Precision measuring system and precision measuring method for positions and diameters of automotive frame assembling holes

A technology for automobile girder and precision measurement, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems of high labor intensity and low manual detection efficiency, and achieve the effect of ensuring local accuracy and global splicing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

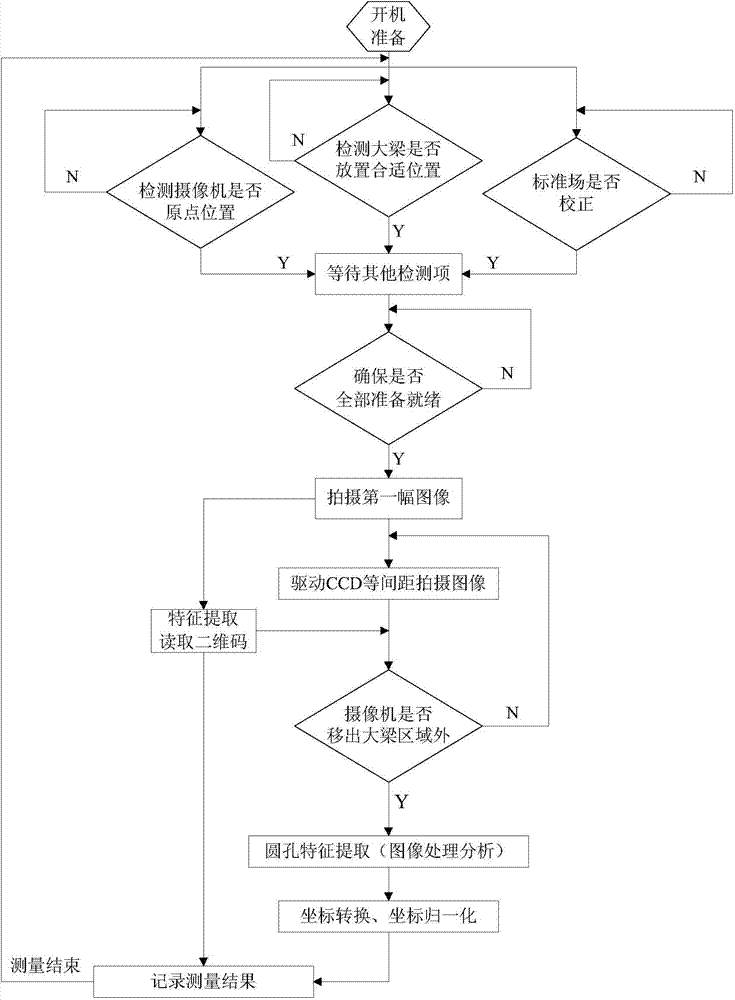

[0058] The technical solutions of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

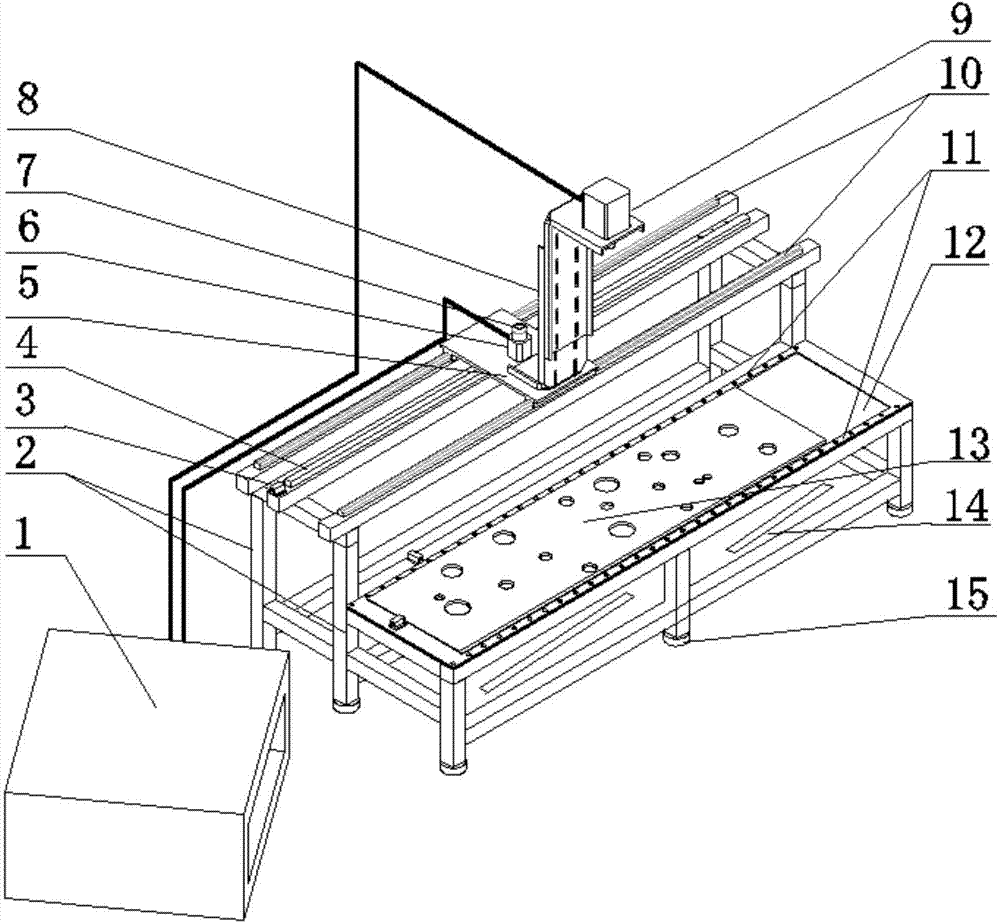

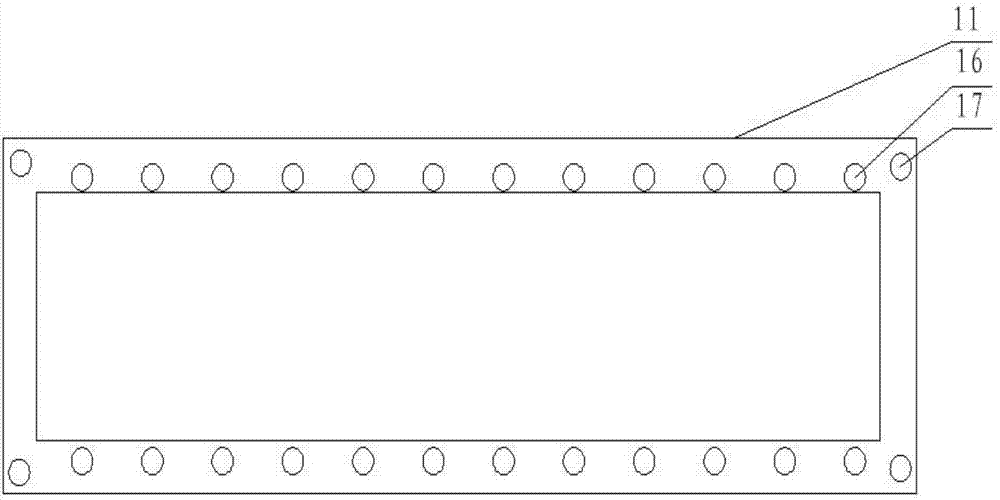

[0059] refer to figure 1 As shown, the automobile frame assembly hole position and aperture precision measurement system of the present invention includes a main console (1), a fixed height frame (2), a position sensor (3), a rack and pinion (4), and a slide table (5), servo motor (6), servo motor encoder (7), camera support frame (8), camera (9), precision horizontal slide rail (10), two-dimensional standard control field (11), tempered glass light source A cover (12), a measured beam (13), a backlight high-frequency light source (14) and a shock absorber (15).

[0060] The main console (1) is provided with a mainframe, and a motion control card and an image acquisition card are respectively inserted in the PCI slots of the mainframe. In the main console (1), the mainframe communicates with the servo motor (6) connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com