Universal cutting machine

A cutting machine and universal technology, applied in the direction of metal sawing equipment, sawing equipment, metal processing equipment, etc., to achieve the effect of improving work efficiency and quality, high quality, and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

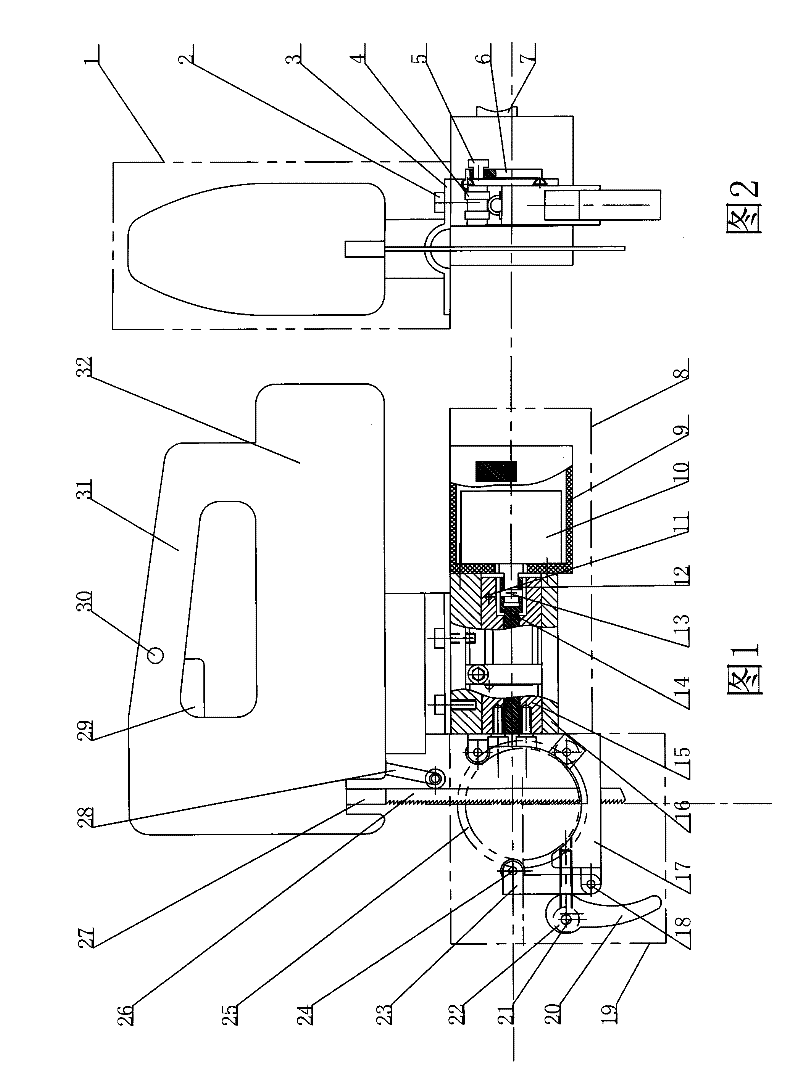

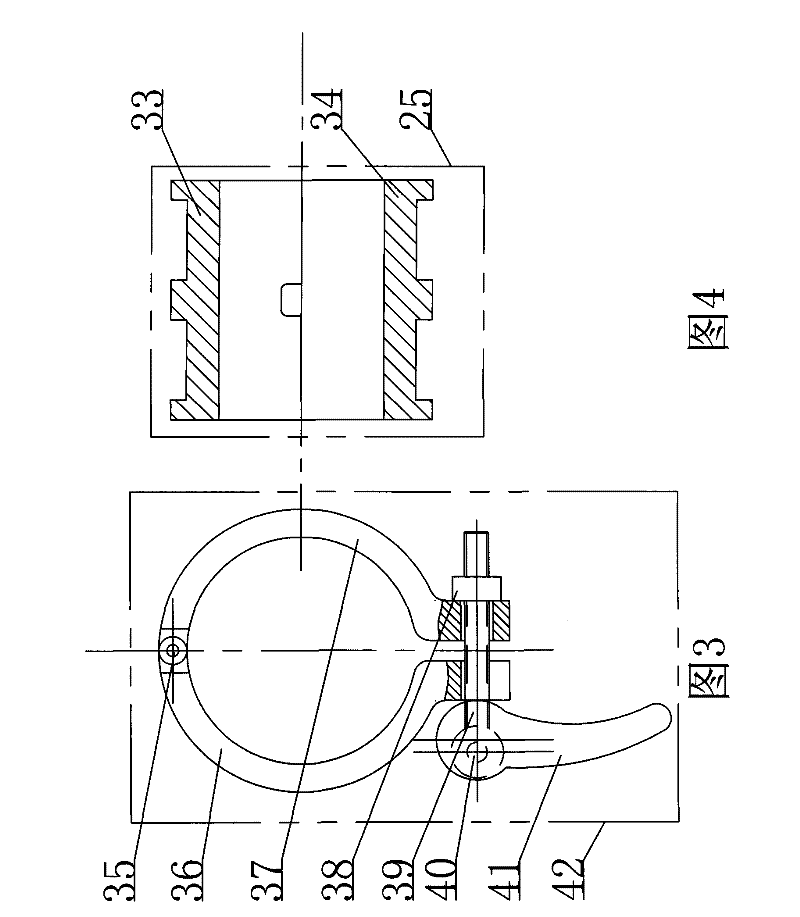

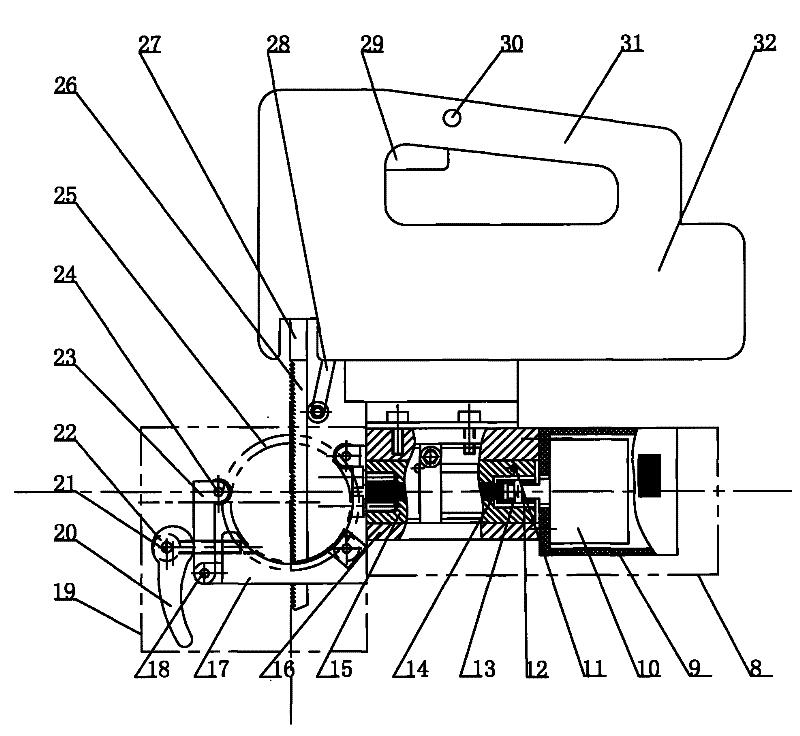

[0016] Depend on Figure 4 It can be seen that first press the mold (25) and clamp the mold (25), the mold (25) is composed of upper and lower molds with positioning steps, and blocks the workpiece to be cut. The shape of the inner hole of the mold (25) is according to the shape of the workpiece Depends, by image 3 It can be seen that the inner circular arc of the beam mold clamp assembly (42) is the same as the shape of the mold outer groove, adjust the adjustment nut (38) and turn the wrench (41) with an eccentric wheel structure to compress the left beam mold clamp (36) and The right bundle mold card (37), clamps mold (25) and workpiece. Depend on figure 1 It can be seen that, after the clamp assembly (19) is snapped into the outer groove of the mold (25), the wrench (20) with the eccentric wheel is pulled to compress the rolling wheel (4) on the movable clamp (23), three Group rolling wheel encircles mould, has three or more groups of rolling wheels (4) that can roll i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com