Standard of angle measurer

A standard and angle measurement technology, applied in the field of goniometer standard and wide-angle standard angle, it can solve the requirements of the on-site verification/calibration of the four-wheel aligner in the metrology department, the influence of wear and tear on the measurement accuracy, and the environmental conditions. Advanced problems, to achieve the effect of intelligent control and operation of the system, reducing the volume and weight of the system, and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

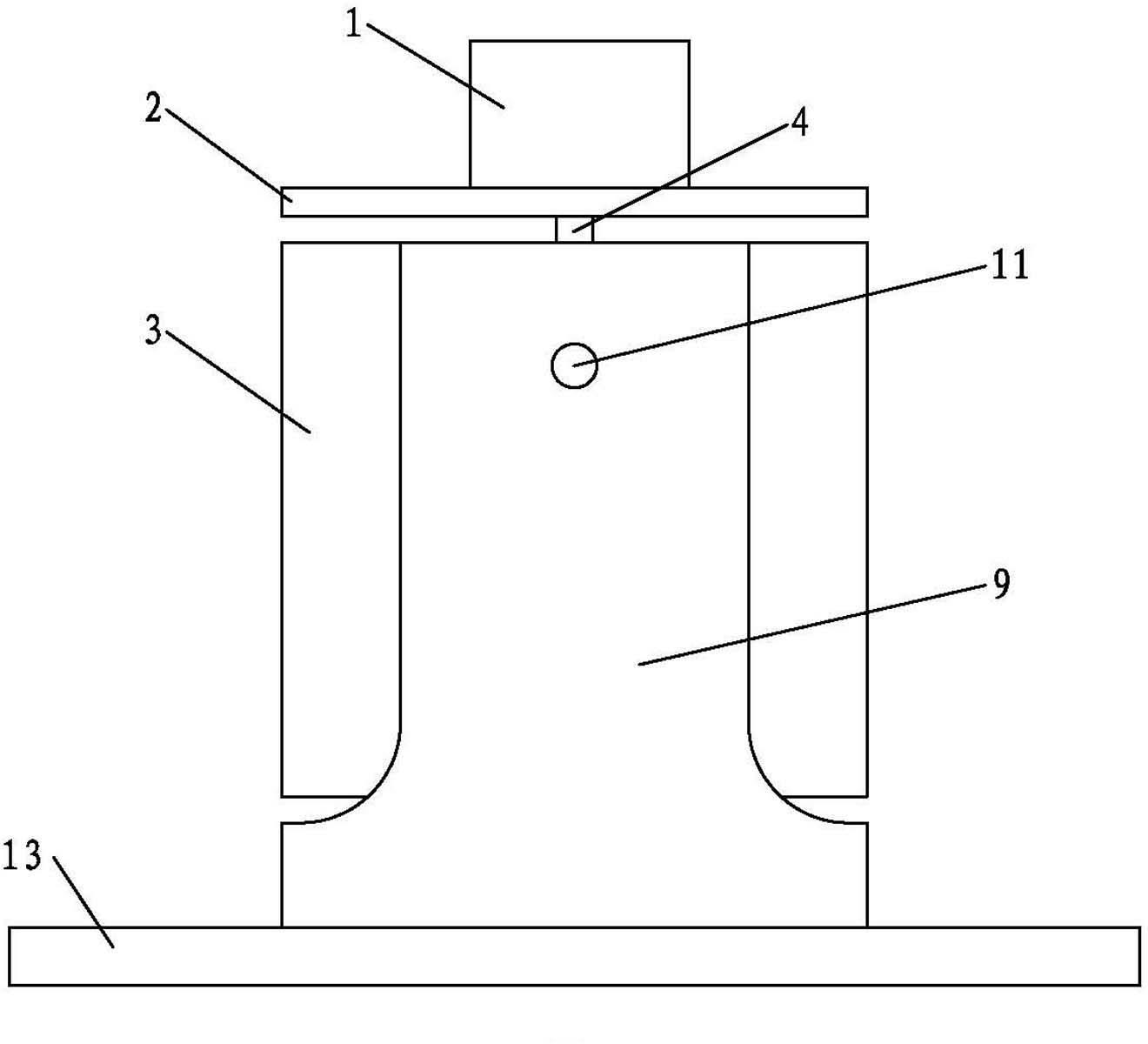

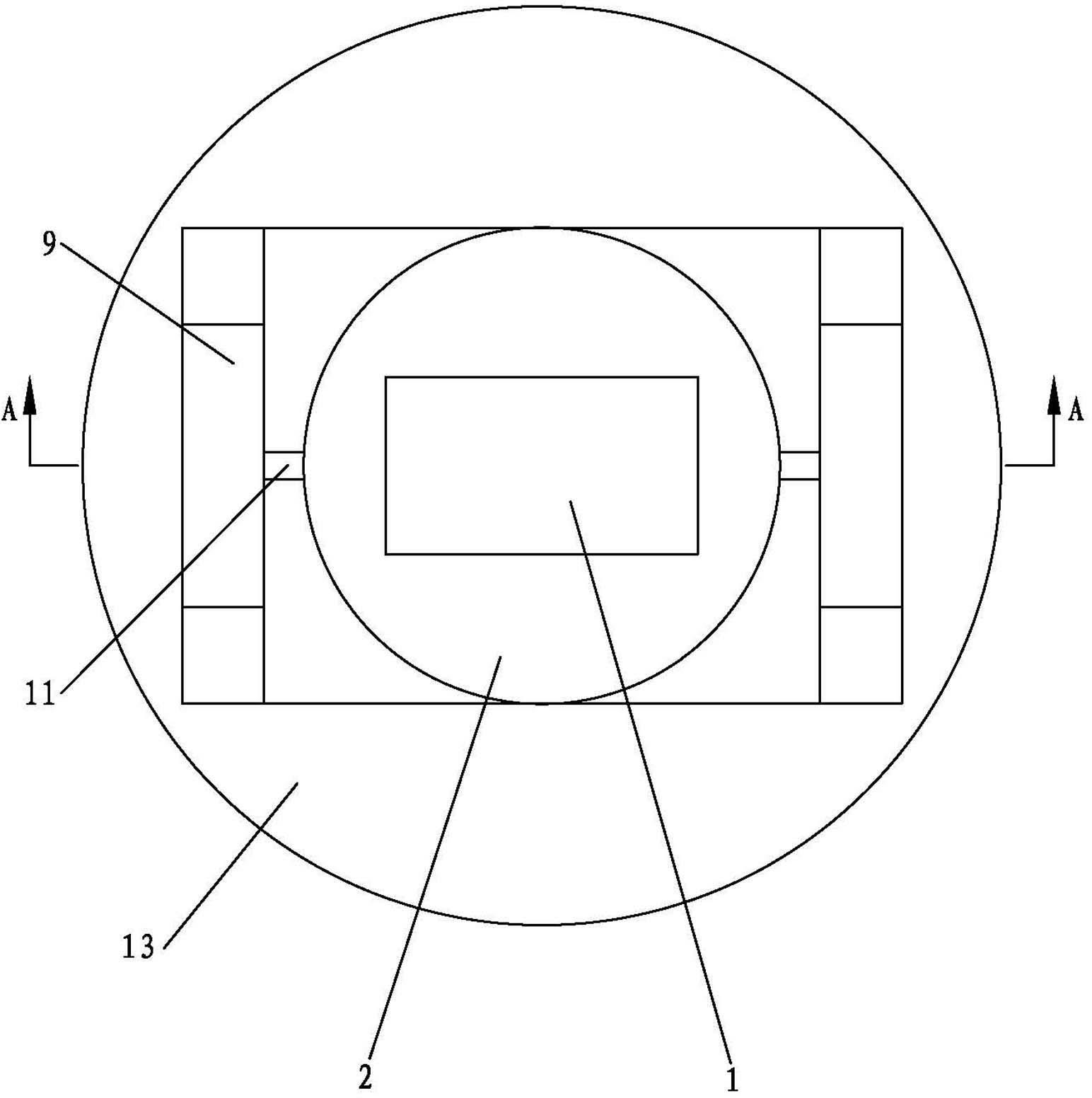

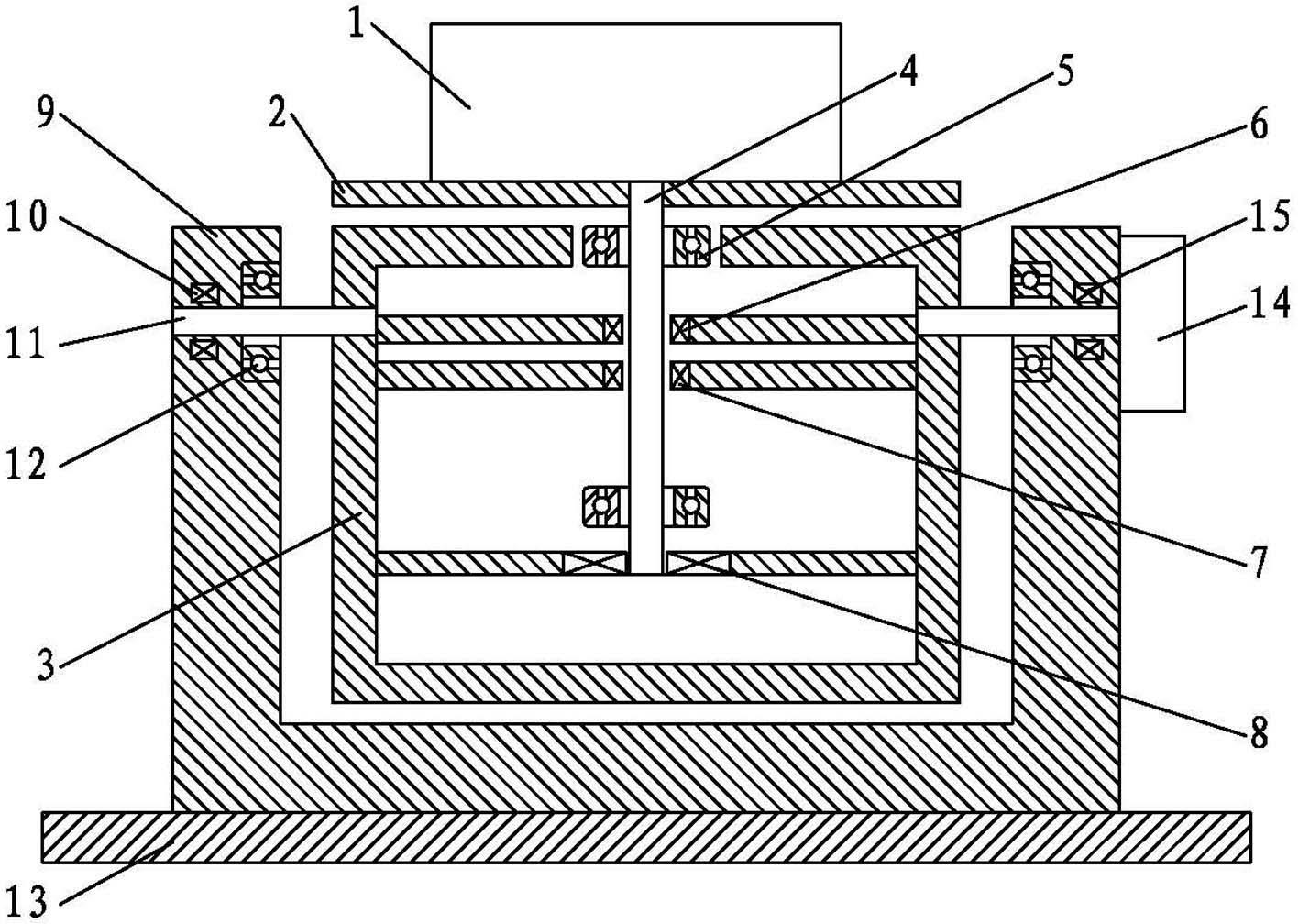

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0036] Such as Figure 1 to Figure 6 As shown, the goniometric instrument standard includes a rotating device and a control system, and is characterized in that the rotating device is a two-axis mechanical rotating device, which includes mutually interconnected and vertical azimuth rotation shafts and pitch rotation shafts , each rotating shaft system is provided with its own electromagnetic locking device, angular contact bearing, permanent magnet DC torque motor and angle measuring element, and the azimuth rotating shaft system is connected with the working table 2 for placing the tested instrument 1; The goniometric elements of the rotating shaft system form the goniometric system.

[0037] The azimuth rotation axis system includes the azimuth axis 4, the azimuth axis turntable and the main shaft frame 3; the pitch rotation axis system includes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com