Fitting eccentric error compensating method based on CNC (Computerized Numerical Control) gear measuring center

A technology of gear measurement and compensation method, which is applied in the field of measurement, can solve problems affecting measurement accuracy, etc., and achieve the effect of improving measurement efficiency, reducing requirements, and realizing precise measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

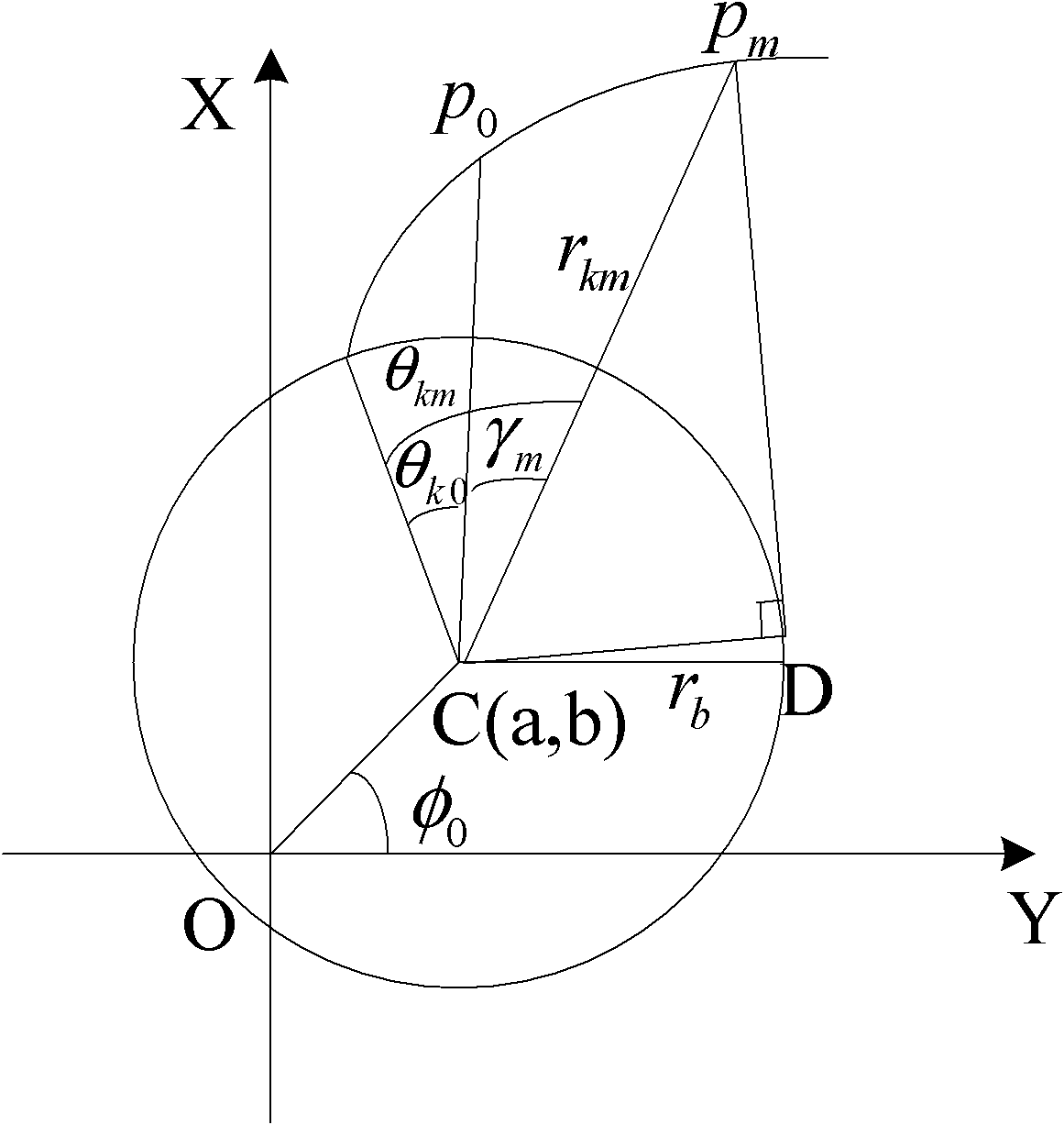

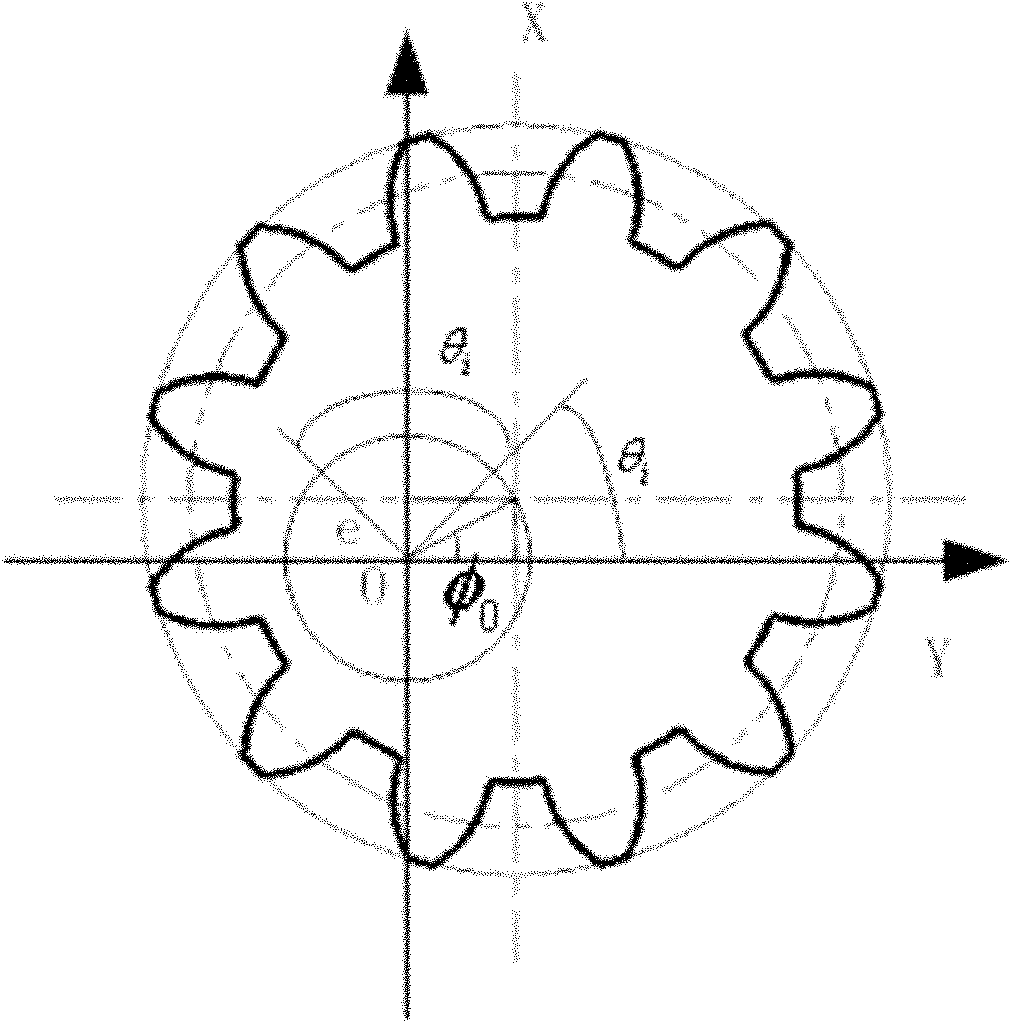

[0027] Specific implementation mode one: this implementation mode comprises the following steps:

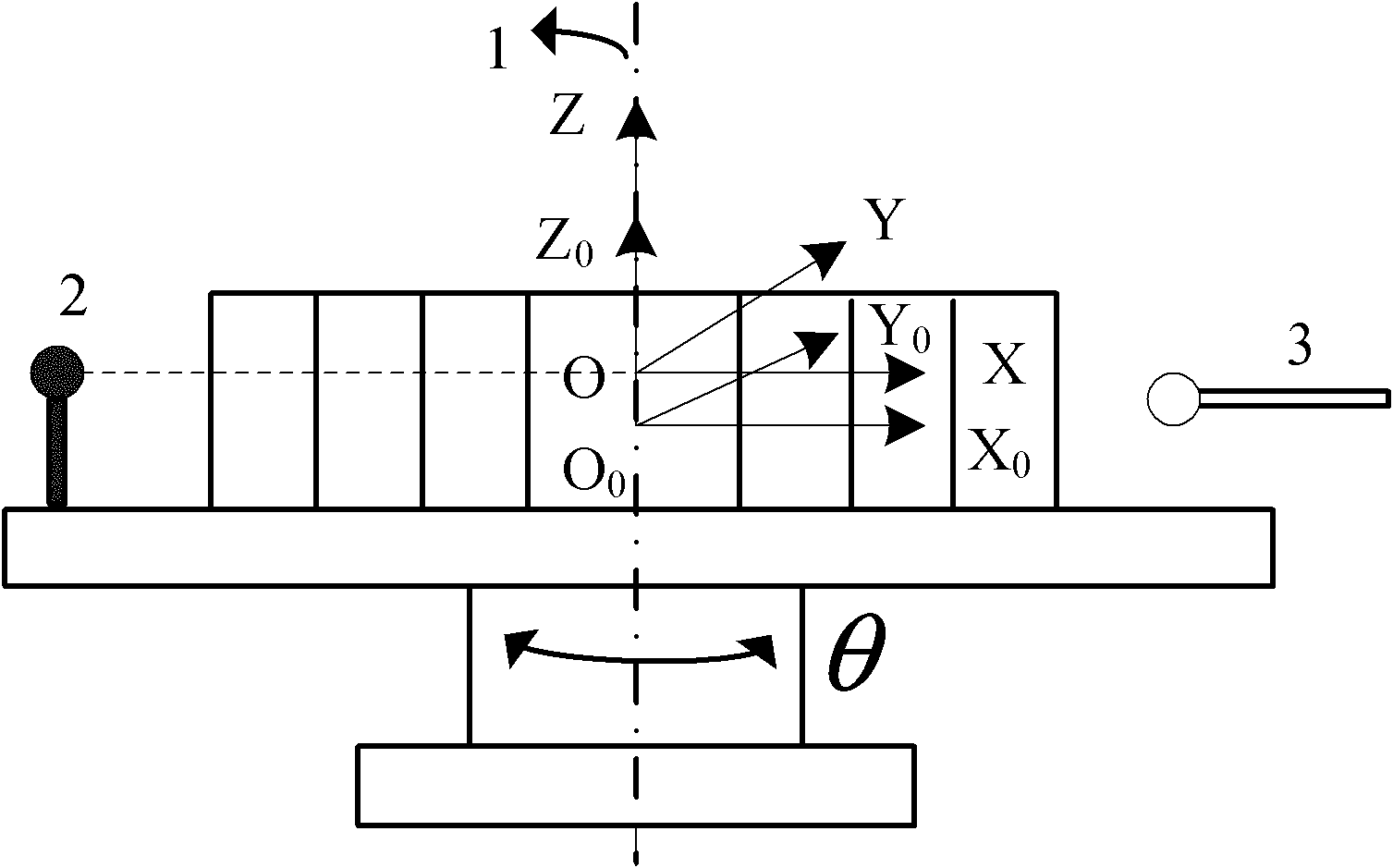

[0028] Step 1: Fix the workpiece to be measured on the measurement position of the CNC gear measurement center, establish the workpiece coordinate system with the geometric center of the workpiece to be measured as the origin, and make the X axis, Y axis and Z axis of the workpiece coordinate system and the instrument coordinate system The directions of the axes are the same; the instrument coordinate system is the coordinate system of the CNC gear measurement center;

[0029] Step 2: Calculate the conversion relationship between the instrument coordinate system and the workpiece coordinate system under the ideal measurement state;

[0030] Step 3: Calculate the conversion relationship between the instrument coordinate system and the workpiece coordinate system in the eccentric measurement state, and obtain the expression of the clamping eccentric vector;

[0031] Step 4: Set th...

specific Embodiment approach 2

[0037] Embodiment 2: This embodiment is a further description of Embodiment 1. The ideal measurement state in step 2 is: the origin of the coordinate system obtained by translating the origin of the instrument coordinate system along its Z-axis direction is used as the origin of the workpiece coordinate system ;

[0038] The conversion relationship between the instrument coordinate system and the workpiece coordinate system under the ideal measurement state is:

[0039] x y z = x 0 y 0 z 0 + 0 ...

specific Embodiment approach 3

[0042] Embodiment 3: This embodiment is a further description of Embodiment 2. The conversion relationship between the instrument coordinate system and the workpiece coordinate system under the eccentric measurement state described in step 3 is:

[0043] x y z = x 0 y 0 z 0 + 0 0 c + β ,

[0044] In the formula, β is the clamping eccentric vector, and its expression is:

[0045] wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com