Non-contact and multi-point measurement method for measuring internal diameter of circular hole

A multi-point measurement and non-contact technology, which is applied in the field of geometric measurement, can solve the problems of large influence of human factors, difficulty in realizing automation, and insufficient information, so as to achieve convenient operation, reduce error chains, and improve measurement accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

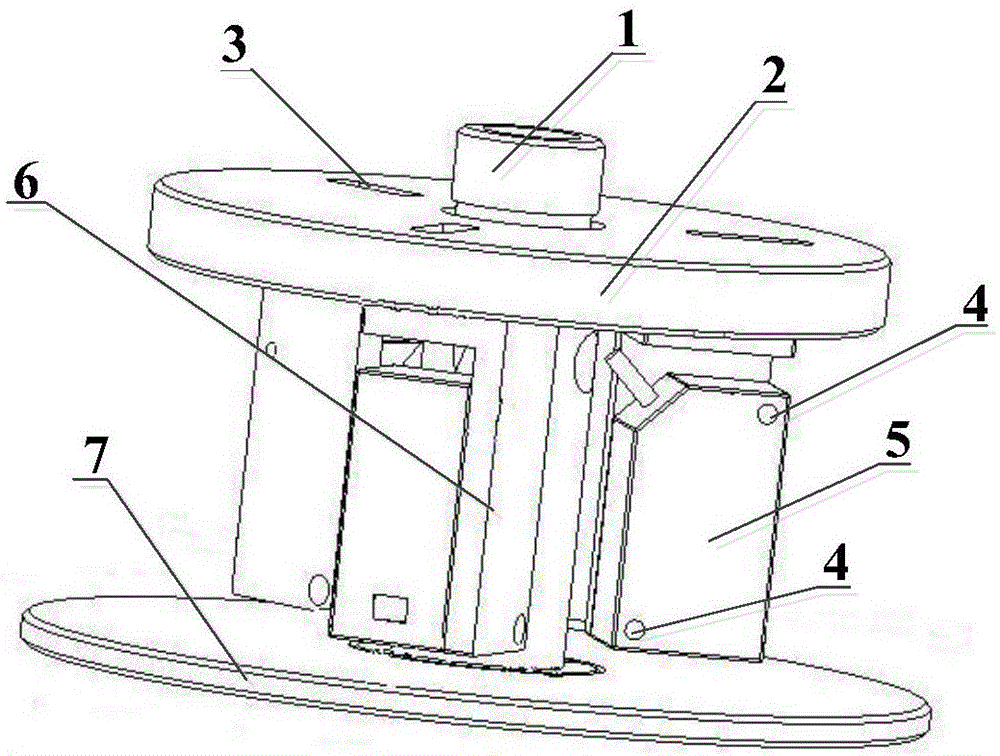

[0047] A method for non-contact multi-point measurement of the inner diameter of a circular hole, see figure 1 , figure 2 , image 3 and Figure 4 , the method for measuring the inner diameter of the circular hole comprises the following steps:

[0048] 101: Build a three-sensor fixed value comparison measuring head;

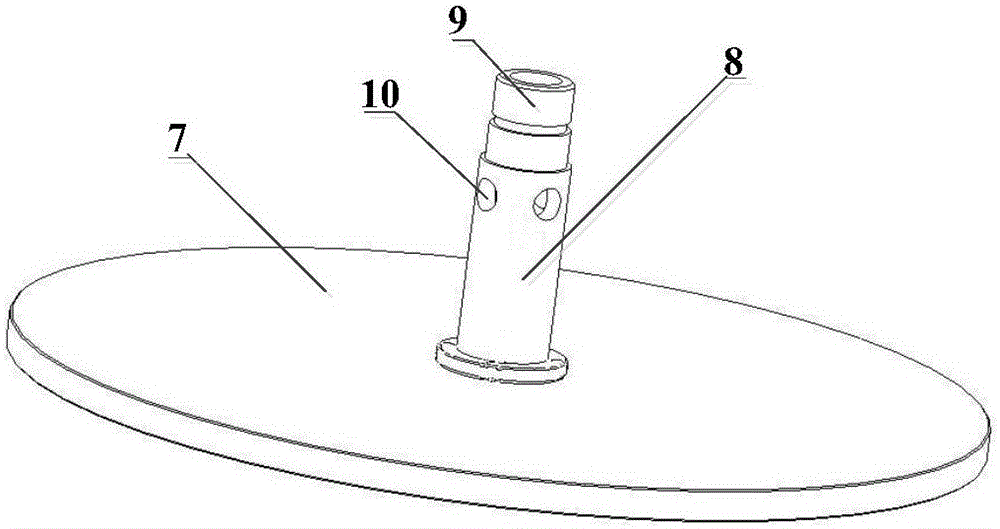

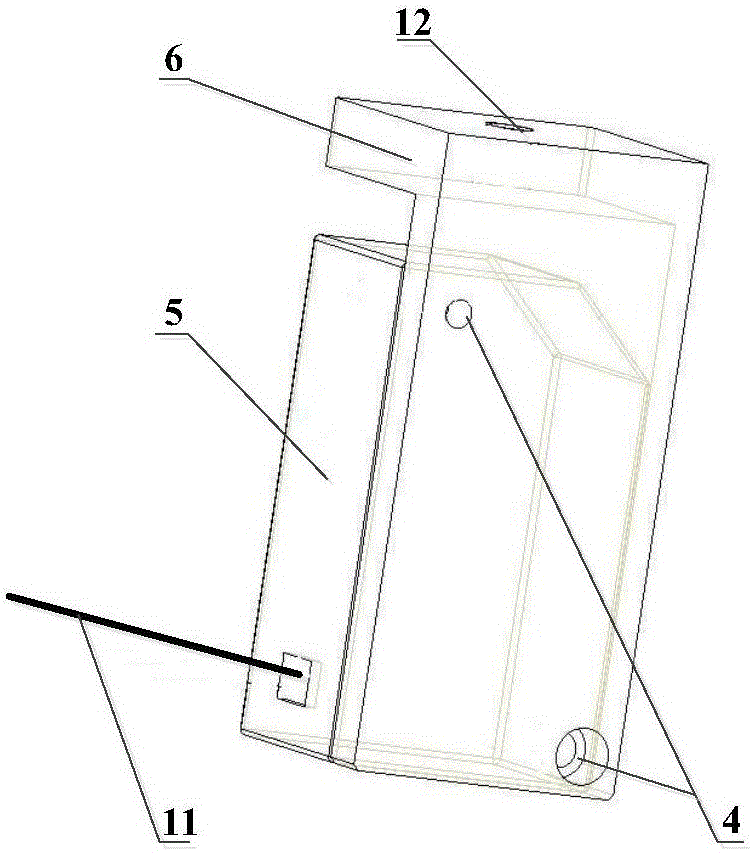

[0049] see figure 1 and figure 2 , The measuring head of the three-sensor fixed value comparison includes: the fixed plate 7 on the bottom surface of the measuring head, the fixed plate 7 on the bottom surface of the measuring head is provided with the central axis 8 of the measuring head, the central axis 8 of the measuring head is sleeved with an angle and range adjusting plate 2, the angle and The range adjustment disc 2 is provided with a fixing and adjusting hole 3, and the central axis 8 of the measuring head is provided with three sensor fixing frames 6, and the sensor fixing frame 6 is equipped with a laser displacement sensor 5, and the laser dis...

Embodiment 2

[0073] A method for non-contact multi-point measurement of the inner diameter of a circular hole, see figure 2 , image 3 , Figure 5 , Figure 6 and Figure 7 , the method for measuring the inner diameter of the circular hole comprises the following steps:

[0074] 201: Build a four-sensor fixed value comparison measuring head;

[0075] see figure 1 , Figure 5 and Figure 6 , the four-sensor fixed value comparison measuring head includes: measuring head bottom surface fixed plate 7, measuring head bottom surface fixed plate 7 is provided with measuring head axis 8, measuring head axis 8 is sleeved with angle and range adjusting plate 2, angle and The range adjustment disc 2 is provided with a fixing and adjustment hole 3, and the measuring head axis 8 is provided with four sensor holders 6, each sensor holder 6 is equipped with a laser displacement sensor 5, and the laser displacement sensor 5 is provided with a sensor Fixing and adjusting screws 4.

[0076] That i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com