Measuring device for measuring displacement or deformation quantity of parts in high- and low-temperature vacuum glass covers

A measuring device and high-temperature vacuum technology, which is applied in the field of measurement of small displacement or deformation, can solve the problems of high-low temperature and vacuum environment, difficulty in ensuring accuracy, low degree of automation, etc., to achieve strong maintainability and improve integration , Improving the effect of image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

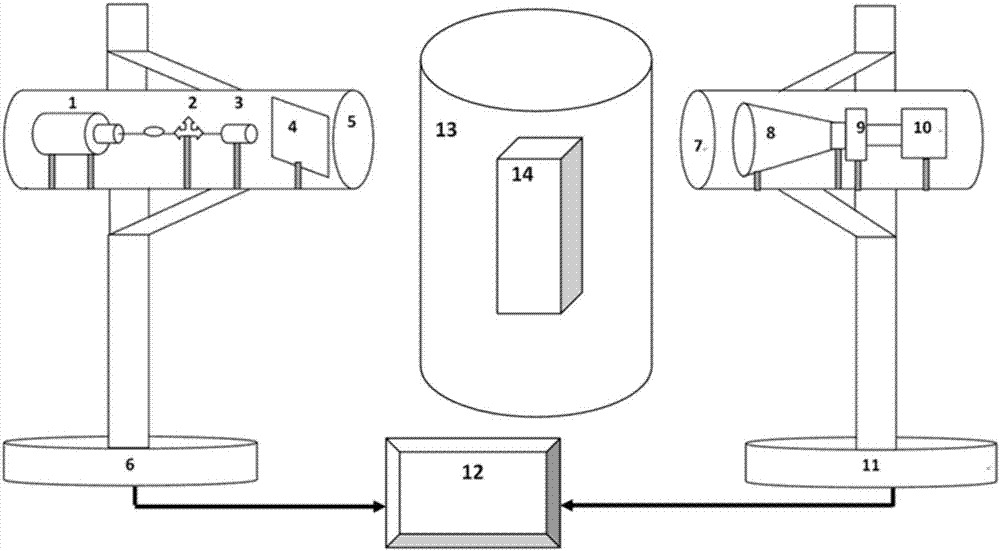

[0020] Such as figure 1 Shown is a schematic diagram of the structure of the measuring device. It can be seen from the figure that the measuring device for the displacement or deformation of parts in the high and low temperature vacuum glass cover includes laser 1, fiber attenuator 2, fiber collimator 3, Fresnel lens 4, The first cylindrical mount 5, the first vertical translation frame 6, the second cylindrical mount 7, the telecentric lens 8, the optical filter 9, the image sensor 10, the second vertical translation frame 11, the computer 12, the high temperature The vacuum glass cover 13 and the measured object 14; wherein, the high temperature vacuum glass cover 13 is a hollow cylindrical structure, and the high temperature vacuum glass cover 13 is placed vertically in the axial direction; the measured object 14 is fixedly installed in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com