Cone wall thickness and wall thickness difference automatic detection device and detection method thereof

A technology of wall thickness difference and cone, which is applied in the field of cone wall thickness and wall thickness difference detection, and can solve problems such as low work efficiency, poor uniformity and poor repeatability of the measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

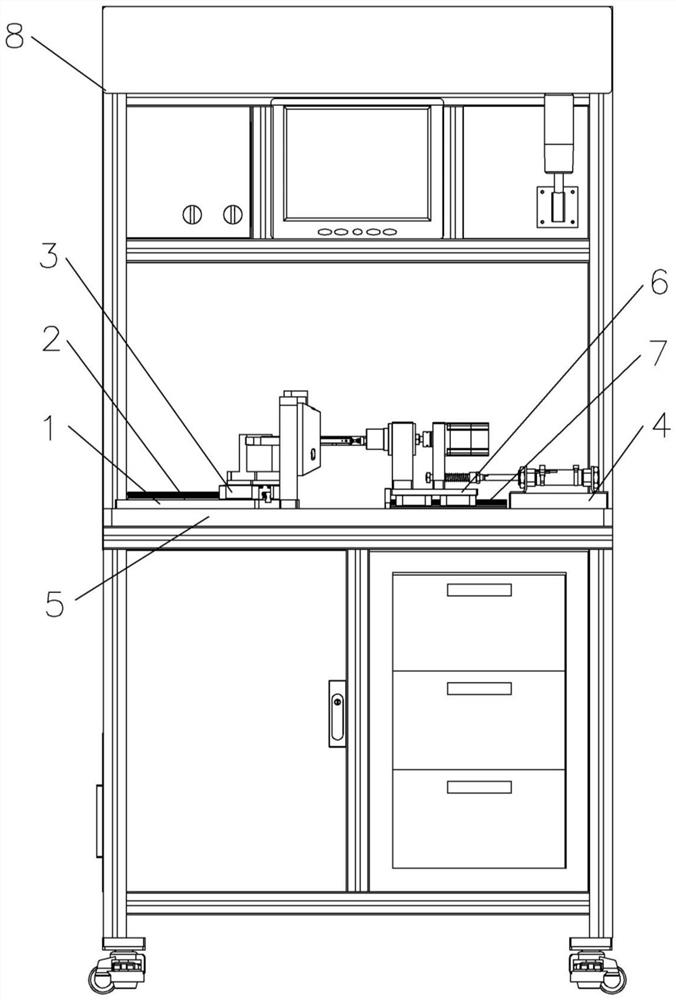

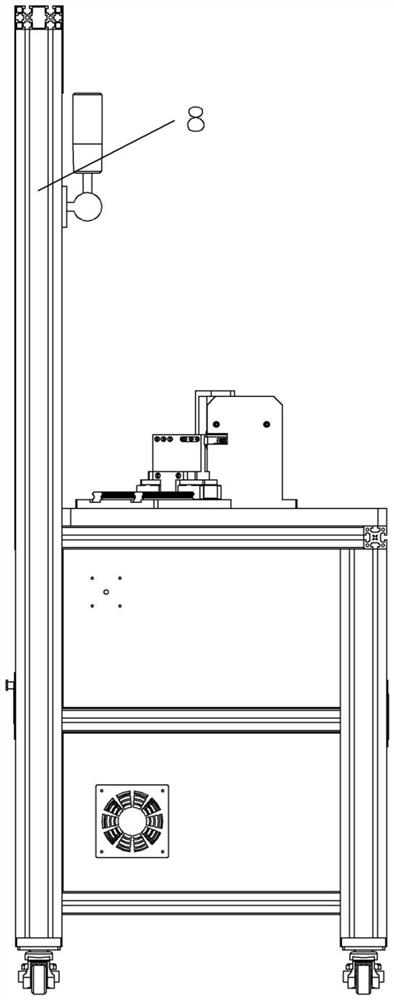

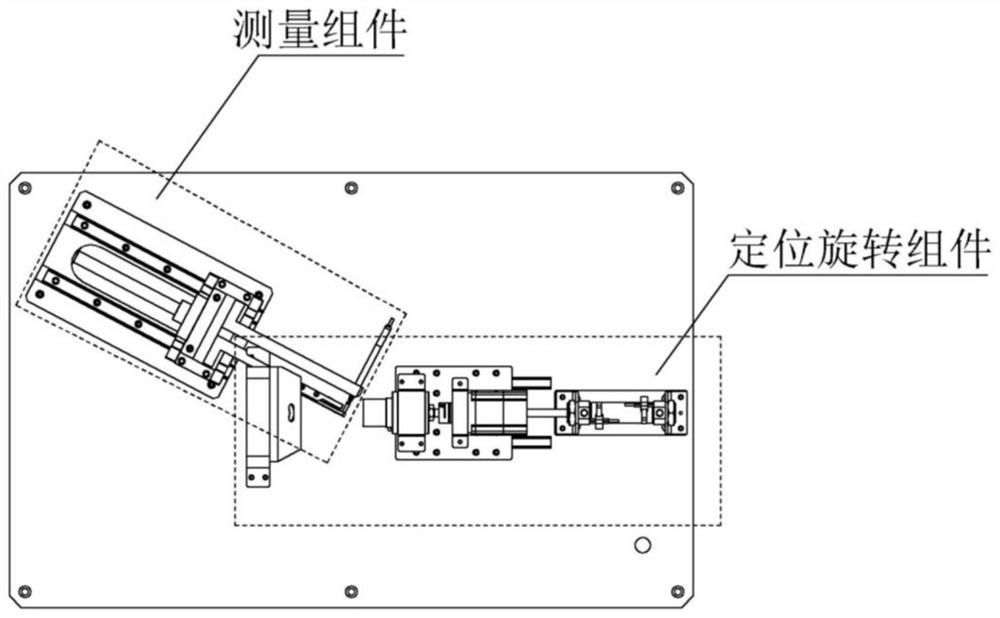

[0038] refer to Figure 1-8 , an automatic detection device for cone wall thickness and wall thickness difference and a detection method thereof, the automatic detection device 8 includes a workbench 5, a measuring assembly, a positioning and rotating assembly, and a moving assembly, and the measuring assembly and the positioning and rotating assembly are arranged above the workbench 5 , the motion assembly is located under the workbench 5 .

[0039] The measuring components include base Ⅰ1, slide rail Ⅰ2, slide seat Ⅰ3, measuring rod 17 outside the cone and measuring rod 14 inside the cone. There is sliding seat Ⅰ3 in the sliding connection. The sliding seat I3 is connected with the measuring base 16 through fastening screws, the measuring base 16 is respectively connected with the measuring rod 14 inside the cone and the measuring rod 17 outside the cone through the fastening screws and the fastening screws, and the lever sensor 10 inside the cone is connected by the fasten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com