Smoking machine control method based on temperature sensing

A technology of trigger control and smoking machine, applied in the direction of electrical program control, program control in sequence/logic controller, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention further explains this method in conjunction with accompanying drawing:

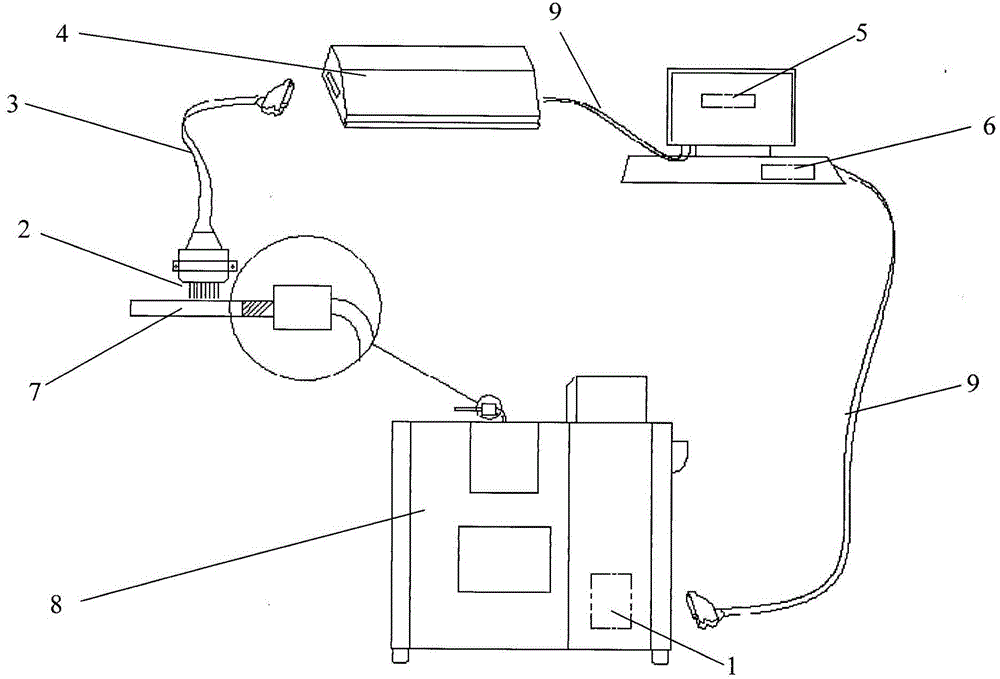

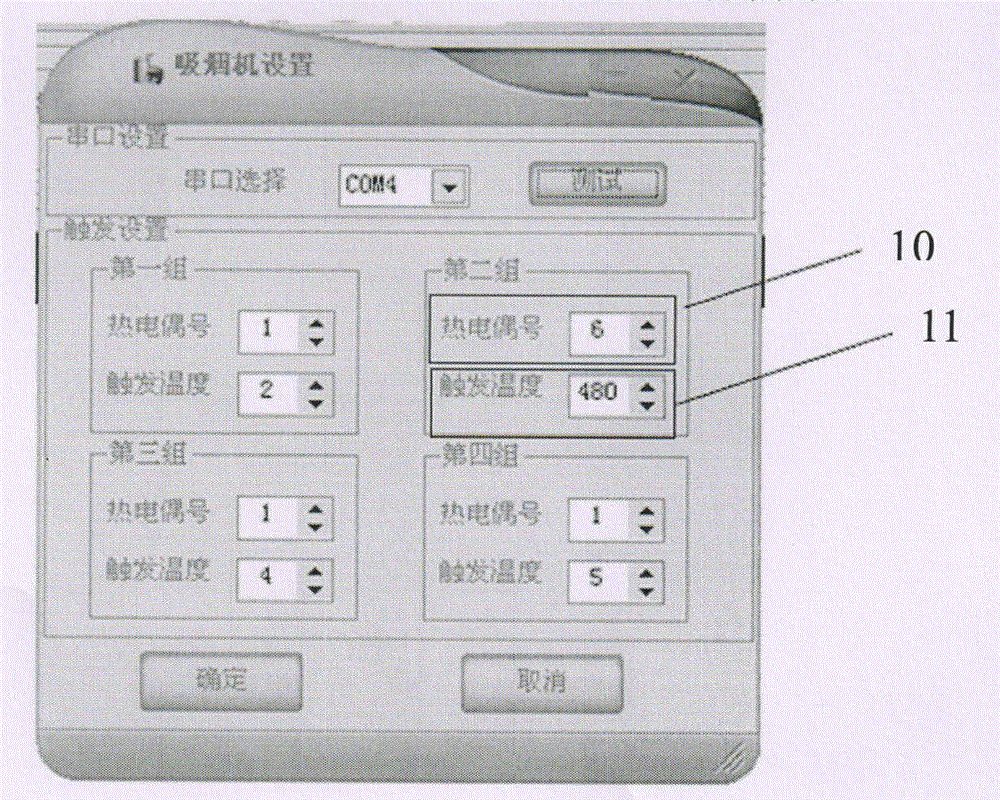

[0021] Such as figure 1 , 2 As shown: the hardware facilities in this automatic control method include trigger module 1 installed on the smoking machine, temperature sensor 2, temperature compensation wire 3, temperature acquisition input module 4, upper computer signal processing software 5, upper computer and smoking machine communication module 6 and other parts. The connection relationship of each hardware facility is that the temperature sensor 2 is connected to the temperature acquisition input module 4 through the temperature compensation wire 3, the temperature acquisition input module 4 communicates with the upper computer signal processing software 5 through the communication cable 9, and the upper computer communicates with the smoking machine communication module 6 through The communication cable 9 is connected with the trigger module 1 installed on the smoking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com