Preparation method of surface anti-friction and oil storage membrane layer of rubber sealing part

A technology of rubber seals and film layers, which is applied in the direction of coating, metal material coating process, gaseous chemical plating, etc., can solve the problems of semi-automatic or automatic mechanical equipment blockage, lubricating oil structure damage, equipment downtime and maintenance, etc. Achieve protection, improve friction performance, and improve oil storage function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1 A method for preparing a friction-reducing and oil-storage film on the surface of a rubber seal, comprising the following steps:

[0038] ⑴ Preparation of base material:

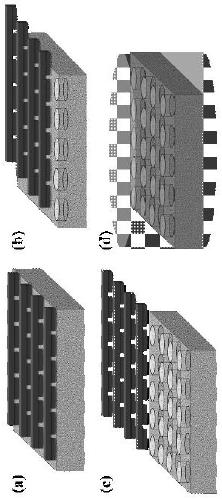

[0039]Grind the nitrile rubber and mix the curing agent sulfur with a weight ratio of 10:1 (kg / kg), cast it on the mother plate mold and bake it at 70°C for 1 hour. Move, and the baking temperature is constant to prevent the uneven physical properties of the rubber matrix itself. The rubber elastomer was then peeled off from the master mold, at which time, it was cured in the master mold to form a uniform array of microdimples with a spacing ratio of 1 cm (see figure 1 ), and the diameter of each micro-pit is 4 μm, and the height is 5 μm, that is, the base material. Air dry naturally under atmospheric conditions.

[0040] Among them: the surface finish of nitrile rubber is Ra<500nm, and there are no excessive impurity particles on the surface.

[0041] The surface of the motherboard mol...

Embodiment 2

[0050] Example 2 A method for preparing a friction-reducing surface of a rubber seal and an oil storage film, comprising the following steps:

[0051] (1) Prepare base material with embodiment 1.

[0052] Among them: rubber elastomer refers to ethylene-propylene rubber, its surface roughness Ra<500nm, and there are no excessive impurity particles on the surface.

[0053] ⑵ ~ ⑶ with embodiment 1.

[0054] ⑷Introduce purified air with a flow rate of 300 sccm into the vacuum chamber to prevent floating dust in the air from entering the chamber. Then use the high-power pulsed ion source to carry out air plasma bombardment. At this time, the air plasma activates the rubber surface to generate a large number of free radicals, which can effectively remove the oxide layer and dirt on the rubber subsurface.

[0055] Among them: air purification uses an air purifier to remove floating dust in the air.

[0056] The conditions for air plasma bombardment are that the air pressure in the...

Embodiment 3

[0059] Embodiment 3 A method for preparing a friction-reducing and oil-storage film on the surface of a rubber seal, comprising the following steps:

[0060] (1) Prepare base material with embodiment 1.

[0061] Among them: rubber elastic body refers to fluorine rubber or silicone rubber, the surface roughness Ra<500nm, and there are no excessive impurity particles on the surface.

[0062] The surface of the motherboard mold is coated with a hydrophobic, slippery coating to prevent the rubber from sticking to the surface of the motherboard. The edge curvature of the pitted area of the surface does not exceed 1 μm.

[0063] ⑵ ~ ⑶ with embodiment 1.

[0064] ⑷Introduce purified air with a flow rate of 300 sccm into the vacuum chamber to prevent floating dust in the air from entering the chamber. Then use the high-power pulsed ion source to carry out air plasma bombardment. At this time, the air plasma activates the rubber surface to generate a large number of free radicals,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com