Ultrasonic liquid-immersing transducer sound field precision measurement method

An ultrasonic transducer, precision measurement technology, applied in the measurement of vibration, measurement device, vibration measurement in fluid, etc. Analysis and calculation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

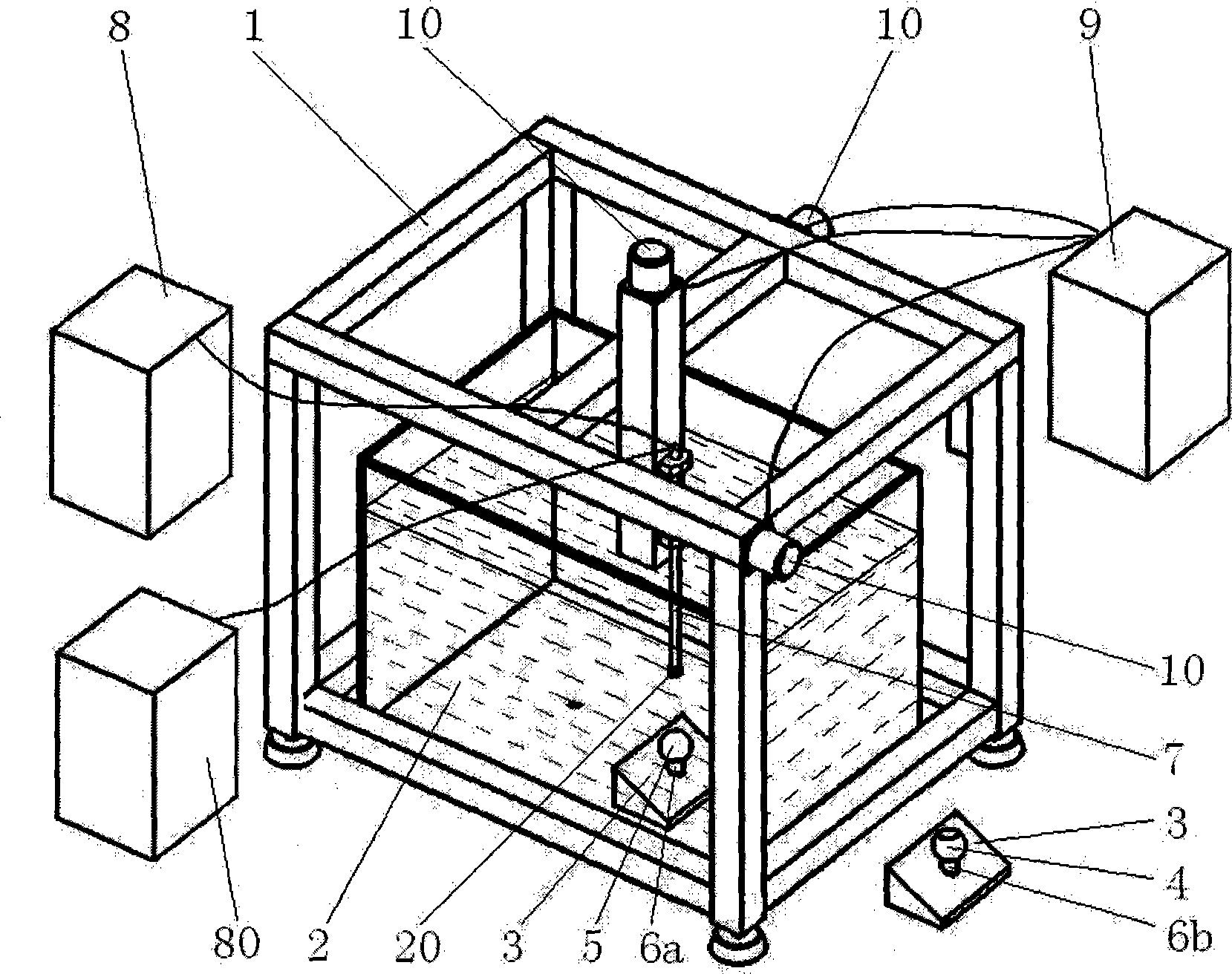

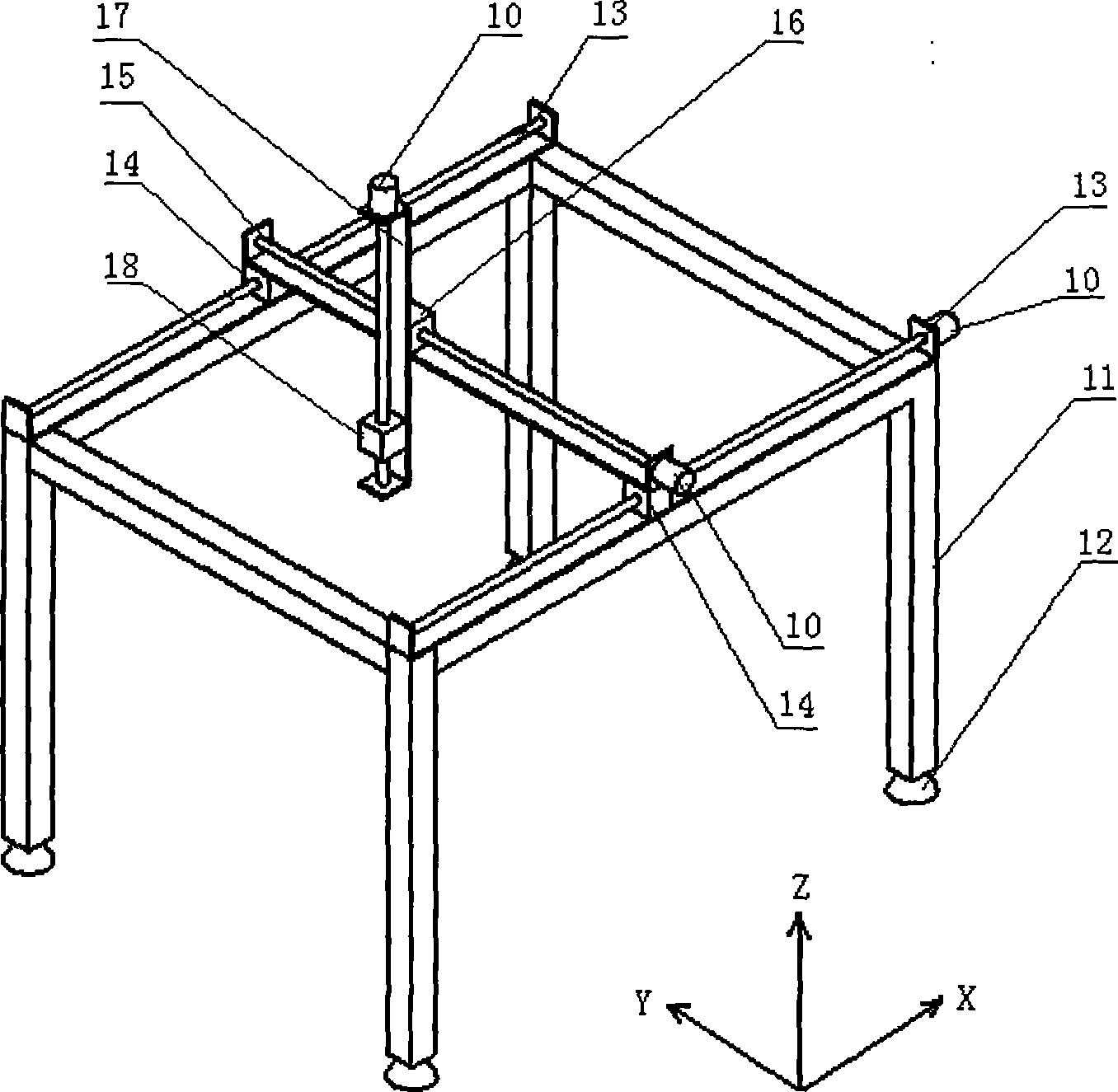

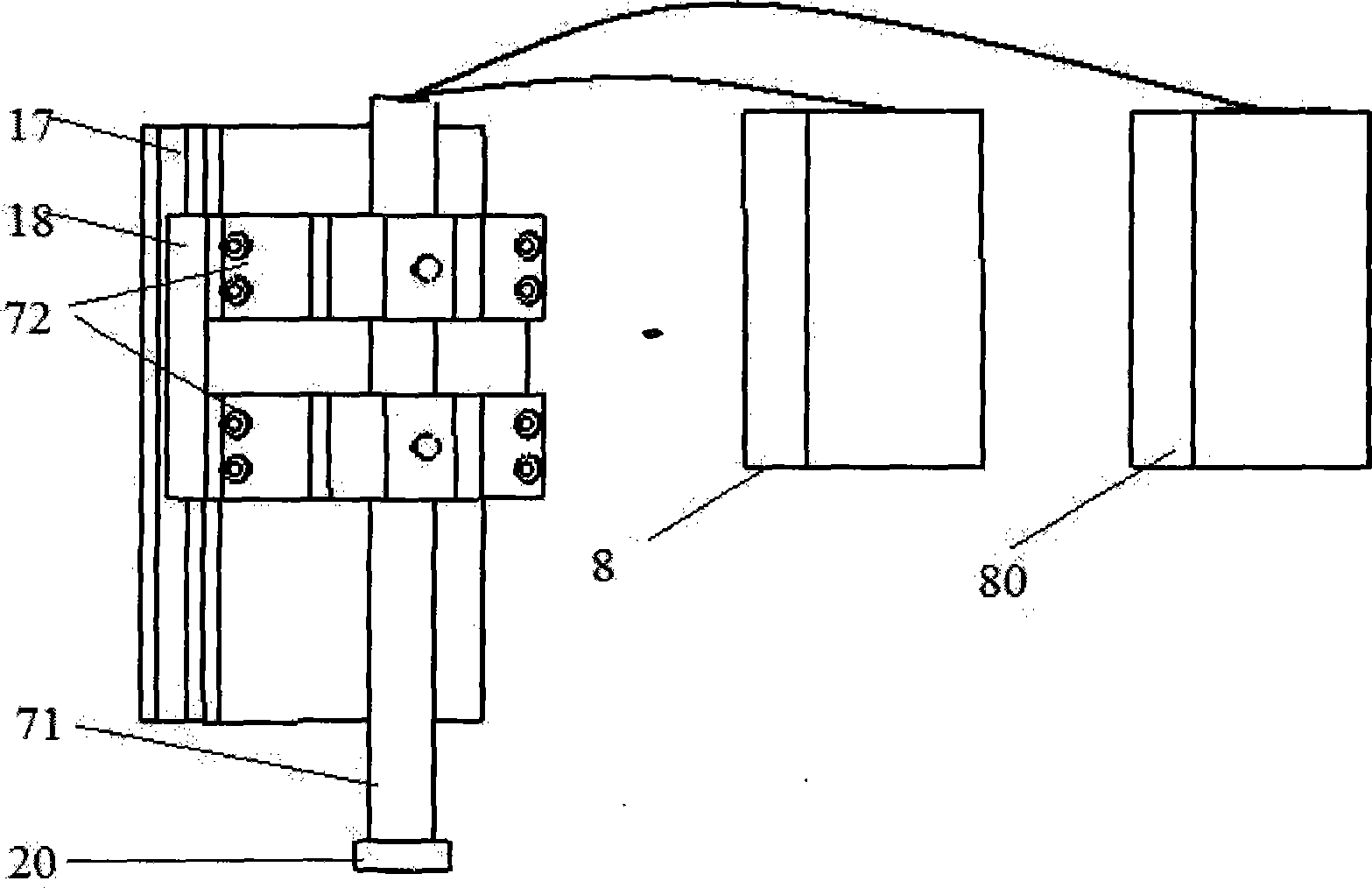

[0022] like figure 1 As shown, the measuring device adopted in the precision measurement method for the sound field of the ultrasonic liquid immersion transducer of the present invention consists of a three-dimensional scanning frame 1, a sound-absorbing water tank 2, a reflective slope seat 3, a small steel ball 4 with a through hole, and a small steel ball without a drill. The small steel ball 5 in the hole, the small steel ball brackets 6a, 6b, the ultrasonic transducer frame 7, the data processing memory 8, the three-dimensional motion controller 9, and the stepper motor 10. The sound-absorbing water tank 2 is located inside the three-dimensional scanning frame 1, and the three-dimensional moving part of the three-dimensional scanning frame 1 is above the sound-absorbing water tank 2; Below the moving part; the ultrasonic transducer frame 7 is fixed on the three-dimensional scanning frame 1 by threads; the data processing memory 8 is connected with the measured ultrasonic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com