Novel automatic calibration device for eddy current liquid level meter

An automatic calibration, liquid level gauge technology, used in measuring devices, test/calibration devices, liquid/fluid solid measurement, etc. Improve efficiency and improve the effect of calibration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

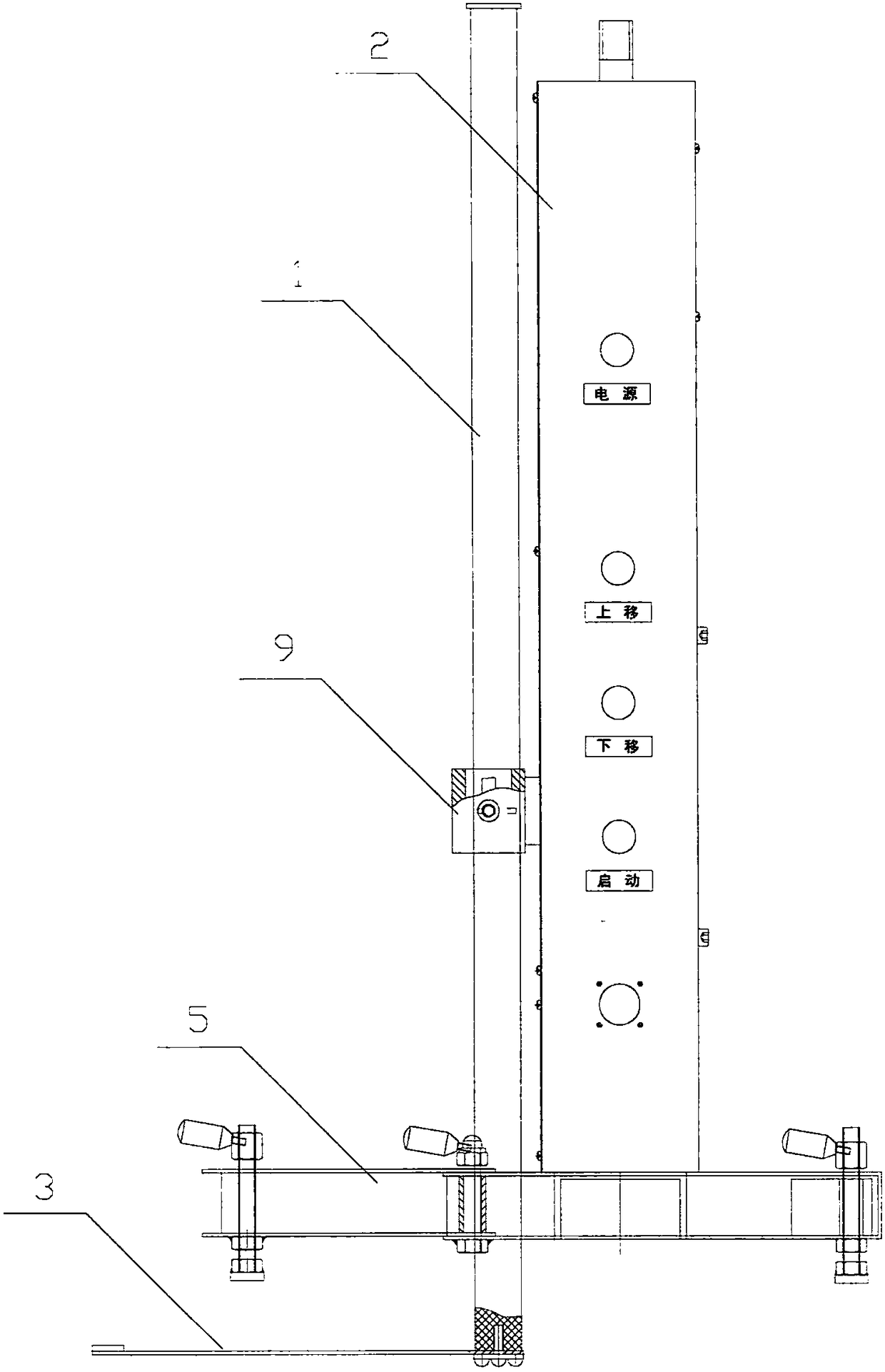

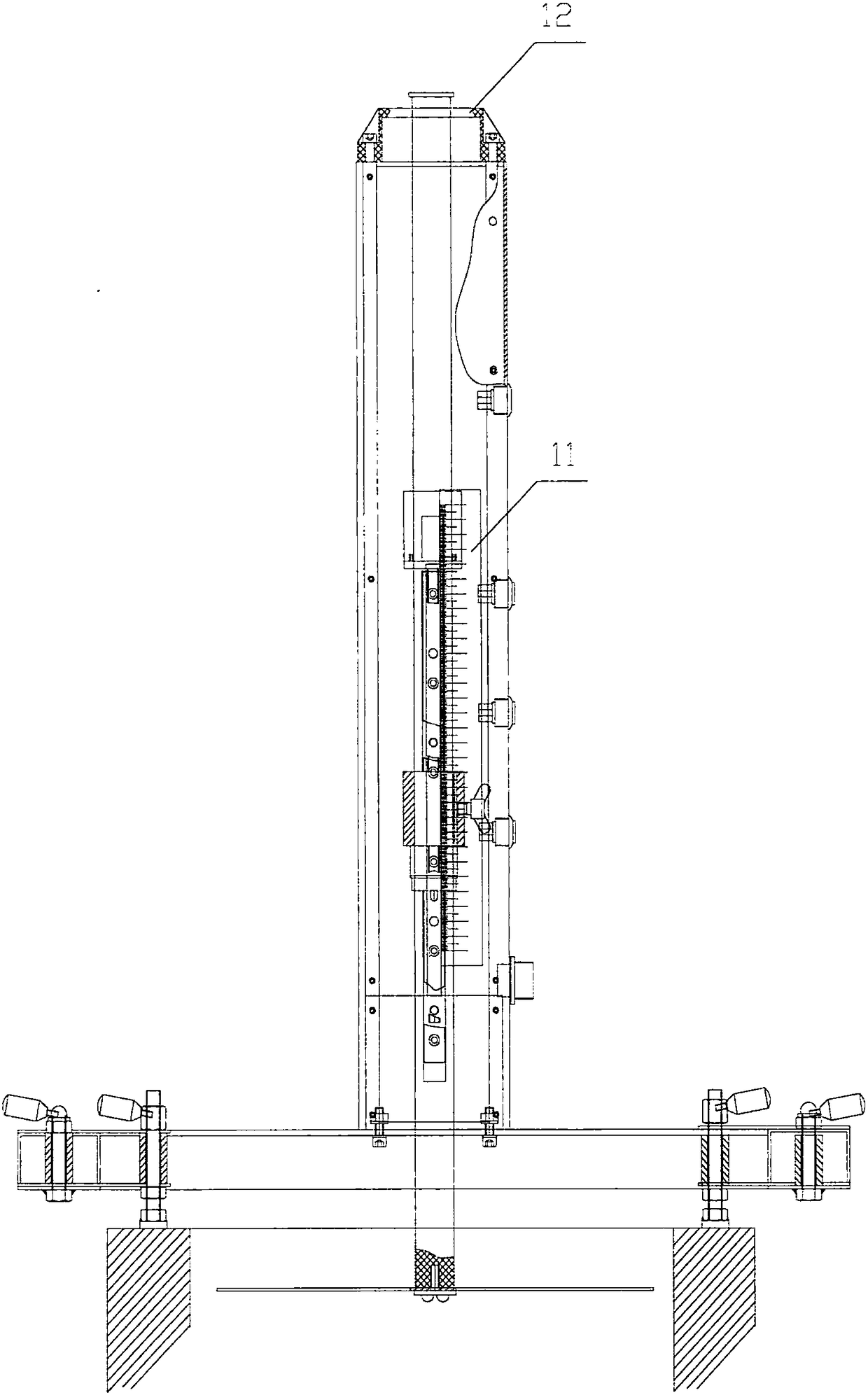

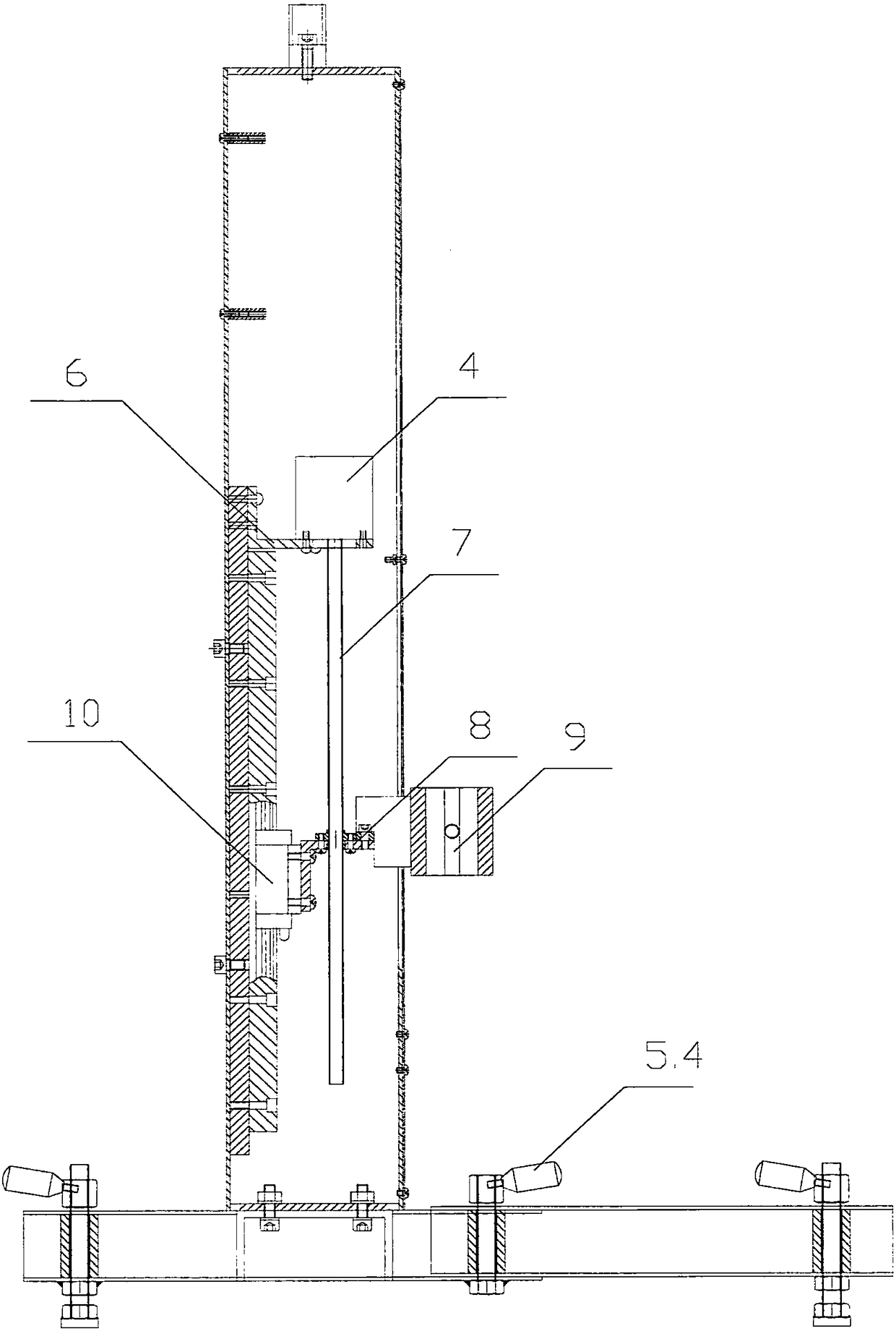

[0030] see figure 1 —4, a kind of eddy current liquid level gauge automatic calibration device of the present invention, comprises calibration rod 1, fixed frame 2, calibration plate 3 and stepper motor 4, and described fixed frame 2 is vertically installed on the base 5, and described calibration The rod 1 is arranged parallel to the fixed frame 2, and the calibration plate 3 is installed at the bottom of the calibration rod 1. The calibration plate is made of a material with a magnetic permeability close to that of liquid steel to ensure that the measurement results during calibration are consistent with the real molten steel. The shape is determined according to the section of the crystallizer. The round billet uses a circular calibration plate, and the square billet uses a square calibration plate. The stepper motor 4 is installed above th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com