Testing device and method for adhesive force between gas hydrate and mineral particles

A technology of gas hydrate and mineral particles, which is applied in the direction of measuring devices, mechanical devices, earthwork drilling and mining, etc., to achieve significant practical value and accurate testing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

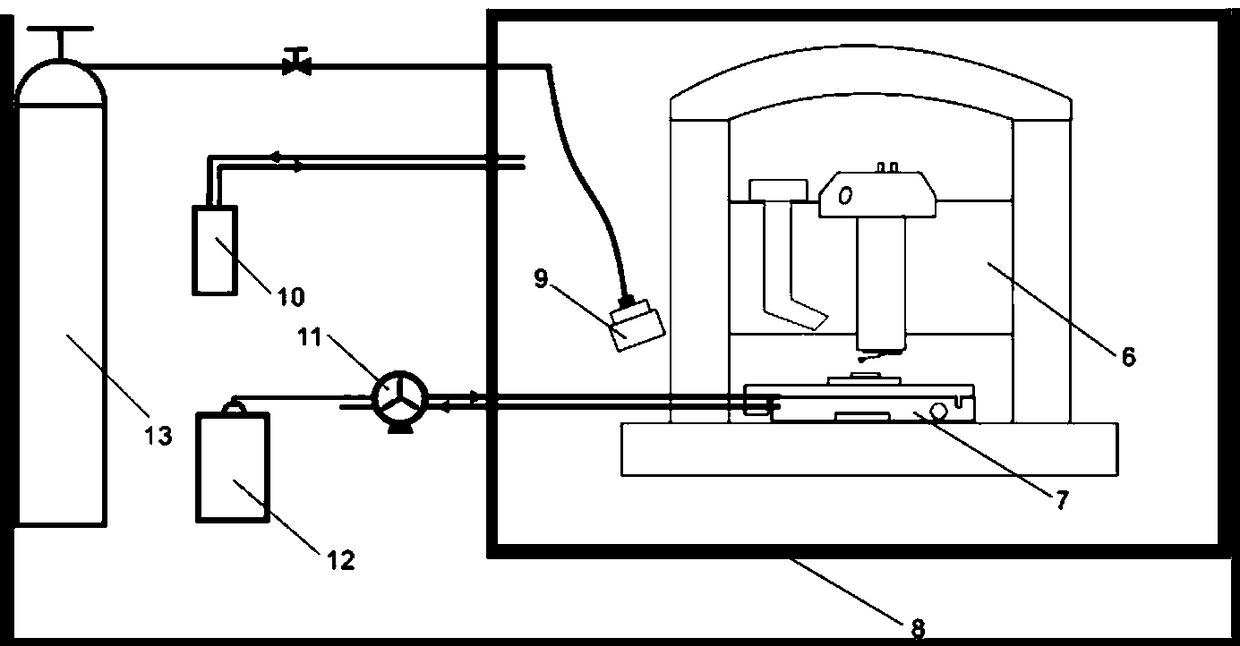

Method used

Image

Examples

Embodiment 1

[0057] The present invention will be further described in detail below in conjunction with the test experiment of the adhesion between carbon dioxide hydrate and mineral particles in the examples of the present invention.

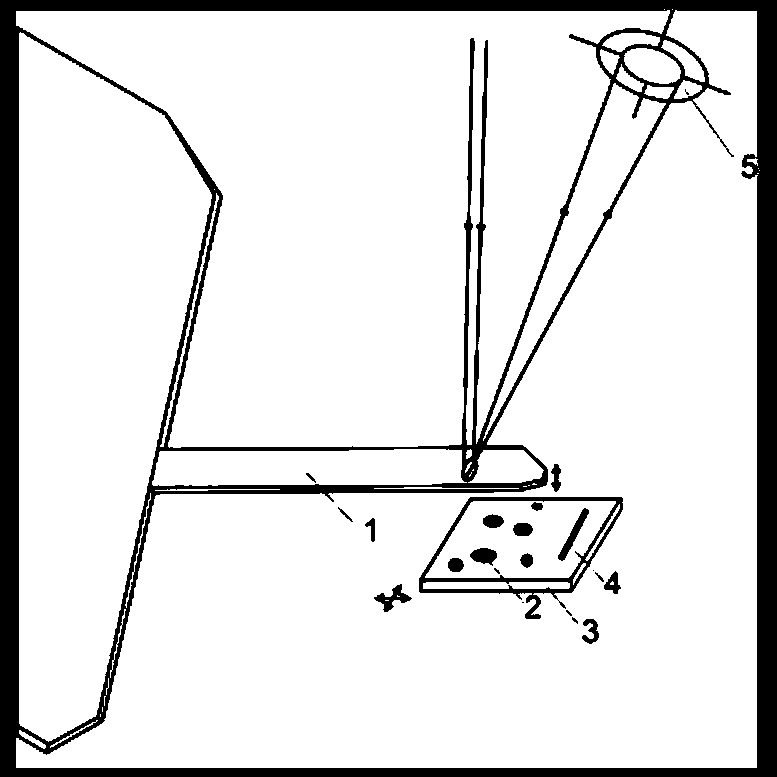

[0058] S1. Selection of AFM probes: Select AFM silicon probes 1 with aluminum coating on the back, rectangular cantilever, and no needle tip, such as figure 2 shown. In this embodiment, the particle size of the mineral particles is about 20 μm, and the elastic constant of the selected probe 1 is about 35 N / m. The cantilever of the silicon probe 1 with this elastic constant is about 115 um in length, 35 um in width, and 3 um in thickness.

[0059] S2. Mineral particles adhered to the probe: figure 2 The mineral particles 2 shown are evenly dispersed in clear water, and a small amount of the prepared turbid liquid is dropped on the surface of the mica sheet substrate 3. After the water evaporates, the mineral particles 2 are dispersed on the surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com