Roller spacing adjustment alarm prompting device

A roller spacing and roller technology, which is applied in the field of silver paste production equipment for battery chips, can solve the problems that the optimal grinding gap cannot be accurately controlled at one time, the quality of the silver paste is greatly affected, and the product quality fluctuates greatly. Save commissioning preparation time, eliminate human influence factors, and improve the effect of daily output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

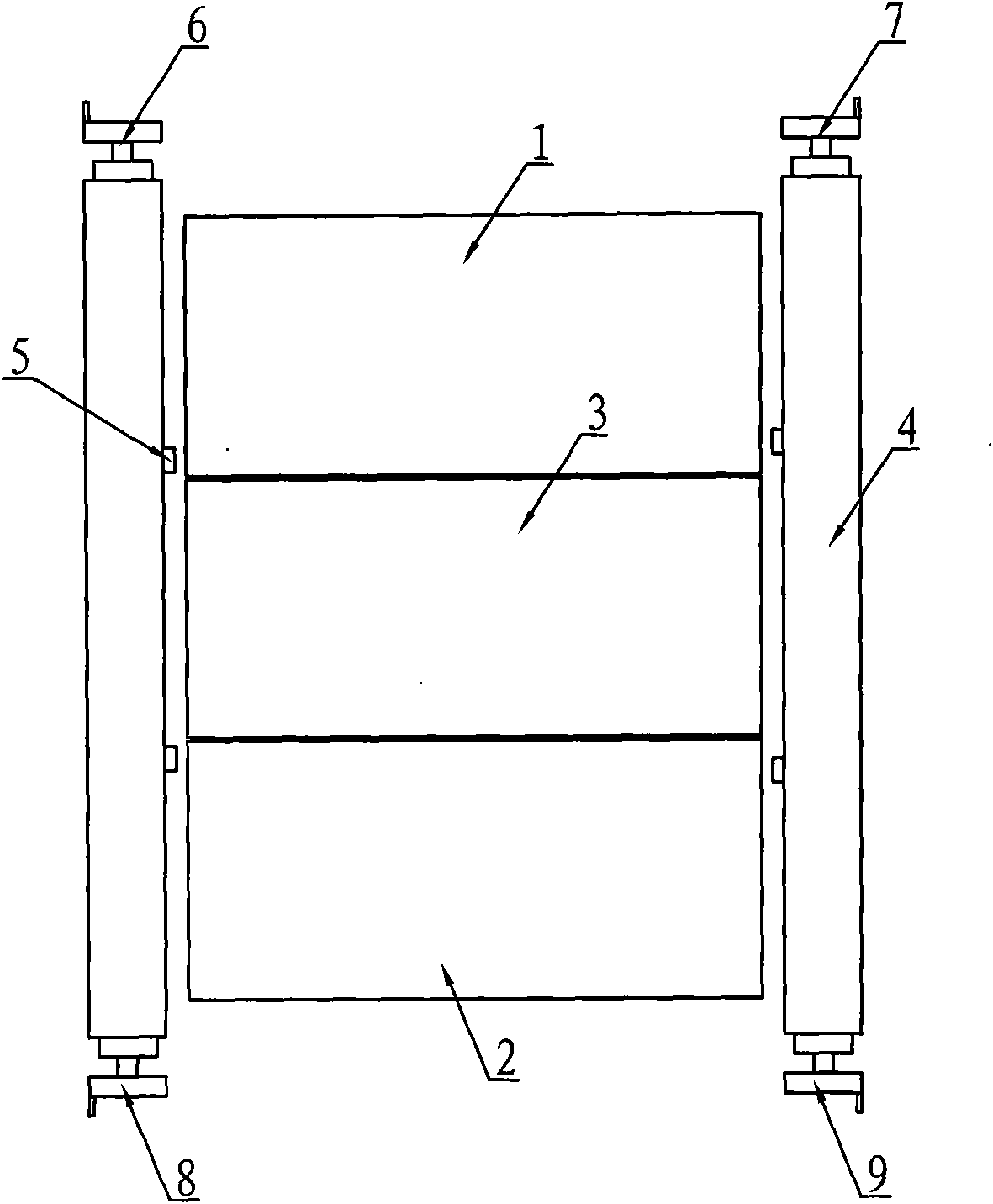

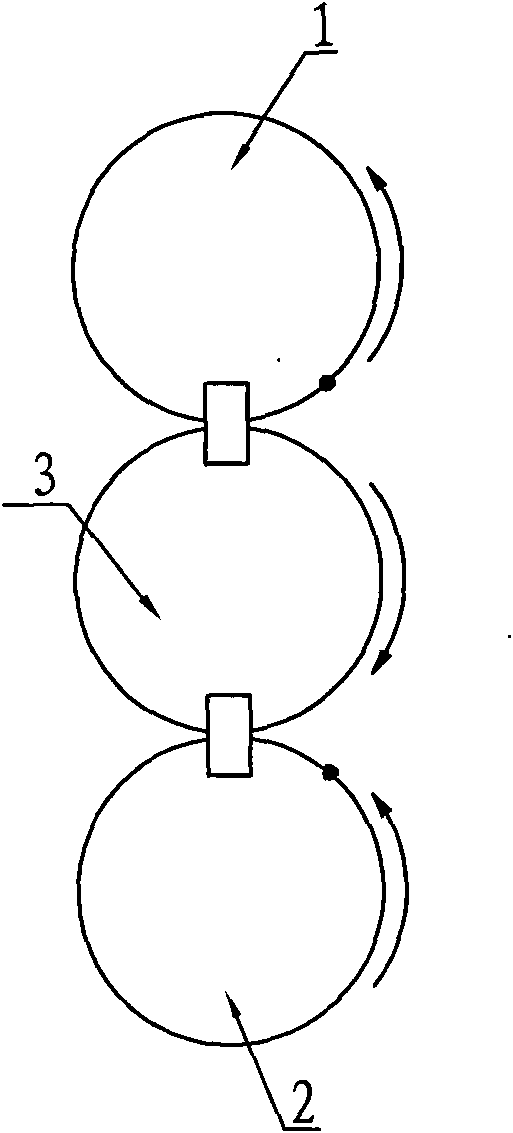

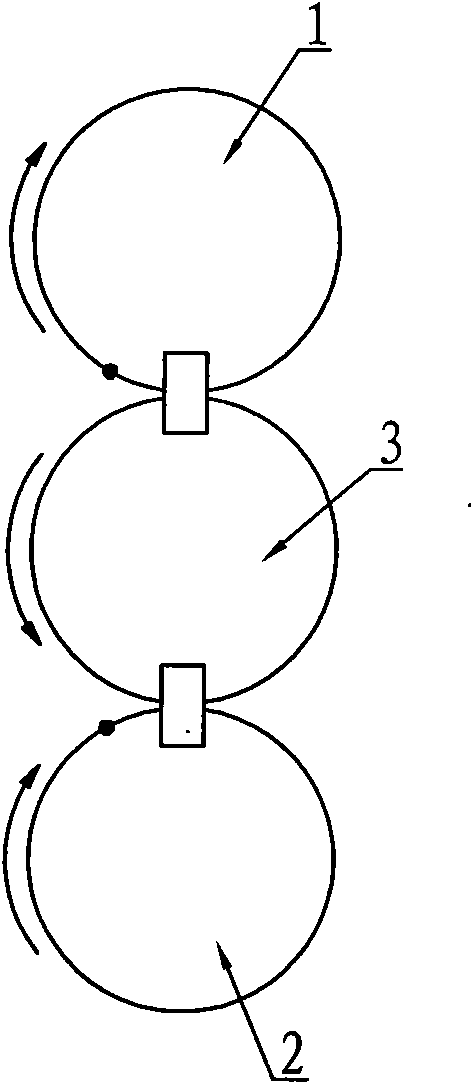

[0015] The roller spacing adjustment alarm prompting device includes a front roller 1, a rear roller 2, a front left photoelectric switch K1, a front right photoelectric switch K2, a rear left photoelectric switch K3, a rear right photoelectric switch K4 and an alarm 5, The front left photoelectric switch K1 and the front right photoelectric switch K2 are respectively arranged on the left and right sides of the front roller 1; the rear left photoelectric switch K3 and the rear right photoelectric switch K4 are respectively arranged on the left and right sides of the rear roller 2, and the front left photoelectric switch The switch K1, the front right photoelectric switch K2, the rear left photoelectric switch K3 and the rear right photoelectric switch K4 are all installed on the frame 4. The installation position requirements of the front left photoelectric switch K1 and the front right photoelectric switch K2 are: the current roller 1 is relatively When the middle roller 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com