Underground reservoir artificial dam body with zigzag clamping grooves

An underground reservoir and zigzag technology is applied in the field of artificial dam bodies of underground reservoirs, which can solve the problems of long construction time, increase reservoir construction and drainage costs, etc., and achieve the effects of fast installation, suitable for large-scale promotion and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

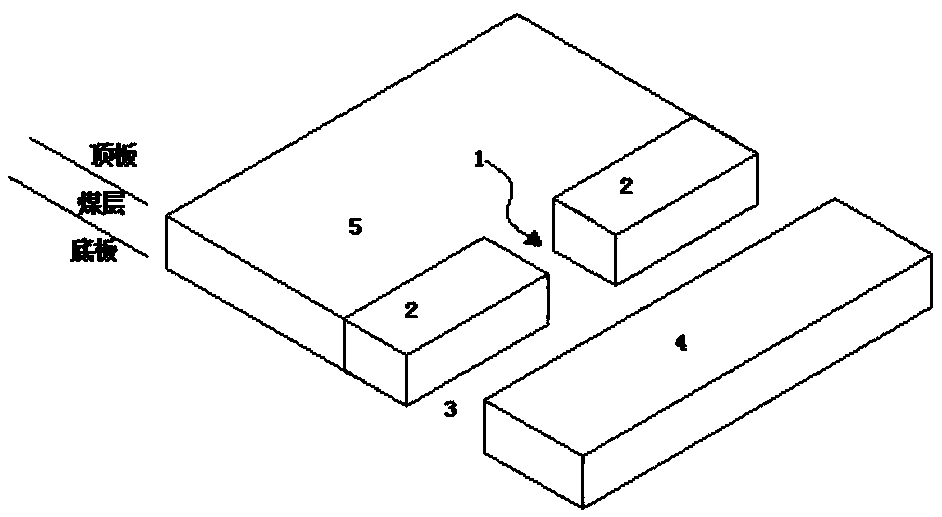

[0039] Such as figure 1 As shown, an artificial dam body of an underground reservoir with a saw-toothed slot includes an artificial dam body construction area 1 and coal pillar dam bodies 2 located on both sides of the artificial dam body construction area 1, and the underground reservoir area 5 is a coal mining goaf The outside is roadway 3 and unmined coal seam 4 or rock formation; the key of underground reservoir is to seal the water inside the reservoir to prevent it from flowing out, so the sealing of artificial dam body is particularly important.

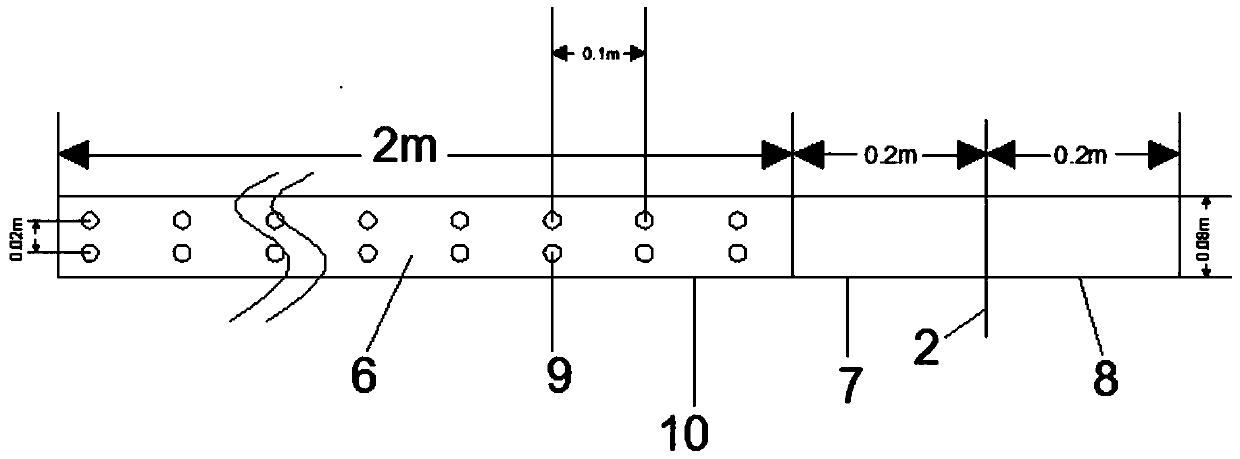

[0040] Such as figure 2 As shown, the uniform grouting elastic steel pipe 10 has a total length of 2.2m, an outer diameter of 0.08m, and a wall thickness of 0.02m. ), the outer area of the coal pillar is composed of 8 (0.2m), the length ratio of the area with grouting holes inside the coal pillar to the area without grouting holes inside the coal pillar, and the outer area of the coal pillar is 10:1:1, and the elastic st...

Embodiment 2

[0055] Such as figure 1 As shown, an artificial dam body of an underground reservoir with a saw-toothed slot includes an artificial dam body construction area 1 and coal pillar dam bodies 2 located on both sides of the artificial dam body construction area 1, and the underground reservoir area 5 is a coal mining goaf The outside is roadway 3 and unmined coal seam 4 or rock formation; the key of underground reservoir is to seal the water inside the reservoir to prevent it from flowing out, so the sealing of artificial dam body is particularly important.

[0056] The uniform grouting elastic steel pipe 10 has a total length of 2.3m, an outer diameter of 0.08m, and a wall thickness of 0.02m. The outer area of the coal pillar is composed of 8 (0.19m), the length ratio of the area with grouting holes inside the coal pillar to the area without grouting holes inside the coal pillar, and the outer area of the coal pillar is about 10:1:1, The material of the uniform grouting elast...

Embodiment 3

[0071] Such as figure 1 As shown, an artificial dam body of an underground reservoir with a saw-toothed slot includes an artificial dam body construction area 1 and coal pillar dam bodies 2 located on both sides of the artificial dam body construction area 1, and the underground reservoir area 5 is a coal mining goaf The outside is roadway 3 and unmined coal seam 4 or rock formation; the key of underground reservoir is to seal the water inside the reservoir to prevent it from flowing out, so the sealing of artificial dam body is particularly important.

[0072] The uniform grouting elastic steel pipe 10 has a total length of 2.4m, an outer diameter of 0.08m, and a wall thickness of 0.02m. The outer area 8 (0.2m) of the coal pillar is composed of the area with grouting holes inside the coal pillar and the area without grouting holes inside the coal pillar, and the length ratio of the outer area of the coal pillar is about 10:1:1. The material of the uniform grouting elastic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com