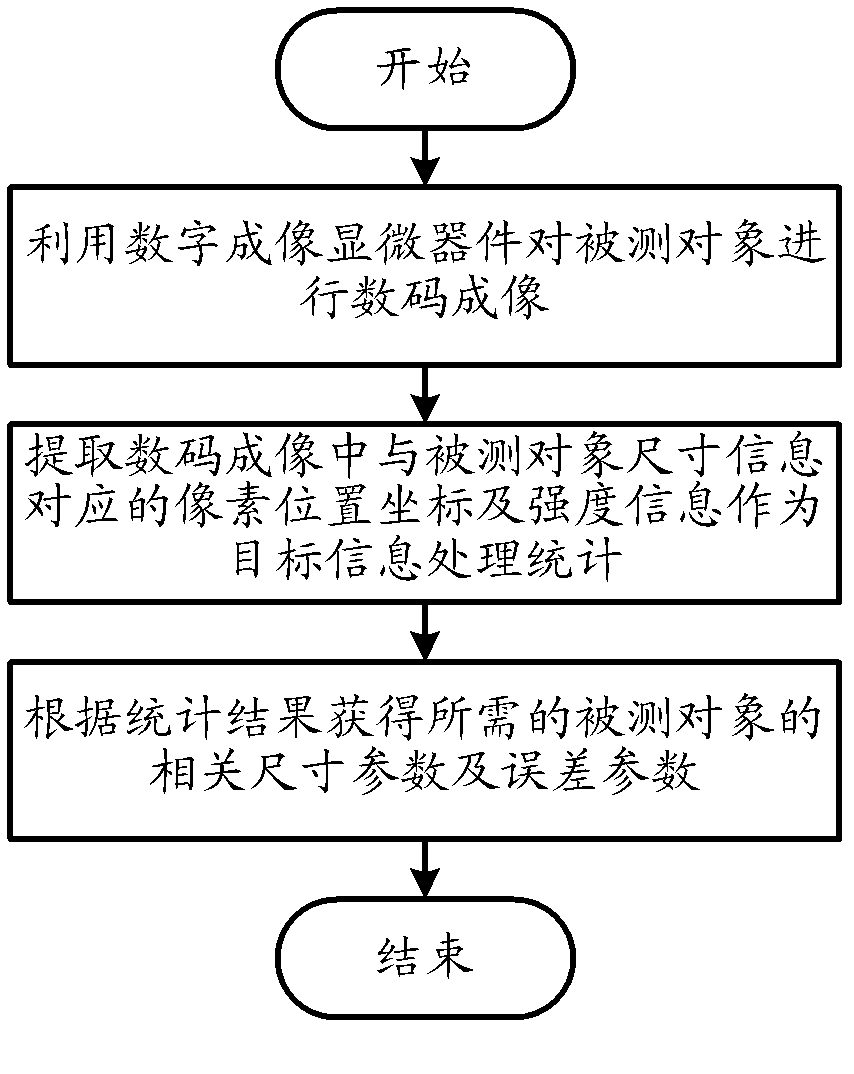

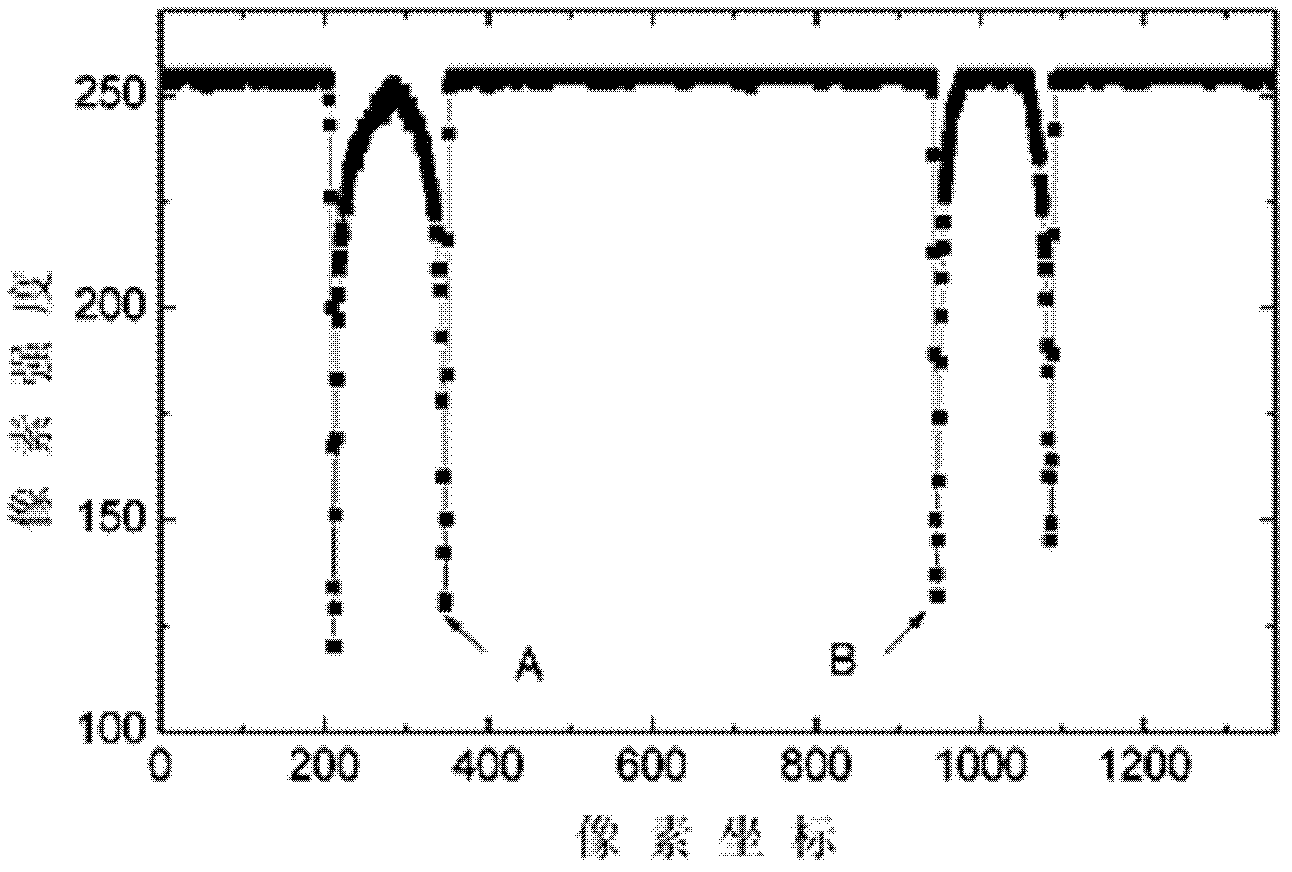

Optical detection method of ten-nanometer-magnitude sizes and errors

ActiveCN102494606AEliminate fluctuationsEliminate human influenceUsing optical meansDigital imagingComputer vision

The invention relates to an optical detection method of ten-nanometer-magnitude sizes and errors. The method comprises the following steps of: utilizing a digital imaging microscopic device to carry out digital imaging on an object to be tested; extracting a pixel position coordinate and strength information which correspond to size information of the object to be tested from the digital imaging process, and processing and counting the pixel position coordinate and the strength information as target information; and obtaining needed relative size parameters and error parameters of the object to be tested according to a counted result. According to the optical detection method of the ten-nanometer-magnitude sizes and errors, the surface appearance resolution ratio of an optical microscopic system can be obviously improved and the influences caused by artificial factors can be eliminated to the greatest extent, so that measured data is more credible and reliable.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

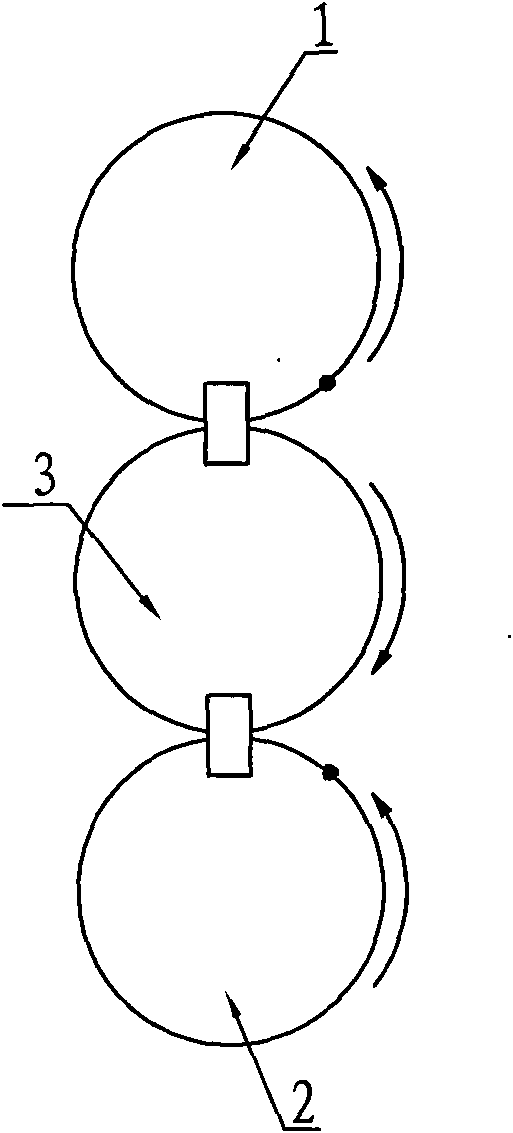

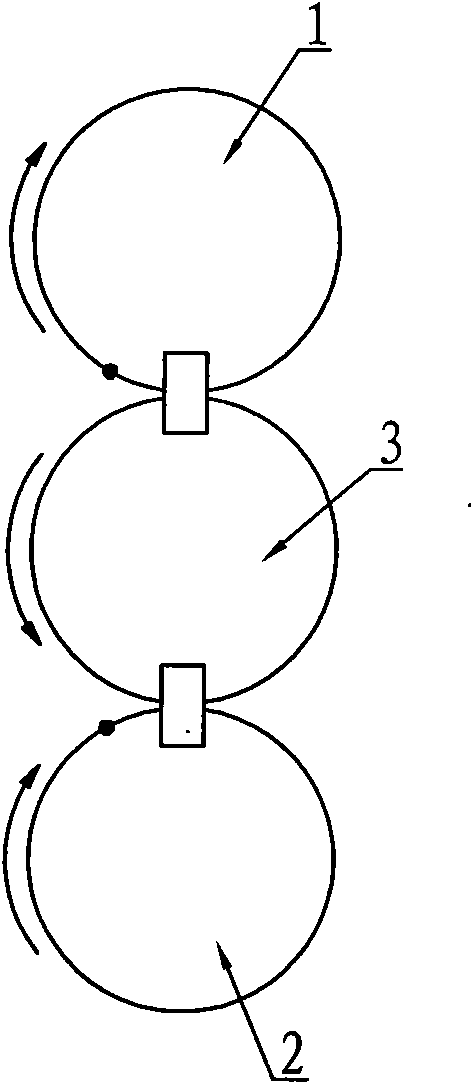

Roller spacing adjustment alarm prompting device

InactiveCN101972681ALower technical skill requirementsGuaranteed grinding qualityAlarmsGrain treatmentsSilver pasteSkill sets

The invention relates to a roller spacing adjustment alarm prompting device comprising a front roller, a rear roller, four optoelectronic switches and an alarm, wherein the left sides and the right sides of the front roller and the rear roller are respectively provided with one optoelectronic switch. When the front roller and the rear roller are at the best position, the probing light beams of the optoelectronic switches are respectively aligned to different buses of the same side of the upper circular arc of the corresponding roller, and the four optoelectronic switches are connected with the alarm after being connected in parallel. An operator can rapidly and accurately adjust the front roller and the rear roller to the best grinding positions according to the prompt of the alarm only by respectively rotating corresponding hand wheels. The invention not only is convenient and rapid to operate but also has good repeatability, reduces the technical skill demand on operation staffs, can more stably ensure the silver paste grinding quality and eliminates the human influencing factor.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

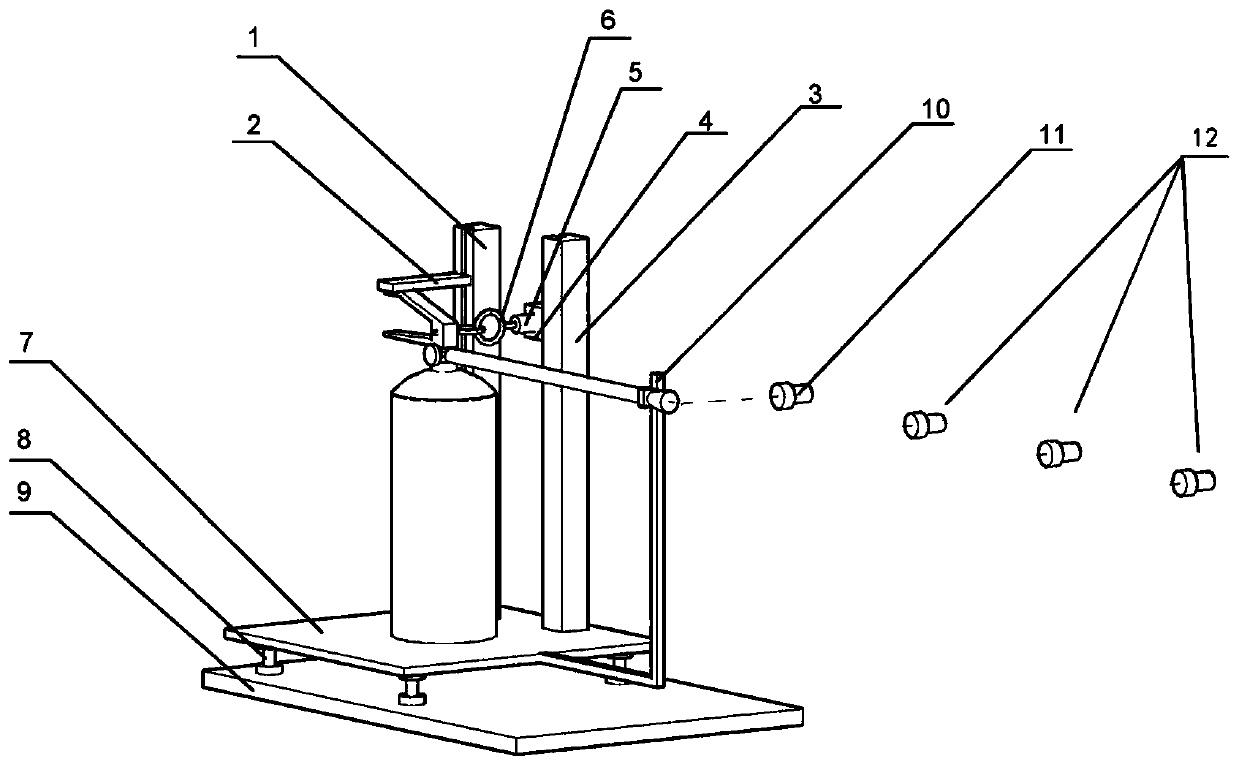

Fire extinguisher injection performance test device and fire extinguisher injection performance testing method

PendingCN111257027AEliminate human influenceReduce labor costsStructural/machines measurementAutomotive engineeringEnvironmental geology

The invention relates to the technical field of fire extinguisher product detection, in particular to a fire extinguisher injection performance test device and a fire extinguisher injection performance testing method. The fire extinguisher injection performance test device comprises a base, first dust concentration sensors, a data acquisition and analysis terminal and a weighing sensor arranged onthe base, the number of the first dust concentration sensors is multiple, the multiple first dust concentration sensors are arranged at intervals in the fire extinguishing agent spraying direction ofa fire extinguisher for testing, and the data acquisition and analysis terminal is connected with the first dust concentration sensors and the weighing sensor. The fire extinguisher injection performance test device provided by the invention can automatically measure the injection distance of the fire extinguisher, and eliminates the influence of manual operation in the test process; the fire extinguisher injection performance test method provided by the invention can save the labor cost.

Owner:北京建筑材料检验研究院股份有限公司

Optical detection method of ten-nanometer-magnitude sizes and errors

ActiveCN102494606BEliminate fluctuationsEliminate human influenceUsing optical meansDigital imagingComputer vision

The invention relates to an optical detection method of ten-nanometer-magnitude sizes and errors. The method comprises the following steps of: utilizing a digital imaging microscopic device to carry out digital imaging on an object to be tested; extracting a pixel position coordinate and strength information which correspond to size information of the object to be tested from the digital imaging process, and processing and counting the pixel position coordinate and the strength information as target information; and obtaining needed relative size parameters and error parameters of the object to be tested according to a counted result. According to the optical detection method of the ten-nanometer-magnitude sizes and errors, the surface appearance resolution ratio of an optical microscopic system can be obviously improved and the influences caused by artificial factors can be eliminated to the greatest extent, so that measured data is more credible and reliable.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Hard disk magnetic head front control soft line board v-l-u bending three-in-one device

ActiveCN103093762BGuaranteed stabilityEliminate human influenceRecord information storageMagnetic recordingFlexible circuitsEngineering

Owner:KERUI AUTOMATION TECH SUZHOU

Fraction gradient soaking and raffinate merging indication scissoring method for fabric aperture determination

InactiveCN102269689BEliminate human influenceSolve technical bottlenecksWeighing by removing componentPermeability/surface area analysisRaffinateLiquid content

The invention discloses a fraction gradient soaking and raffinate merging indication scissoring method for fabric aperture determination, and relates to a method which belongs to the technical field of aperture dimension determination, and provides an accurate combination method aiming at a lining indication step and a fraction scissoring step in capillary aperture distribution determination of a flexible porous material. A fraction gradient soaking indication method is employed to ensure that a cloth sample maintains a same soaking state during the lining indication and cloth sample scissoring, so as to realize consistent tension force, least deformation and the most accurate lining indication. A raffinate merging method is employed to collect and weigh raffinate on a holder and a scissor together during the scissoring process, so as to reduce an liquid content weighing error. A fraction dimension correcting method is employed to correct a real weight of each scissored fraction into a standard weight, so as to eliminate an error caused by different dimensions of the scissored fractions. The three technologies are combined to substantially increase data precision and reappearance of a weight grading method for determining aperture distribution of the flexible material.

Owner:WUYI UNIV

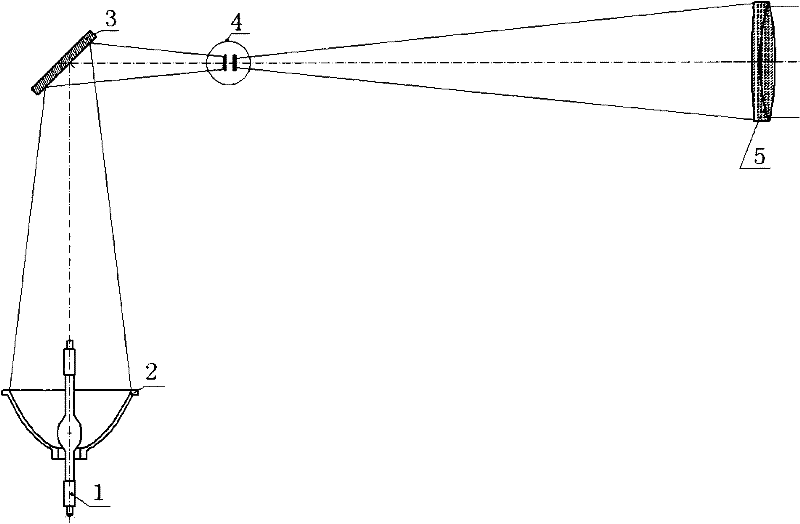

High-collimation solar simulator optical system with auto-collimation aiming system

InactiveCN101907773BAccurate zero calibrationEliminate human influenceIndividual semiconductor device testingFixed installationEyepiecePlane mirror

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Method and device for judging release of traffic incident

ActiveCN102622883BImprove accuracyEliminate human influenceDetection of traffic movementTraffic systemReal-time computing

Owner:CENNAVI TECH

Configuration method of energy station group control system

ActiveCN104898604BImprove availabilityAvoid negligenceTotal factory controlProgramme total factory controlSimulationEngineering

The invention provides an energy station group control system configuration method comprising the following steps: S1, establishing an energy station data model; S2, establishing an equipment adjacency relation matrix; S3, establishing a user interface generation module; S4, establishing an optimization control module; S5, establishing a dangerous operation prevention module; and S6, establishing a statistical statement module. By adopting the energy station group control system configuration method, most of the energy station group control system configuration work is completed by a computer, and manual negligence, prejudice and error are avoided. An engineer inputs a data model representing an energy station into a computer in accordance with the requirements of the invention, and the computer can use a software module provided by the invention to automatically complete optimization control, dangerous operation prevention, operation interface generation, data statistics and other work.

Owner:NANJING YOUZHU INTELLIGENT TECH

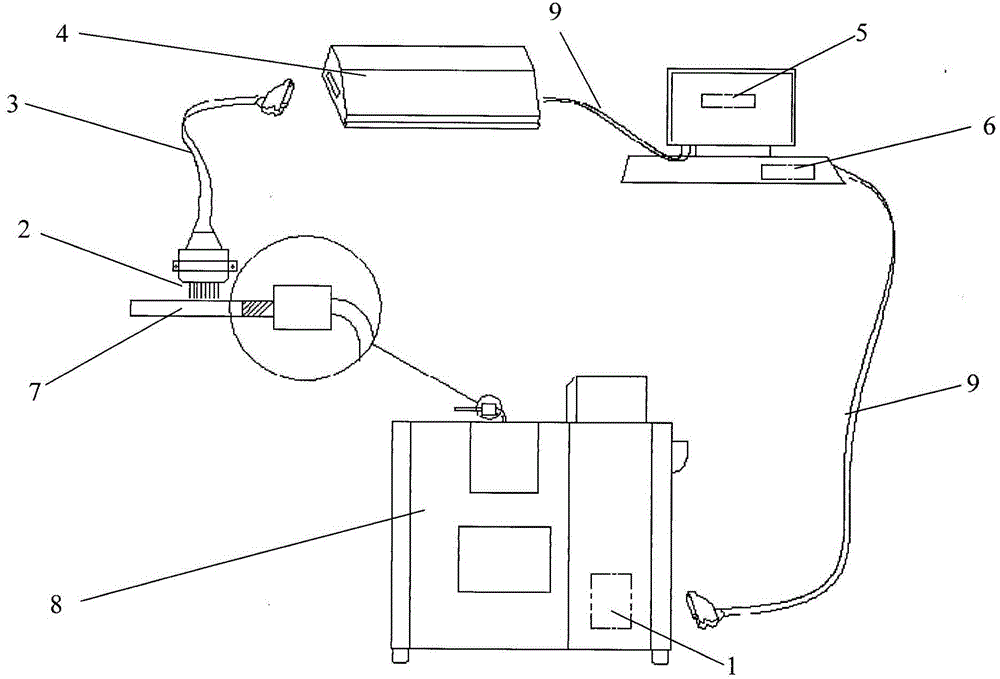

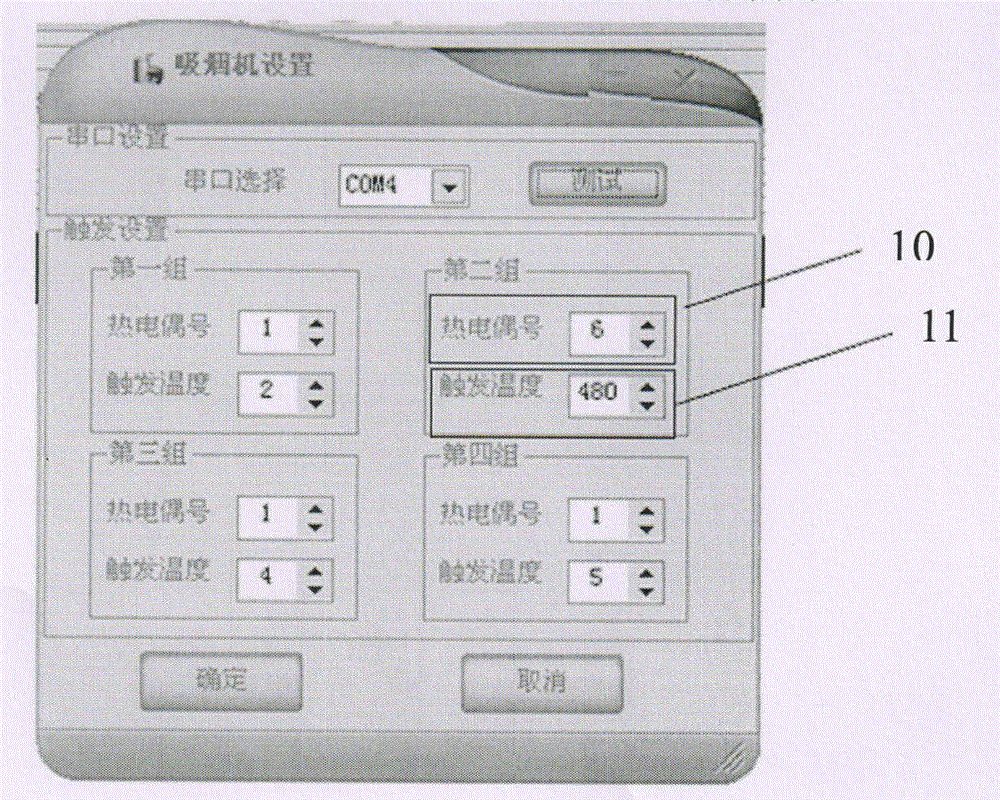

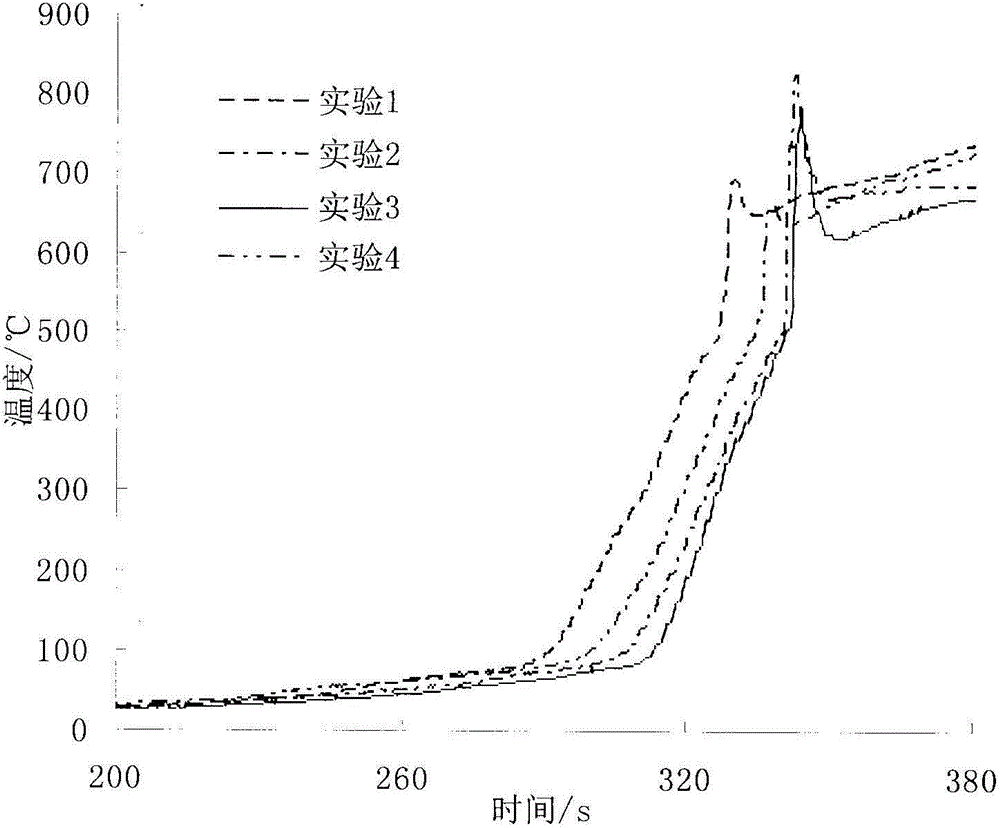

Smoking machine control method based on temperature sensing

ActiveCN103116291BEliminate human influenceImprove accuracyProgramme control in sequence/logic controllersAutomatic controlMachine control

Disclosed is a smoking machine control method based on temperature sensing. The control method is realized by related hardware facilities and a control path. The related hardware facilities comprises a triggering module added to a smoking machine, a temperature sensor, a temperature compensating wire, a temperature collecting input module, upper computer signal processing software, an upper computer and a smoking machine communication module which are sequentially connected. The control path includes: when a cigarette is lighted and burns continuously and statically, a digital temperate collecting system starts to collect temperature data during static burning of the cigarette continuously, when temperature, detected by the temperature sensor, at a certain point reaches at the set temperature, the upper computer signal processing software transmits an instruction to the upper computer and the smoking machine communication module, the instruction is transmitted to the triggering module added to the smoking machine, and the smoking machine is triggered to perform a cigarette smoking mode. Triggering automatic control is achieved by the method, human influence caused by manually starting the smoking machine is eliminated, and accuracy and repeatability of related detection are improved.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +2

led bulb lamp welding system

ActiveCN105478949BGuaranteed cooling effectRealize automatic weldingMetal working apparatusSoldering auxillary devicesEngineeringWelding

The invention discloses an LED bulb lamp welding system which comprises a rack. A rotary disc mechanism is arranged on the rack. The rotary disc mechanism comprises a disc and a rotary disc motor driving the disc to rotate. A plurality of material positions are arranged on the disc in the circumferential direction, and rotating clamping head mechanisms used for fixing bulb lamps are arranged on the material positions respectively. The outer side of the disc is provided with a side face welding mechanism, a top welding mechanism, a rosin removing mechanism and a discharging mechanism in sequence. The rotary disc motor drives the disc to rotate. The rotating clamping head mechanisms are used for clamping the LED bulb lamps to be welded. The feeding mechanism conducts feeding. The side face welding mechanism is used for welding the side faces of the LED bulb lamps. The top welding mechanism is used for welding the tops of the LED bulb lamps. The rosin removing mechanism is used for removing rosin on the tops of the LED bulb lamps. The discharging mechanism is used for performing discharging after rosin is removed, and automatic welding and rosin removing of the LED bulb lamps are achieved.

Owner:SUZHOU JINGSHUO AUTOMATION EQUIP CO LTD

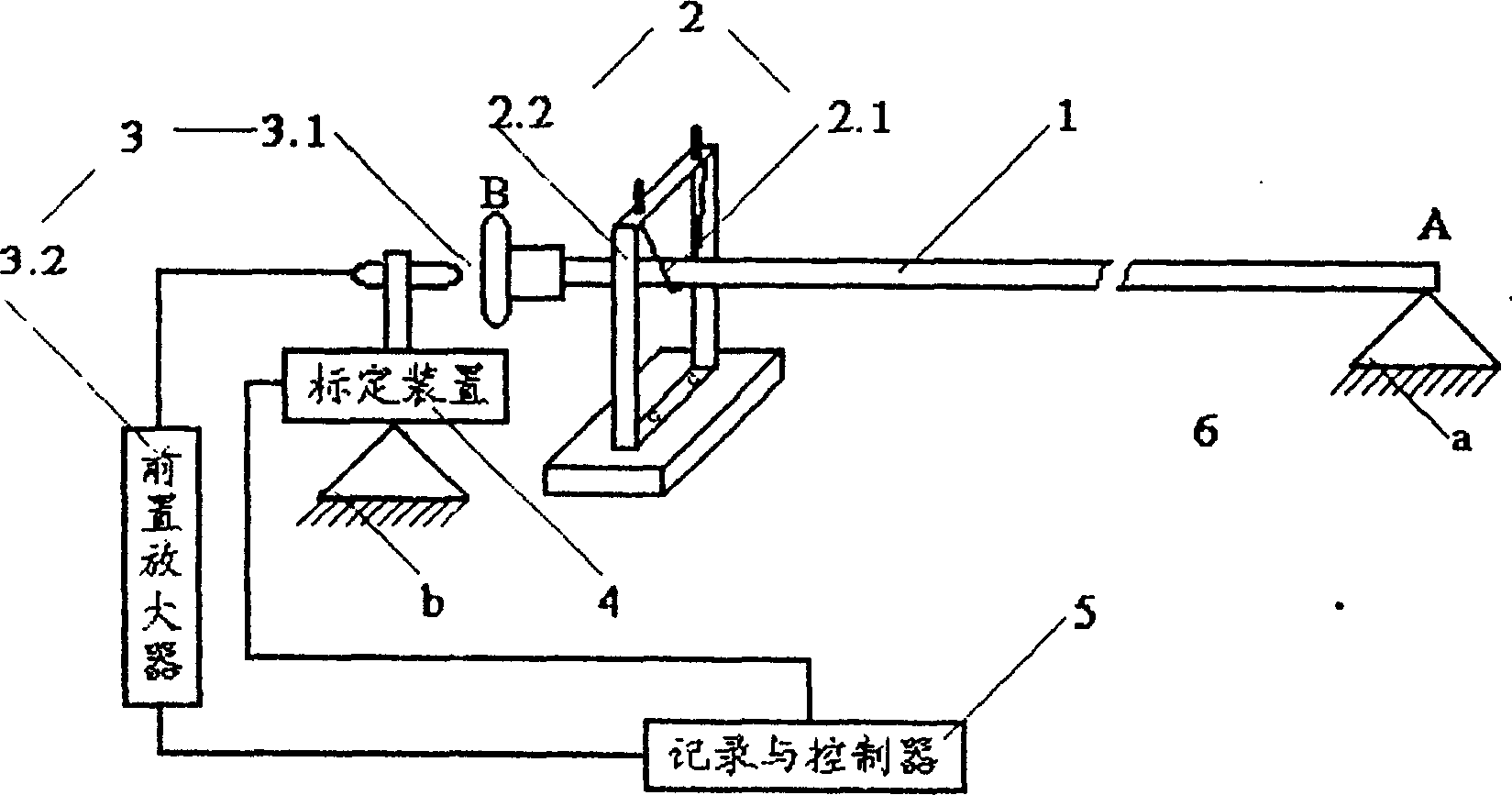

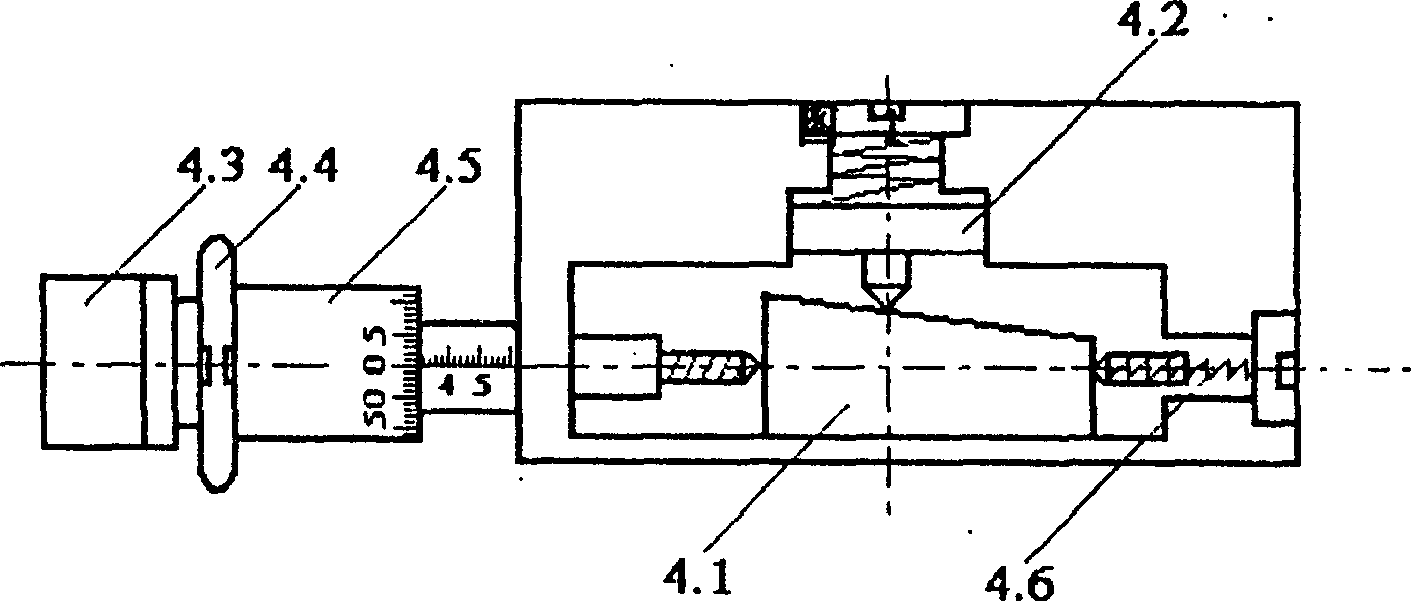

Short-base line telescoping instrument

InactiveCN1128372CHigh sensitivityImprove long-term stabilitySeismic signal receiversEngineeringBase line

The present invention discloses a short-baseline extension instrument, relating to an observation technology of geoscience, specially applicable to observation of concrete strain solid tide. In order to solve the problems of that baseline is long and easy to burst and mercury is easy to leak from mercury box which are being in existent technology said invention uses indium steel rod as baseline and said indium steel rod is vertically and freely hung, and uses electric vortex sensor as senson, and adopts the precision ultramicro-displacement scaling platform, so that it not only solves said problems, but also its sensitivity can be up to 10 to the minus eleventh power order, and its automation extent is high.

Owner:INST OF EARTHQUAKE CHINA EARTHQUAKE ADMINISTRATION

Fuse porcelain bottle forming production line and process

PendingCN114474333AImprove molding qualityEliminate setup errorsCeramic shaping plantsAuxillary shaping apparatusProduction linePunching

The fuse porcelain bottle forming production line comprises a mounting bottom plate, a rotary workbench, a first punching head, a second punching head, a pressing air cylinder and a pressing block, a power box is arranged on one side of the top of the mounting bottom plate, and a station motor is fixedly mounted at the bottom end of the interior of the power box. Through mutual cooperation of a second punching head and a first punching head, a mud blank is fixed, then forming machining of the mud blank is completed in sequence along with a rotary workbench, clamping errors occurring in production are eliminated, the forming quality of the mud blank is improved, through mutual cooperation of a punching motor, a first grooving air cylinder and a second grooving air cylinder, the machining efficiency is improved, and the machining efficiency is improved. According to the porcelain bottle punching and grooving device, the punching and grooving process is automatically completed without depending on the operation experience of workers, so that the man-made influence in porcelain bottle machining is eliminated, meanwhile, the production efficiency is improved, the arranged pressing air cylinder, the pressing block and the flushing pipe are used for replacing manual work to flush and clean a sponge mat, and therefore the labor intensity of the workers is reduced.

Owner:醴陵市精工瓷业有限公司

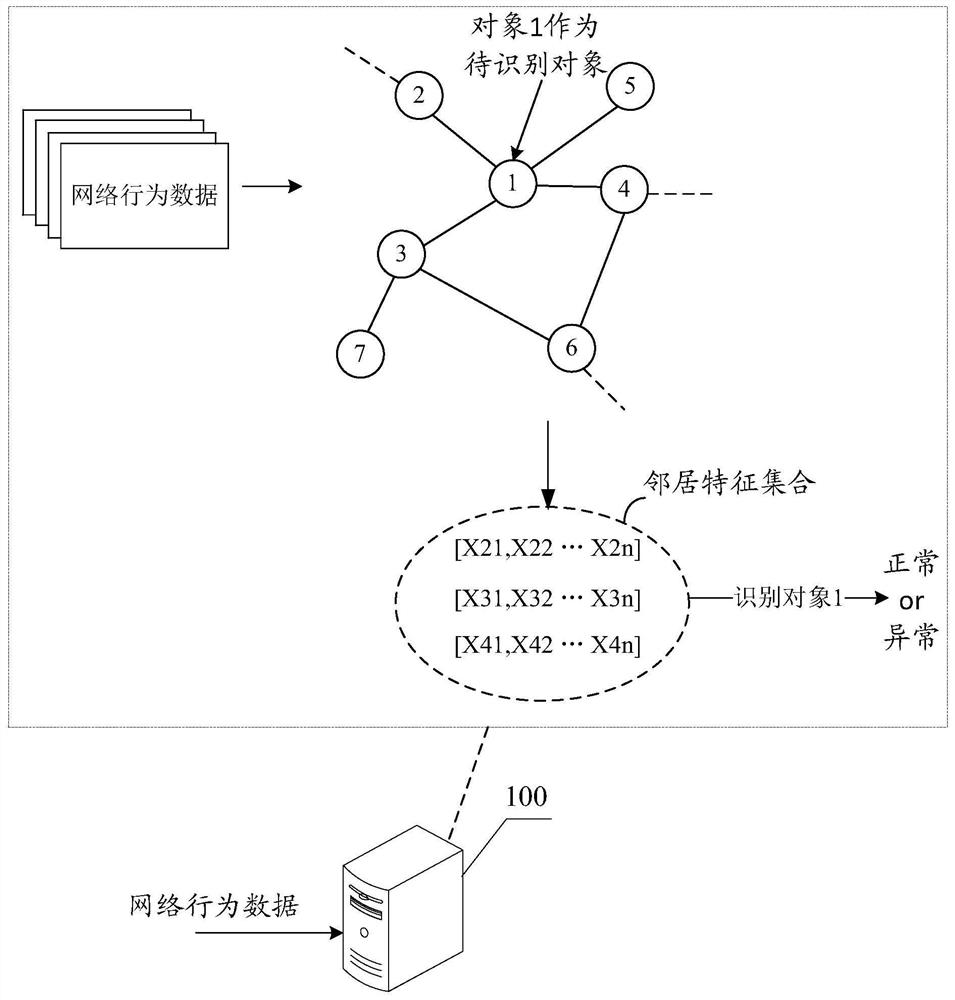

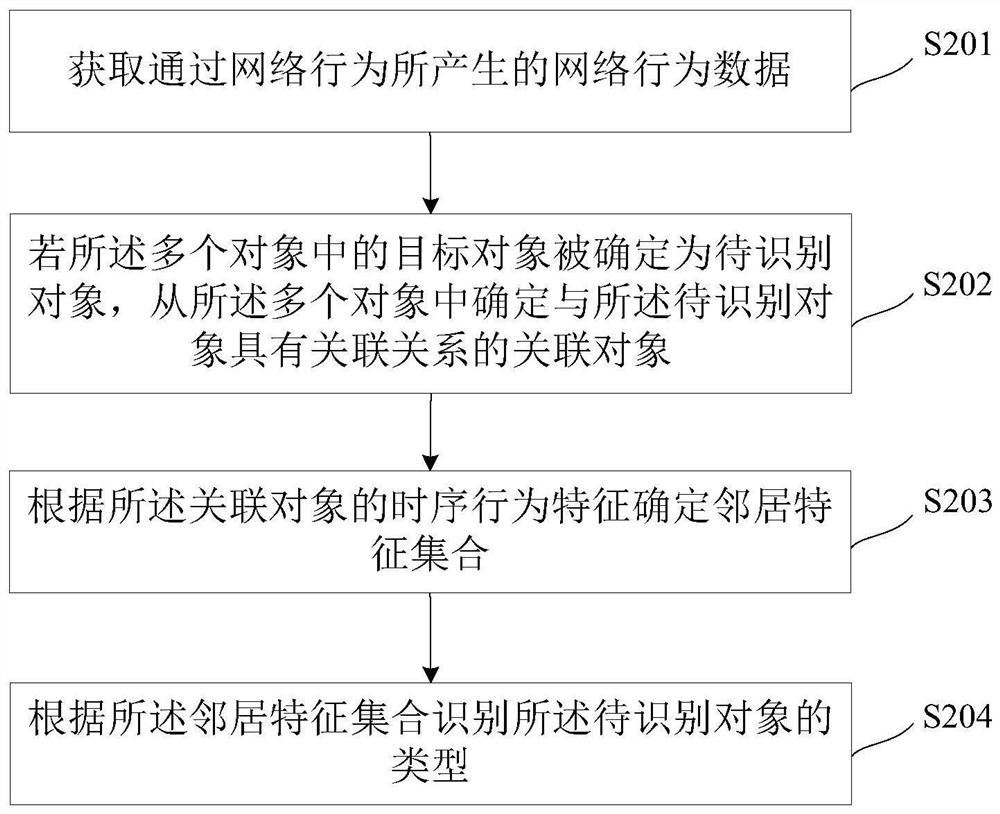

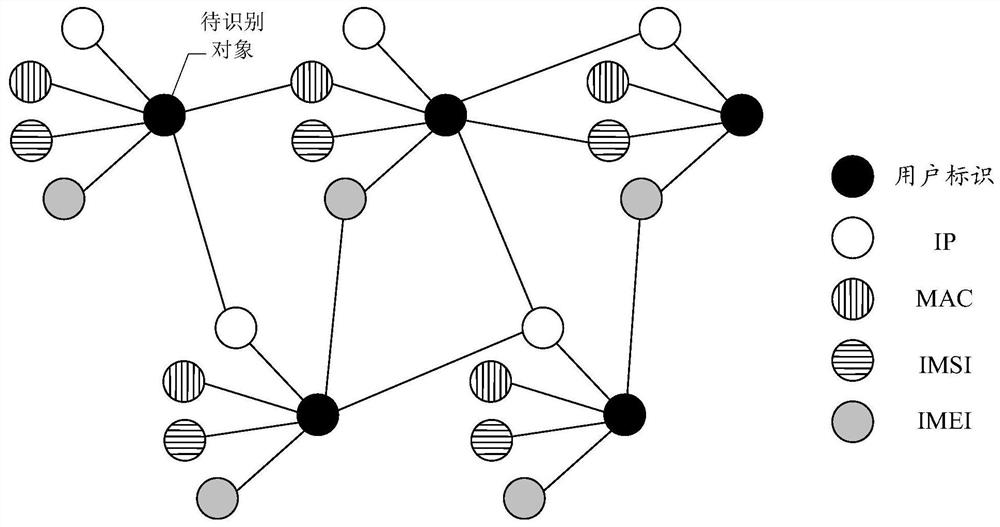

A kind of object recognition method and related device based on artificial intelligence

ActiveCN110995810BImprove feature consistencyImprove generalizationTransmissionNeural learning methodsFeature setNetwork behavior

The embodiment of the present application discloses an artificial intelligence-based object recognition method and related devices. By acquiring network behavior data, multiple objects that implement network behaviors and the implemented network behaviors can be determined. For the types of objects to be identified, The associated object can be determined based on the association established between the network behavior and the object to be identified, and the time series behavior characteristics of the associated object carry a large amount of effective content related to the type of the object to be identified, which can provide a basis for identifying the object to be identified. Moreover, for any object to be identified, the constructed neighbor feature set includes a specified number of time-series behavior features. Through this unified construction method, a neighbor feature set with high feature consistency is determined. This unified construction method can provide It has good generalizability, can be effectively applied to different network behavior data, has stable recognition accuracy, improves computing performance and computing efficiency, and excludes human influence in object recognition.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Machine for automatically testing and sorting code devices

InactiveCN101474618BSolve the problem of difficult product quality inspectionImprove consistencySortingInstrumentsDisplay deviceEngineering

The invention relates to an automatic testing and sorting machine of encoders, belonging to the field of encoder quality detecting device. The quality detection of existing encoders is carried out manually. The invention comprises a bench panel, a display, an operation panel and a movable mold core; the bench panel is designed with a mold entering device, a testing device, a sorting device and a mold stripping device in sequence; the chassis is internally designed with a principle shaft rotating mechanism and a test control circuit board; the testing device is connected with the principle shaft rotating mechanism; the display, the operation panel, the mold entering device, the testing device, the sorting device, the mold stripping device and the principle shaft rotating mechanism are respectively connected with the test control circuit board; the mold entering device comprises a mold pushing cylinder, a mold core baffle, a conveyer belt and a motor; the testing device comprises upper and lower probe cylinders and a probe box; the sorting device comprises a reject gate component, a splitting mold cylinder A, a splitting mold cylinder B, a splitting mold draw plate A, a splitting mold draw plate B, a stuck material sensor and a reject gate driver. The automatic testing and sorting machine can carry out automatic test on the encoders and sort the unqualified products out.

Owner:SOUNDWELL ELECTRONICS PROD GUANGDONG

A flight plan data processing method and device

InactiveCN104463491BLearn about usageImprove allocation efficiencyFlight plan managementResourcesProgram planningComputerized system

The embodiment of the invention discloses a flight plan data processing method and device. A system acquires flight data of a flight plan in jurisdiction airspace, the system receives an application for undetermined figure flight operation, and the system carries out corresponding aerospace deployment on the application for the undetermined figure flight operation according to the deployment rule, the flight data of the flight plan in the jurisdiction airspace, the flight data of the undetermined figure flight operation and the data feature of the undetermined figure flight operation. Therefore, the system can comprehensively know the use condition of the jurisdiction airspace by acquiring the flight data of the flight plan in the jurisdiction airspace, when the application for any undetermined flight operation is received, the computer system can automatically carry out the corresponding aerospace deployment on the application for the undetermined figure flight operation fast and effectively, human influence in the aerospace deployment is removed, and therefore deployment efficiency and precision on the figure flight operation are improved.

Owner:BEIJING WEATHER MODIFICATION OFFICE +2

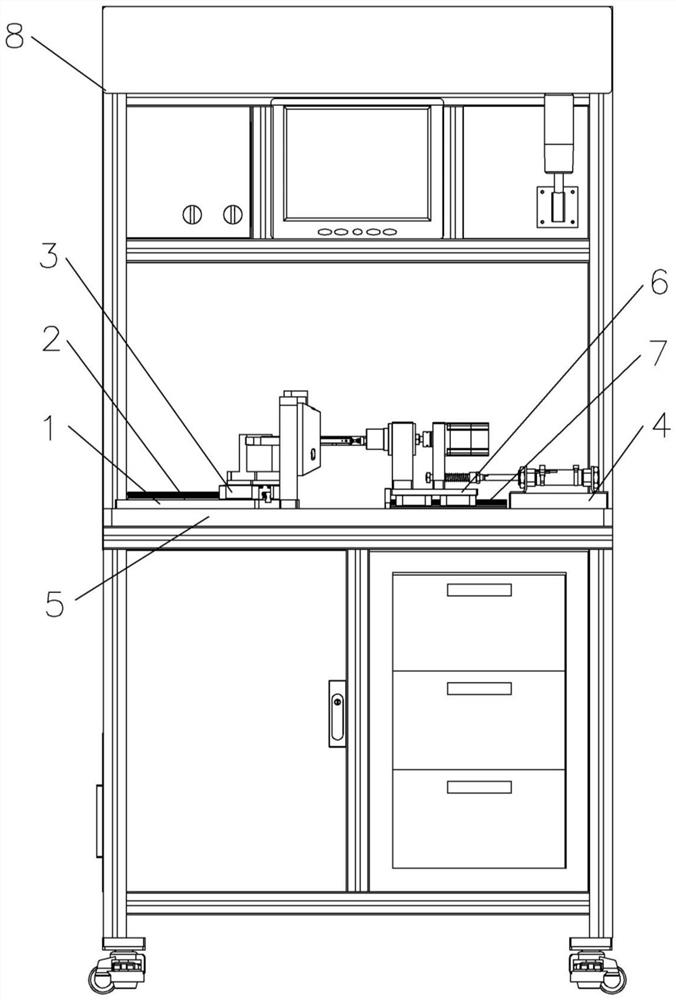

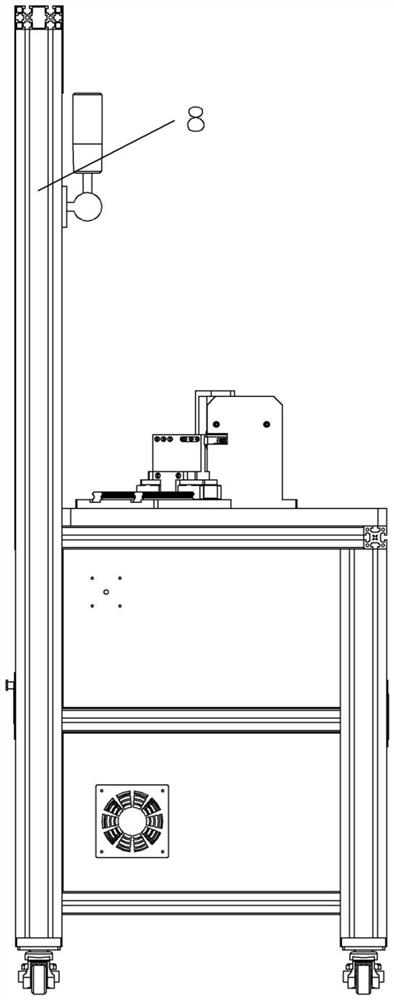

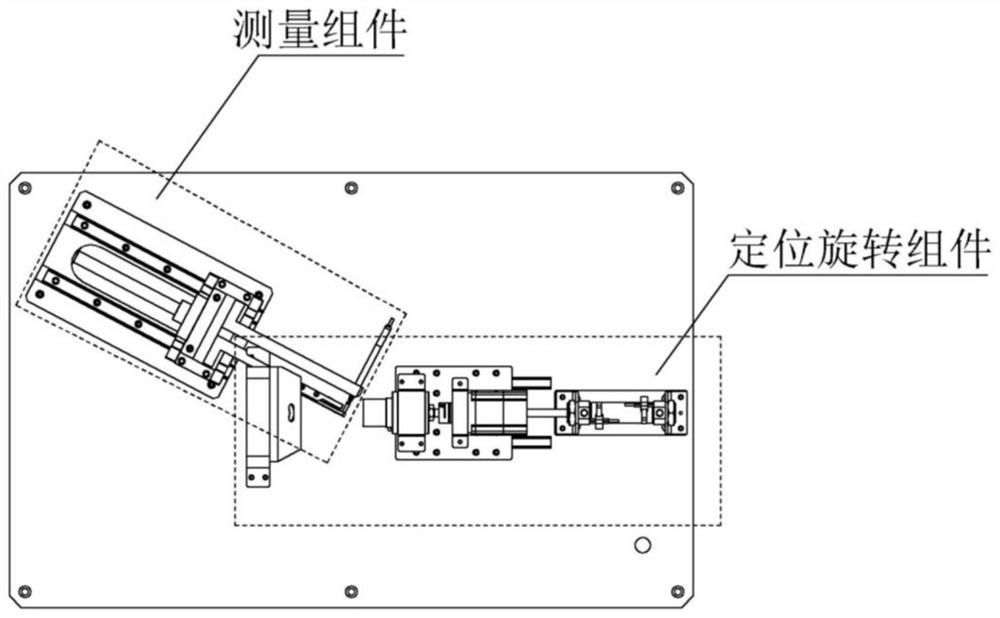

Cone wall thickness and wall thickness difference automatic detection device and detection method thereof

InactiveCN112683219AEasy to operateEliminate systematic errorsMeasurement devicesEngineeringStructural engineering

The invention discloses a cone wall thickness and wall thickness difference automatic detection device and a detection method thereof. The automatic detection device comprises a workbench, a cone measurement assembly, a positioning rotation assembly and a motion assembly. The cone measuring assembly and the positioning rotating seat assembly are installed on the workbench, the measuring motion assembly is installed below the workbench, and the cone positioning rotating assembly automatically clamps a variable wall thickness cone workpiece and enables the variable wall thickness cone workpiece to rotate freely. The cone measuring assembly is arranged beside the large end of the cone workpiece; the measuring assembly detects the wall thickness and the wall thickness difference of any selected cross section of the detected cone workpiece. According to the invention, automatic detection, automatic clamping and loosening, zero calibration, system error elimination, automatic data reading, automatic analysis, processing and evaluation, and automatic storage and output can be carried out on the wall thickness and the wall thickness difference of any section of the single cone, the influence of human factors on a measurement result is reduced, the measurement precision is greatly improved, the detection process is simplified, and detection work efficiency is improved.

Owner:江南工业集团有限公司

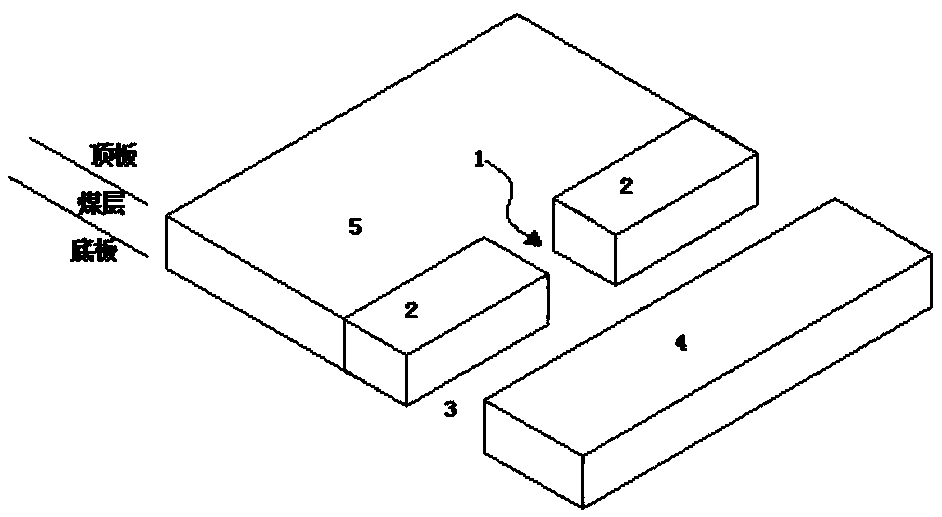

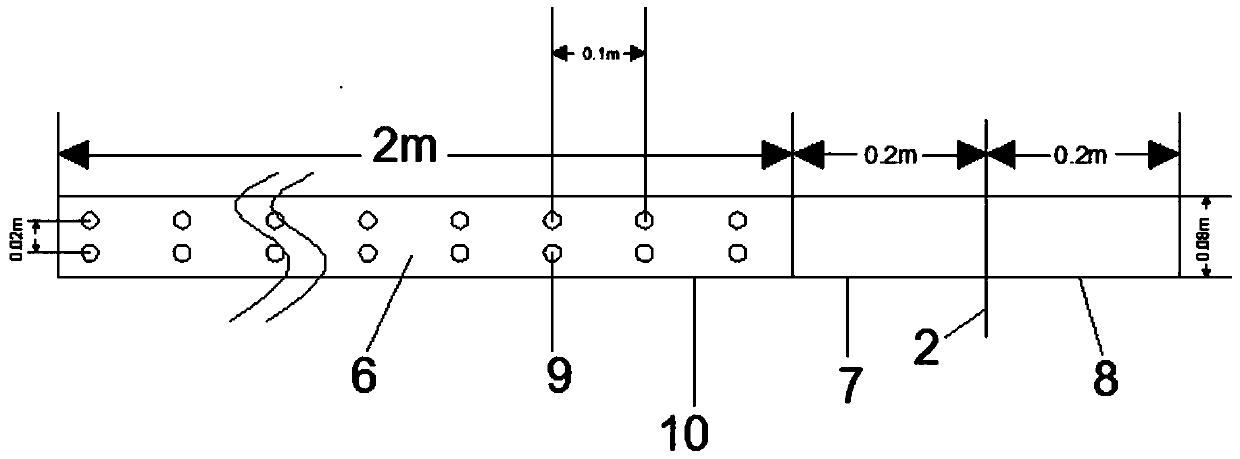

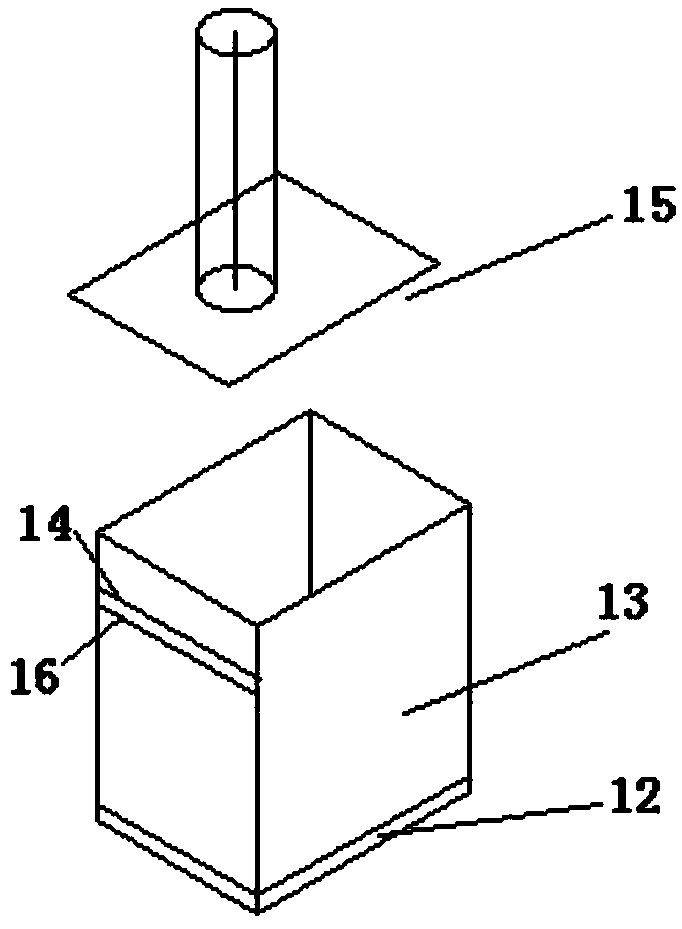

Underground reservoir artificial dam body with zigzag clamping grooves

InactiveCN109594527ASimple processQuick installationBarrages/weirsFoundation engineeringSteel tubeGroundwater resources

The invention provides an underground reservoir artificial dam body with zigzag clamping grooves, and relates to the field of groundwater resource protection. The underground reservoir artificial dambody comprises an artificial dam body and coal pillar dam bodies positioned on two sides of the artificial dam body, wherein the artificial dam body comprises an upper sealing sleeve piece and dam body modules, the upper sealing sleeve piece comprises uniform slip casting elastic steel tubes and slip casting drill holes, and the dam body modules comprise dam body modules with the zigzag clamping grooves and ordinary dam body modules; a plurality of uniform slip casting elastic steel tubes are arranged on the outer side of the coal pillar dam bodies; the other ends of the uniform slip casting elastic steel tubes are arranged inside the zigzag clamping grooves of the dam body modules with the zigzag clamping grooves; the uniform slip casting elastic steel tubes in the same vertical directionare communicated with the slip casting drill holes respectively; the tail ends of the slip casting drill holes extend to the outside of the coal pillar dam bodies; the dam body modules with the zigzag clamping grooves are fixedly connected through the ordinary dam bodies. The underground reservoir artificial dam body is constructed quickly, and the sealing performance of underground reservoir coal pillar upper and the artificial dam body is improved while the period and cost of reservoir construction are reduced.

Owner:ANHUI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com