Non-contact hole diameter measuring device

A non-contact, measuring device technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of reduced measurement efficiency and increased measurement cost, and achieve the effects of improved efficiency, simple structure, and low measurement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

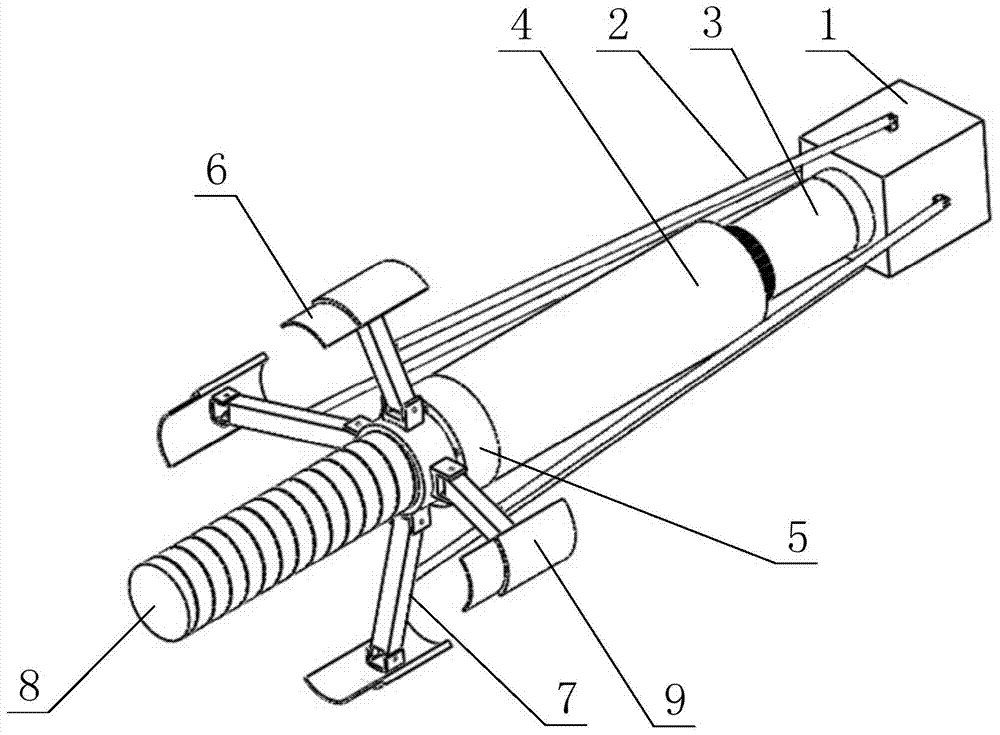

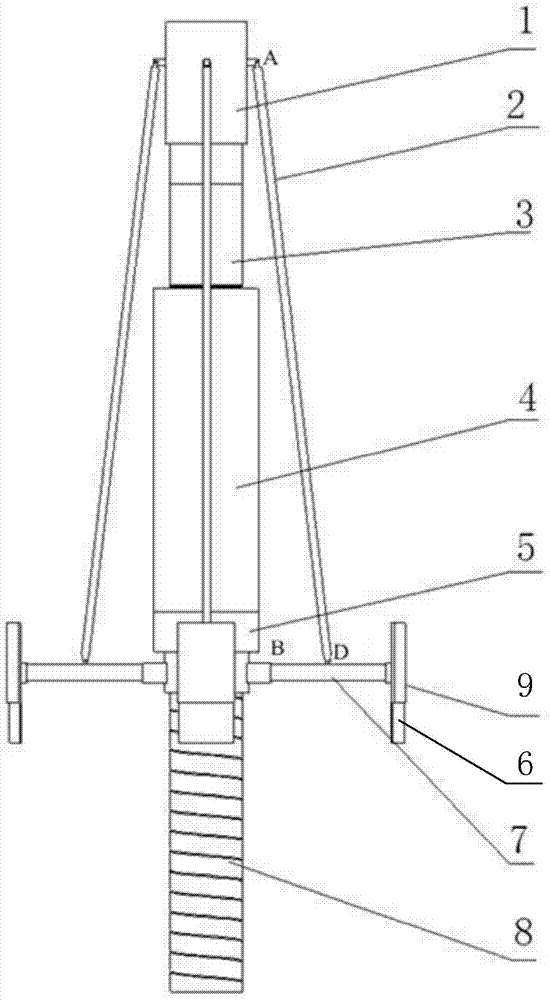

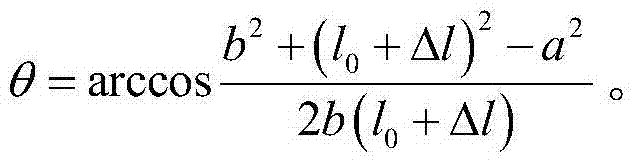

[0014] Such as figure 1 with 2 As shown, the non-contact aperture measuring device includes an adjusting motor 1, a connecting rod 2, a scale grating 3, an indicating grating 4, a screw nut 5, an electrode plate 6, a push rod 7, a ball screw 8 and an electrode plate bushing 9 . The ball screw 8 is fixed to the output shaft of the adjusting motor 1, the scale grating 3 is fixedly set on the ball screw 8; the screw nut 5 is connected to the ball screw 8, the indicator grating 4 is fixed to the screw nut 5, and set Outside the scale grating 3; one end of the four connecting rods 2 is hinged with the motor seat of the adjusting motor 1, and the other end is respectively hinged with a push rod 7; one end of the four push rods 7 is hinged with the screw nut 5, and the other One end is respectively fixed with an electrode plate lining seat 9; four electrode plate lining seats 9 are evenly distributed along the circumference, and an electrode plate 6 is respectively fixed on the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com