Combination space precision measurement system

A precision measurement and combined technology, applied in the field of precision measurement, can solve the problems of limited measurement space, inability to complete three-dimensional measurement of super-large parts, and inability to measure local features, so as to achieve the effect of complete precision measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and example the present invention is described in further detail.

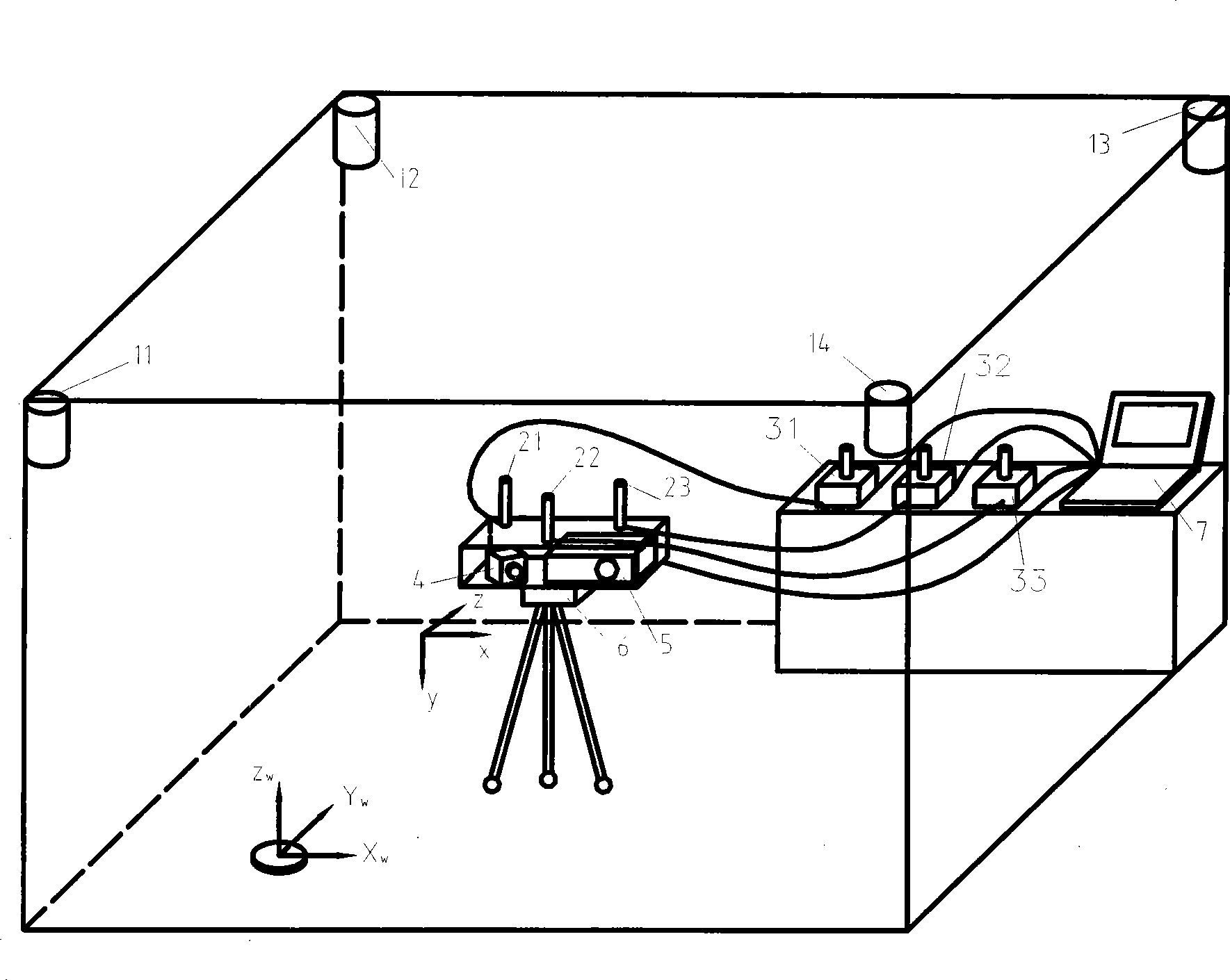

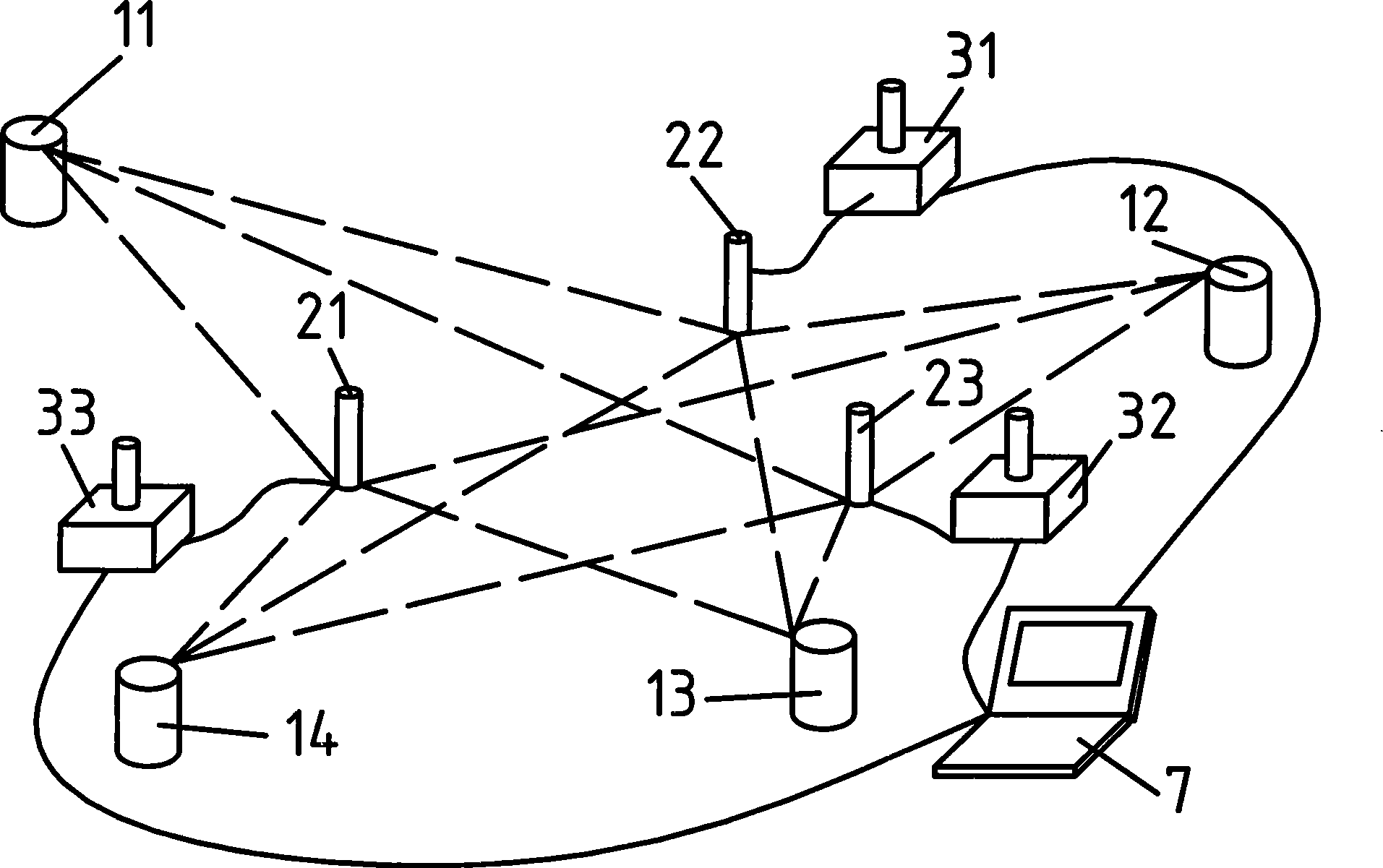

[0024] The system of the present invention includes a structured light measurement subsystem based on digital optical projection and a large-scale photoelectric tracking and positioning subsystem based on the GPS principle, which includes at least four infrared laser emitters, at least three sensors, at least three receivers, and a CCD (Charge Coupled Device, Charge Coupled Device) camera, a DLP (Digital Light processing, digital optical processor) projector, a tripod and a computer. Such as figure 1 As shown, this example includes four infrared laser emitters 11, 12, 13 and 14, three sensors 21, 22 and 23, and three receivers 31, 32 and 33 as an example to illustrate the structure of the present invention.

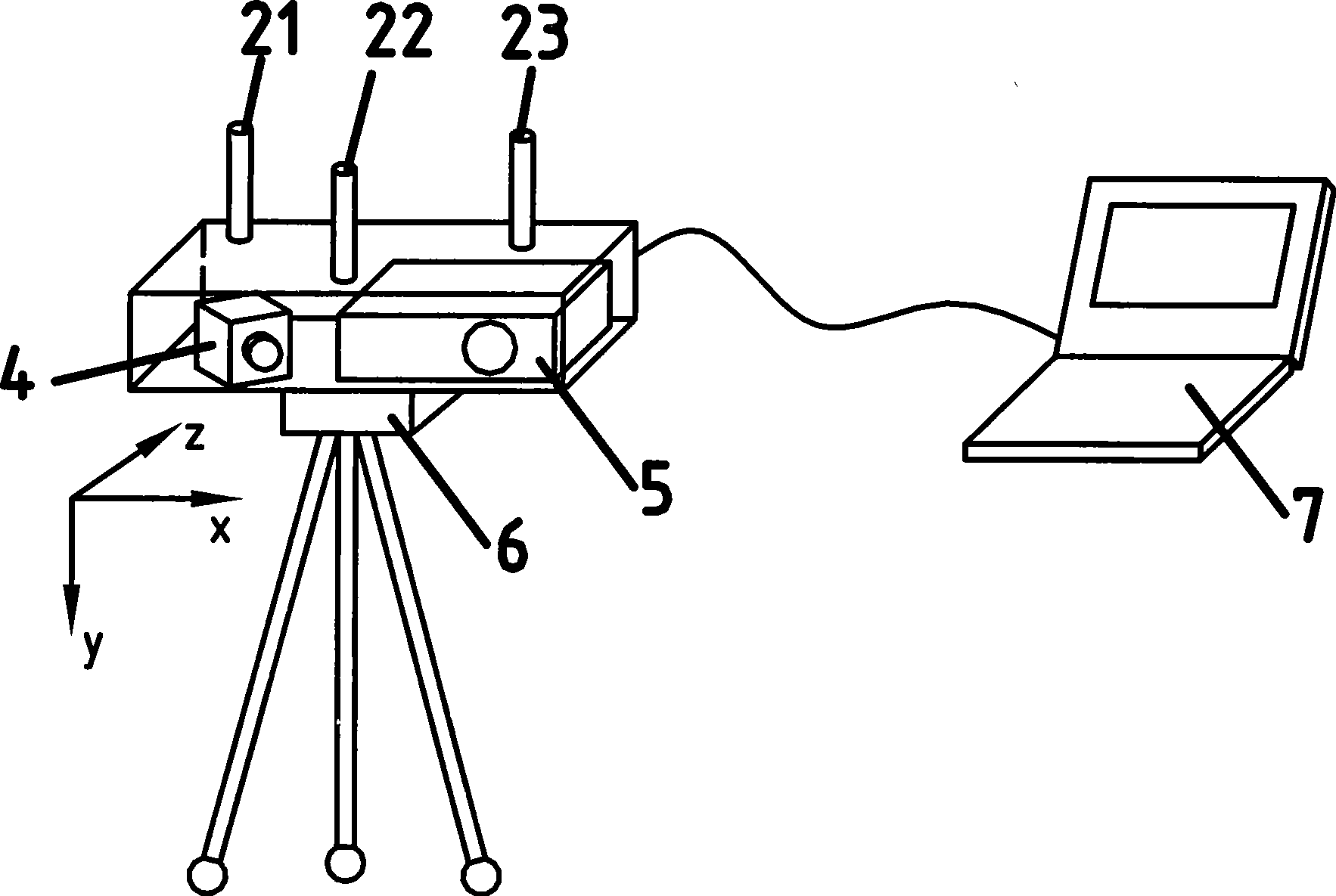

[0025] Such as figure 2 As shown, the structured light measurement subsystem based on digital optical projection includes a CCD camera 4 , a DLP pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com