A multi-line optical fiber thermal stripper

A stripper and optical fiber technology, applied in the direction of light guides, optics, instruments, etc., can solve the problems of easily damaged fibers, low work efficiency, and excessive operation actions, so as to improve work efficiency, ensure stripping quality, and work intensity Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

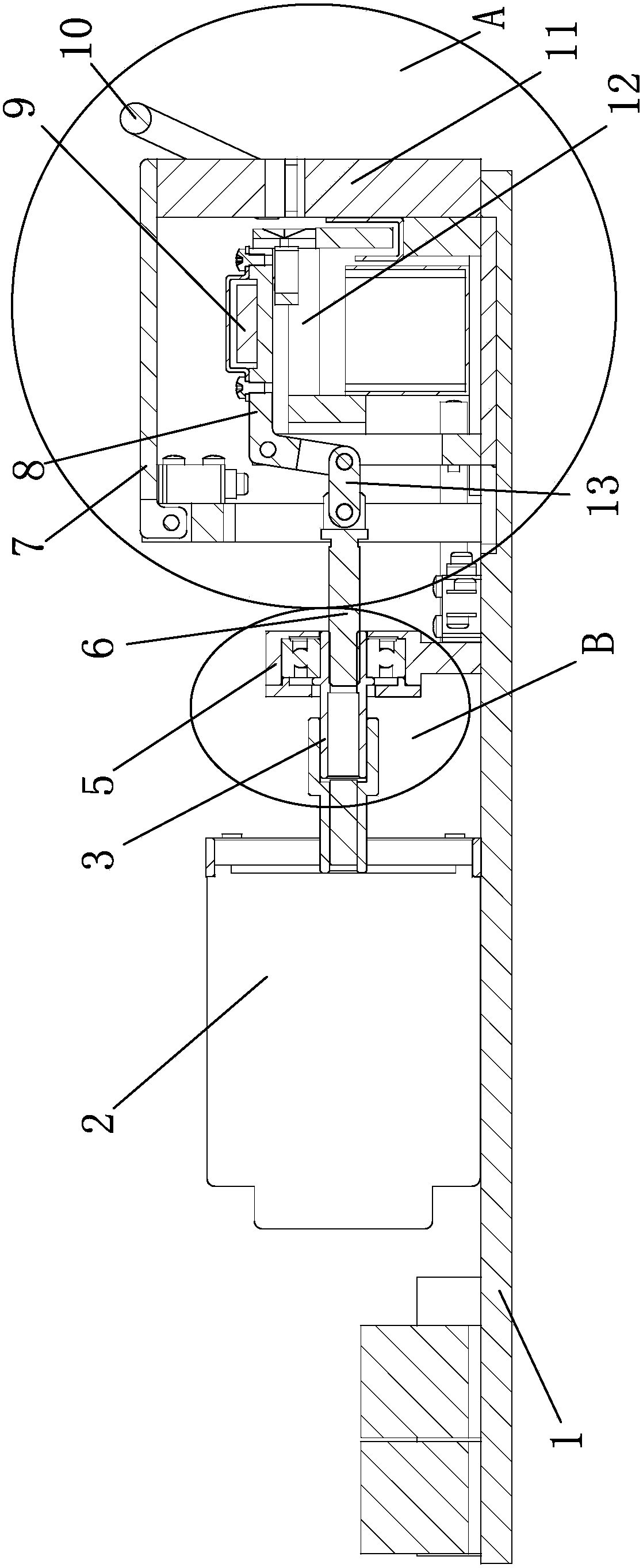

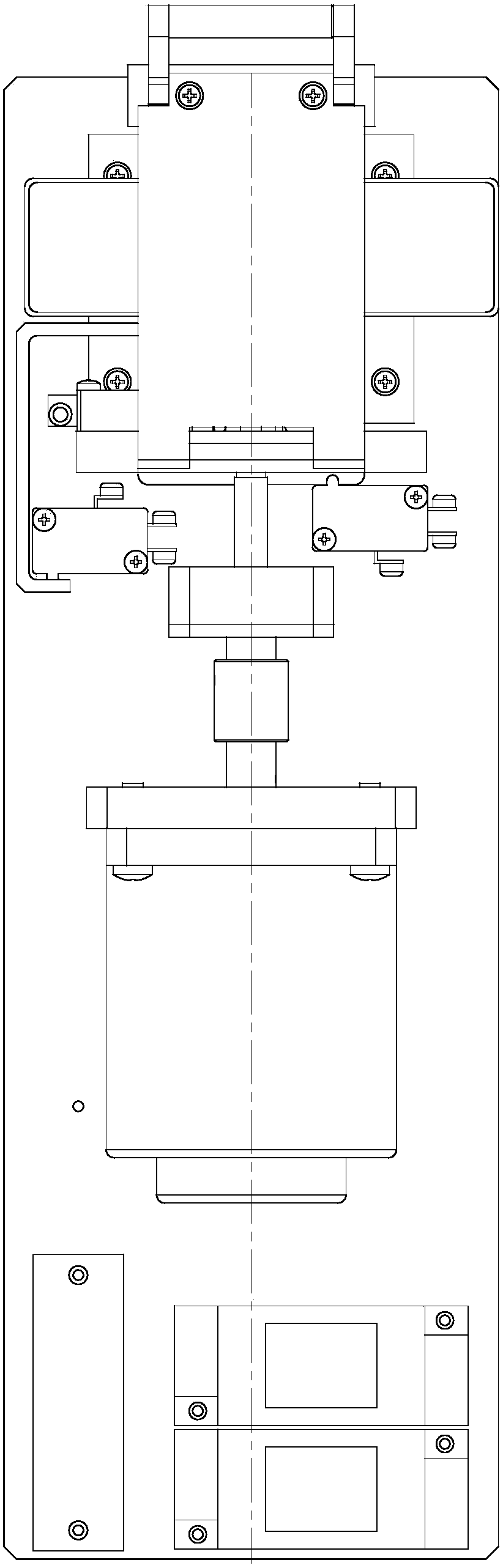

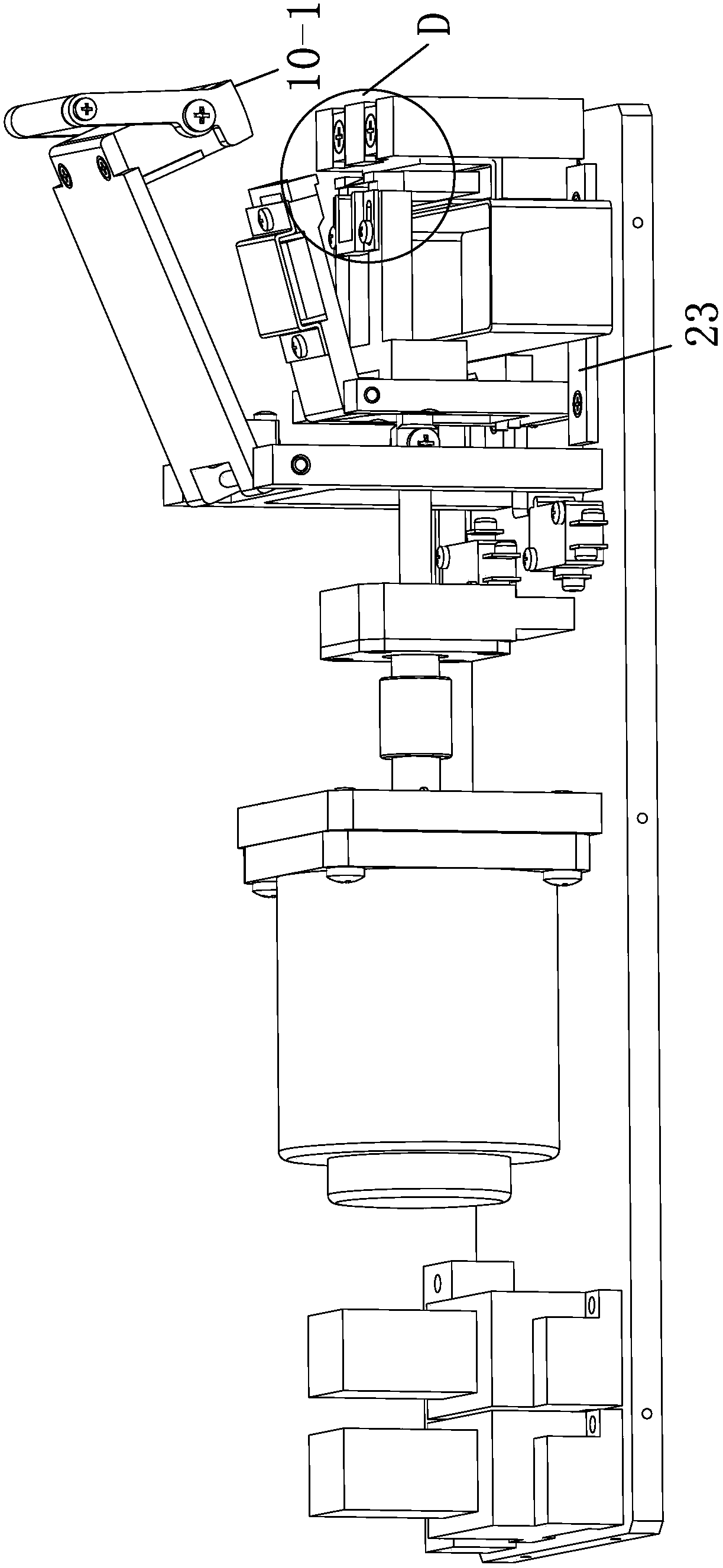

[0024] In the multi-core optical fiber stripper as shown in the figure, the clamping frame for clamping the optical cable is fixed on the base body 1, the cutter frame and the heater for heating the optical fiber are positioned in the clamping frame, and the power mechanism is used to drag The movement of the movable cutter holder.

[0025] The clamping frame is rotatably hinged as a whole by the upper pressing plate 7 and the lower pressing plate 11, and the middle parts of the upper and lower pressing plates are respectively equipped with rubber pads 24 (the view of the rubber pad of the upper pressing plate is omitted), thus forming a meshing mouth. It is used to clamp and fix the optical fiber so that it does not move during the stripping operation; magnets 20 are installed on both sides of the eng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com