Machine for automatically testing and sorting code devices

An automatic testing and sorting machine technology, applied in instruments, sorting and other directions, can solve the problems of reducing inspection personnel and difficulty in quality inspection of encoder products, so as to reduce inspection personnel, eliminate human influence, and meet high-quality requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

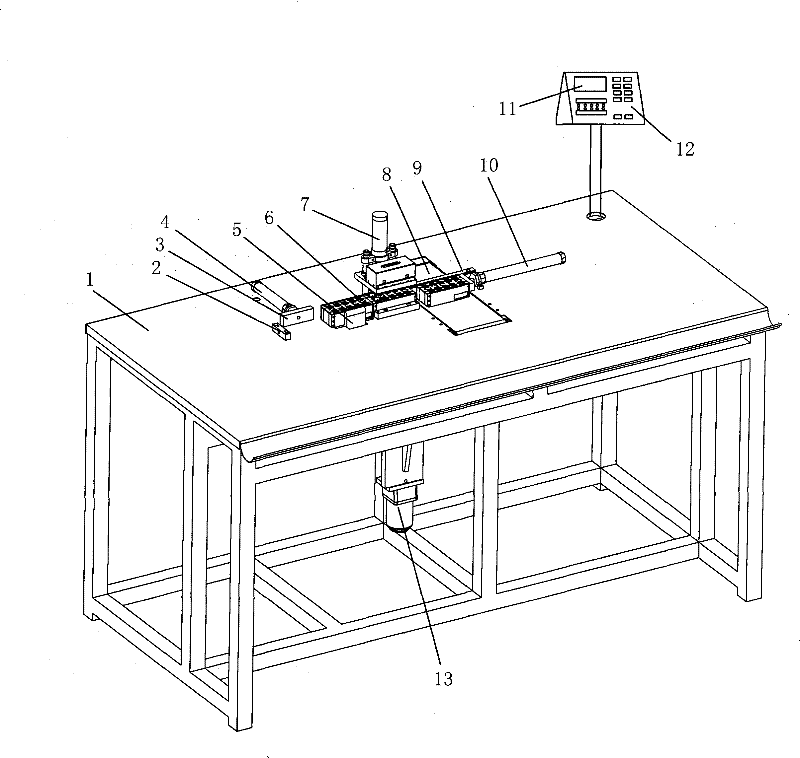

[0023] see figure 1 with Figure 4 , a kind of coder automatic testing and sorting machine described in the present embodiment, comprises multifunctional detection software, machine panel 1, display 11 and operation panel 12, is characterized in that: also comprises movable mold core 6, on the machine panel 1. A mold feeding device, a testing device, a sorting device and a mold ejecting device are sequentially designed on the upper part. A main shaft rotation mechanism and a test control circuit board are designed in the chassis. The testing device is connected to the main shaft rotation mechanism. Display 11, operation panel 12, feeding The mold device, the testing device, the sorting device, the mold ejecting device and the spindle rotating mechanism are respectively connected to the test control circuit board.

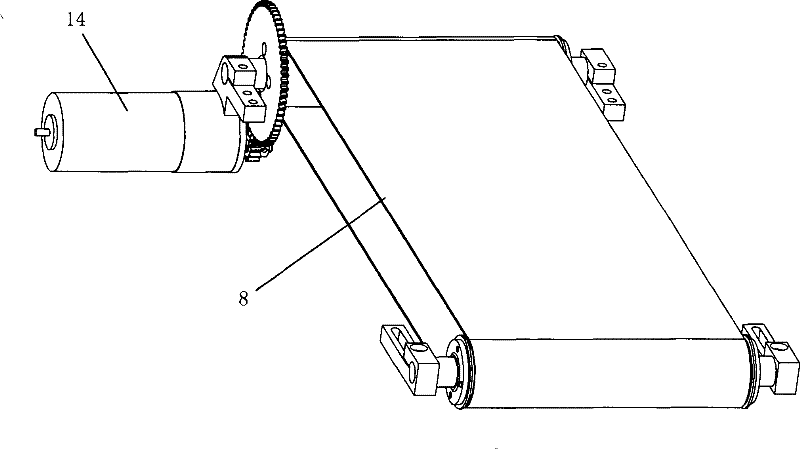

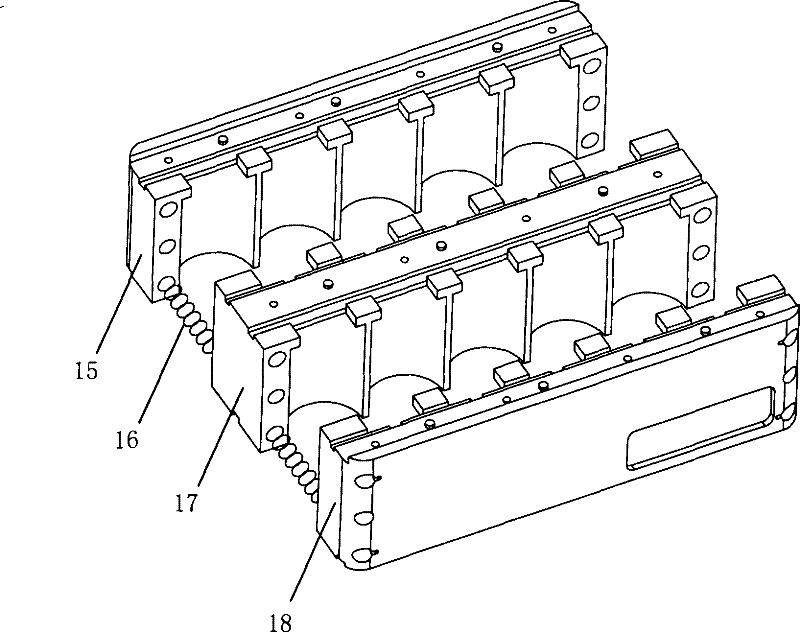

[0024] see figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com