Patents

Literature

101results about How to "Realize precise measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-station and multi-parameter vision measuring system and method for rotary parts

InactiveCN102553833AHigh degree of automationFast measurementUsing optical meansSortingMeasuring equipmentQuality control

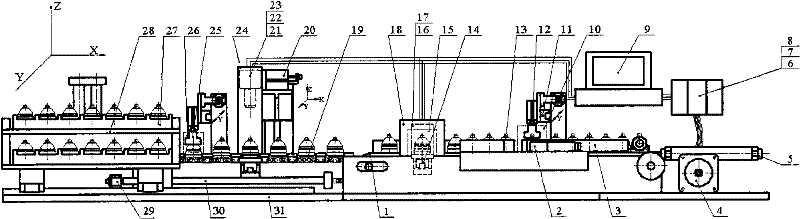

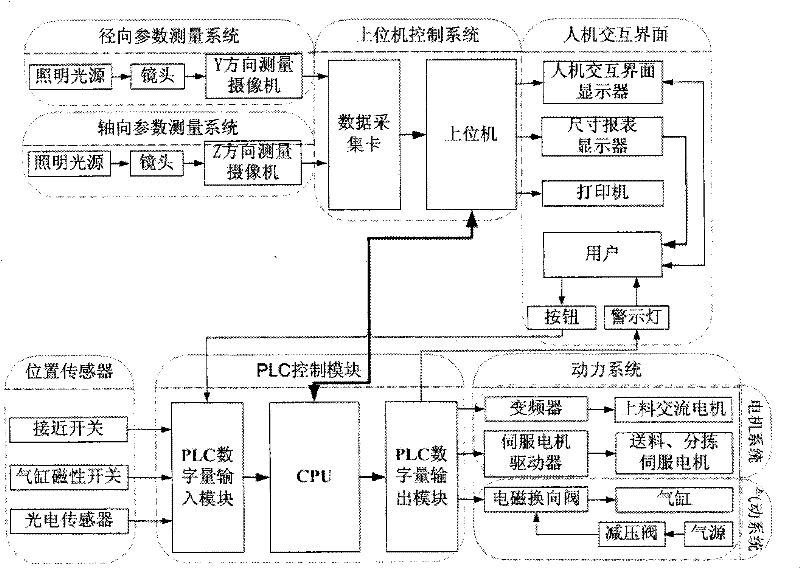

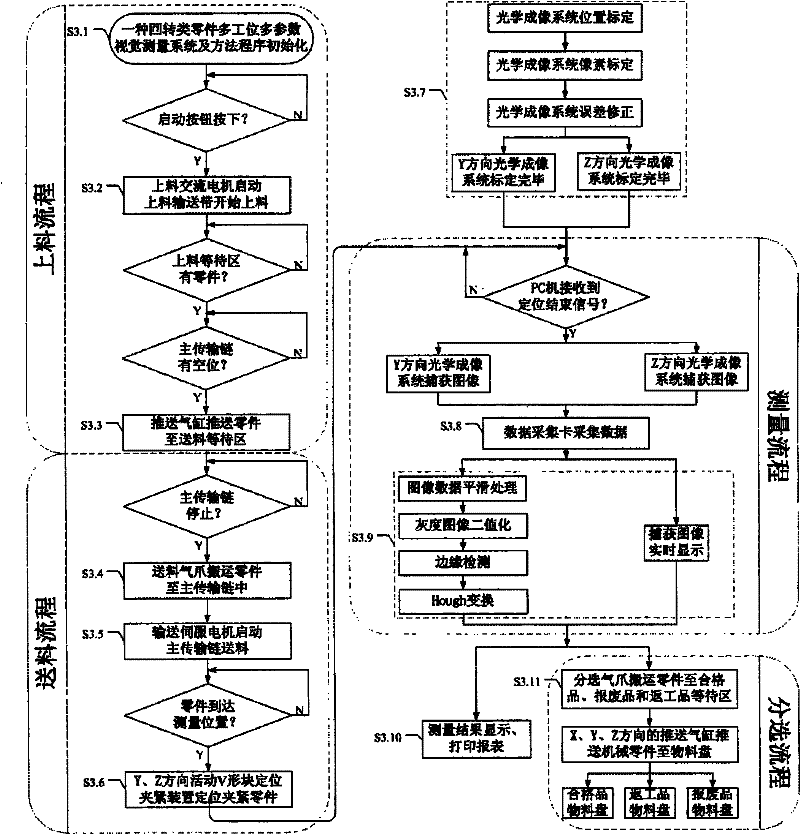

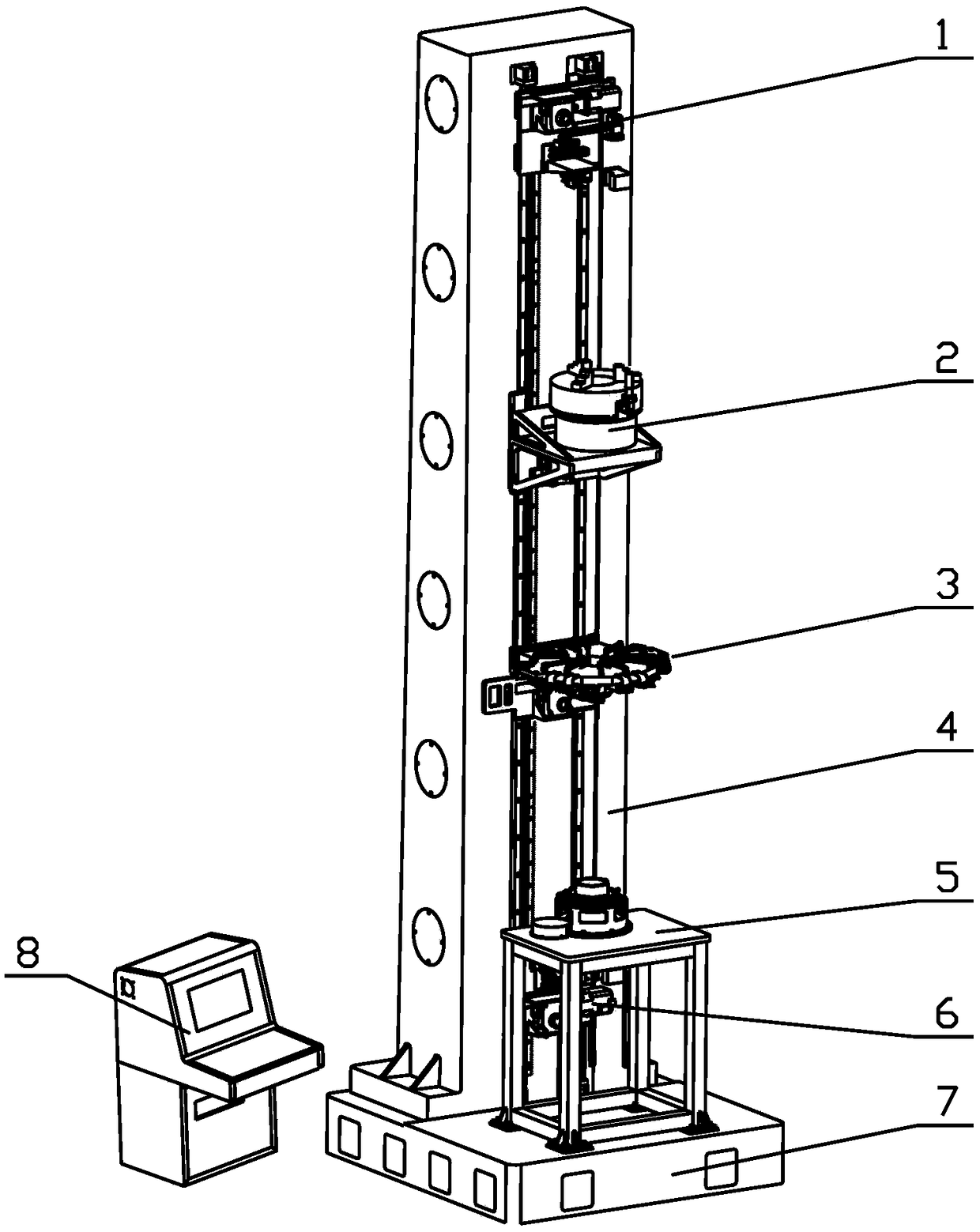

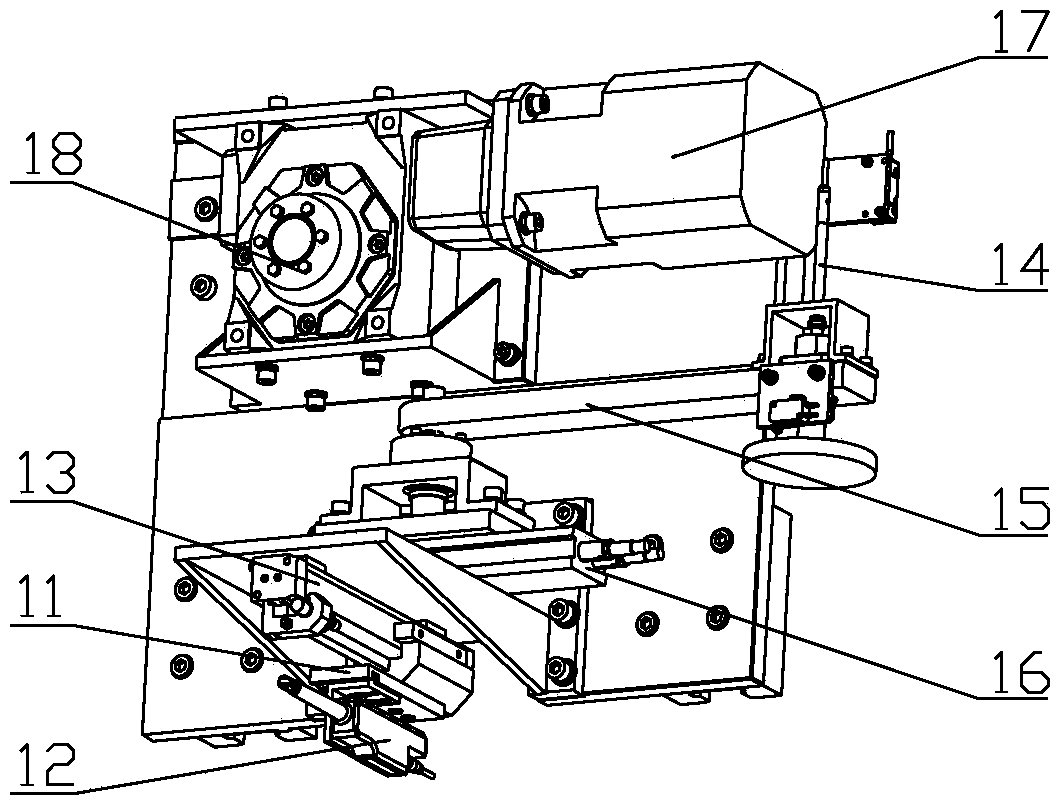

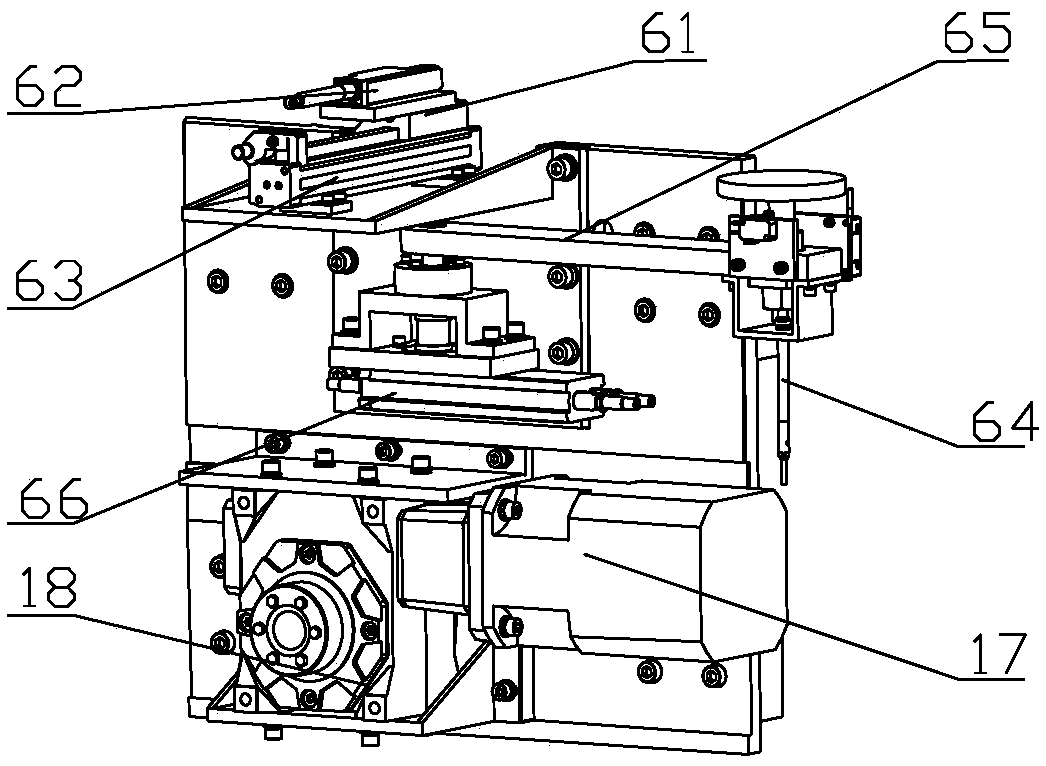

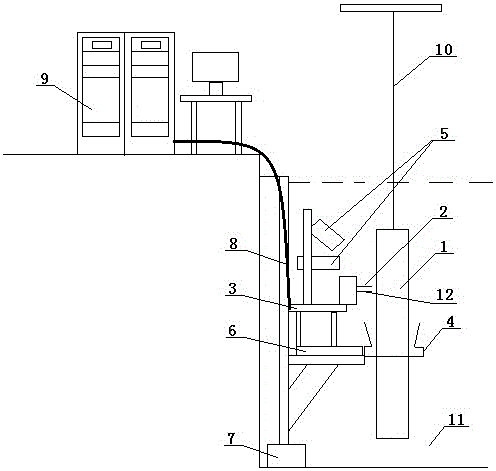

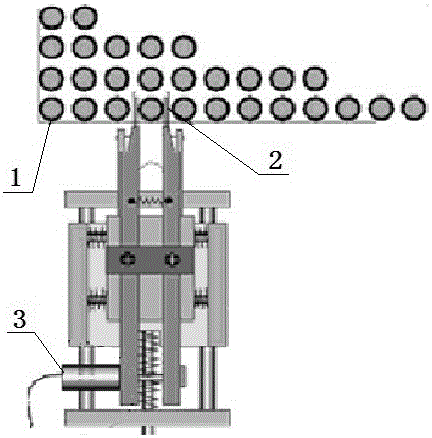

The invention discloses a multi-station and multi-parameter vision measuring system and method for rotary parts. The multi-station and multi-parameter vision measuring system comprises a Y-shaped feeding mechanism, a multi-station chain type feeding mechanism, a radial parameter measuring device, an axial parameter measuring device, a warehousing type three-dimensional sorting mechanism, a PLC (Programmable Logic Controller) control module, a human-machine interaction interface and an upper computer control system. The invention can provide geometrical quantity precision measuring equipment for the quality control of processing of the rotary parts on industrial field. The geometrical quantity precision measuring equipment can be used for detecting the geometric dimension error, shape error and position error and counting and analyzing the detection result of the same batch of parts to grasp the fluctuation condition of the batch quality of products. Meanwhile, the equipment has functions of automatically feeding parts and automatically sorting according to the measuring result and can be directly connected in series to the production line in series for on-line and full-detection of the parts.

Owner:ZHEJIANG UNIV

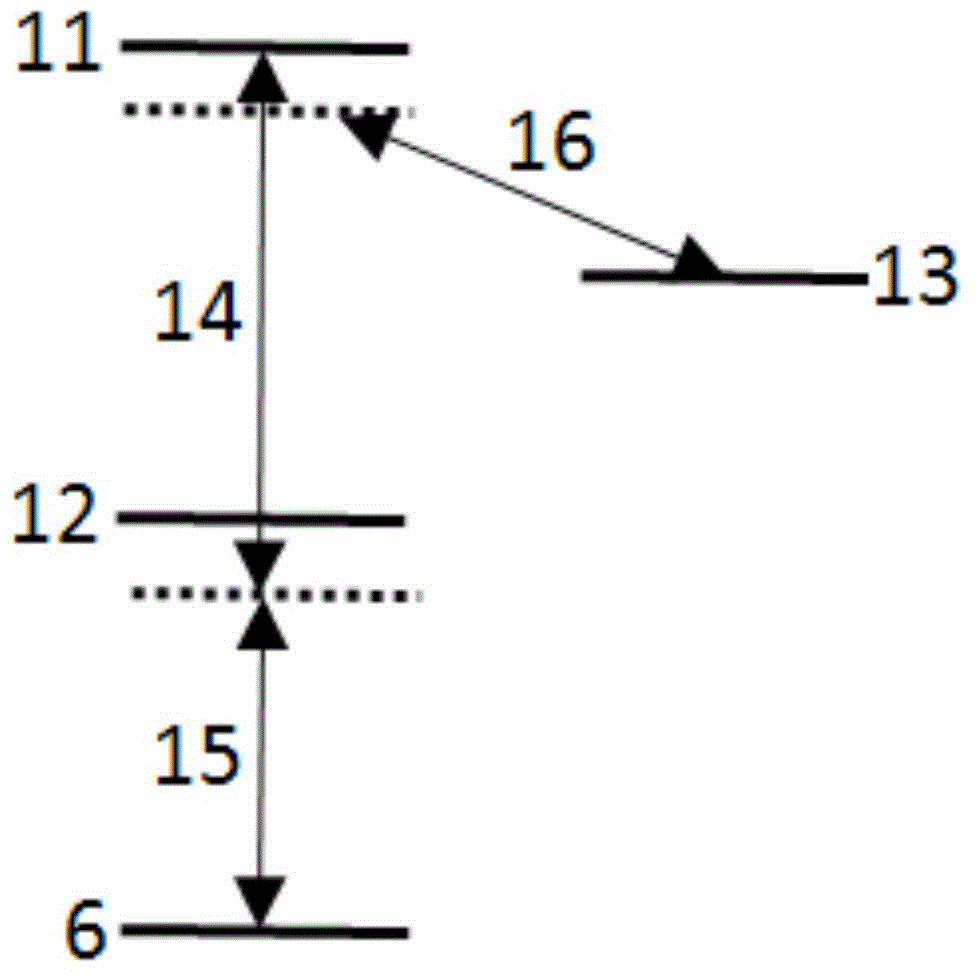

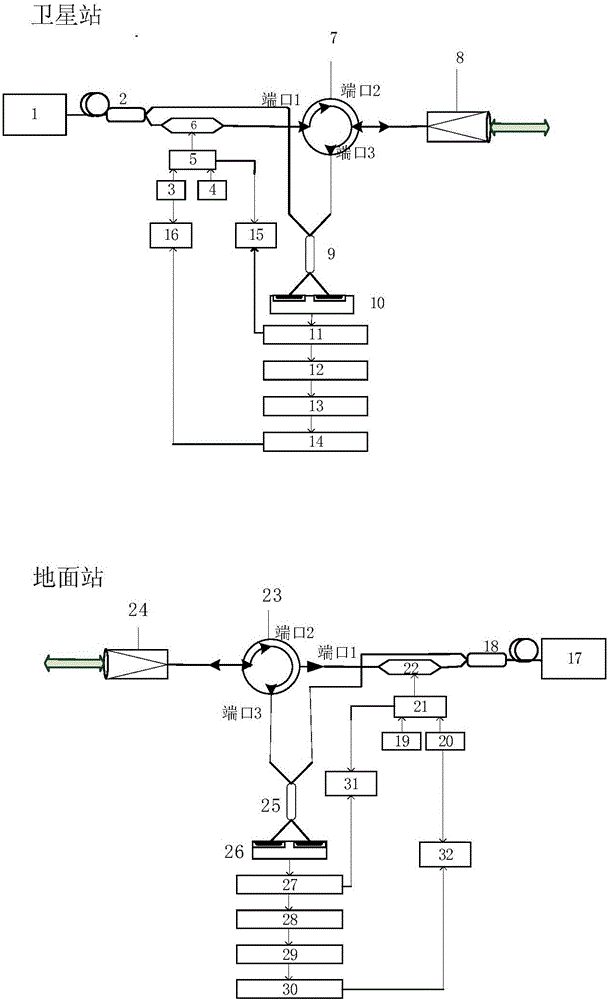

Microwave electric field intensity meter based on cold Rydberg atom interferometer and measuring method thereof

ActiveCN104880614AHigh measurement accuracyMake up for the defect that only point frequency measurement can be realizedElectrostatic field measurementsRydberg atomBeam splitting

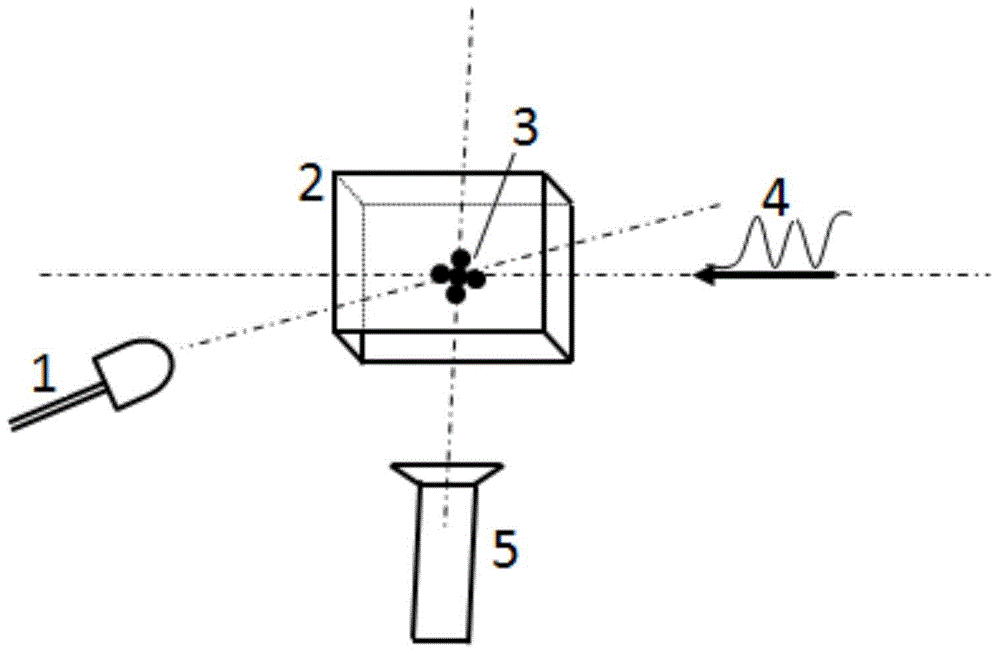

The invention discloses a microwave electric field intensity meter based on a cold Rydberg atom interferometer and a measuring method thereof. The microwave electric field intensity meter comprises: a vacuum system, which is used for cooling and trapping atom to generate a cold atom cloud for preparing a Rydberg state and generating an interference effect so as to generate a phase difference by coherent atomic states; a laser, which is used for generating coupling light and detection light and exciting the cold atom in the vacuum system from a ground state to the Rydberg state coherently; a photoelectric detector, which is used for detecting an interference fringe generated by two beams of cold atom clouds due to coherence; and a microwave source, which is used for generating a microwave electric field. According to the invention, when the microwave electric field intensity meter is applied to the evolution process of coherent beam splitting and combination, the atom cloud in the Rydberg state interacts with a to-be-measured microwave electric field, thereby generating an alternating-current stark effect; and the to-be-measured microwave electric field intensity is associated with a phase generated by the an alternating-current stark, thereby realizing precise measurement of the microwave electric field.

Owner:清远市天之衡量子科技有限公司

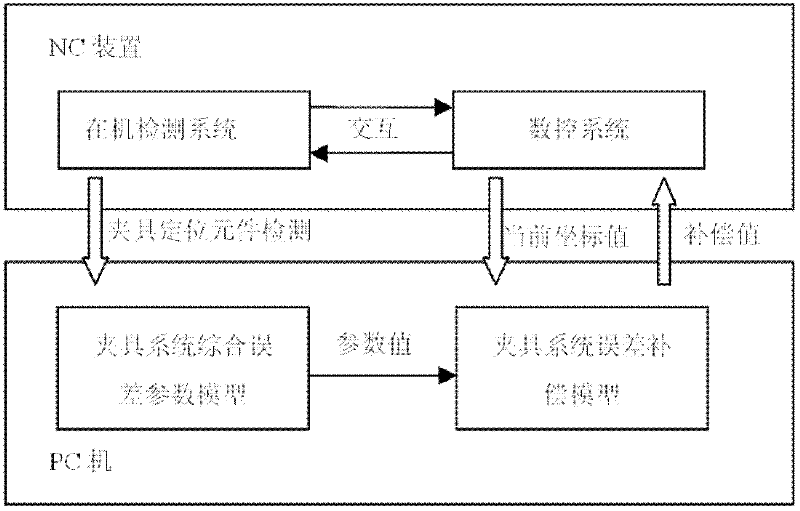

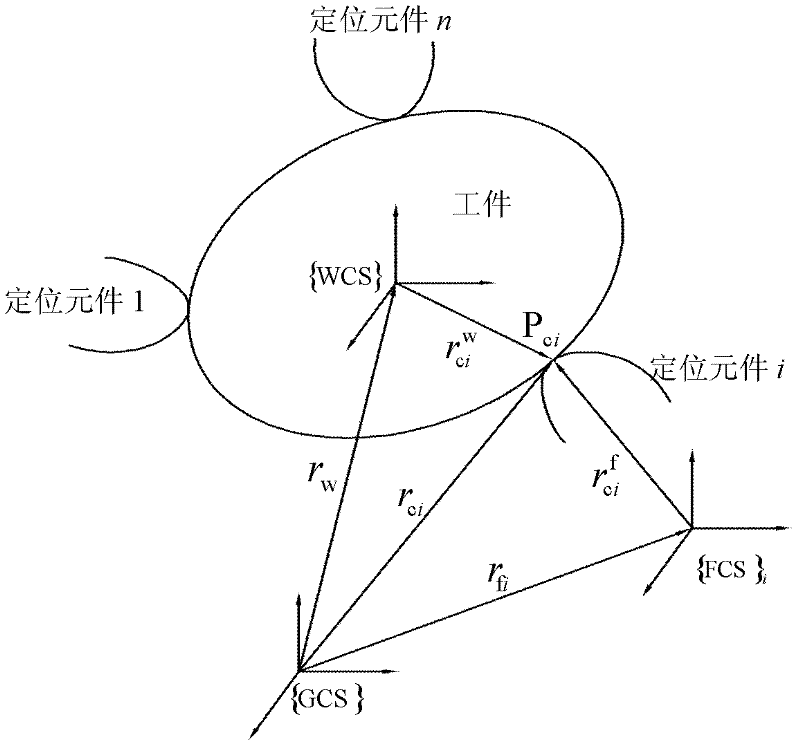

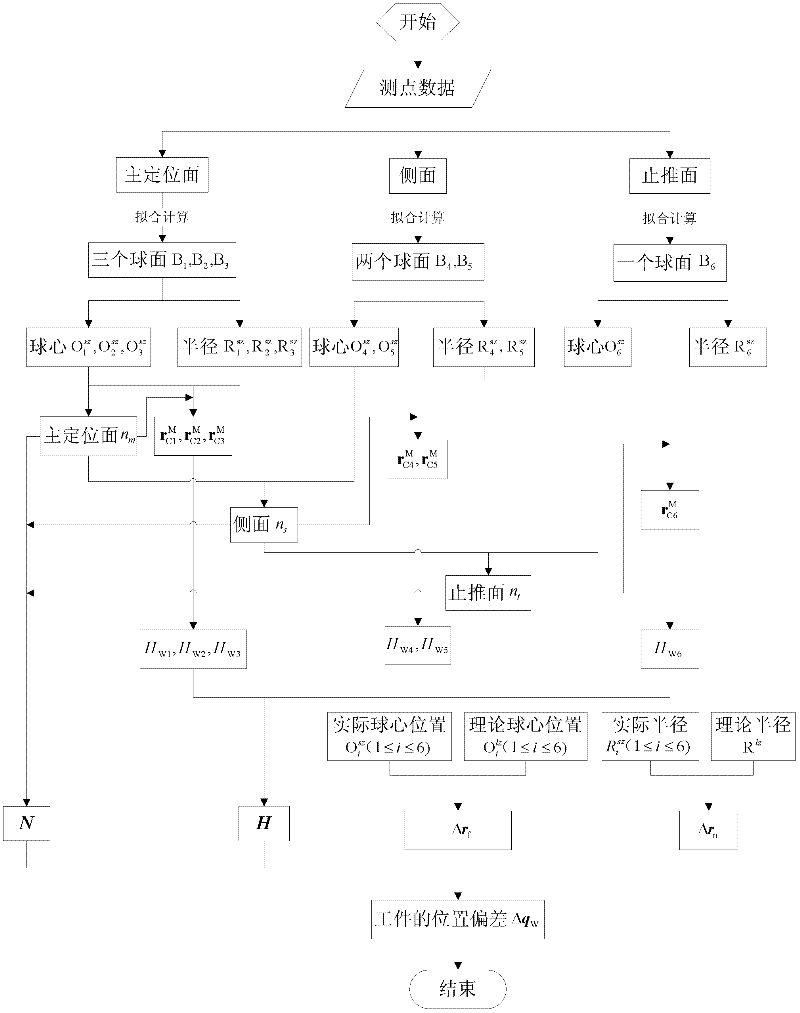

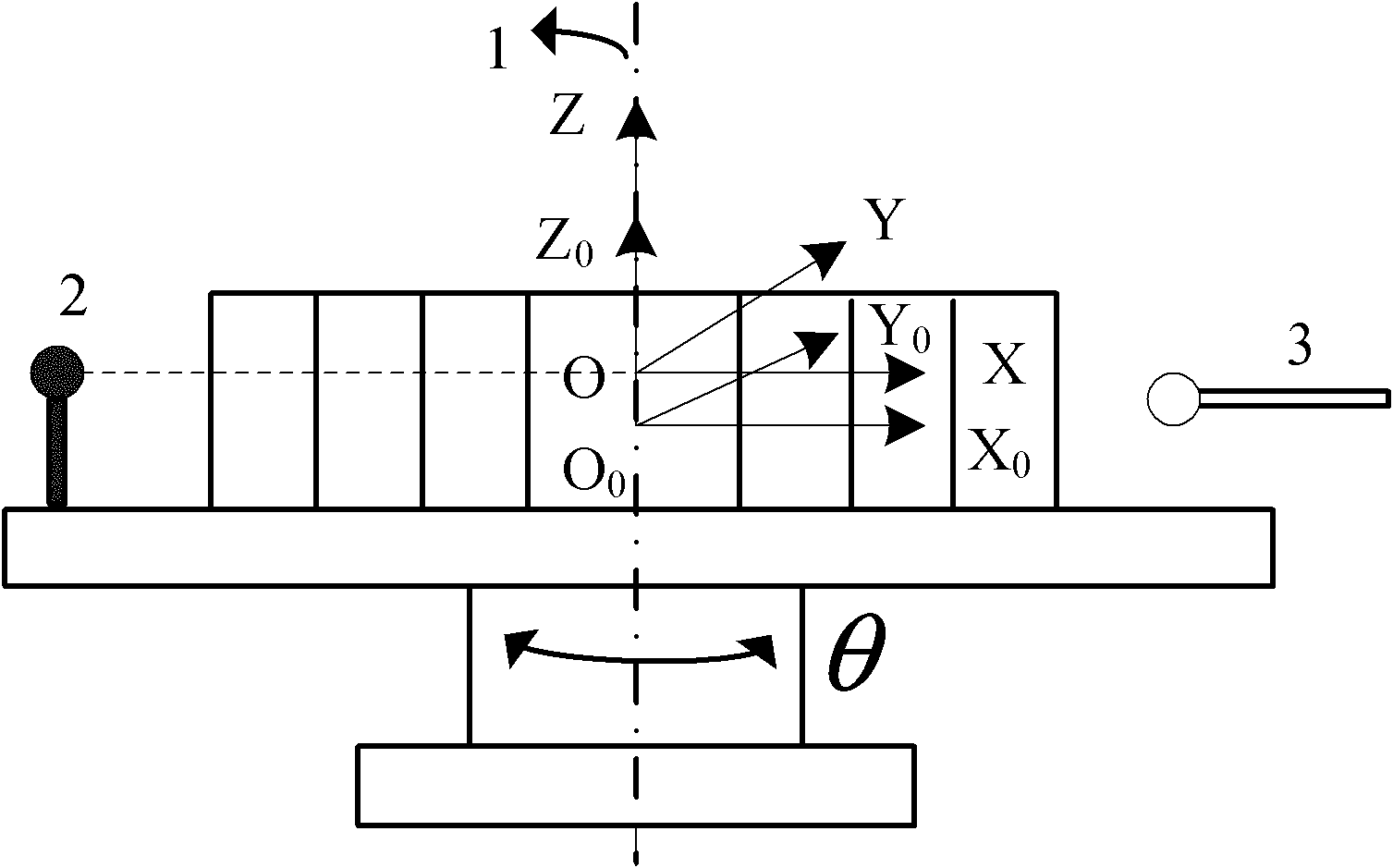

Method for realizing extraction of comprehensive errors and determination of compensation values for jig system

InactiveCN102225516AClarify the mapping relationshipEasy to chooseAutomatic control devicesFeeding apparatusSimulationErrors and residuals

The invention discloses a method for realizing extraction of comprehensive errors and determination of compensation values for a jig system, and relates to the field of mechanical processing. The method includes the following steps of: acquiring a comprehensive error parameter model of the jig system; establishing an on-machine detection platform, and determining the position and the posture deviation delta qW of a workpiece below a machine tool coordinate system on the basis of an on-machine detection technique and the comprehensive error parameter model of the system; establishing a comprehensive error compensating model of the jig system according to a coordinate transformation theory, and determining compensation values of the machine tool in three directions at each point of the motion track of a cutter by compensating operation. The method clearly and simply clarifies the mapping relation between the jig system error and the workpiece posture offset, and has a sufficient theoretical basis; a concise and precise error extraction method is provided; the precise measurement and calculation of jig errors can be realized. According to the method, the real-time processing compensation can be carried out, and the processing precision is further improved.

Owner:TIANJIN UNIV

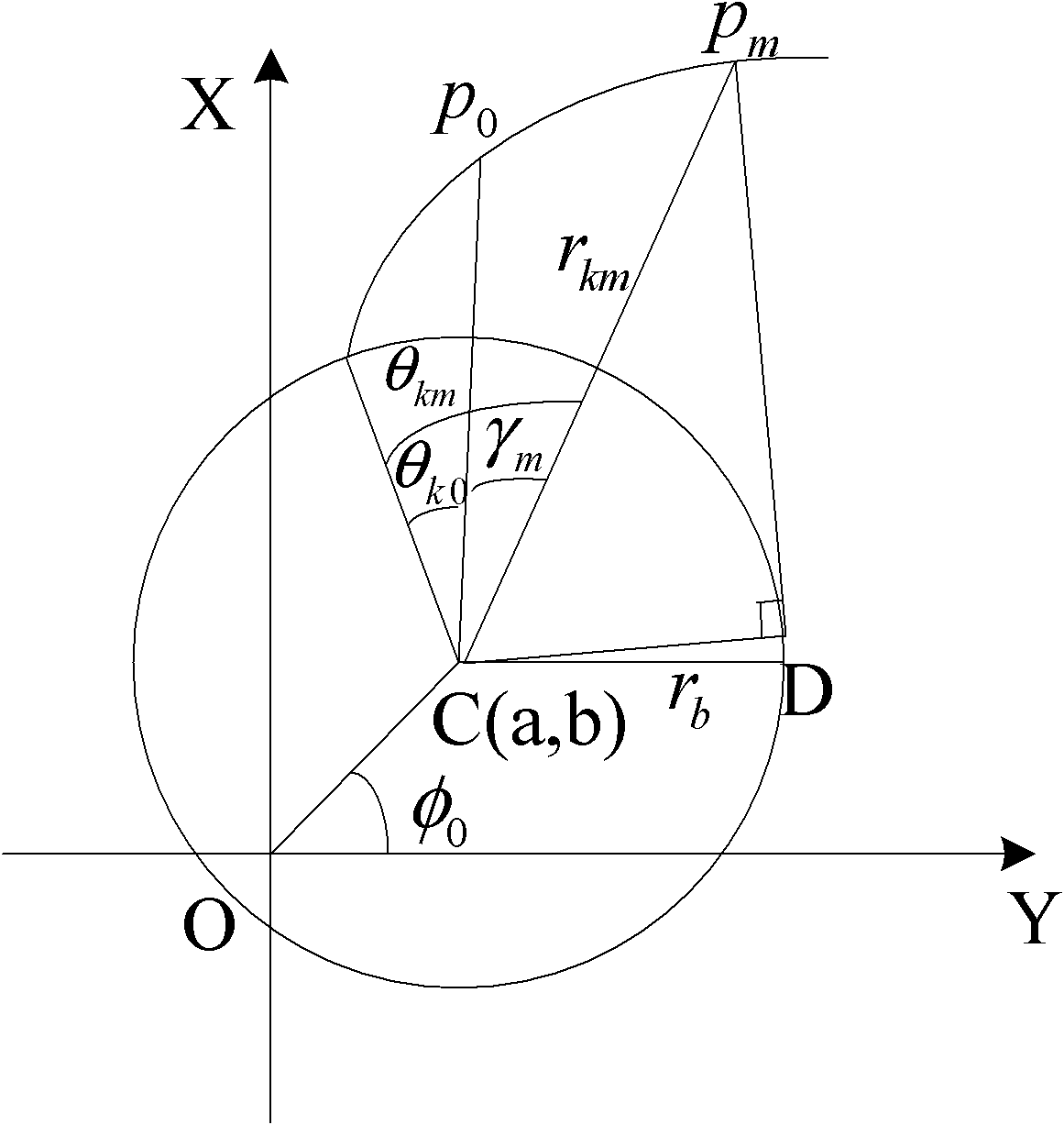

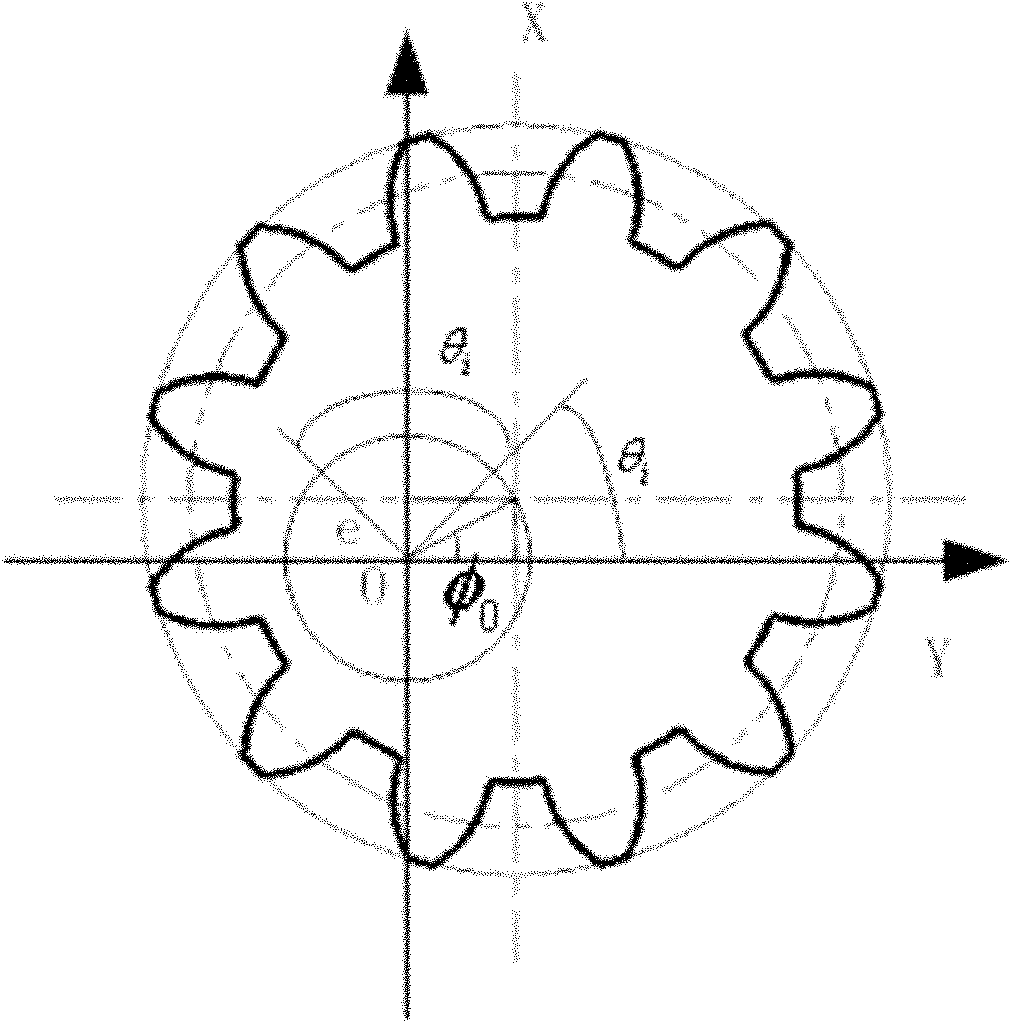

Fitting eccentric error compensating method based on CNC (Computerized Numerical Control) gear measuring center

InactiveCN102147331AAchieve separationImprove accuracyMachine gearing/transmission testingElectric/magnetic contours/curvatures measurementsNumerical controlAlgorithm

The invention discloses a fitting eccentric error compensating method based on a CNC (Computerized Numerical Control) gear measuring center, belonging to the technical field of measurement and solving the problem that the measurement precision is influenced in the traditional gear measuring process because the geometric center of a gear deviates from an instrument center of gyration. The fitting eccentric error compensating method comprises the following steps of: firstly, establishing a workpiece coordinate system and an instrument coordinate system; acquiring an expression of a fitting eccentric vector by means of a transformational relation between the two coordinate systems in an eccentric measurement state; setting an initial eccentric parameter of a workpiece to be detected, and acquiring an expression of a polar angle of the deviation of an original point of the workpiece coordinate system from the original point of the instrument coordinate system; establishing the transformational relation between the two original points of the two coordinate systems in the fitting eccentric measuring state; transforming a measurement value of the workpiece to be detected into a spatial coordinate value in the instrument coordinate system; calculating the initial eccentric parameter value of the workpiece to be detected; calculating a fitting eccentric vector value; and compensating the measurement value for error evaluation. The fitting eccentric error compensating method disclosed by the invention is used for error compensation in the gear measuring process.

Owner:HARBIN INST OF TECH

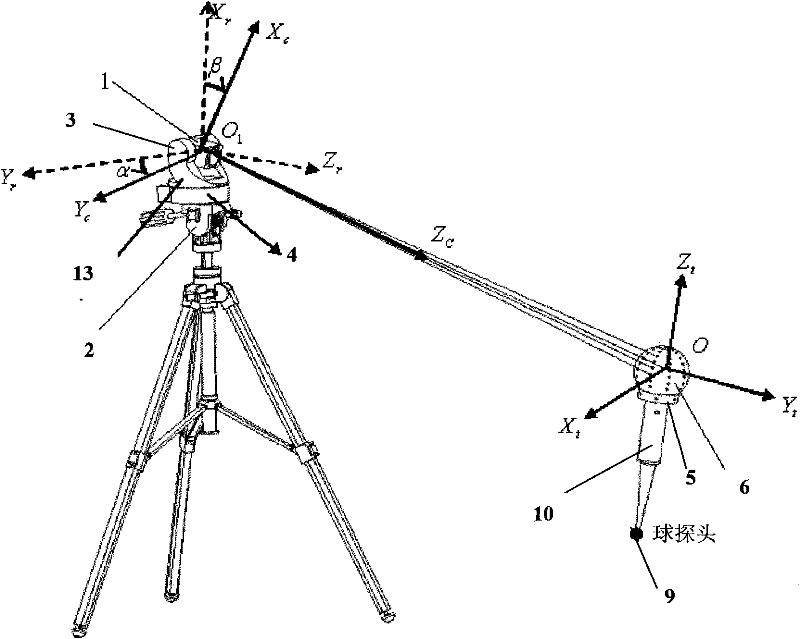

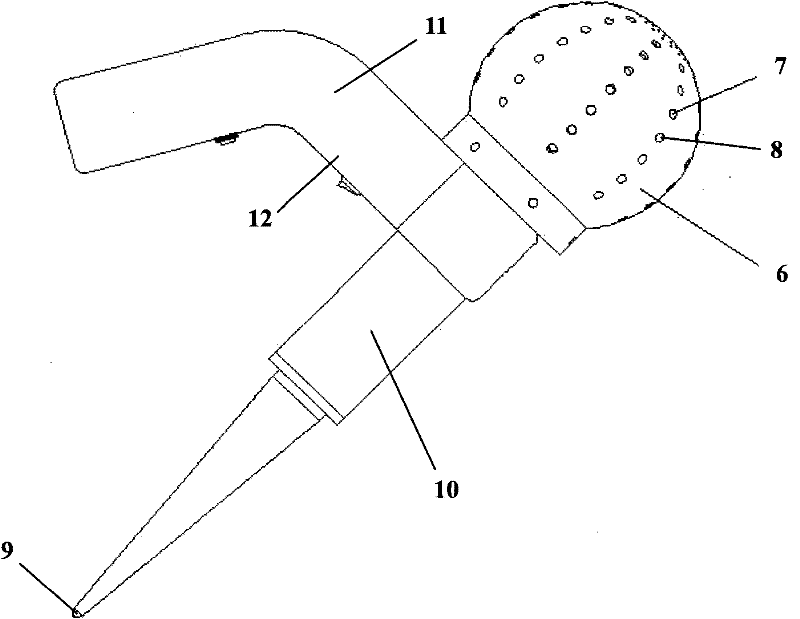

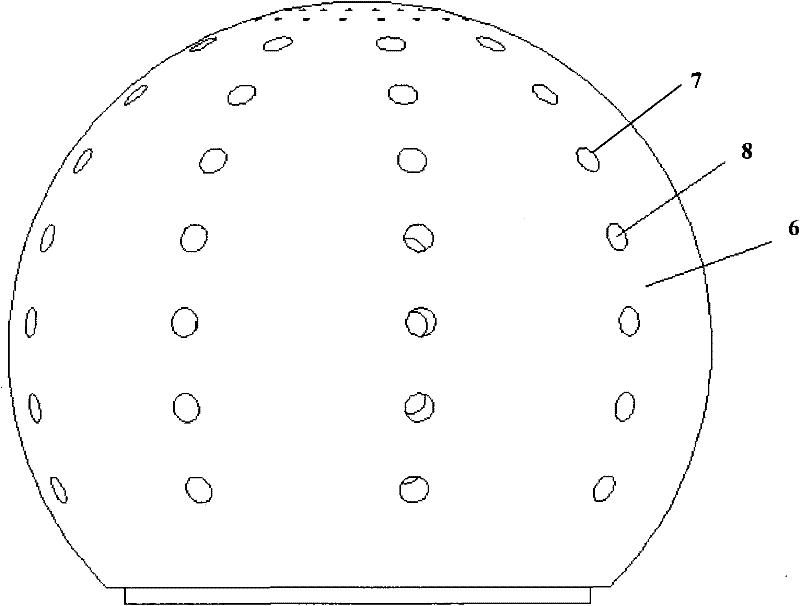

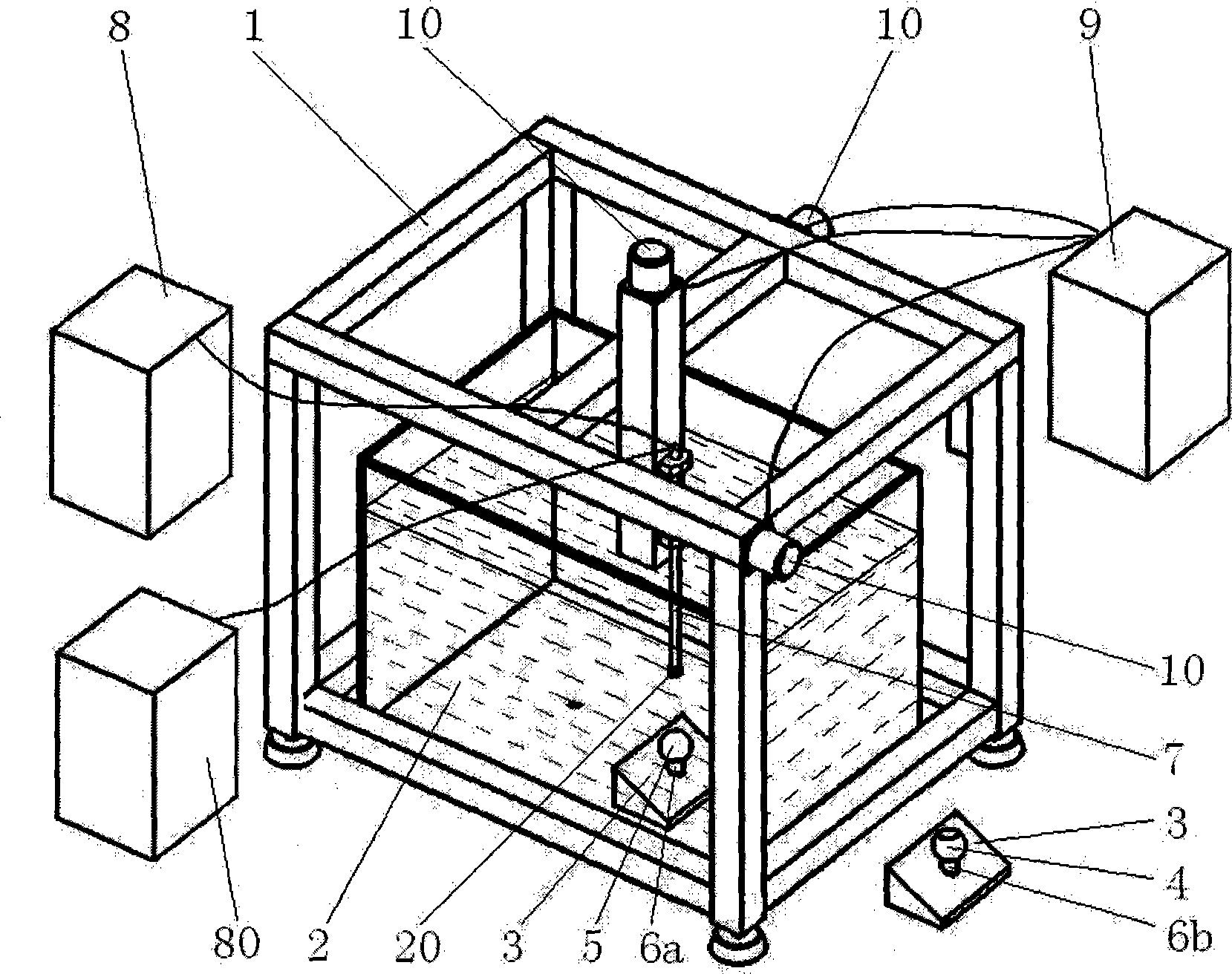

Large-space visual tracking 6D measurement system and measurement method

InactiveCN102288106AAssembly precisionImprove adaptabilityAngle measurementTelevision system detailsCombined useCoordinate-measuring machine

The invention discloses a large-space visual tracking six-dimensional measurement system and method. The system mainly comprises a self-zooming visual tracking camera and a color paseudorandom coding six-freedom degree measuring head. The gesture and space position coordinates of the measuring head are confirmed by utilizing the position change of a hole center with color paseudorandom coding expression on a target ball so as to realize the measurement of large-size space six-freedom degree. The system can be combined with a joint arm coordinate measuring machine to realize local high-precision measurement and positioning and can be also combined with assembly equipment of electric drilling, and the like to realize the precise assembly of large equipment.

Owner:HEFEI UNIV OF TECH

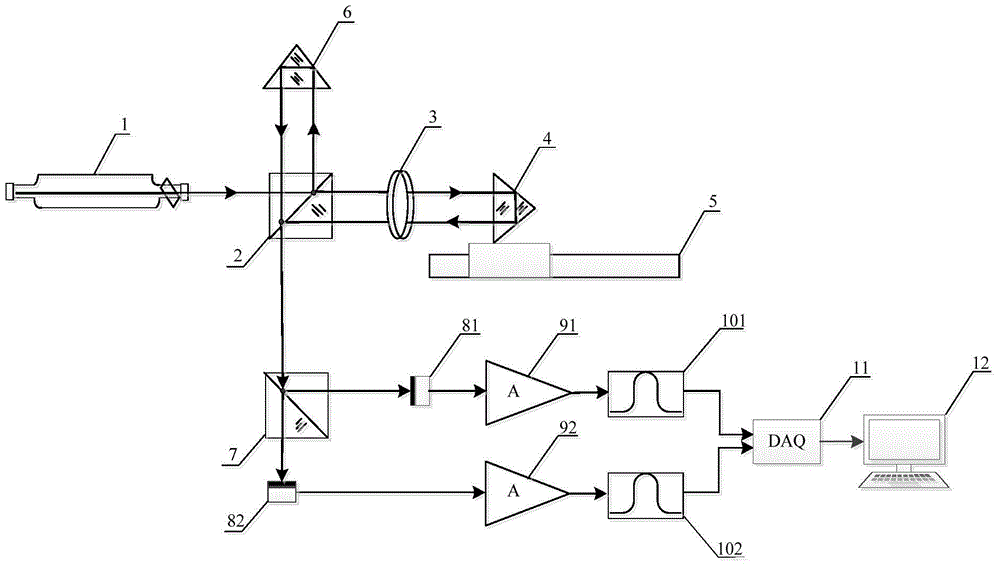

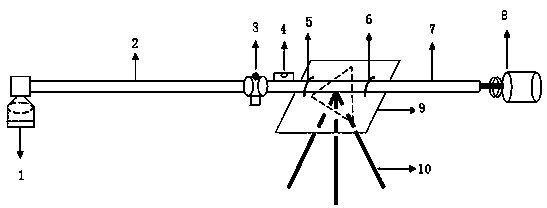

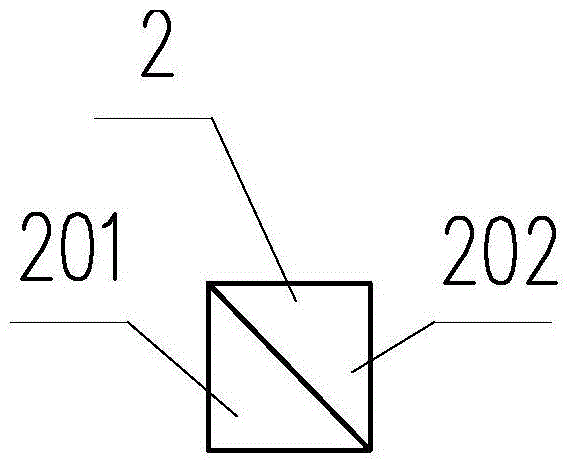

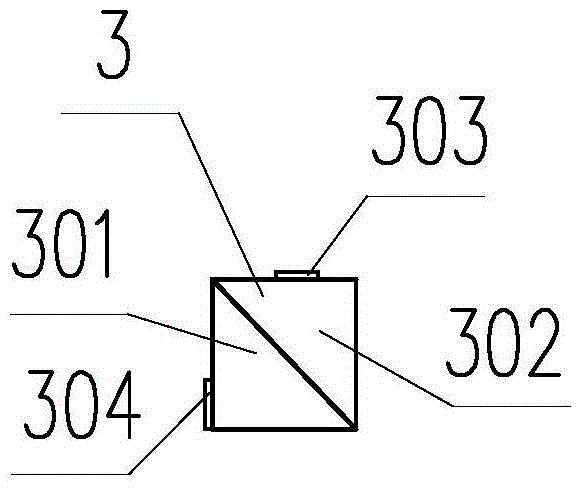

Orthogonal homodyne laser interferometer and measurement method thereof

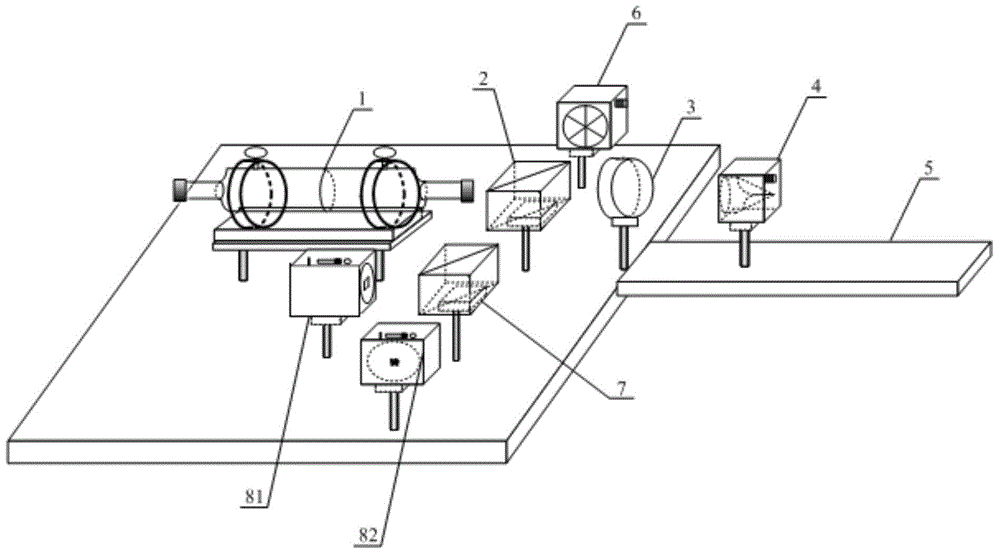

InactiveCN105043243AImprove general performanceImprove performanceUsing optical meansBeam splitterBand-pass filter

The invention discloses an orthogonal homodyne laser interferometer and a measurement method thereof. The interferometer is simple and reliable in structure, and comprises a helium-neon laser, a beam splitter prism, a lambda / 8 wave plate, a cubic pyramid prism, a measuring cubic pyramid prism, a precision guide rail, a photoelectric detector, a small signal amplification module, a band-pass filter module, an analog-to-digital conversion unit and a computer data processing unit. According to the invention, laser light emitting by the laser is split into reference light and measuring light after passing through the beam splitter prism, the measuring light firstly passes through the lambda / 8 wave plate and is then reflected by the measuring cubic pyramid prism so as to acquire a light beam, the light beam passes through the lambda / 8 wave plate again and generates interference with a reference light beam reflected by a reference cubic pyramid prism, and finally, two paths of orthogonal polarized light are acquired after passing through a polarization splitting prism; the photoelectric detector receives light signals and converts the light signals into electric signals, and signal conditioning is carried out by an amplification and filtering module; and the analog-to-digital conversion unit is controlled by a computer unit to acquire the conditioned electric signals, the phase is demodulated, and the real-time displacement of the measuring cubic pyramid prism is acquired and displayed.

Owner:NANJING NORMAL UNIVERSITY

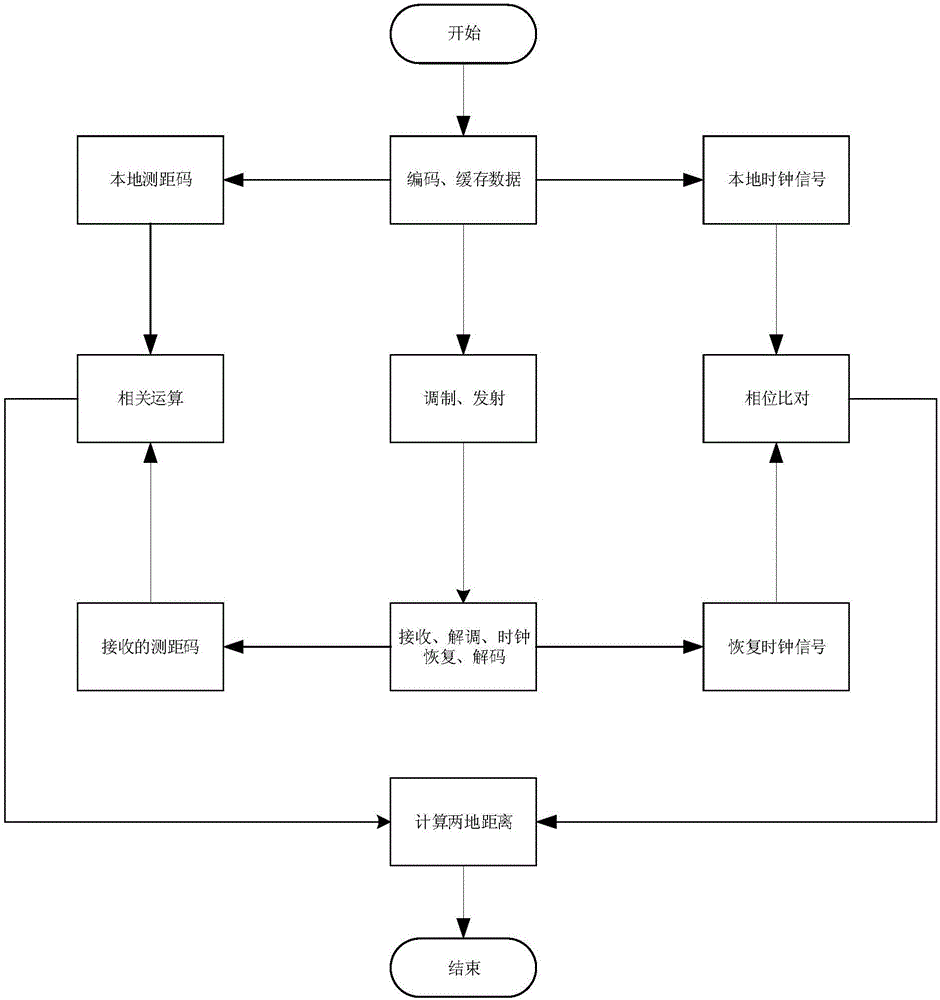

Integration method for high-speed laser communication method and high-precision laser ranging

ActiveCN106603149AHigh precision rangingRealize precise measurementFree-space transmissionElectromagnetic wave reradiationLaser rangingCommunications system

The invention discloses an integration method for high-speed laser communication and high-precision ranging. A ranging technology is integrated in a laser communication system, a ranging code with uniqueness, good self-correlation and cross-correlation properties is embedded into communication data, and is transmitted in series with the communication data after coding to achieve high-speed communication; and the received ranging code and a local ranging code are subjected to correlation operation at a receiving end to obtain a rough measurement time value of a code element width of integer multiples, and meanwhile, an accurate measurement time value in a code element of the ranging code is computed by virtue of a phase difference between a local clock and a receive recovery clock, thereby achieving integration of high-speed laser communication and high-precision ranging. The integration method disclosed by the invention adopts bidirectional single-way communication to accomplish time frequency transmission of clocks while ranging; and the integrated method disclosed by the invention can achieve high-speed laser communication and high-precision ranging without high-speed A / D conversion.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

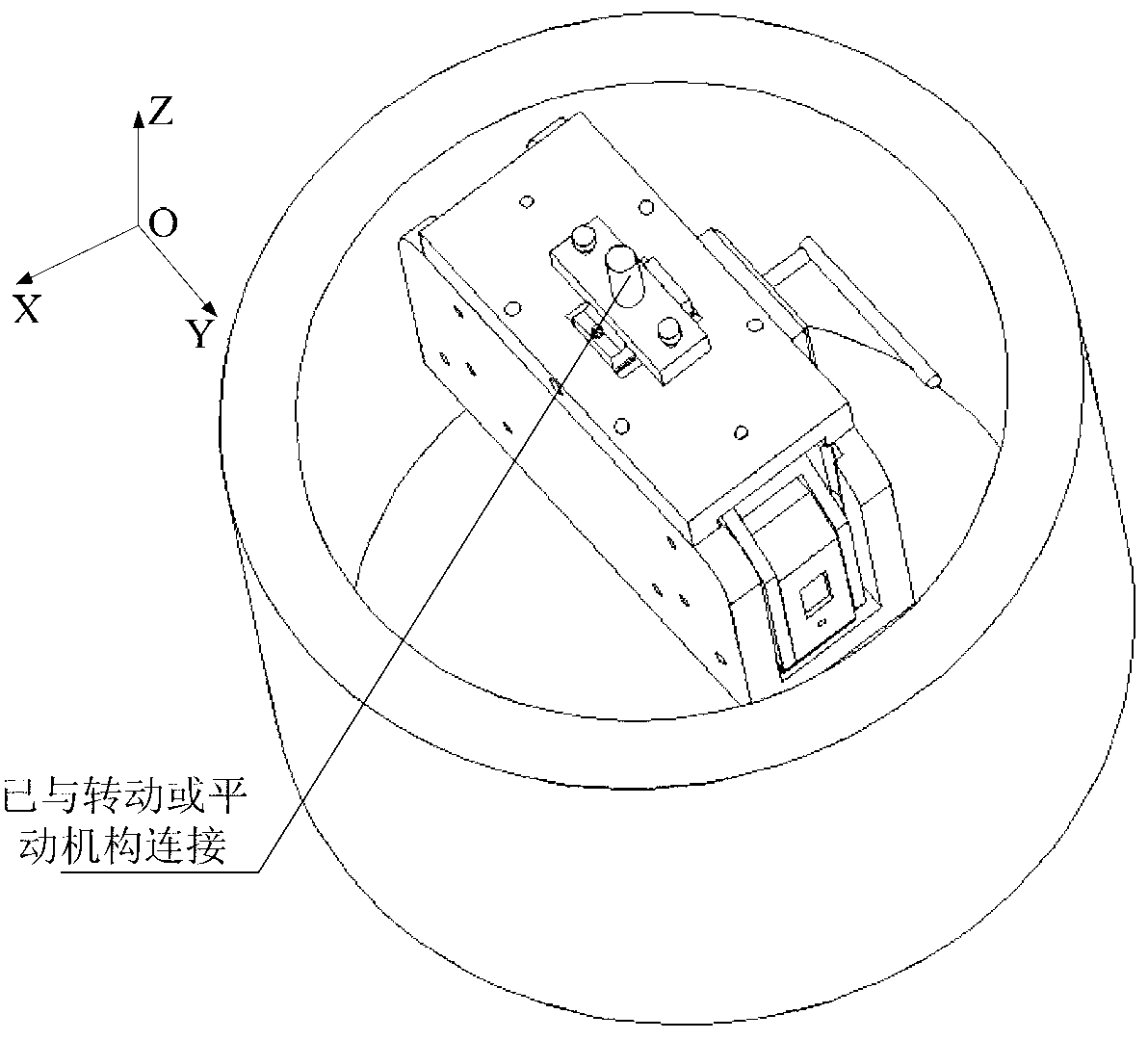

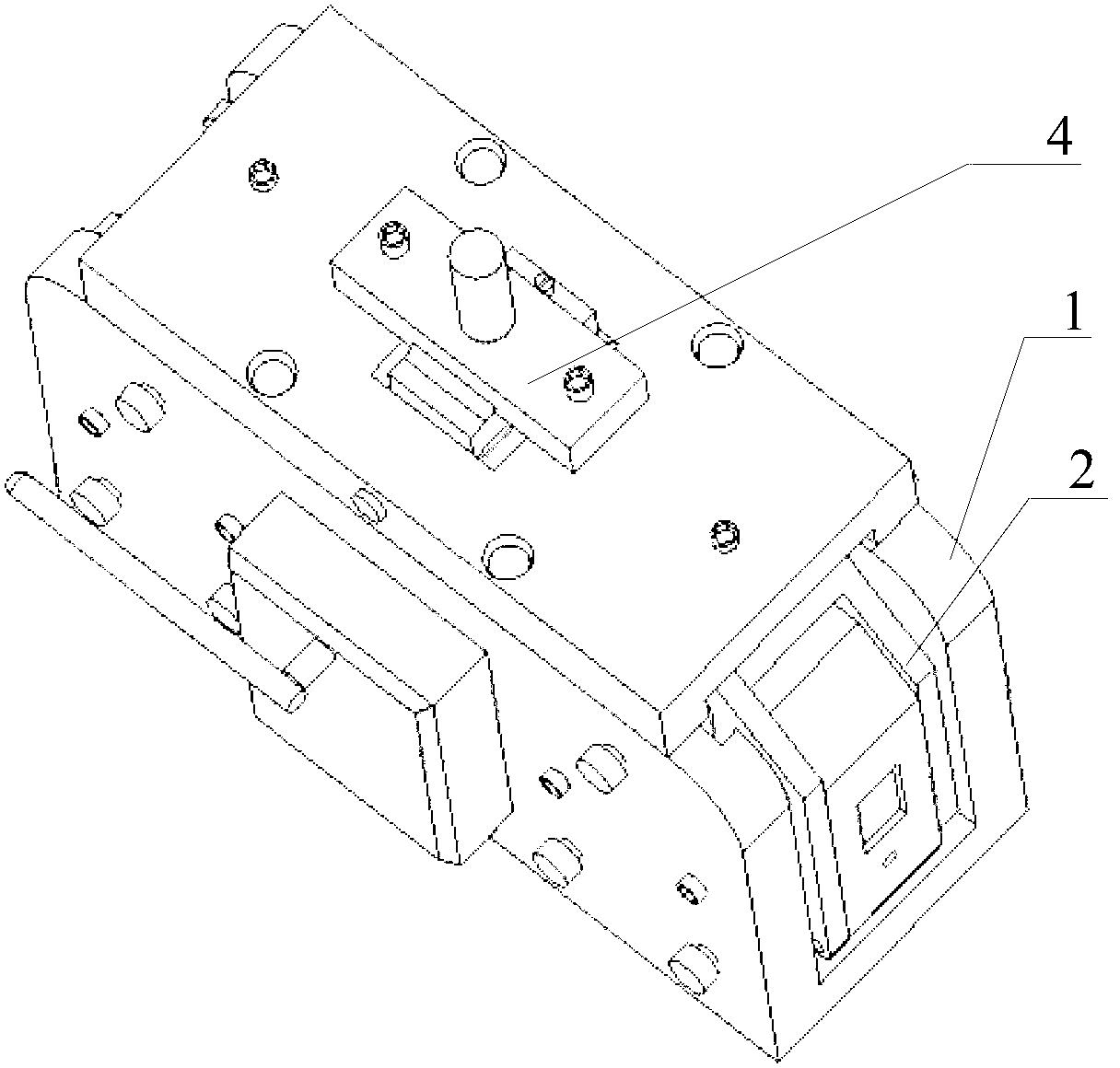

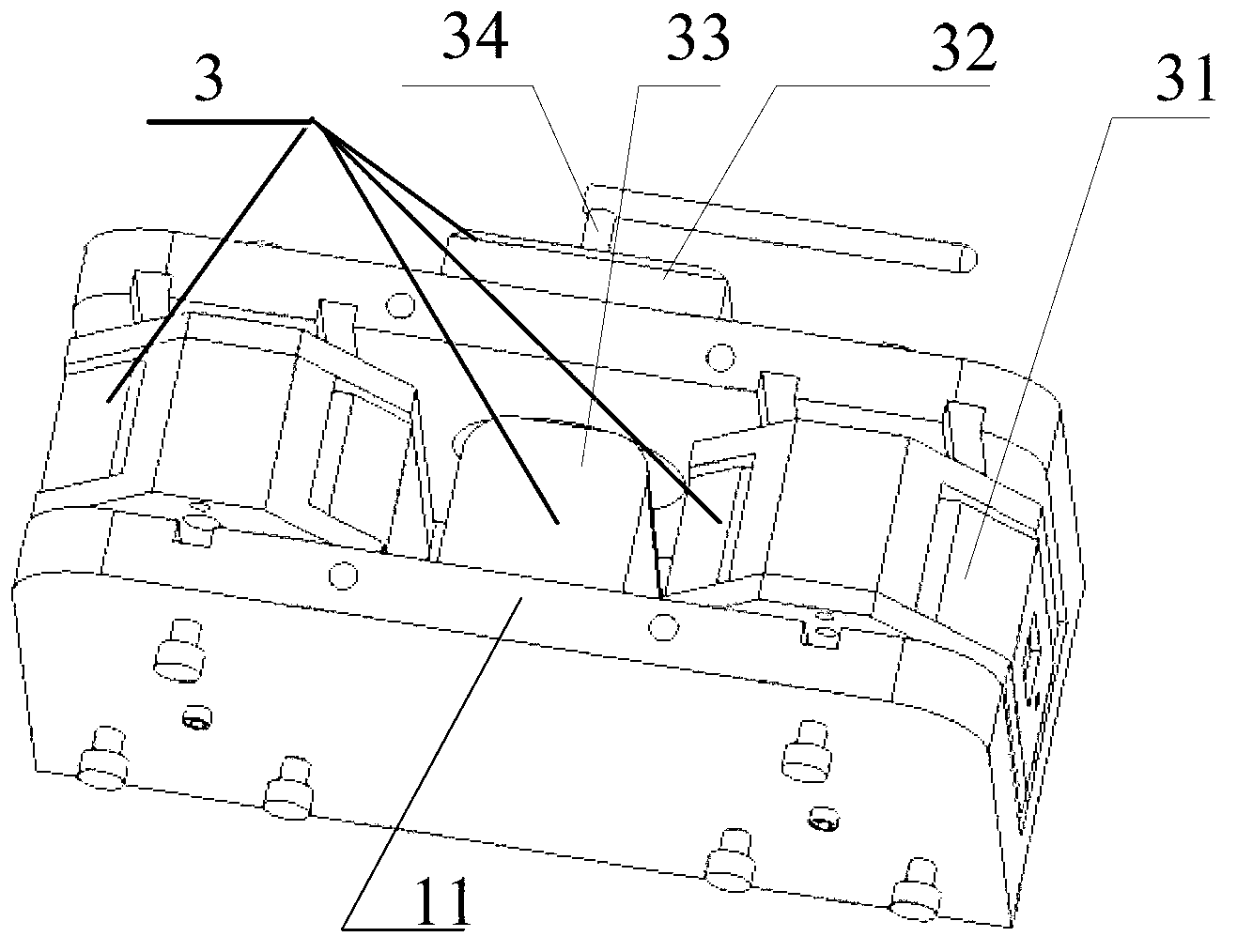

Aperture measuring method based on non-contacting type sensor combination

InactiveCN103278100AQuick and accurate measurementImprove detection accuracyUsing optical meansOptical axisDual sensor

The invention discloses an aperture measuring method based on non-contacting type sensor combination, is suitable for measuring the size of the inner diameter of a workpiece, and relates to the geometric sense measuring field. The method comprises the following steps: first, installing a main shaft of a double-sensor measuring head on a mechanism with the horizontal moving function so as to form a complete set of measuring system which is arranged in a workpiece to be measured; at measuring time, measuring optical axes of two sensors on the double-sensor measuring head being enabled to be on the same straight line; the double-sensor measuring head first rotating on a ZOY face, and then horizontally moving on an XOY face, finally the diameter of an inner hole of the workpiece to be measured is obtained; or, the double-sensor measuring head sequentially rotates on the ZOY face and the XOY face to obtain the diameter of the inner hole of the workpiece to be measured. When the method is used for measuring the diameter of the inner hole of the workpiece to be measured, only two procedures need operating theoretically, so that measuring efficiency is greatly improved, and a large number of measuring labor hours are saved. Moreover, the non-contacting measuring head is arranged on a lathe, a motion execution mechanism of the lathe is used for enabling the measuring head to rotate or move horizontally, so that on-machine accurate measuring can be achieved.

Owner:TIANJIN UNIV

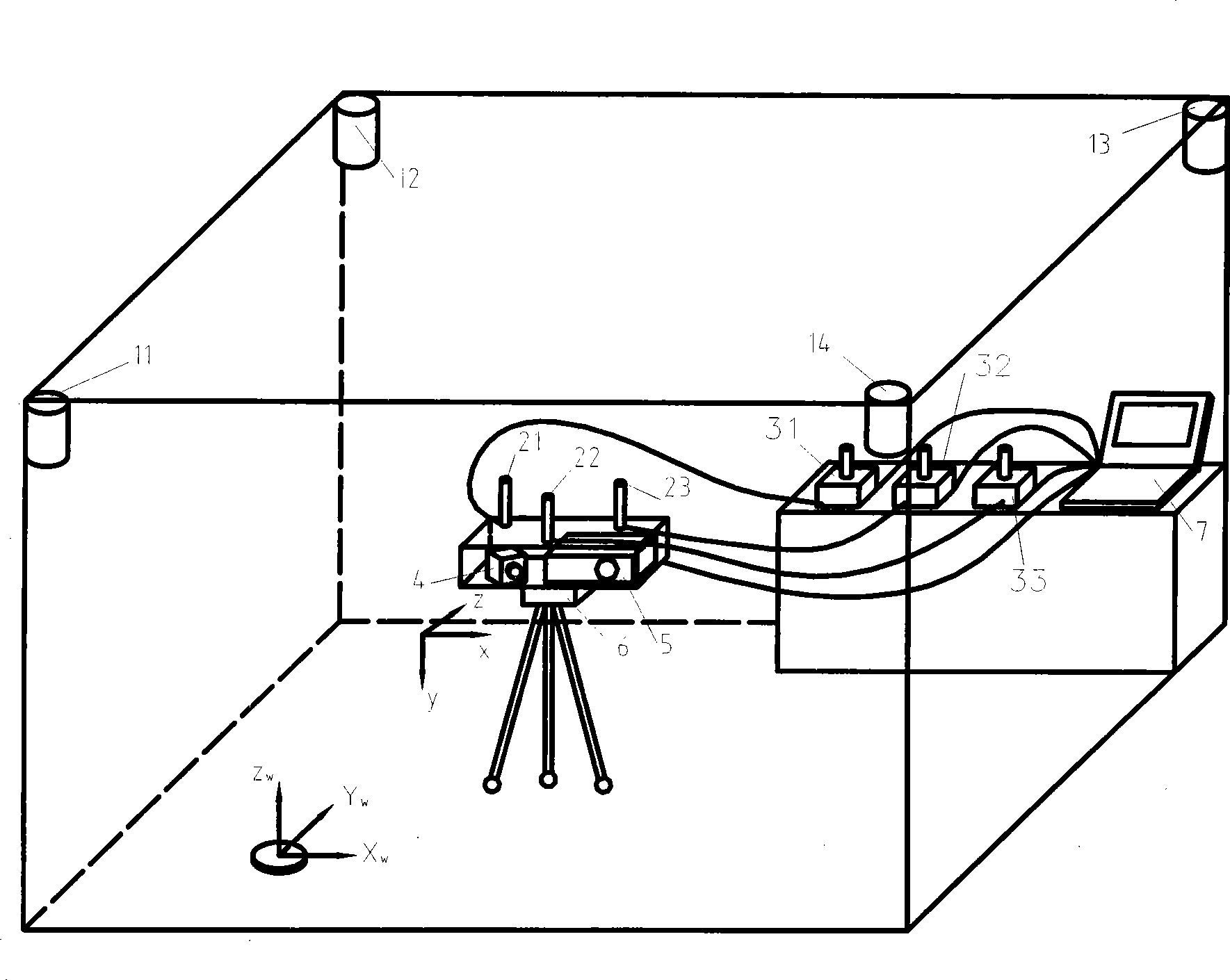

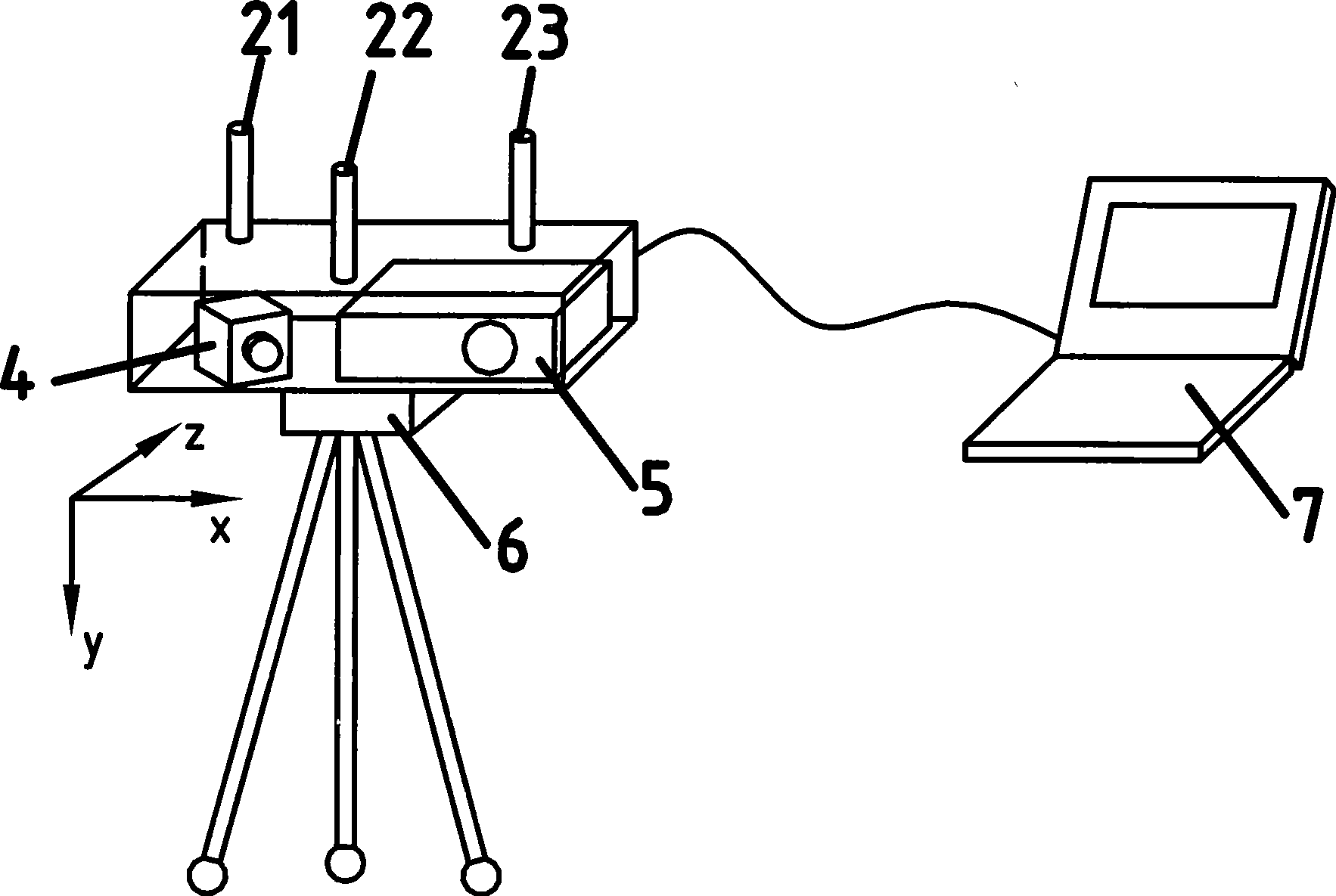

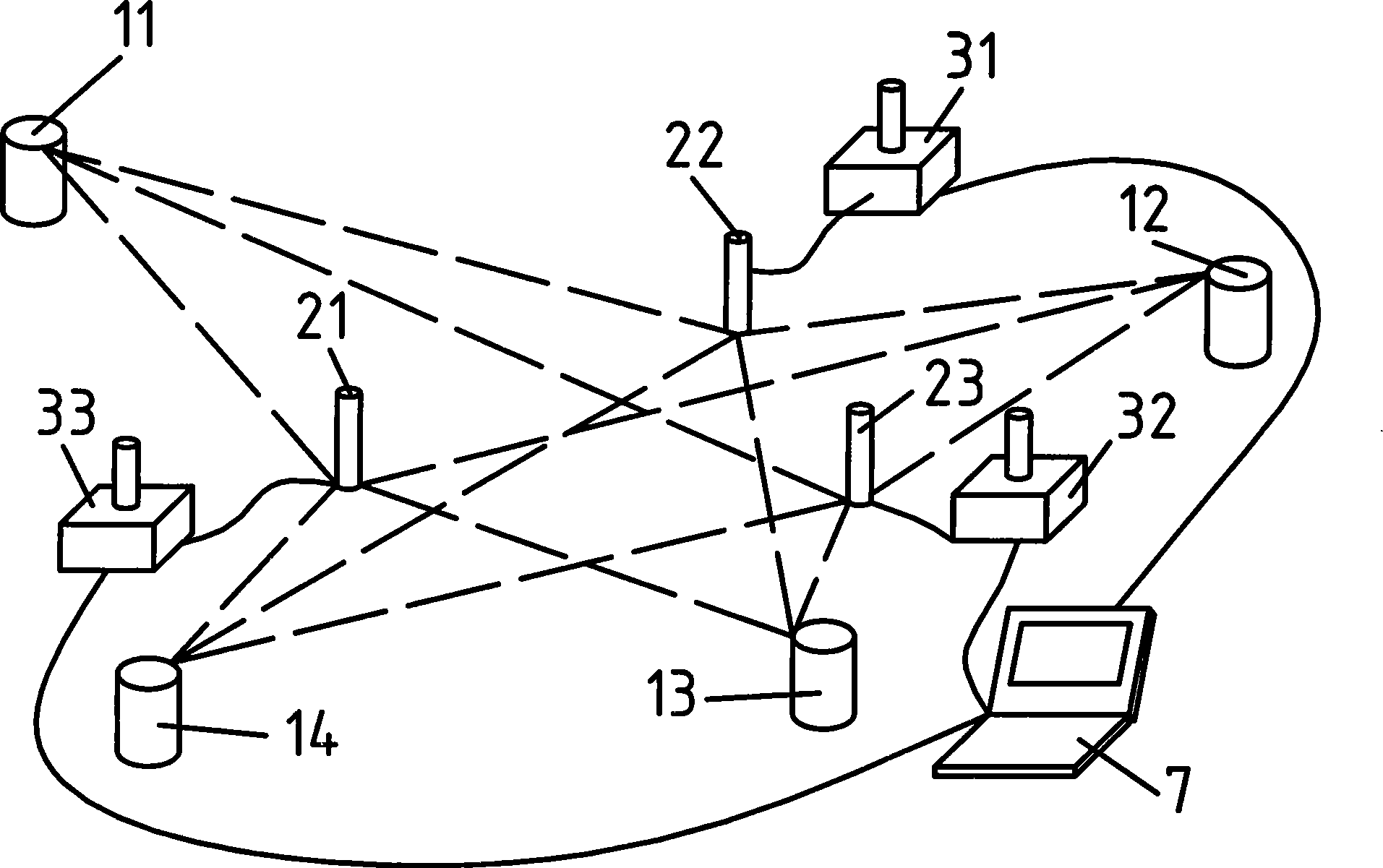

Combination space precision measurement system

ActiveCN101363716AAccurate measurementAchieve complete precision measurementUsing optical meansLaser transmitterOptoelectronics

The invention discloses a combined space precise measurement system comprising a CCD camera, a DLP projector, a tripod and a computer, as well as at least four infrared laser transmitters and at least three sensors and receives. The sensors receive infrared signals which are transmitted by the infrared laser transmitters and respectively transmit light signals to the receivers, and then the receivers convert the signals to digital angle information to be transmitted to the computer to carry out the processing. The combined space precise measurement system combines the advantages of the indoor GPS positioning technology and the structured light measurement technology, takes a structured light measurement subsystem which is based on the digital optical projection as a measurement terminal and precisely measures dense point cloud data of a complicated curved surface of a workpiece in the local scope; at the same time, the combined space precise measurement system uses a large-scale electro-optical tracking positioning subsystem which is based on the GPS principle to carry out the monitoring of a large-scale global coordinate system, carries out the real-time tracking of precise coordinates of the structured light measurement subsystem under a whole-field coordinate system of the workpiece, automatically fuses the obtained dense point cloud data under the same coordinate system and realizes the complete precise measurement of the workpiece with the ultra-large size.

Owner:HUAZHONG UNIV OF SCI & TECH

Non-contact and multi-point measurement method for measuring internal diameter of circular hole

InactiveCN105043278AImprove securityReduce error chainUsing optical meansPhysicsNon contact measurement

The invention provides a non-contact and multi-point measurement method for measuring the internal diameter of a circular hole. The method comprises the steps of constructing a three-sensor / four-sensor constant-value comparison and measurement head; adjusting the measurement optical axis of a laser displacement sensor and meeting preset conditions before measurement and after measurement respectively; and acquiring the radius of a to-be-measured circular hole. According to the technical scheme of the invention, the non-contact constant-value comparison and measurement method is adopted, and a non-contact measurement head is kept far away from the surface of a to-be-measured object. The measurement safety is improved. When the aperture of an inner hole on a workpiece is measured, the measurement head is placed in the to-be-measured hole to complete the measurement. Therefore, the centering or adjusting operation is avoided, and the measurement efficiency is greatly improved.

Owner:TIANJIN UNIV

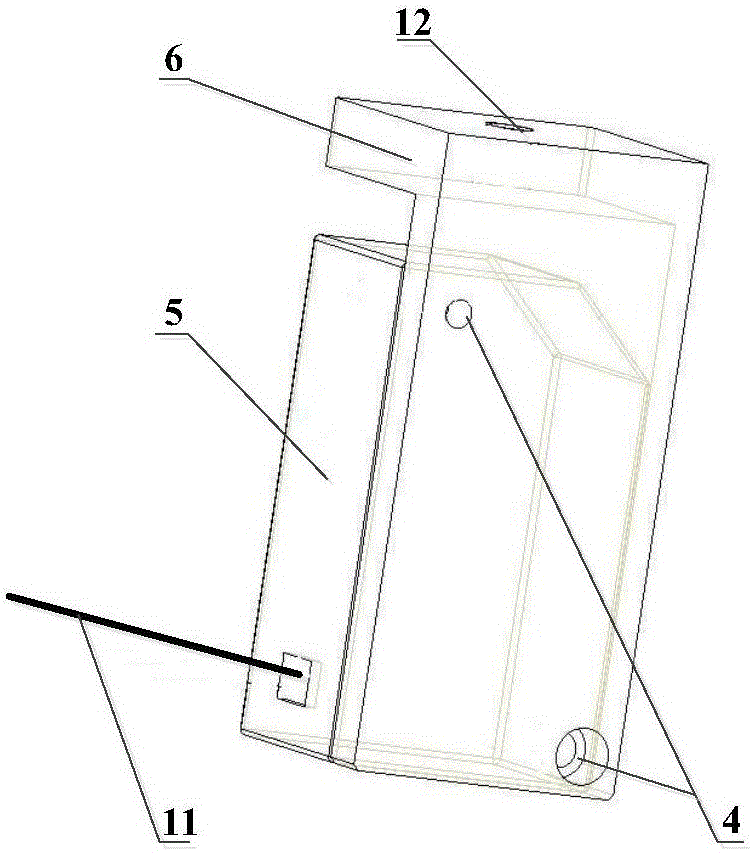

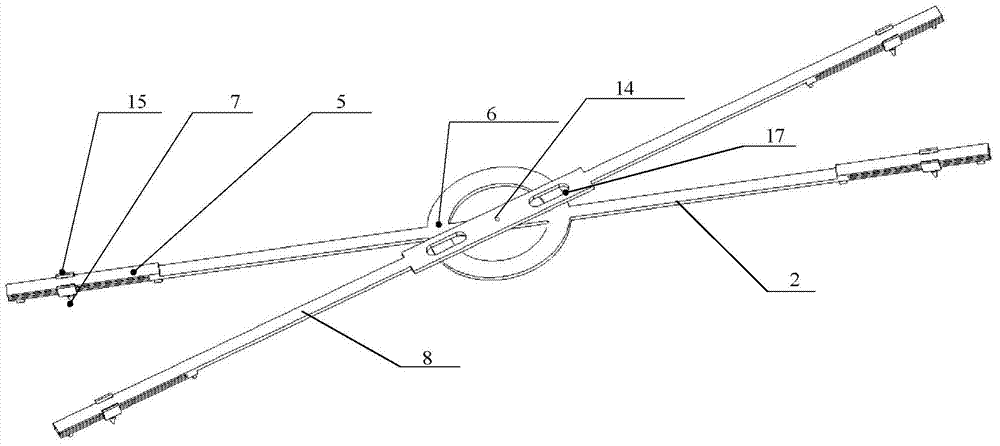

Flange multi-parameter integrated measuring method and device

ActiveCN103542791AHigh precisionImprove measurement efficiencyAngles/taper measurementsMechanical counters/curvatures measurementsVernier scaleMeasurement device

The invention provides a flange multi-parameter integrated measuring device comprising an upper ruler, a lower ruler, a rotary device, a sliding device and a slider. Two sides of the upper ruler and the lower ruler are provided with scale values, the middle of the lower ruler is provided with an angle-measuring indexing plate, and the middle of the upper ruler is provided with a portion indexing plate corresponding to the angle-measuring indexing plate; the upper ruler and the lower ruler are arranged in a crossed manner, and the rotary device is arranged at the center of the cross point of the upper ruler and the lower ruler and is connected to the upper ruler and the lower ruler; the sliding device is flexibly connected to the ruler range of the upper ruler and the lower ruler whose two sides are provided with the scale values and is provided with vernier scales; the slider is connected with the sliding device and provided with scale values. The invention further provides a corresponding measuring method. The device has the advantages of simple structure, convenience for usage, high measuring efficiency and high measuring accuracy.

Owner:SHANGHAI INST OF SATELLITE EQUIP

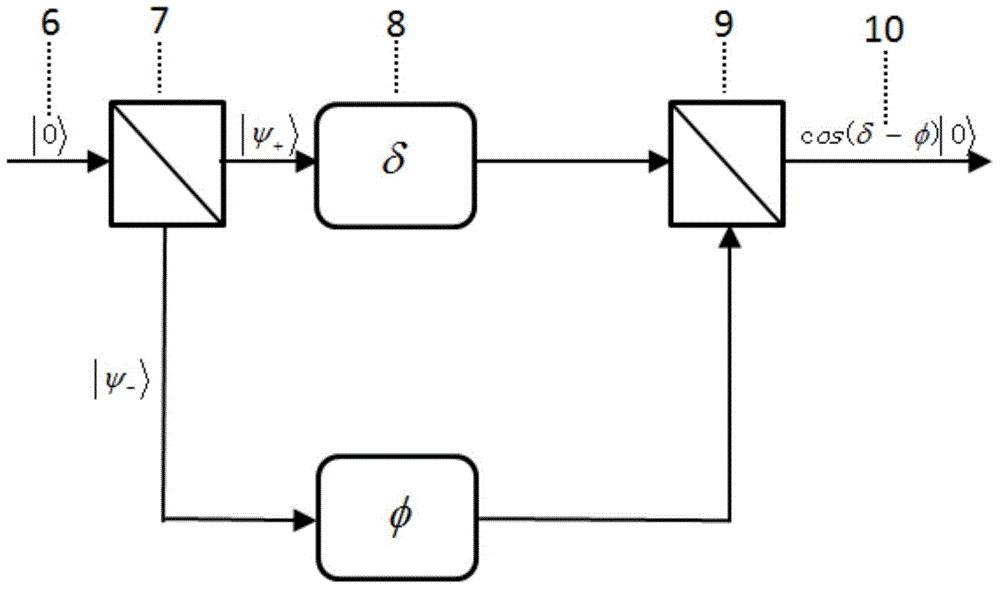

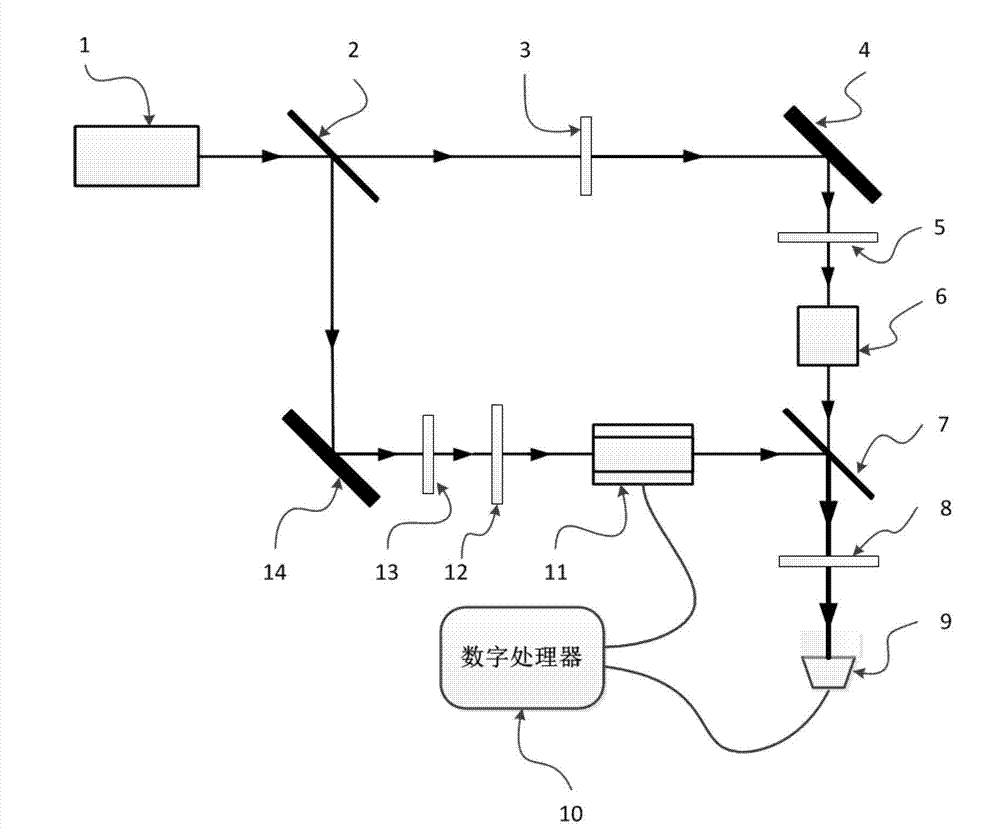

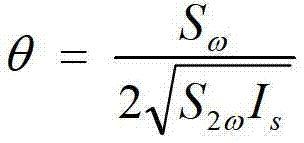

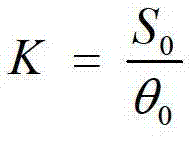

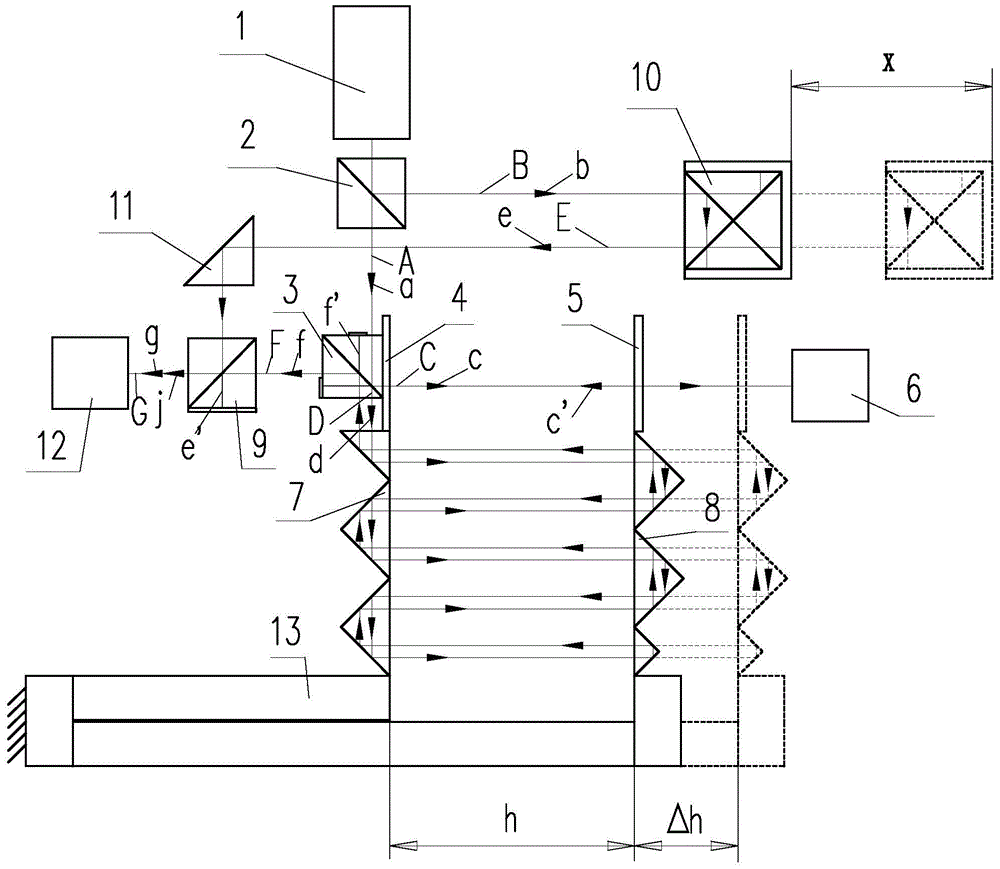

Device and method for detecting optical interference of light polarization tiny corner

ActiveCN103162836AHigh strengthRealize precise measurementLight polarisation measurementBeam splitterGyroscope

The invention relates to a device and a method which are formed through combining a light polarization direction modulation component with optical interference and used for detecting a light polarization tiny corner. A light beam generated by a laser device becomes two bunches of linearly polarized light after passing through a beam splitter and a polarizer, wherein a tiny corner can be added on the polarization direction of one bunch of light after the bunch of light passes through optical rotation mediums, the polarization direction of the other bunch of light is modulated after the light passes through the light polarization direction modulation component, then the two bunches of light become two bunches of coherent light beams after passing through a depolarizing beam splitting prism and a polarization analyzer, the two bunches of coherent light become electrical signals after entering into a photoelectric detector, and a digital processor is used for extracting and calculating first harmonic and second harmonics signals in electrical signals, the first and second harmonics signals are consistent with modulation frequency of the modulation component, and therefore measurement of the light polarization tiny corner is achieved. The device and a method which are formed through combining a light polarization direction modulation component with optical interference achieve optical enlargement of light polarization tiny corner signals, and can be used in precision measurement of light polarization tiny corners through instruments of atomic spin magnetometers, atomic spin gyroscopes and the like.

Owner:杭州诺驰生命科学有限公司

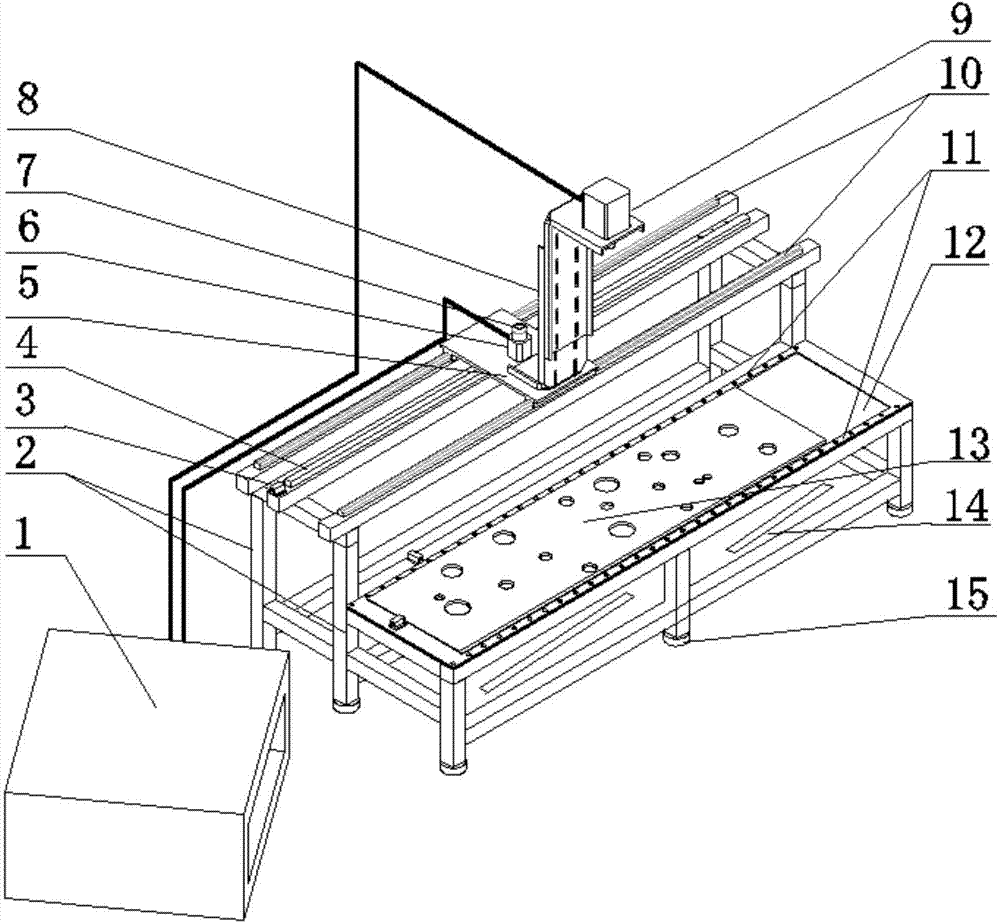

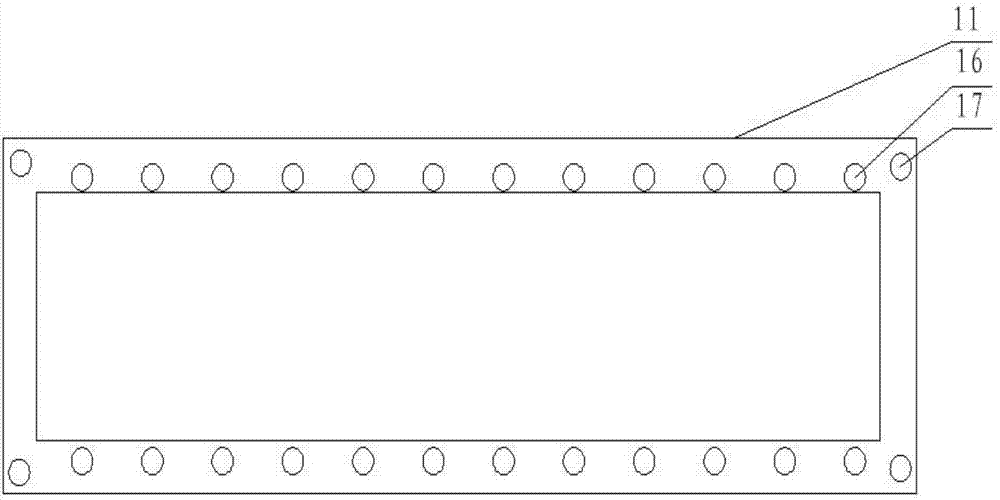

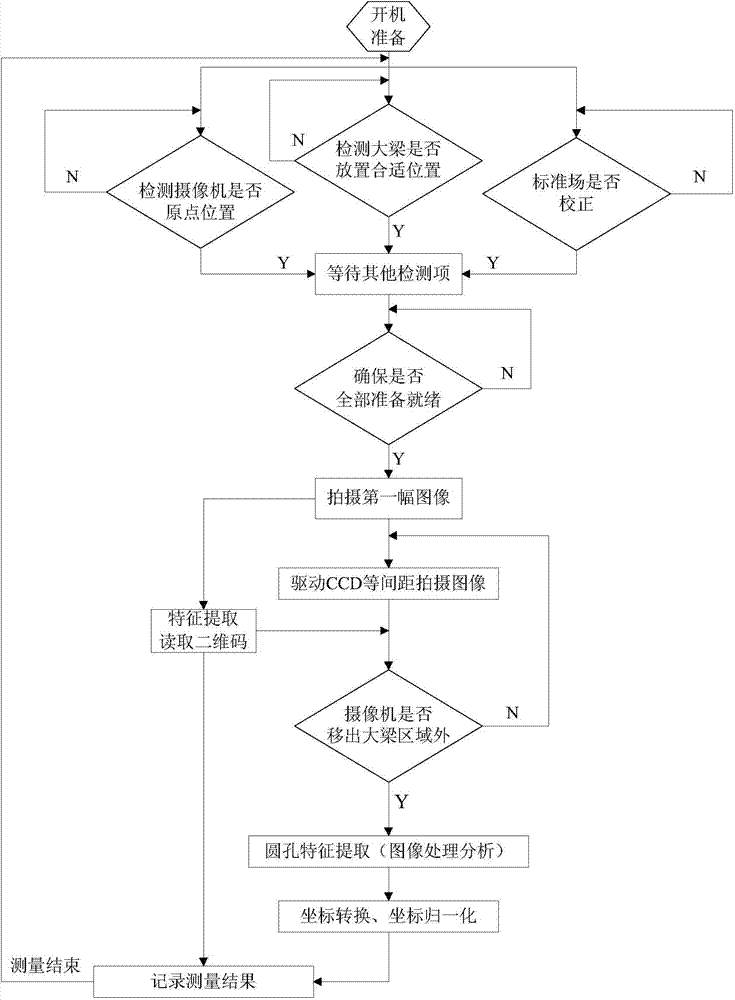

Precision measuring system and precision measuring method for positions and diameters of automotive frame assembling holes

InactiveCN104121854AEasy to identifyConvenient recording of measurement resultsUsing optical meansFeature extractionFixed frame

The invention provides a precision measuring system and a precision measuring method for positions and diameters of automotive frame assembling holes. The precision measuring system comprises a main manipulation table, a height-fixed frame, a slide table, a servo motor, a servo motor encoder, a camera, horizontal precise slide rails, a standard two-dimensional control field, a toughened glass light source cover, a measured frame and a damper. The precision measuring method includes the steps of acquiring continuous local images of the tested frame, subjecting every image to feature extraction, conducting coordinate transformation by the aid of the extracted information of the images and the measurement control field to finish precision measurement of the diameters and the positions of the automotive frame assembling holes, and finally writing measurement results into a two-dimension code anti-counterfeiting and tracing system. The precision measuring system and the precision measuring method for the positions and the diameters of the automotive frame assembling holes have the advantages that difficulties of low manual measuring efficiency and large labor intensity are overcome, conveniences are provided for subsequent frame maintenance, information querying and the like, and the precision measuring system and the precision measuring method are particularly applicable to measurement on assembling holes for U-shaped flat frames.

Owner:HUBEI UNIV OF TECH

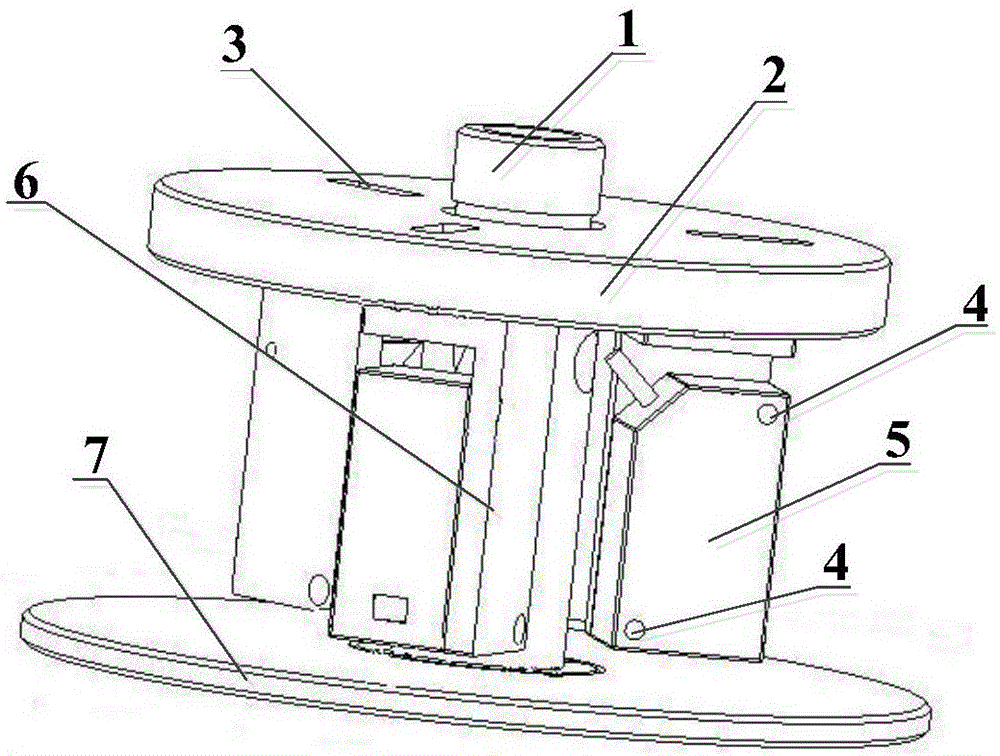

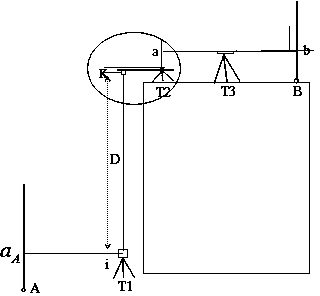

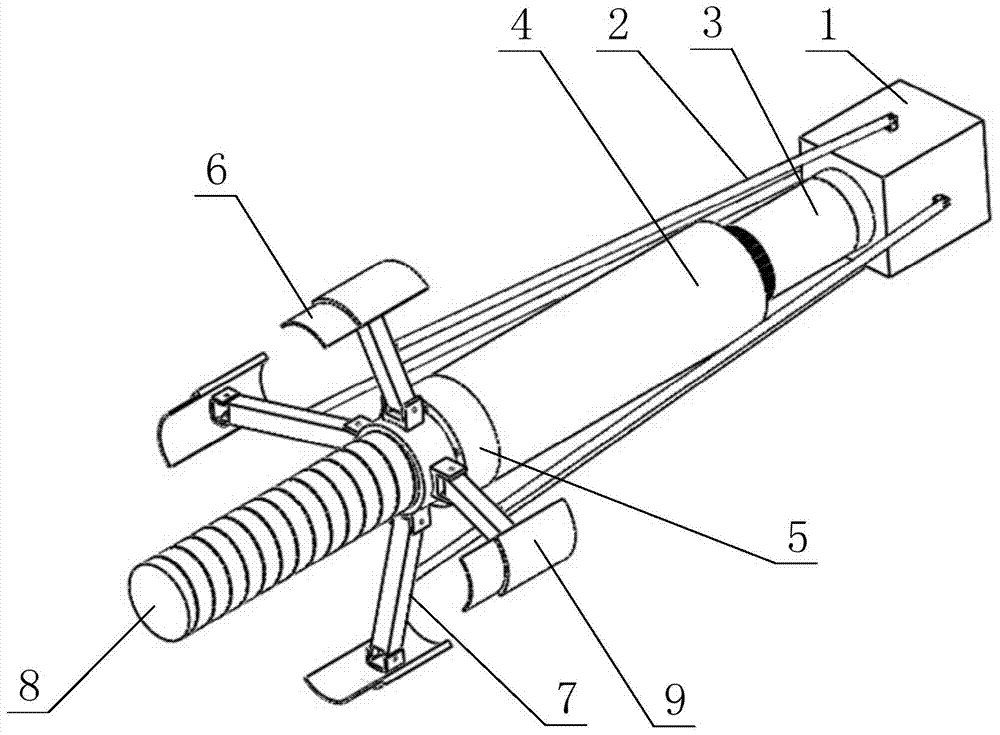

Measurement device and measurement method for vertical great-height difference height transmission

InactiveCN103499340ASimple structureEasy to useHydrostatic levellingMeasurement deviceHeight difference

The invention discloses a measurement device for vertical great-height difference height transmission. The device comprises a prism case, a left balancing pole, a horizontal rod supporting connecting piece, a bubble tube, a first fixing screw, a second fixing screw, a right balancing pole, a counterweight, a base and a tripod, wherein the prism case is connected with one end of the left balancing pole; the other end of the left balancing pole is connected with one end of the right balancing pole through the horizontal rod supporting connecting piece; the bubble tube is arranged at one end of the right balancing pole; the other end of the right balancing pole is connected with the counterweight; the right balancing pole is fixedly arranged on a connecting plate on the base through the first and second screws; the lower surface of the base is connected with the tripod. The invention also discloses a measurement method for the measurement device. According to the measurement device and the measurement method, a height transmission device is used for assisting great-height difference height transmission measurement, so that measurement is simplified, the measurement device and the measurement method are easier to implement, and more accurate measurement results can be obtained; the height transmission device is easy to design and convenient to use.

Owner:HOHAI UNIV

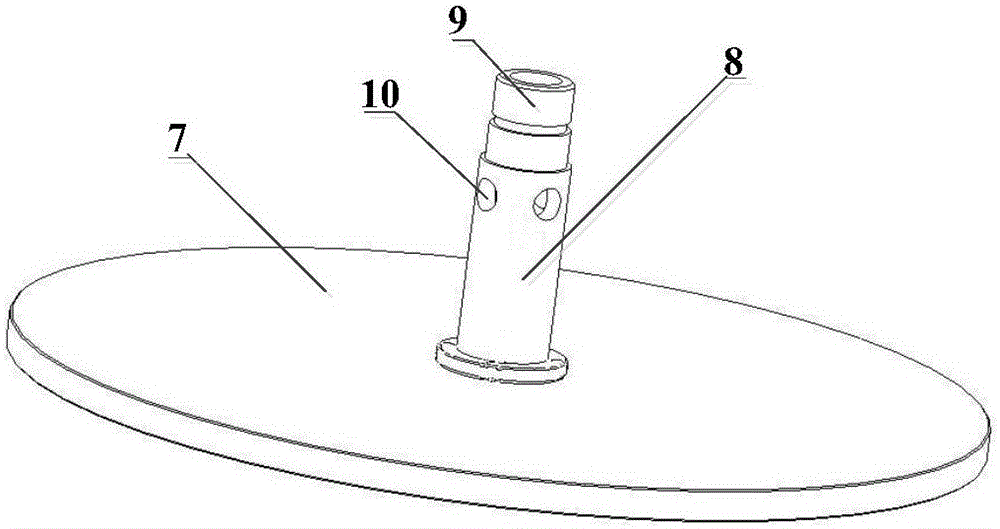

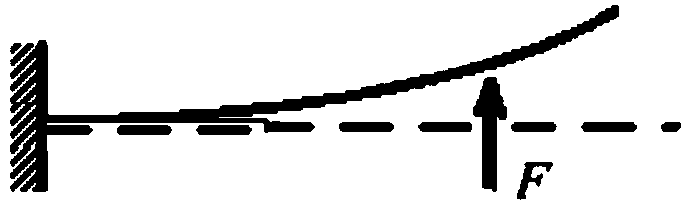

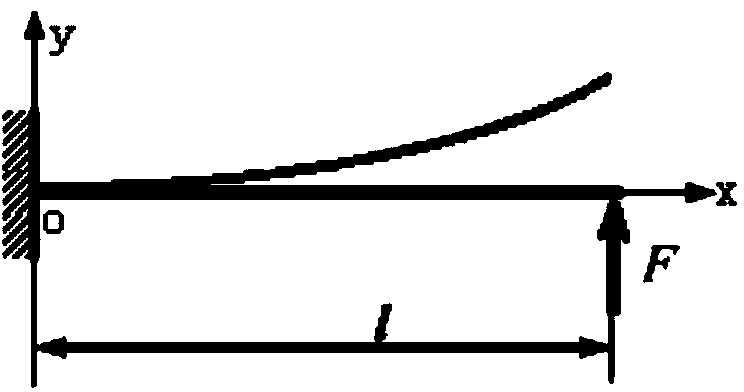

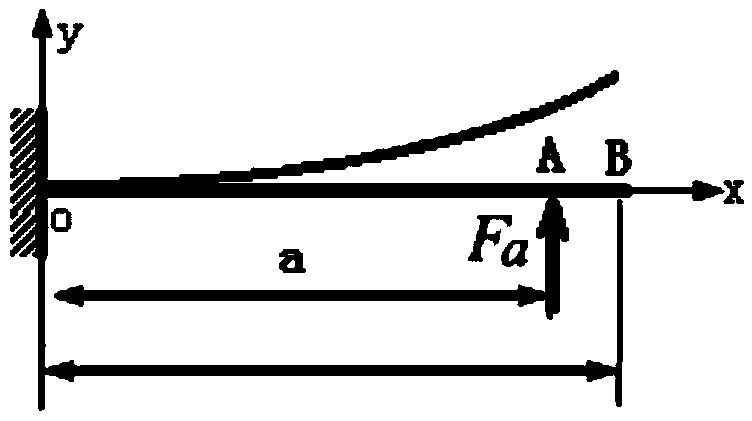

Method and system for measuring contact force of satellite-borne slip ring based on cantilever beam theory

InactiveCN103837280AEasy to analyzeRealize precise measurementApparatus for force/torque/work measurementSatelliteLeast squares

The invention discloses a method and system for measuring the contact force of a satellite-borne slip ring based on the cantilever beam theory. According to the method, the contact force of the satellite-borne slip ring is indirectly and accurately measured, namely, a measuring point is set near a contact point between an electric brush wire and the electric conductive slip ring, a relational expression between the initial measuring force exerted on the measuring point and the contact pressure at the contact point is elicited according to a deflection curve equation of a uniform-section straight girder, monadic regressive analysis is conducted on data measured at the measuring point through the least square method according to the linear rule of deformation, so that the accurate initial measuring force is obtained, the contact force is obtained, and the measuring accuracy is high. The system for measuring the contact force is composed of the electric conductive slip ring, the electric brush wire, a loading lifting hook, a force sensor, a displacement sensor, a connecting board, an accurate electric control motion table, a motor driver, a motor control card, a multichannel data acquisition card, a current sensor, an industrial personal computer and a displayer. Design is ingenious, operation is convenient and measurement is accurate.

Owner:ZHONGWEI ELECTRONICS INSTR FACTORY ZHANGZHOU CITY

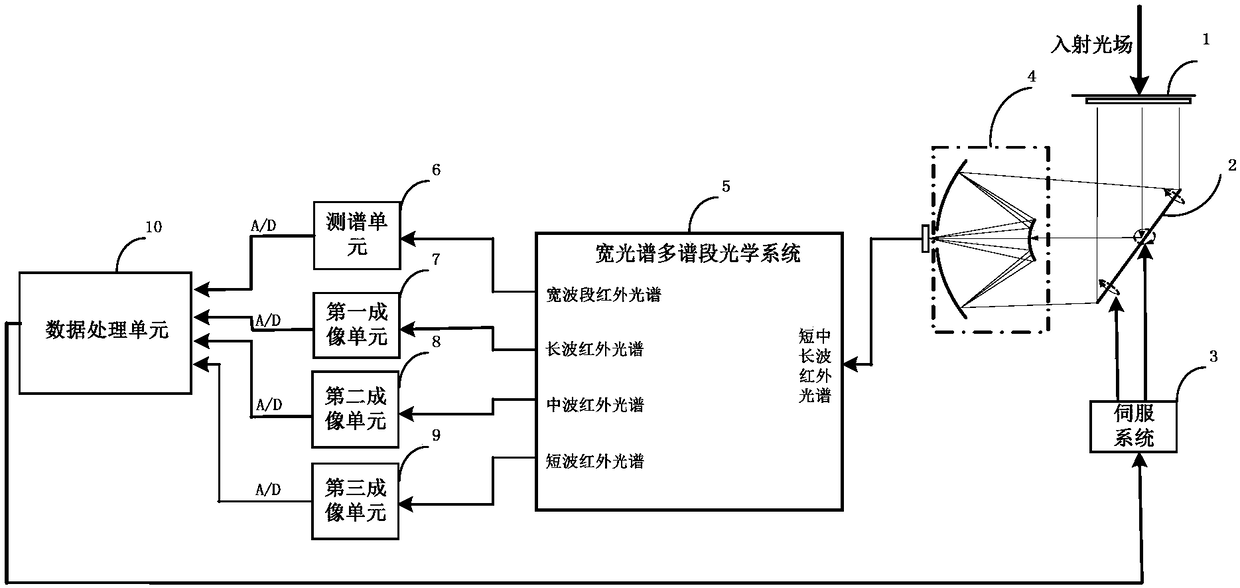

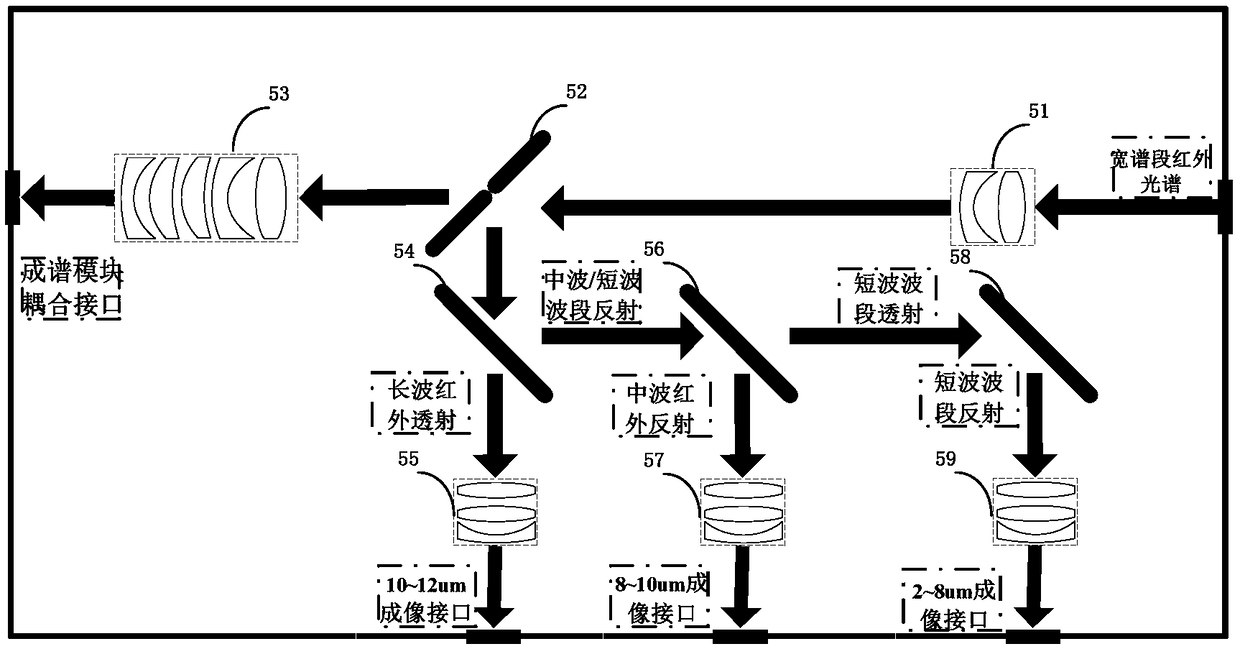

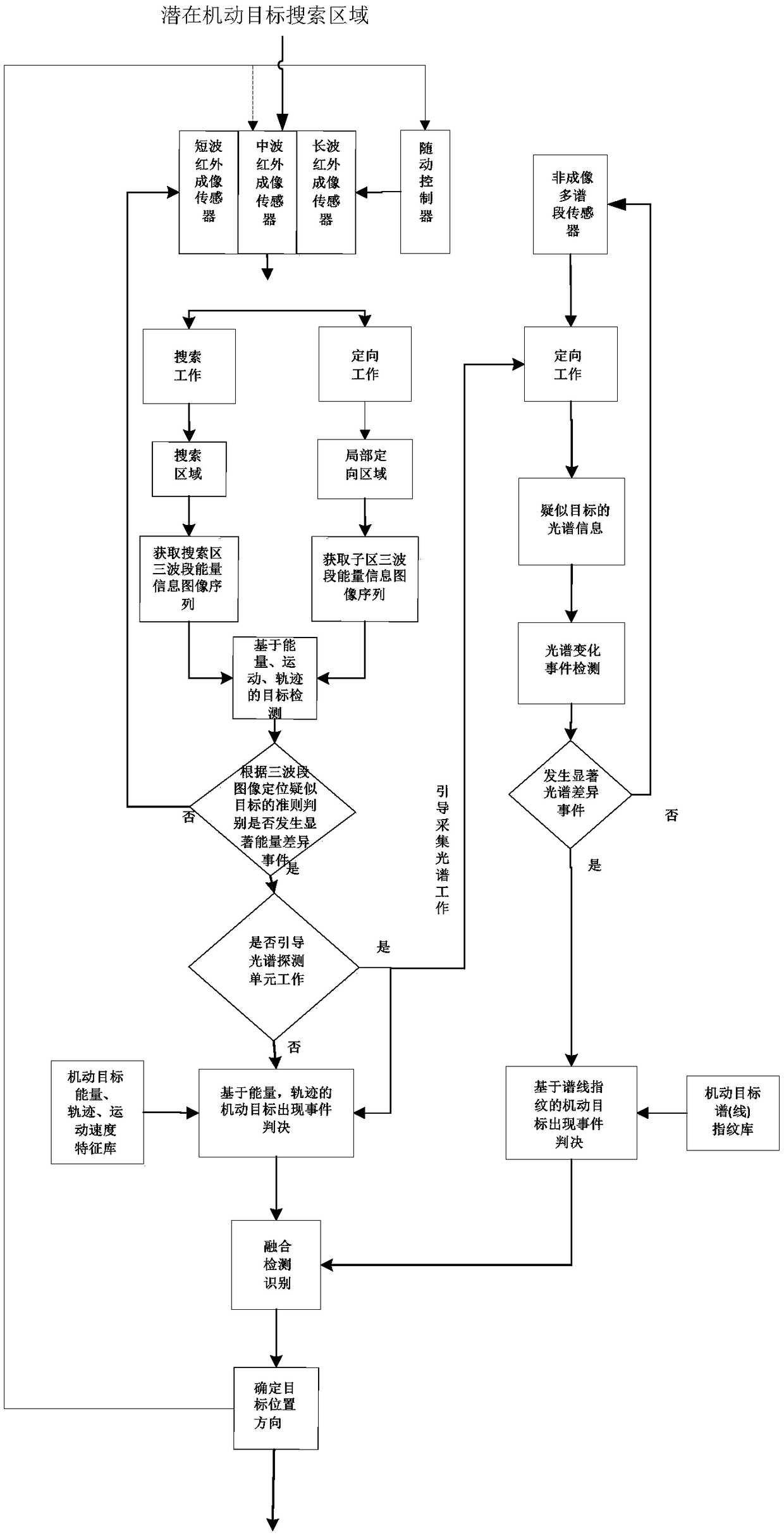

Multi-waveband infrared imaging spectrum collaborative detection system and method

ActiveCN108415097AEasy to captureRealize precise measurementOptical detectionImage detectionSmall hole

The invention discloses a multi-waveband infrared imaging spectrum collaborative detection system. In a spectrum correlation detection system optical path of the system, the region beside the center small hole of a spectroscope totally reflects wide spectral infrared energy, short-wave infrared / medium-wave infrared / long-wave infrared imaging modules are respectively constructed, a dynamic targetcapturing subsystem with three-waveband infrared fusion is formed, and the imaging detection capability of a moving target is improved. Meanwhile, full-spectrum infrared energy transmitted by the central small hole of the spectroscope reaches an infrared wide spectrum detection module for measuring a target in the center of the view field or a background infrared spectrum to form a spectrum measuring sub-system. These subsystems and servo control, multi-waveband image processing and infrared spectrum processing modules form an infrared spectrum collaborative detection and recognition system with strong dynamic target detection and recognition capability.

Owner:HUAZHONG UNIV OF SCI & TECH

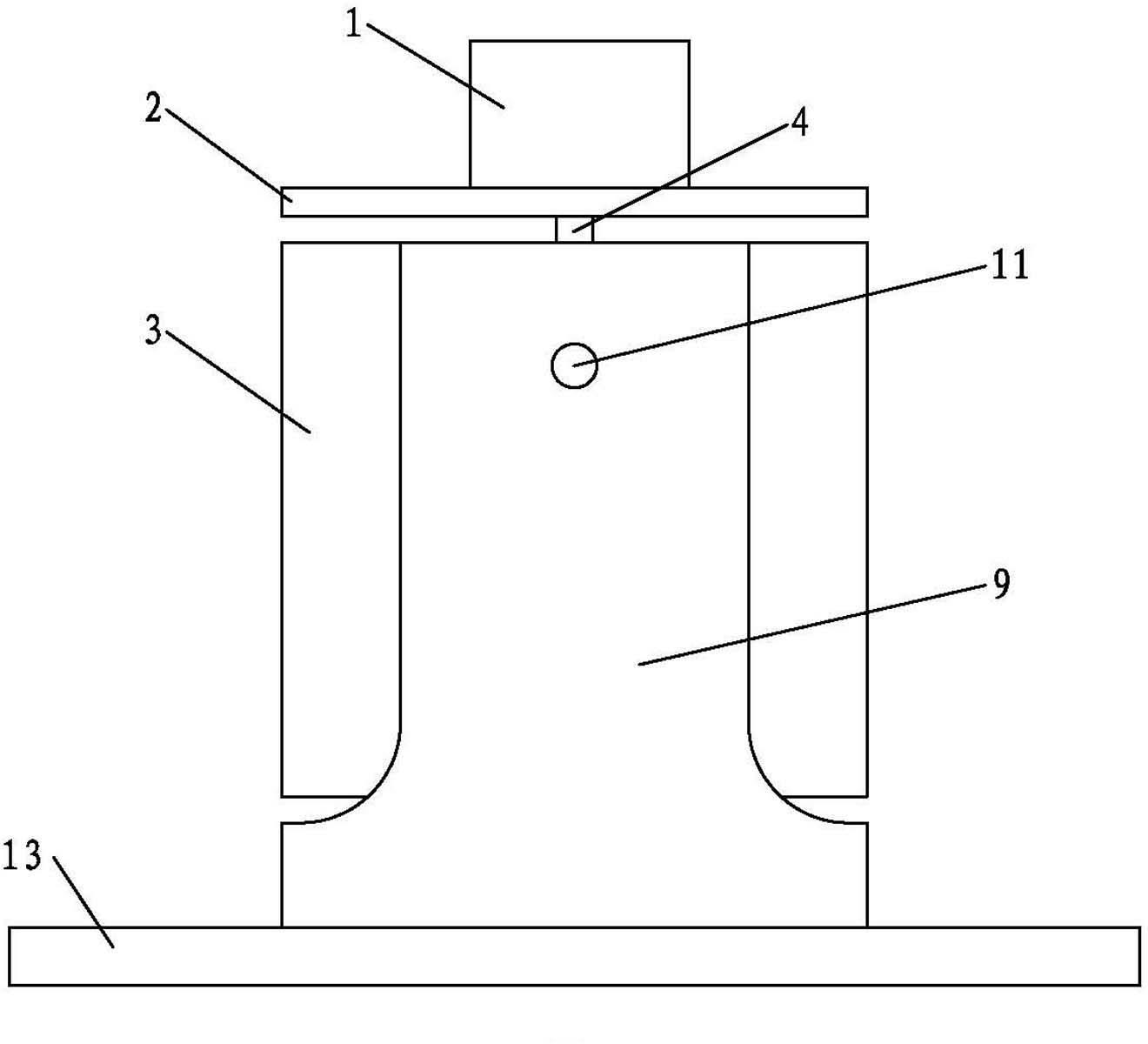

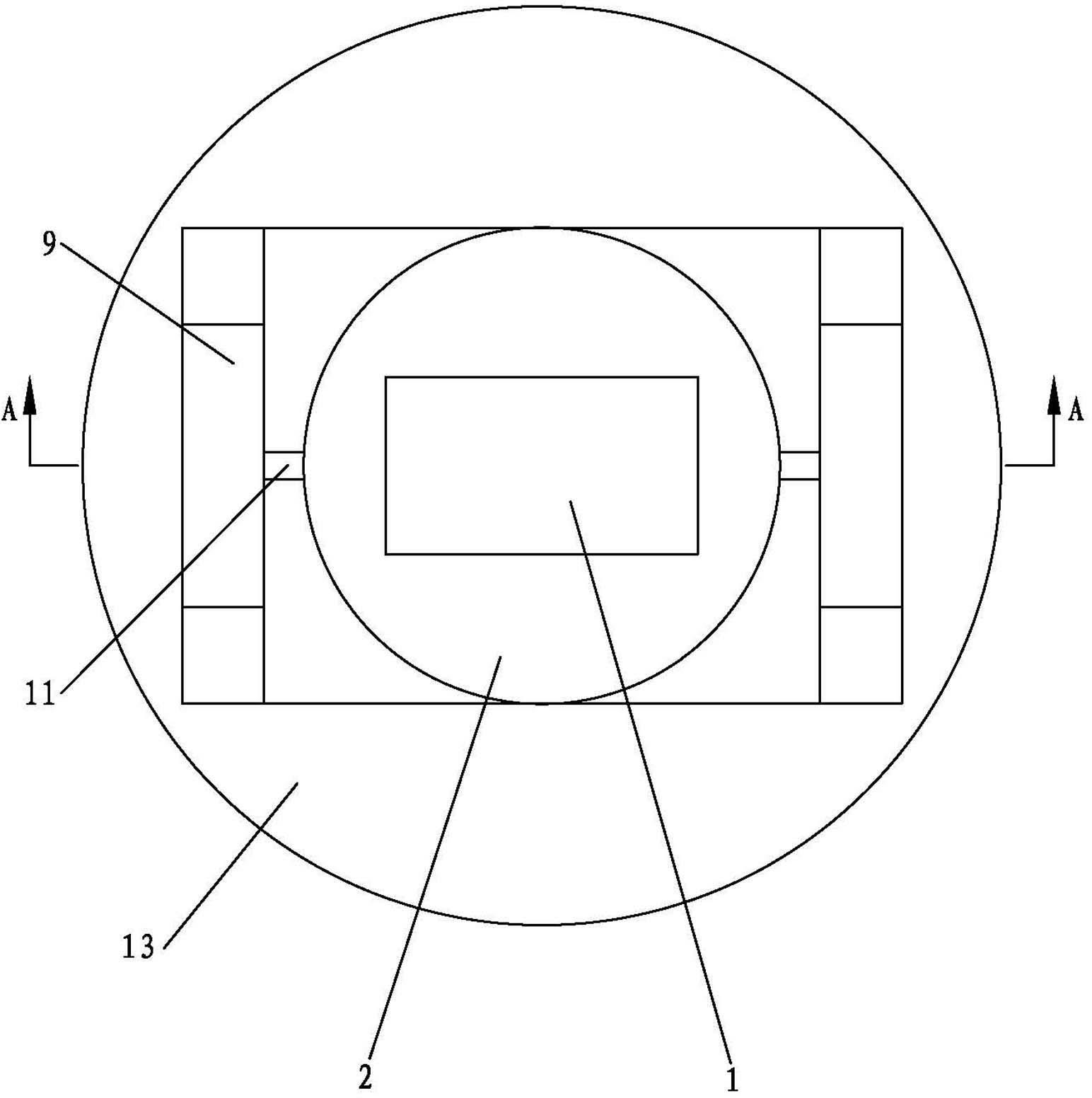

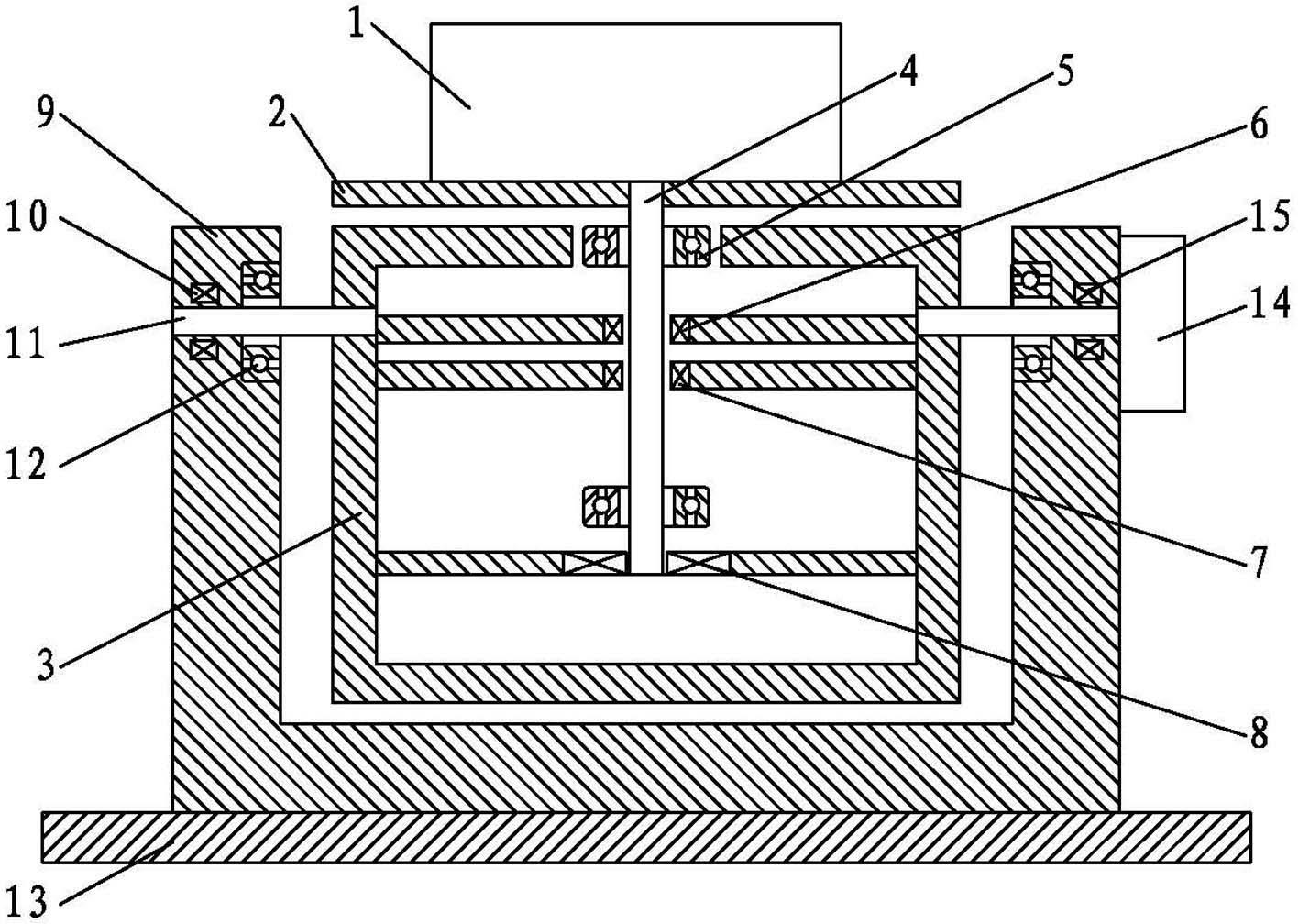

Standard of angle measurer

ActiveCN102620703AImplement servo controlHigh precisionVehicle wheel testingAutomatic controlProgrammable logic controller

The invention discloses a standard of an angle measurer. The standard comprises a rotating device and a control system, and is characterized in that: the rotating device is a double-shaft mechanical rotating device and comprises a direction and position rotary axis system and a pitch rotary axis system which are interconnected and vertical, wherein each rotary axis system is provided with an electromagnetic locking device, an angular contact bearing, a permanent-magnetic direct-current torque motor and an angle measuring element; the direction and position rotary axis system is connected with a worktable top used for placing an apparatus to be detected; and the angle measuring element of each rotary axis system forms an angle measuring system. The standard adopts the technology of combining low-speed large-torque driving technology, automatic control technology, precise measuring technology, touch screen artificial intelligent technology and programmable logic controller (PLC), so standard angle technology with high precision and high load, which can output at any angle, is realized, and a plurality of types of angle measurers, such as various wheel positioning apparatuses, are subjected to metrological verification / calibration.

Owner:佛山市质量计量监督检测中心

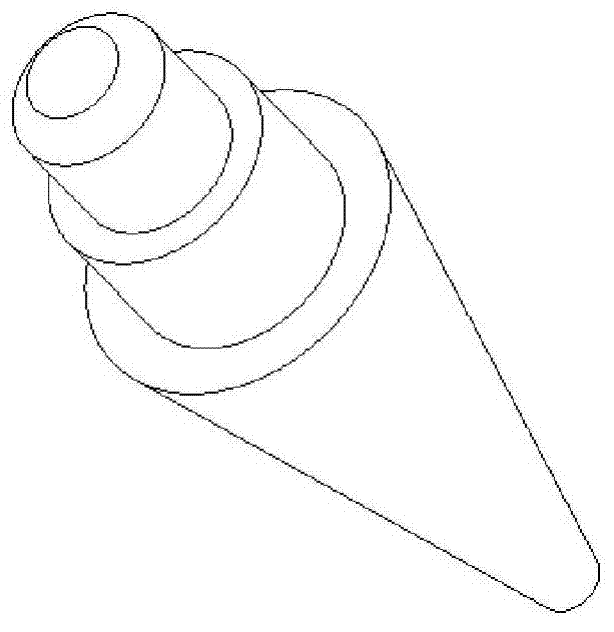

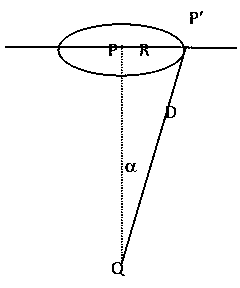

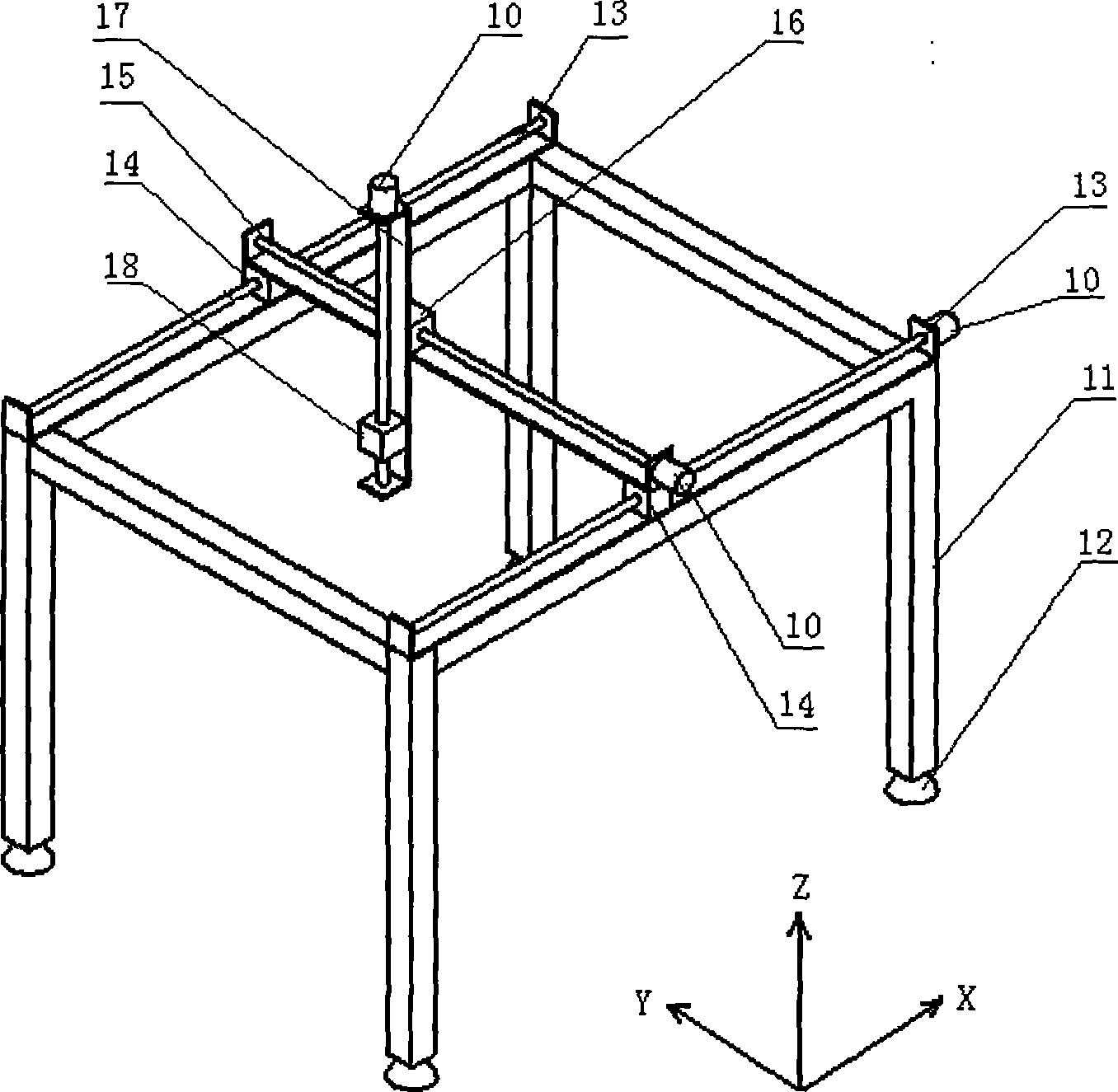

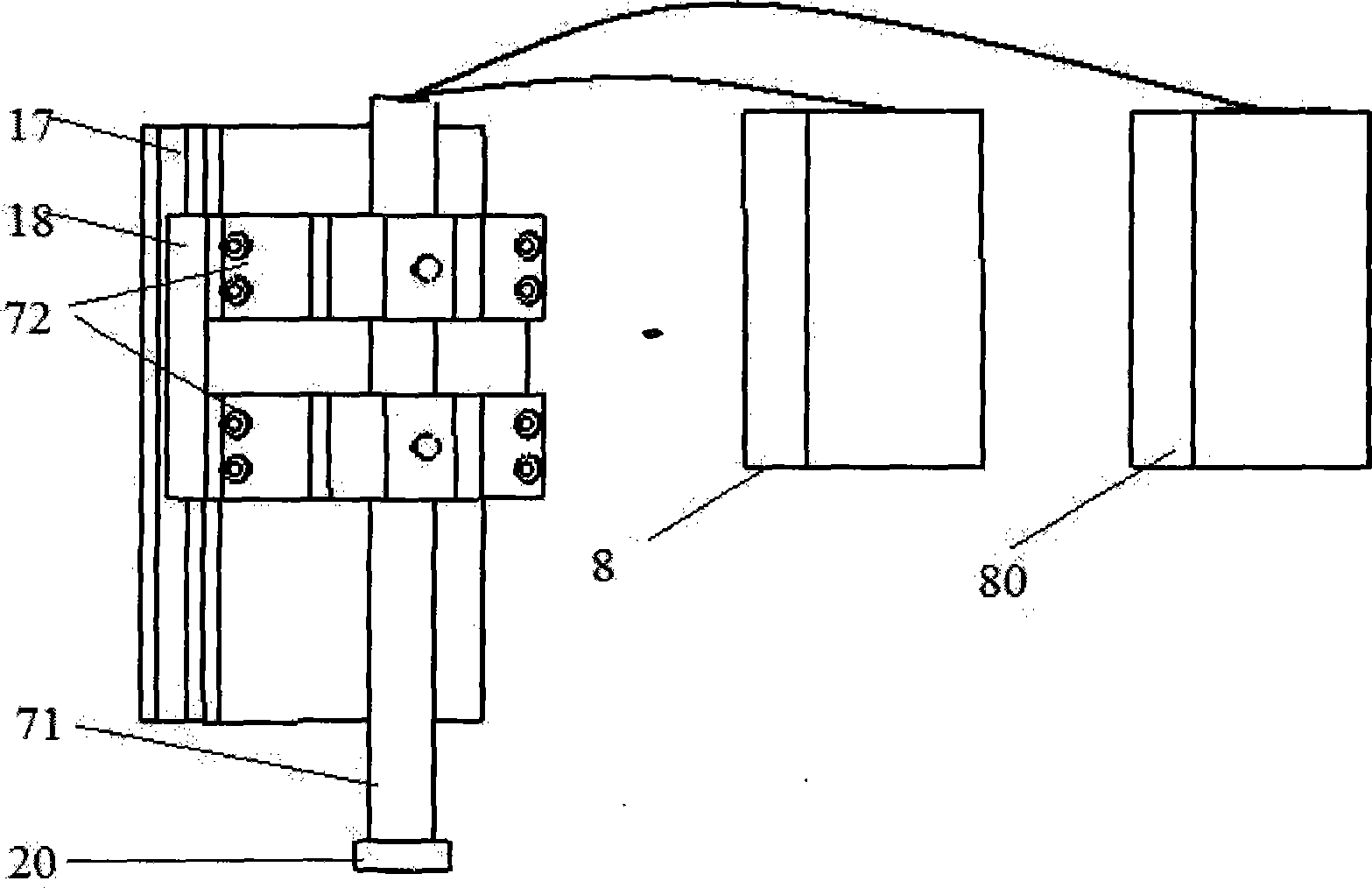

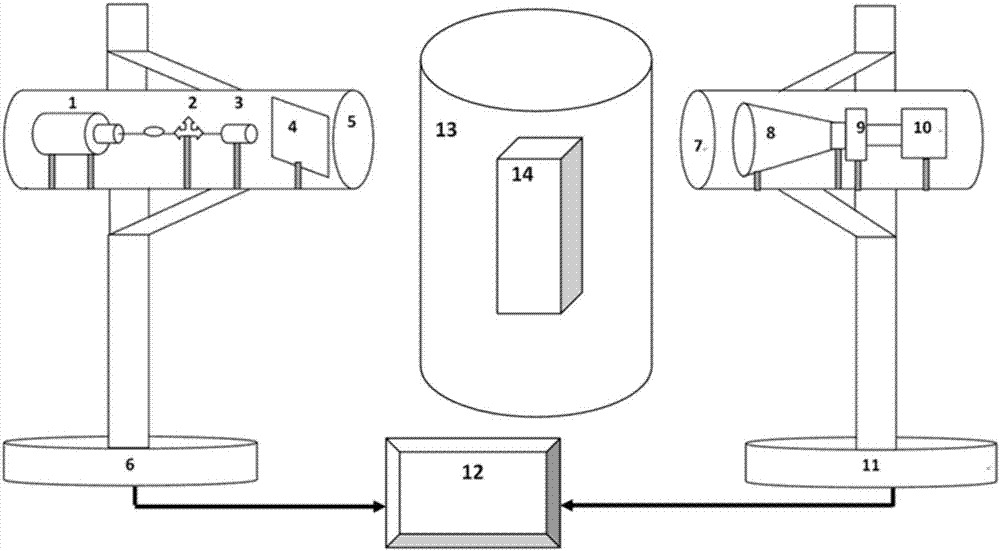

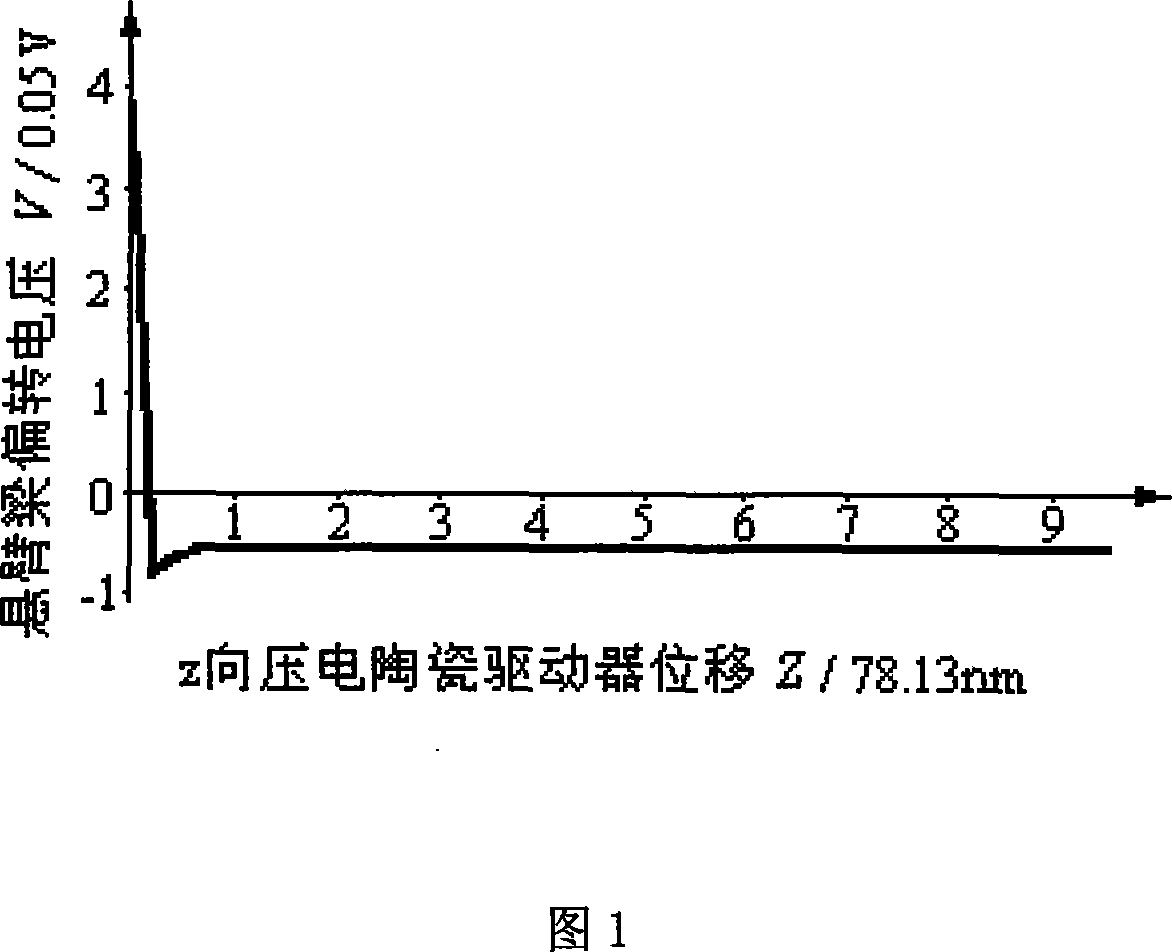

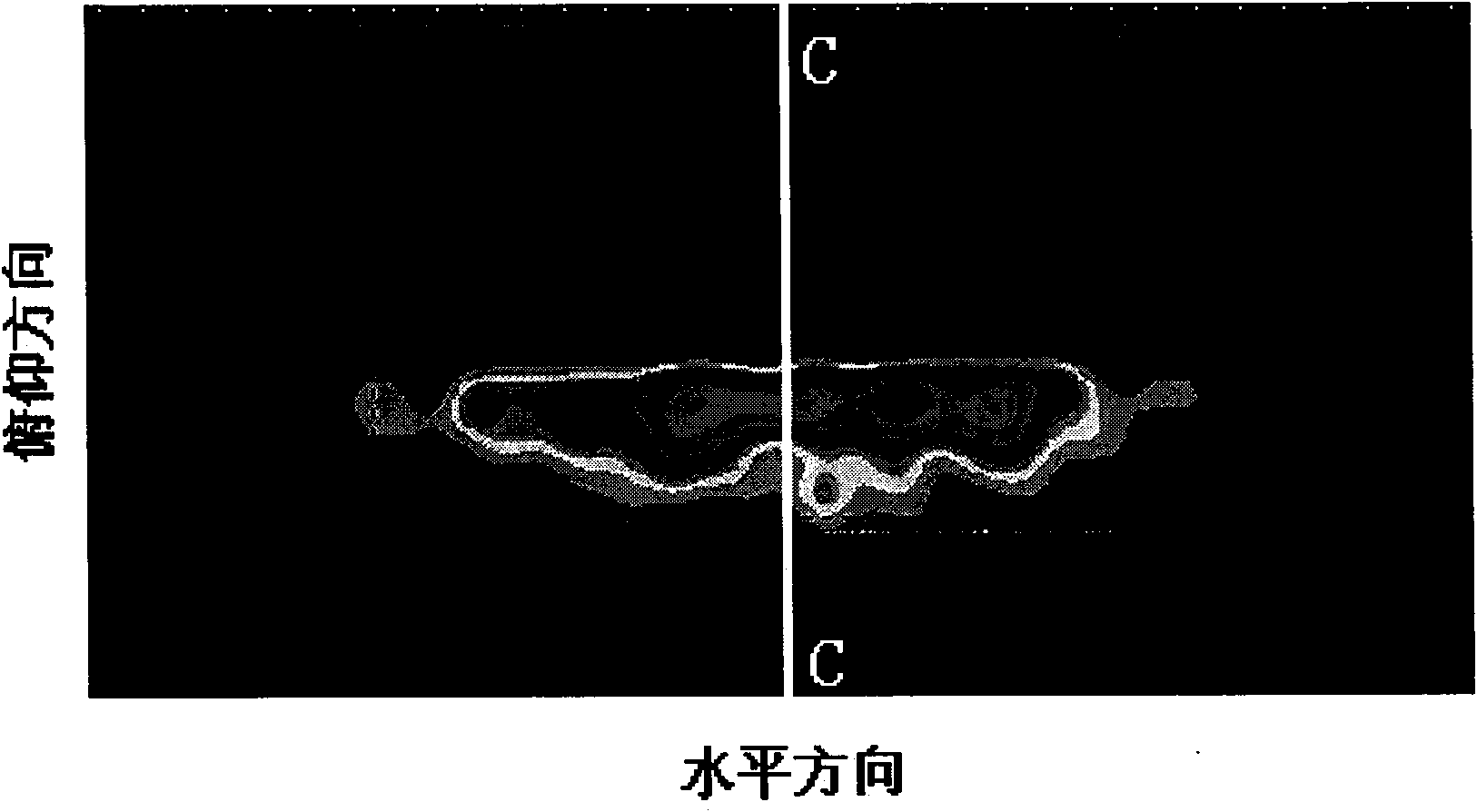

Ultrasonic liquid-immersing transducer sound field precision measurement method

The invention relates to a precise measuring method of a sound field of an ultrasound liquid-immersed transducer, which is characterized by comprising three steps, wherein, the first step is that sound pressure value at each measuring point in the sound field of the measured transducer and reflected by a small steel ball without a borehole is measured and store; the second step is that the sound pressure value at each measuring point in the sound field of the measured transducer and reflected with the steel ball drilled with a through hole is measured and stored; the third step is that the stored sound pressure value at each measuring point in the sound field of the measured transducer and reflected by the steel ball without a borehole minus the stored sound value at each measuring point in the sound field of the measured transducer and reflected by the steel ball drilled with the through hole so as to obtain the sound pressure value with the same value as the through hole diameter of the steel ball drilled with the through hole, the smaller the through hole, the closer the calculated sound pressure value to the sound pressure value of one point.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

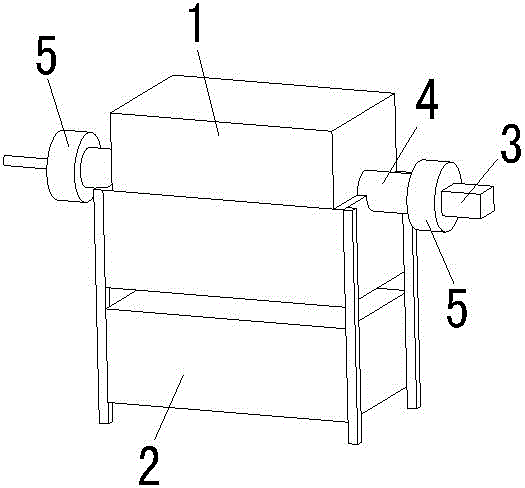

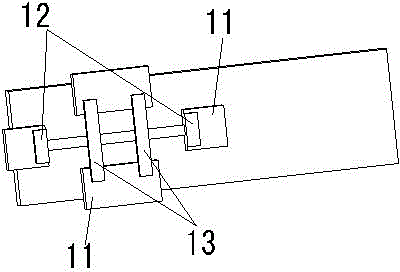

Measuring device for measuring displacement or deformation quantity of parts in high- and low-temperature vacuum glass covers

InactiveCN107957243AImprove image qualityAchieve clear imagingUsing optical meansGlass coverMeasurement device

The invention relates to a measuring device for measuring the displacement or deformation quantity of parts in high- and low-temperature vacuum glass covers and belongs to the measurement field of small displacement or deformation quantity of parts or objects. The measuring device includes a laser, a first cylindrical mounting seat, a first vertical translation frame, a second cylindrical mountingseat, an image sensor, a second vertical translation frame, a computer, a high-temperature vacuum glass cover and a measured object; the high-temperature vacuum glass cover is placed vertically in anaxial direction; the measured object is fixedly installed inside the high-temperature vacuum glass cover; the first vertical translation frame and the second vertical translation frame are respectively arranged at two sides of the high-temperature vacuum glass cover; the first cylindrical mounting seat is fixedly installed on the top of the first vertical translation frame; the second cylindricalmounting seat is fixedly installed at the top of the second vertical translation frame; the laser is fixedly installed inside the first cylindrical mounting seat; and the laser and the image sensor are both communicated with the computer. The measuring device of the present invention directly calculates the displacement or deformation quantity of the measured object, and has the advantages of non-contact measurement, high efficiency, high precision, automated measurement and the like.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

Non-destructive measurement method of nanometer cantilever thickness based on force curve of atomic force microscope

InactiveCN101046374ARealize precise measurementAccurate measurementSemi-permeable membranesMeasurement devicesNon destructiveForce curves

The non-destructive measurement method of nanometer cantilever thickness based on force curve of atomic force microscope includes the first scanning measurement to obtain the 3D topographic information of the nanometer cantilever area and the distance between the upper surface and the base of the nanometer cantilever; the subsequent reducing the scanning range to locate the probe of the atomic force microscope precisely and to load and unload vertically with the probe until the lower surface of the nanometer cantilever contacts with the base and the force curve exhibits turnover, and recording the real-time force curve of the atomic force microscope during loading and unloading to obtain the distance between the lower surface and the substrate of the nanometer cantilever; and finally subtracting the data obtained in the foregoing steps to calculate the nanometer cantilever thickness. The said method may be also used in measuring other dimensions of nanometer structure.

Owner:TIANJIN UNIV

Compressor blade runner surface profile tolerance detecting device and method

ActiveCN105387793ASolving Detection ChallengesImprove pass rateMechanical counters/curvatures measurementsMechanical engineeringProcessing Site

The invention discloses a compressor blade runner surface profile tolerance detecting device and a compressor blade runner surface profile tolerance detecting method. The compressor blade runner surface profile tolerance detecting device comprises a support, wherein a positioning and clamping device, a standard surface block and a differential meter frame are arranged on the support, the positioning and clamping device is used for fixing compressor blades, the standard surface block is used for being compared with the compressor blades, the differential meter frame is used for detecting runner surface profile tolerance of the compressor blades, the differential meter frame comprises a differential meter frame body, an upper measuring rod and a lower measuring rod which can move up and down are arranged on the differential meter frame body, the end part of the upper measuring rod is provided with a measuring head used for measuring runner surfaces of the compressor blades, the end part of the lower measuring rod is provided with a measuring head used for measuring surfaces of the standard surface block, a dial indicator used for displaying compressor blade runner surface profile tolerance deviation is arranged on the differential meter frame body, and a meter-correcting block used for carrying out zero setting on the dial indicator is arranged on the support. The compressor blade runner surface profile tolerance detecting device and the compressor blade runner surface profile tolerance detecting method achieve accurate measurement of the blade runner surface profile tolerance, have small error and high efficiency, and solve the detection difficulty of blade processing site.

Owner:AECC AVIATION POWER CO LTD

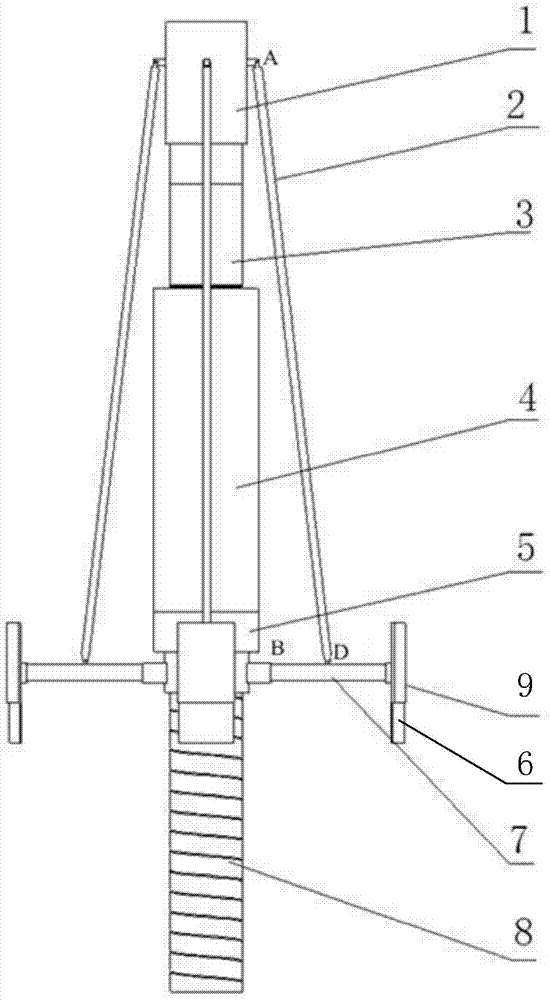

Measuring device for elongate assembly of polygonal ball seat

ActiveCN108731617ARealize precise measurementHigh measurement accuracyMeasurement devicesEngineeringMechanical engineering

The invention relates to a measuring device for elongate assemblies of a polygonal ball seat. The measuring device comprises a vertical supporting base vertically arranged on a horizontal supporting base, wherein a vertical guide rail and a grating rule assembly are parallelly arranged on the vertical supporting base, an upper measurement sliding table, an upper clamping sliding table, an intermediate measuring disc and a lower measurement sliding table which can slide along the vertical guide rail are sequentially mounted on the vertical supporting base from top to bottom, a lower fixing basewith adjustable planar position is further arranged on the vertical supporting base, a spherical surface supporting base is fixed on the lower fixing base, coaxial mounting through holes used for mounting the measured elongate assembly are formed in the upper clamping sliding table, the intermediate measuring disc and the spherical surface supporting base respectively, the spherical surface supporting base is used for mounting the ball seat of the measured elongate assembly, the upper clamping sliding table is used for clamping and positioning the upper part of the elongate assembly, and theupper measurement sliding table, the intermediate measuring disc and the lower measurement sliding table are provided with measurement sensors corresponding to different measured parts respectively.

Owner:CHINA PRECISION ENG INST FOR AIRCRAFT IND AVIC +1

Post-irradiation fuel rod underwater diameter measuring system and measuring method thereof

ActiveCN106229019ANo secondary damageRealize precise measurementNuclear energy generationNuclear monitoringEngineeringDiameter measurement

The invention discloses a post-irradiation fuel rod underwater diameter measuring system, which comprises a spent fuel pool. A diameter measuring unit, which faces a fuel component, is arranged in the spent fuel pool. The diameter measuring unit is connected to a signal collecting and processing system. The operation is convenient. Through the micro displacement change between contact sheets, the displacement change is converted into the coil mutual inductance coefficient change, finally the displacement change is converted into voltage, the conversion between non electrical quantity and electrical quantity is realized, the diameter of a peripheral fuel rod of a fuel assembly can be rapidly and instantly measured underwater on site; a contact type electric signal transmission and conversion mode is adopted, and the measurement precision and detection efficiency are largely improved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Method for measuring beam intensity distribution of LED precision approach path indicator

InactiveCN101608949ARealize precise measurementGeometric image transformationPhotometryOptical measurementsComputer image

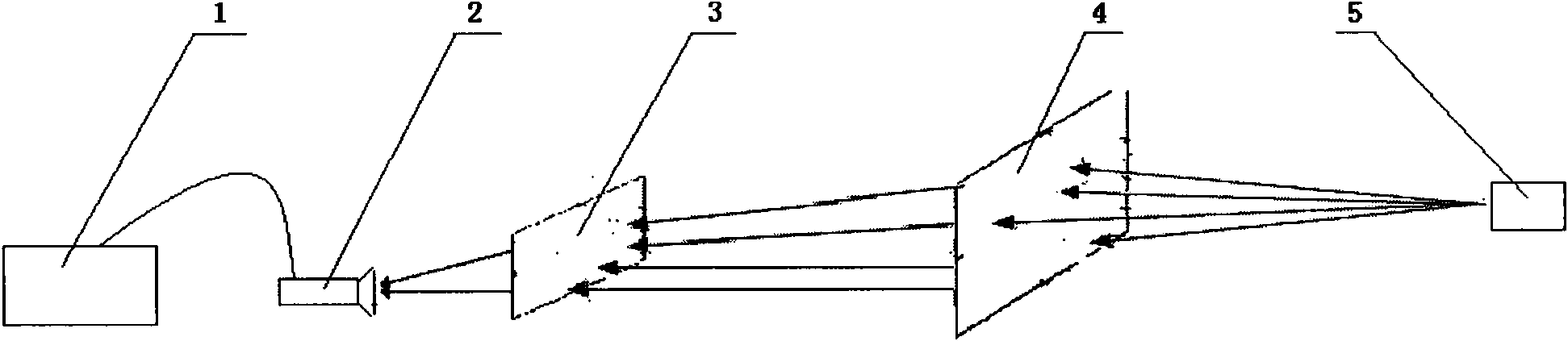

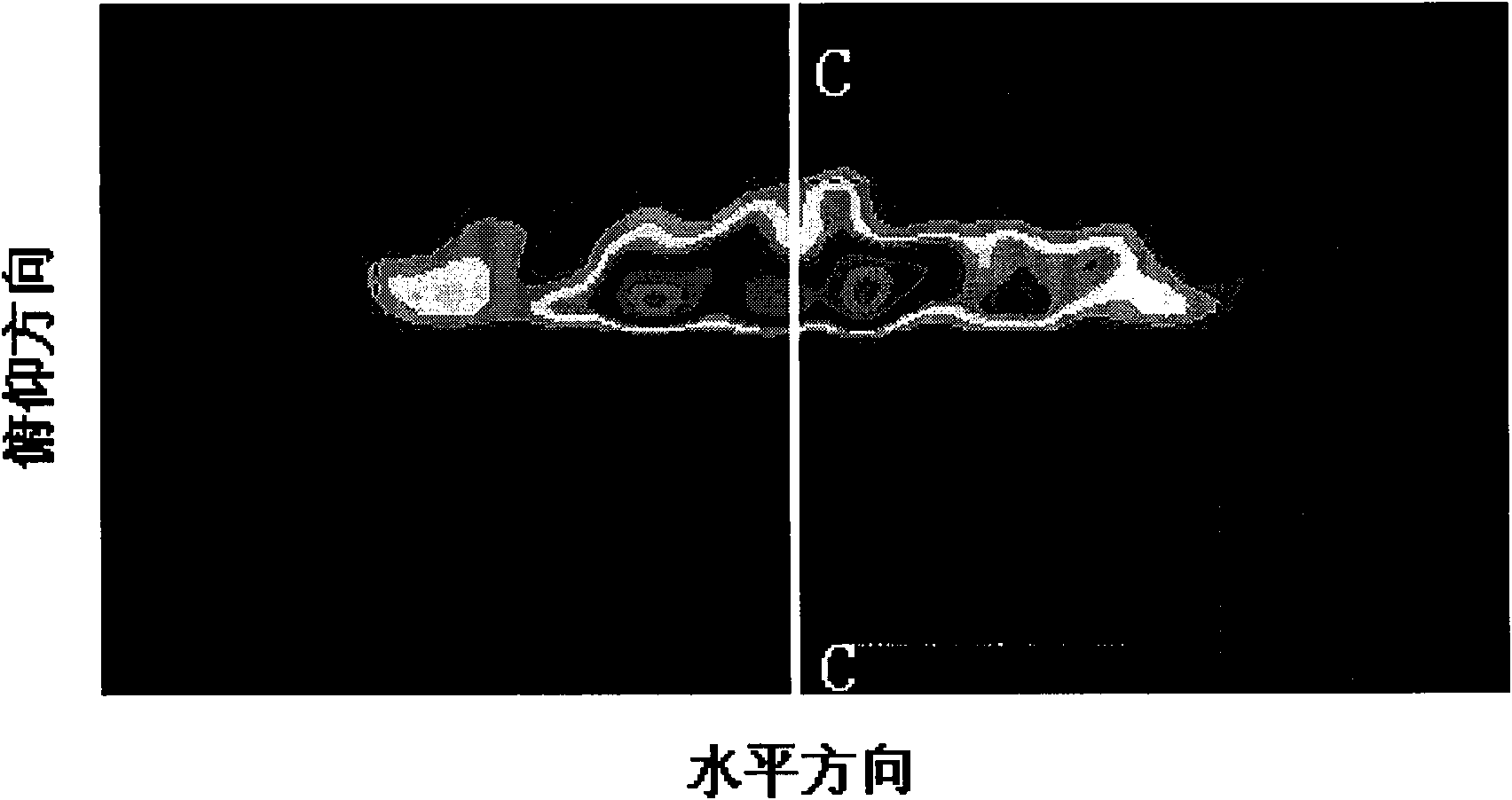

The invention belongs to the field of optical measuring technologies, in particular to a method for testing the beam intensity distribution of an LED precision approach path indicator. The method comprises test system building, testing and sampling, data processing, and the like. A test system comprises an LED precision approach path indicator to be tested, a test screen, a V (lambda) optical filter, a CCD video camera and a computer. The V (lambda) optical filter and the CCD video camera are used for acquiring the gray-scale value images of two-color beams sent by the LED precision approach path indicator; and an illuminance meter is used for sampling illuminance values at a plurality of key points; and by marking illuminance values and gray-scale values, the acquired images and data are processed by a mathematical method and a computer image processing technology to obtain the intensity distribution of beams in the whole space, thereby precisely testing the intensity distribution.

Owner:FUDAN UNIV

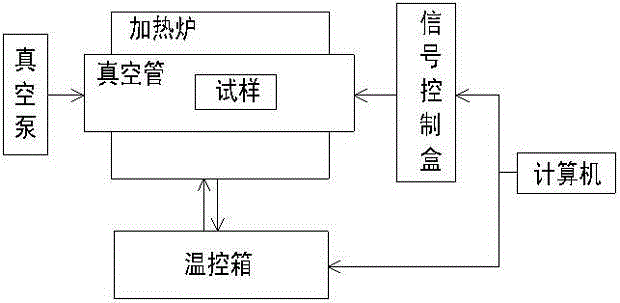

Device for testing metal electrical resistivity change within continuous temperature range

InactiveCN104459329ARealize precise measurementResistance/reactance/impedenceTemperature controlHeating furnace

The invention discloses a device for testing metal electrical resistivity change within a continuous temperature range. The device comprises a positioning mechanism, a heating system and a measurement system. The heating system comprises a heating furnace and a temperature control box connected with the heating furnace. The measurement system comprises a computer and a signal control box connected with the computer, the computer is connected with the temperature control box through a communication line, a vacuum pipe is arranged in the heating furnace, the positioning mechanism is arranged in the vacuum pipe, sealing valve bodies are arranged at the two ends of the vacuum pipe, the sealing valve body at one end of the vacuum pipe is connected with a vacuum pump, the sealing valve body at the other end of the vacuum pipe is connected with the signal control box, a temperature sensor, a current signal input clamp and a signal collecting clamp are arranged in the vacuum pipe, and the current signal input clamp and the signal collecting clamp are connected with the signal control box through wires. Through the method, the device can realize precise measurement of the metal electrical resistivity change at different heating speeds.

Owner:SUZHOU VOCATIONAL UNIV

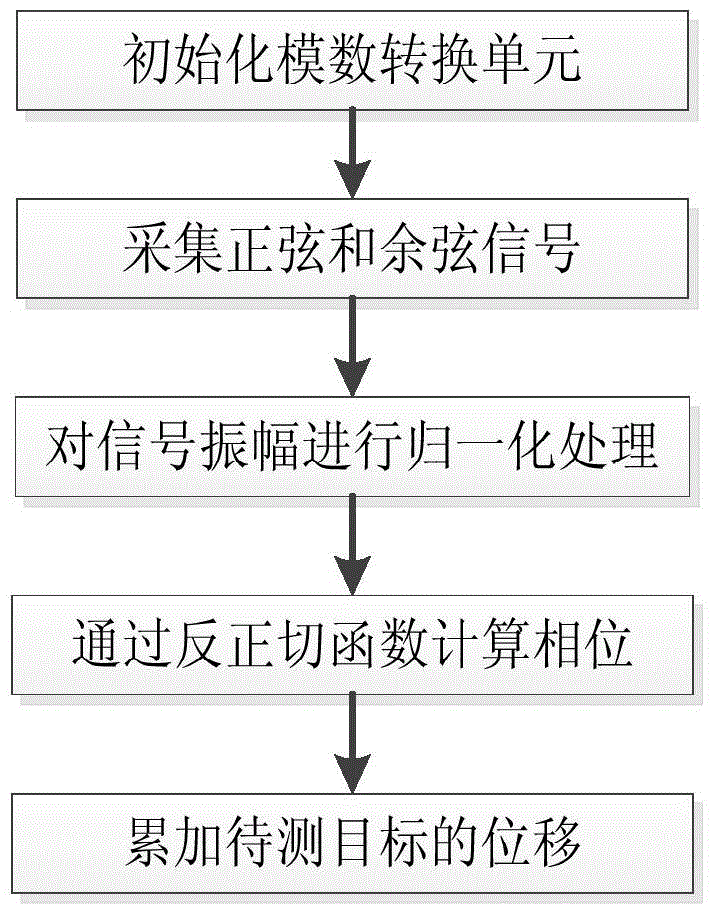

Displacement measurement method based on light interference

ActiveCN105674889ARealize precise measurementHigh precisionUsing optical meansResonant cavityClassical mechanics

The invention provides a displacement measurement method based on light interference and relates to the displacement measurement method. The method is characterized in that, by utilizing a feature that an optical resonant cavity enables wave lengths to be passed selectively, and by analyzing the wave length of transmitted light, cavity length is obtained; when the cavity length changes, the transmission wave length changes therewith; and a photoelectric receiving device detects and analyzes the transmission wave length to obtain cavity length change amount, and displacement of a measured object is calculated through the cavity length change amount. The displacement measurement method can realize precise measurement of the displacement, has the advantages of being high in measurement precision, large in range, capable of crossing from the nm level to the m level, and capable of greatly improving system response time and the like, and is easy to be widely generalized.

Owner:苏州市鼎苏科技咨询服务有限公司

Non-contact hole diameter measuring device

The invention discloses a non-contact hole diameter measuring device. At present, a capacitance type sensor measuring head applied to hole diameter of a micro hole is restricted to measuring some fixed hole diameter and is low in measuring efficiency. A ball screw is fixed with an output shaft of an adjusting motor, a scale grating is fixed on the ball screw, a screw rod nut is connected with the ball screw, and an indicating grating is fixed with the screw rod nut. One end of each of four connecting rods is hinged to a motor base of the adjusting motor, and the other end of each connecting rod is respectively hinged to one push rod. One end of each of four push rods is hinged to the screw rod nut, and the other end of each push rod is respectively fixed with one electrode plate liner base. Electrode plates are respectively fixed on the end faces of the same ends of four electrode plate liner bases, the electrode plate liner bases and electrode plates are cylinders with the cross sections in a fan shape, and the four electrode plates are evenly distributed along the circumference. The electrode plates are adjustable in the radial direction, and precision measurement of variable hole diameters, including measurement of micro holes with large length-diameter ratios and stepped holes, can be achieved.

Owner:HANGZHOU DIANZI UNIV

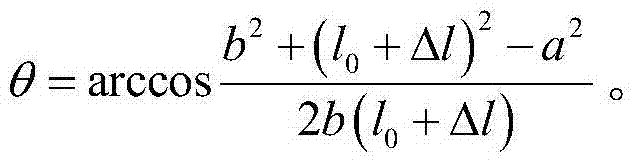

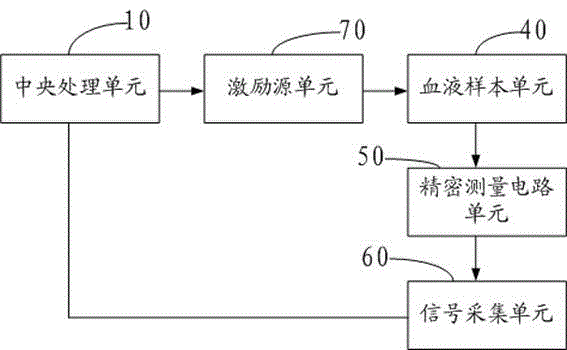

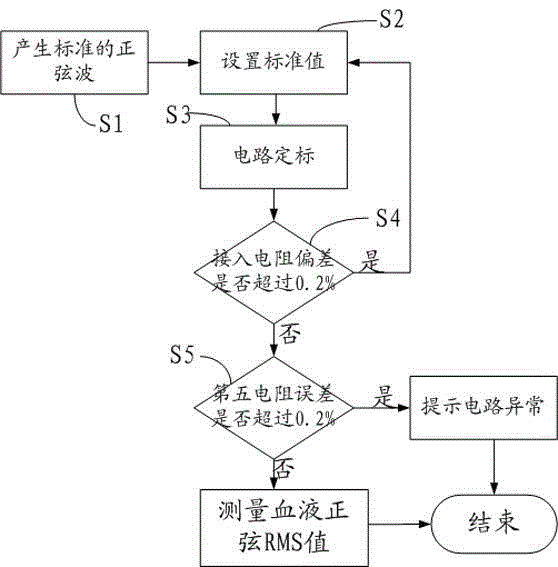

Detection system for improving accuracy of measuring packed cell volume accuracy and operating control method

InactiveCN103149132AHigh precisionRealize precise measurementDiagnostic recording/measuringSedimentation analysisHemt circuitsEngineering

The invention provides a detection system for improving the accuracy of measuring the packed cell volume and an operating control method. The detection system for measuring the packed cell volume comprises a central processing unit, an excitation source unit, a blood sample unit, a precision measurement circuit unit and a signal acquisition unit. The detection system provided by the invention has the beneficial effects that a sine wave is generated through the excitation source unit, the central processing unit is used for controlling, and the measurement accuracy of HCT is improved; the detection system provided by the invention is simple and reliable, and the precision measurement is realized; and the measuring accuracy is higher than the traditional measuring technique and can achieve 0.2%. As the detection system is provided with a self-detection function, the measurement is very reliable, and no circuit fault is generated to lead to wrong measured data.

Owner:EDAN INSTR

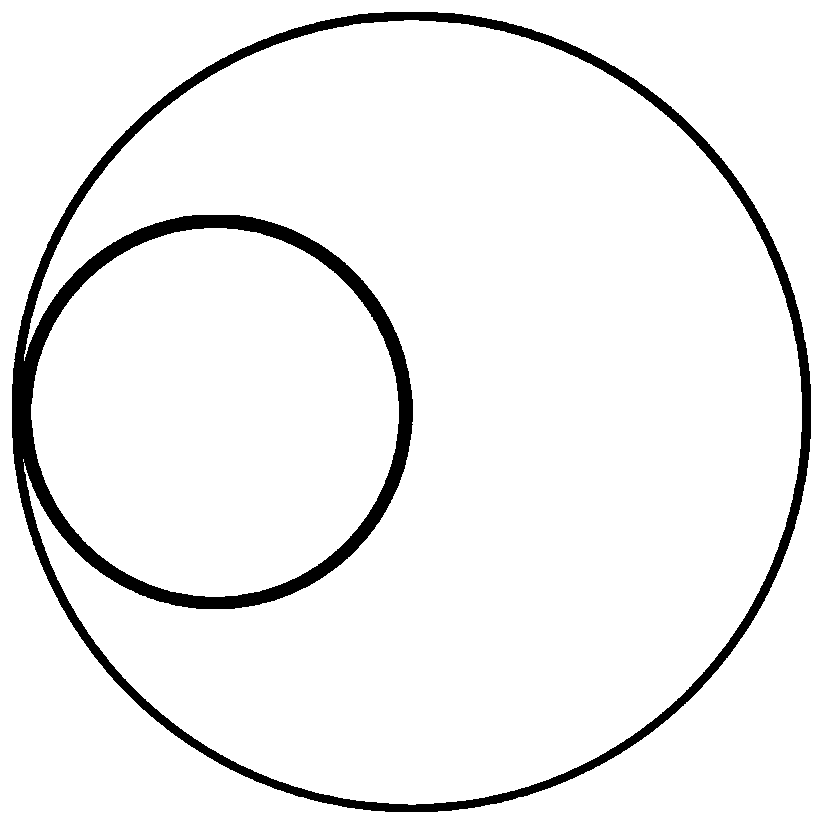

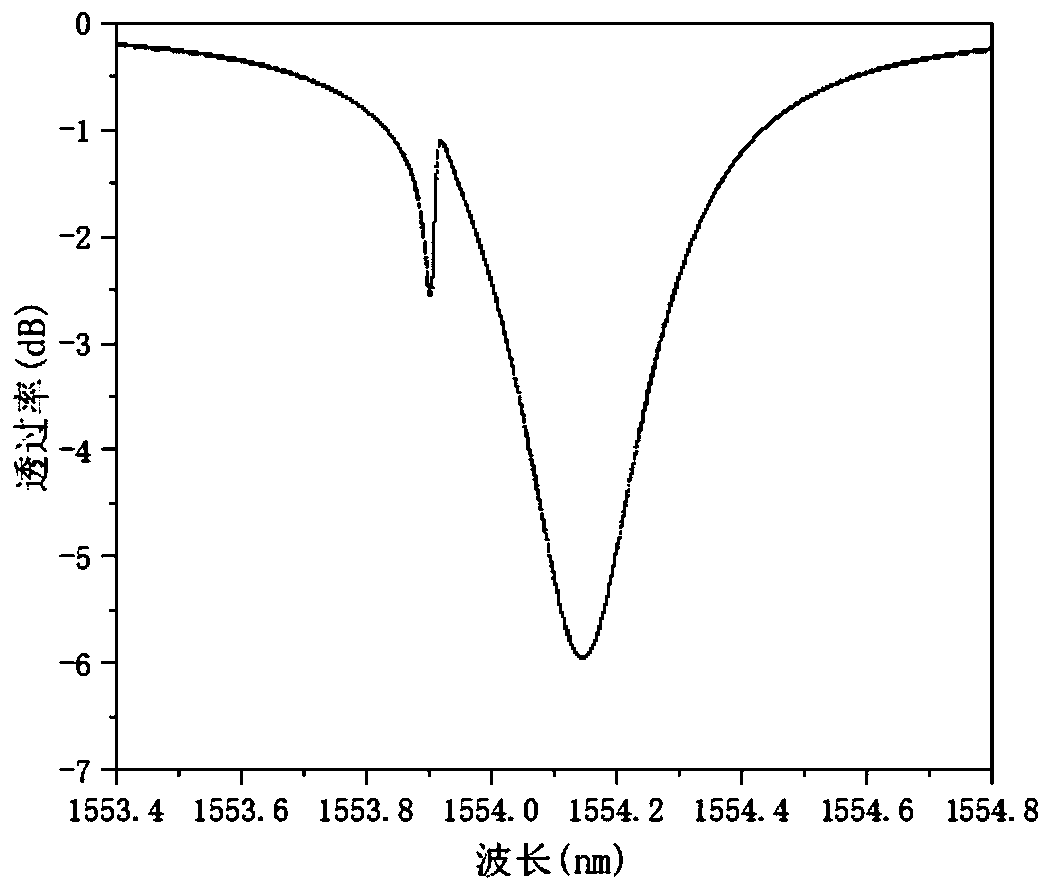

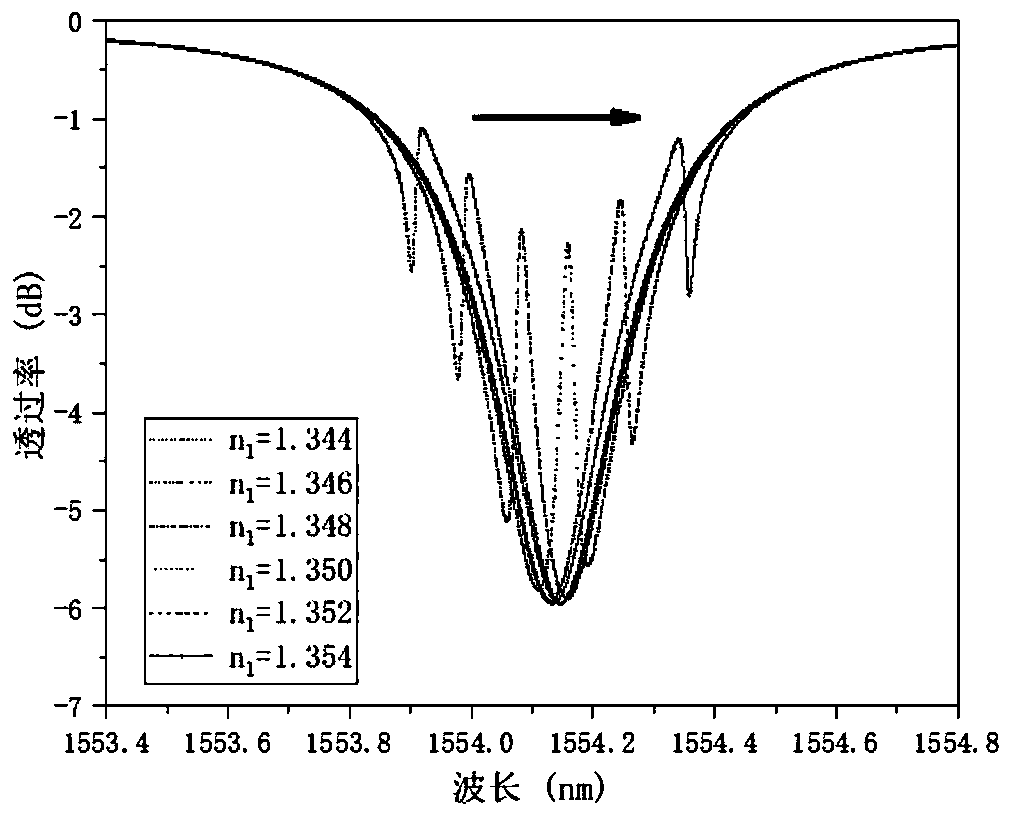

Eccentric hole microstructure optical fiber light-operated tunable Fano resonance filter integrated with azobenzene material

InactiveCN111538124AHighly integratedEasy to tunePhase-affecting property measurementsOptical waveguide light guideRefractive indexResonance spectrum

The invention discloses an eccentric hole microstructure optical fiber light-operated tunable Fano resonance filter integrated with an azobenzene material. The inner wall of the eccentric hole of theeccentric hole microstructure optical fiber is formed by a germanium-doped high-refractive-index ring, a layer of azobenzene film is integrated on the outer surface of the eccentric hole optical fiber, and echo wall modes can be obtained in the azobenzene film and the germanium-doped high-refractive-index ring of the eccentric hole optical fiber at the same time. When the quality factor of the echo wall mode in the azobenzene film is lower than the quality factor of the echo wall mode in the eccentric hole optical fiber germanium-doped high refractive index ring by more than one order of magnitude and a phase matching condition is met, a Fano resonance phenomenon occurs, and a Fano resonance spectrum is obtained. The filter can be applied to the fields of tunable optical filtering, tunablerefractive index sensing, light intensity detection and the like. The filter has the advantages of high sensing sensitivity, wide wavelength tuning range, large refractive index sensing range, simpleand feasible tuning means, high tuning linearity and the like.

Owner:NANKAI UNIV

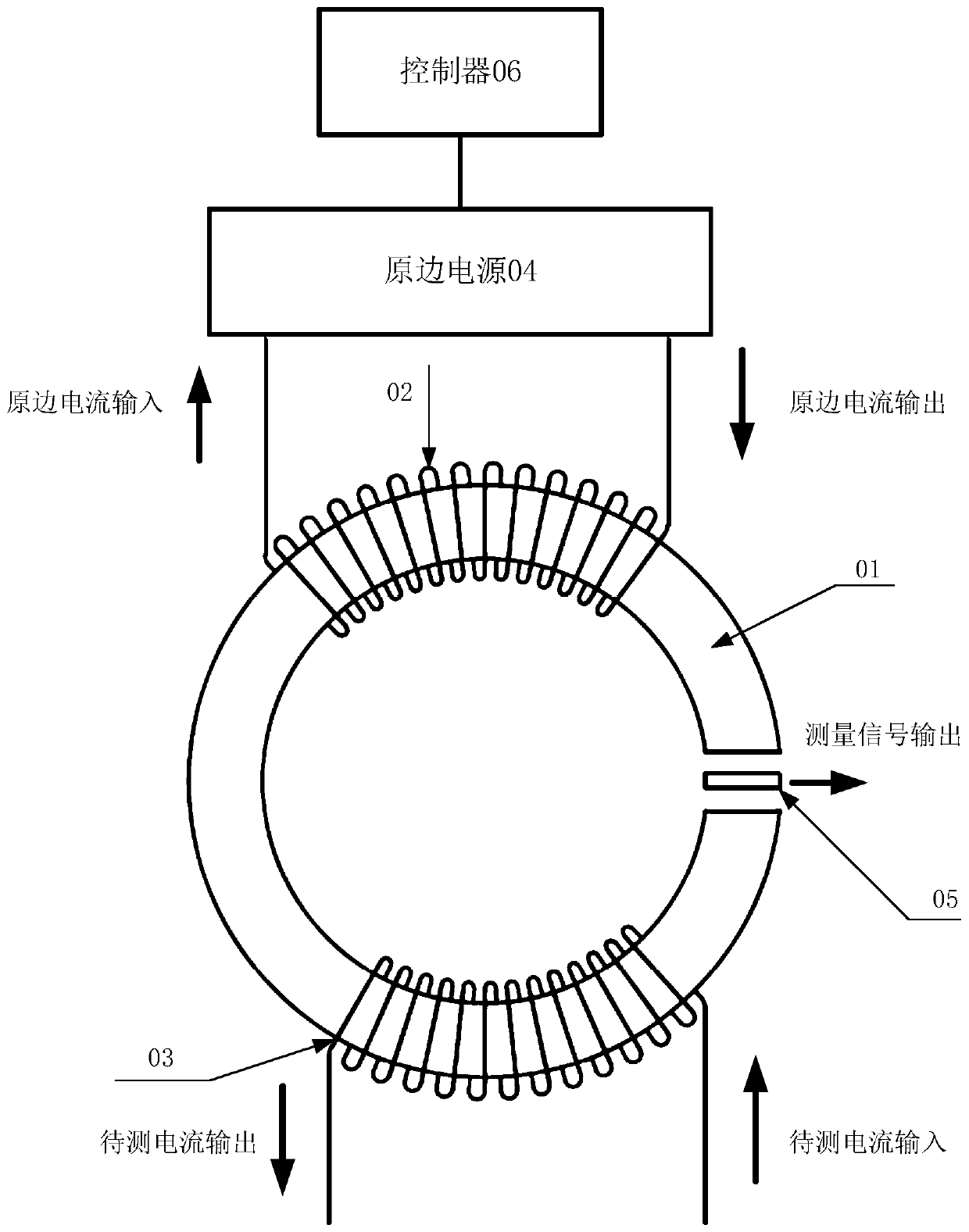

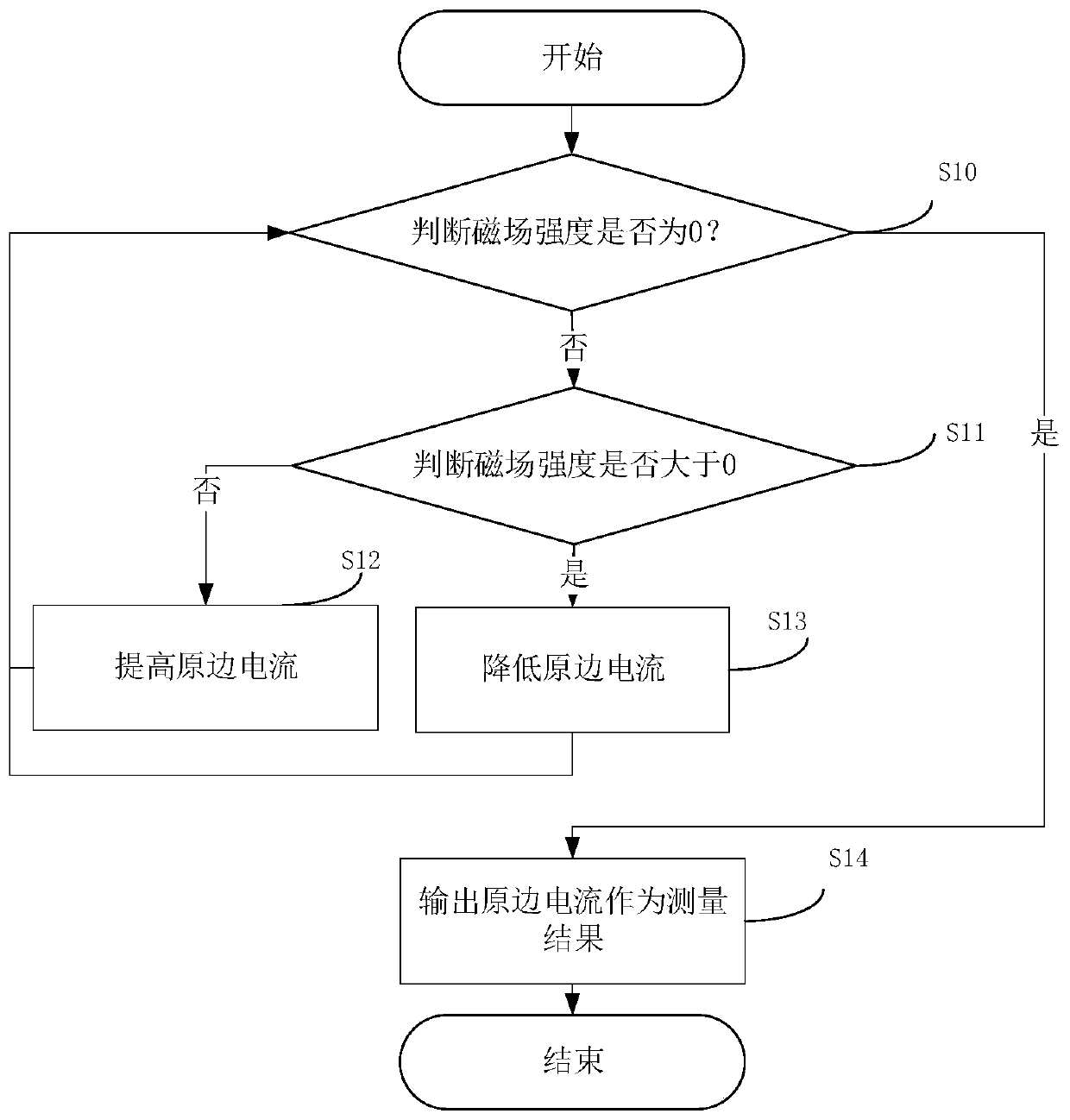

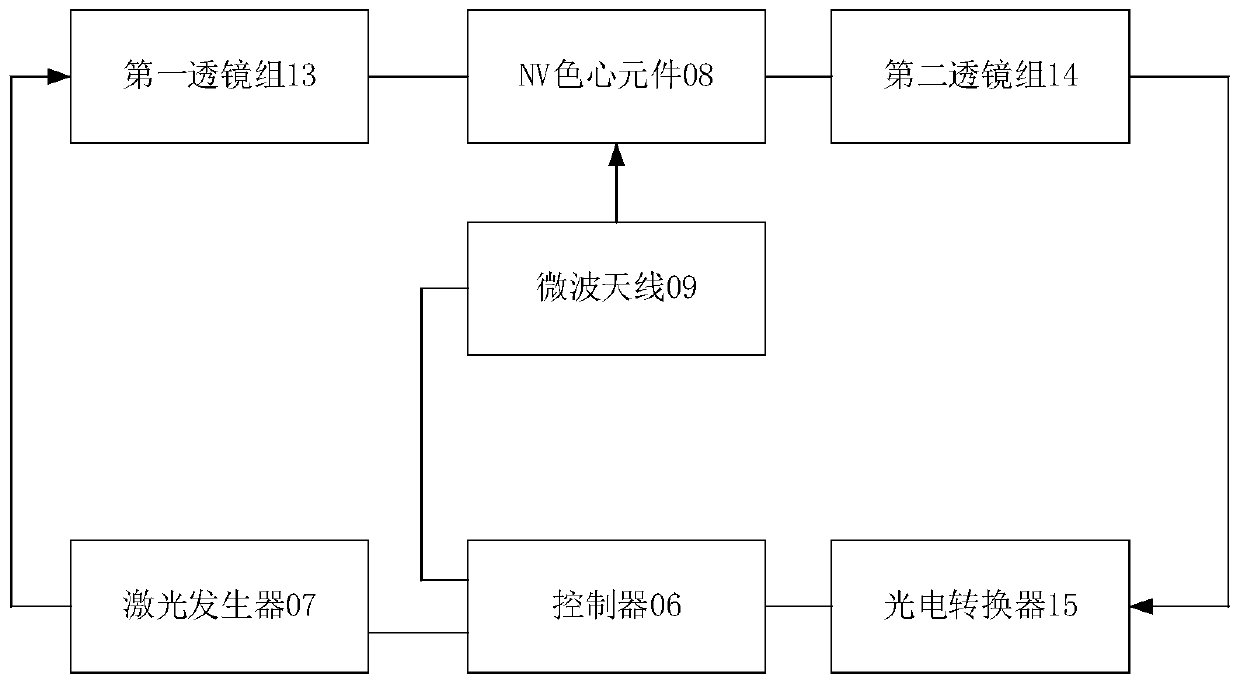

Current standard device based on quantum precision measurement

PendingCN110045310AImprove robustnessRealize precise measurementElectrical measurementsQuantum sensorBroadband

The embodiment of the invention provides a current standard device based on quantum precision measurement and belongs to the technical field of precisionmeasurement of currents. The current standard device comprises a magnetic conducting ring provided with a gap, a first coil, a second coil, a primary side power supply, a quantum sensor and a controller. The first coil and the second coil are embedded into the magnetic conducting ring, and the second coil is used for inputting currents to be measured, wherein the number of turns of the first coil is equal to the number of turns of the second coil. The primary side power supply is connected with the first coil and used for inputting primary side currents. The quantum sensor is arranged in the gap and used for measuring magnetic field strength of the gap. The controller is connected with the primary side power supply and the quantum sensor. The controller is used for controlling the primary side power supply according to the magnetic field strength to input the primary side currents to the first coil and calculating the currents to be measured according to the primary side currents. According to the current standard device, the precision measurement of the currents can be achieved within the broadband range.

Owner:STATE GRID CORP OF CHINA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com