Compressor blade runner surface profile tolerance detecting device and method

A blade flow channel and detection device technology, which is applied in mechanical counter/curvature measurement and other directions, can solve the problems of the complex shape of the blade flow channel surface, the inability to meet the measurement requirements with the metering tool, and the inability to solve the processing site inspection, etc. The effect of difficult problems, small errors, and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

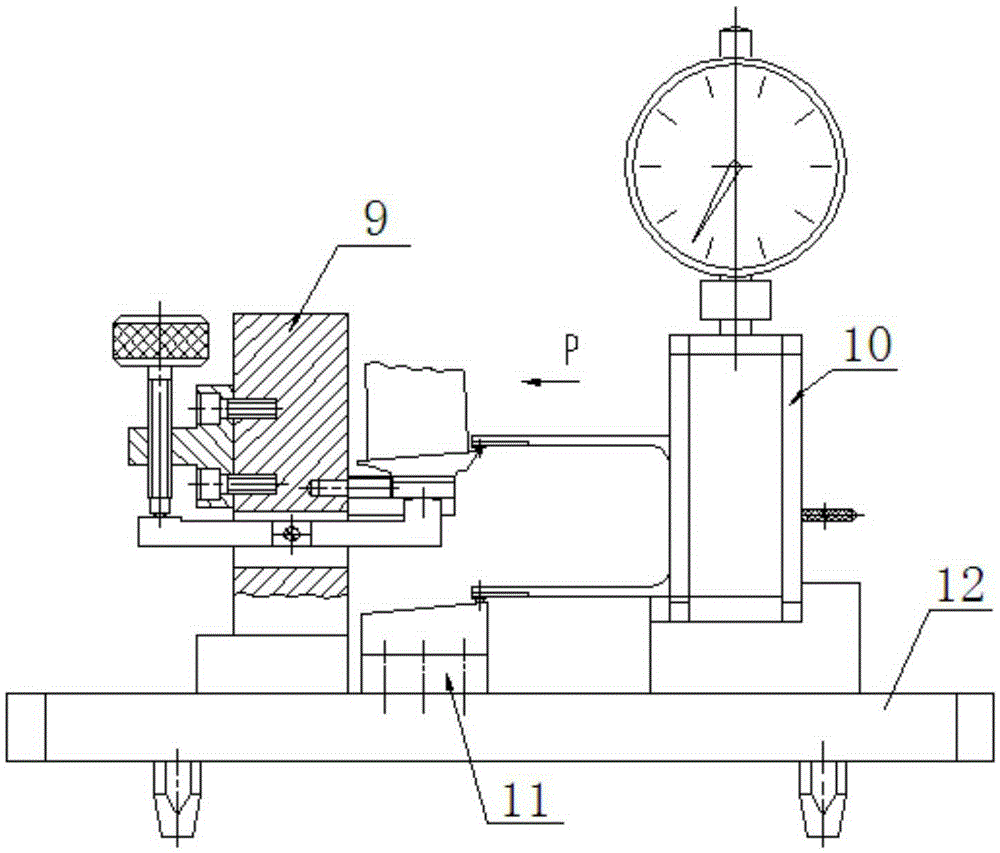

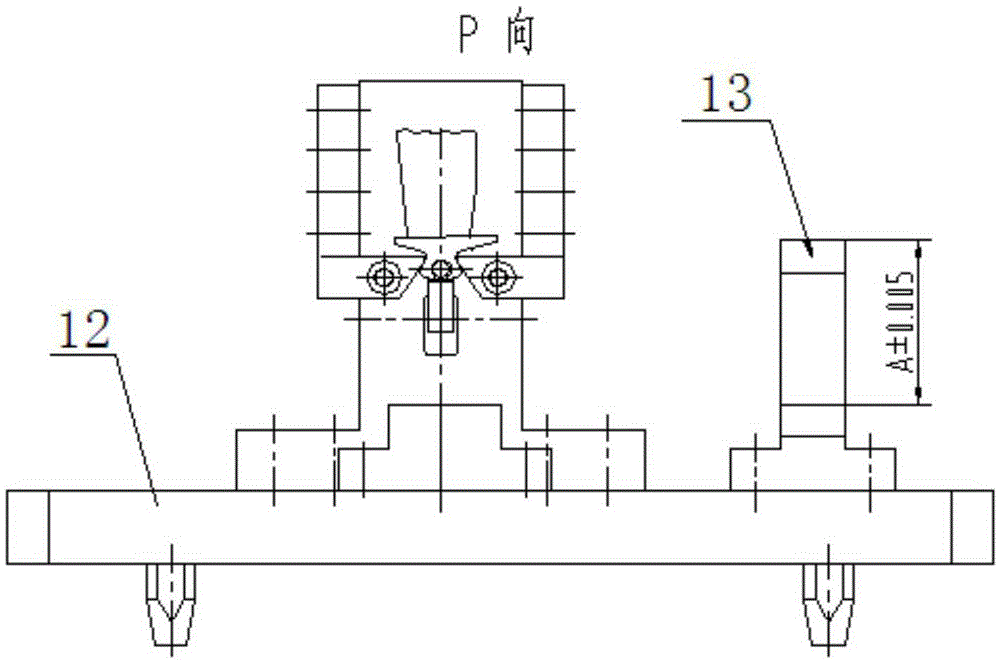

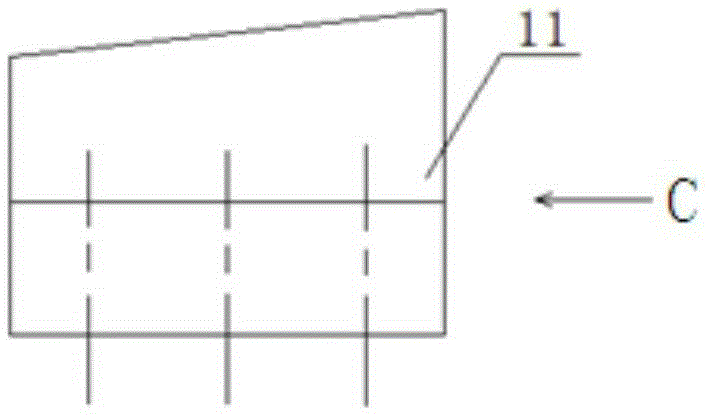

[0032] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0033] see Figure 1 to Figure 9 , a compressor blade runner surface profile detection device, including a support 12, the support 12 is provided with a positioning and clamping device 9 for fixing the compressor blade, and a standard profile block 11 for comparison with the compressor blade As well as the differential meter frame 10 used to detect the contour of the compressor blade runner surface, the positioning and clamping device 9 includes a bracket 15 fixed on the support 12, the middle part of the bracket 15 is provided with a through hole, and the through hole is inserted There is a clamping lever 20 that can provide clamping force for the bottom surface of the tenon of the compressor blade. A rotating shaft 18 is also fixed in the through hole. The clamping lever 20 can rotate around the rotating shaft 18. Two sides of the upper part of the bracket 15 are fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com