Preparation method of static end tooth for electric tool

A technology for electric tools and static ends, which is applied in the field of preparation of static end teeth for electric tools, can solve the problems of limited local density improvement, and achieve the effect of increasing hardness and embryo body density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

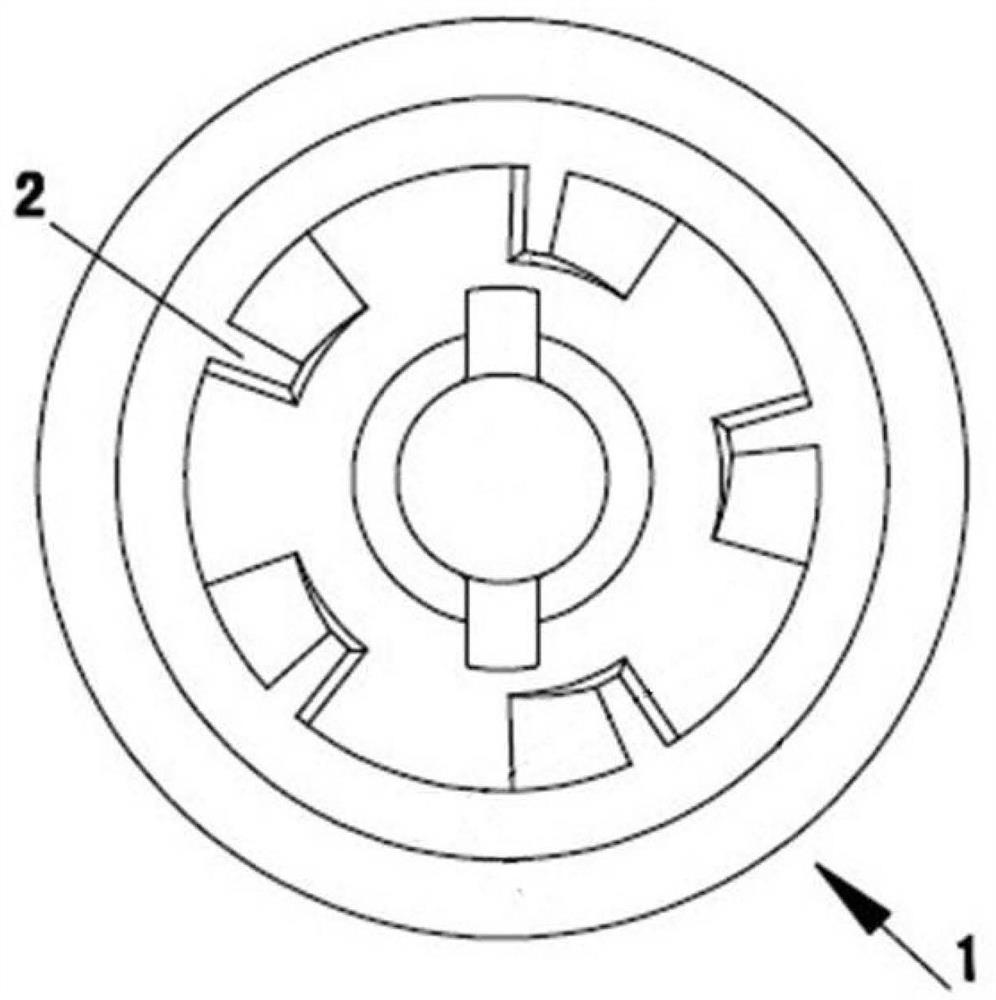

[0014] Specific embodiment one, please refer to figure 1 , a method for preparing static end teeth for electric tools, characterized in that the steps are:

[0015] (1) A plurality of bosses 2 are evenly distributed on the upper surface of the static end tooth body 1; top powder holes are respectively opened on the lower surface of the static end tooth body 1 corresponding to the plurality of bosses 2;

[0016] (2) There are five bosses 2, which are evenly distributed on the upper surface of the static end tooth body 1, and there are five top powder holes, which are respectively arranged on the static end tooth body corresponding to the bosses 2 on the lower surface of the

[0017] (3) On the lower surface of the static end tooth corresponding to the boss 2 on the upper surface, there are powder ejector holes respectively, and the powder ejector holes play the role of powder ejector when the static end teeth are pressed; during pressing, the powder ejector The metallurgical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com