Device for rapidly detecting trace water content

A technology of trace water and speed tester, applied in the direction of material resistance, can solve the problems of difficult to measure, time-consuming and troublesome, and inaccurate, and achieve the effect of shortening the detection speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

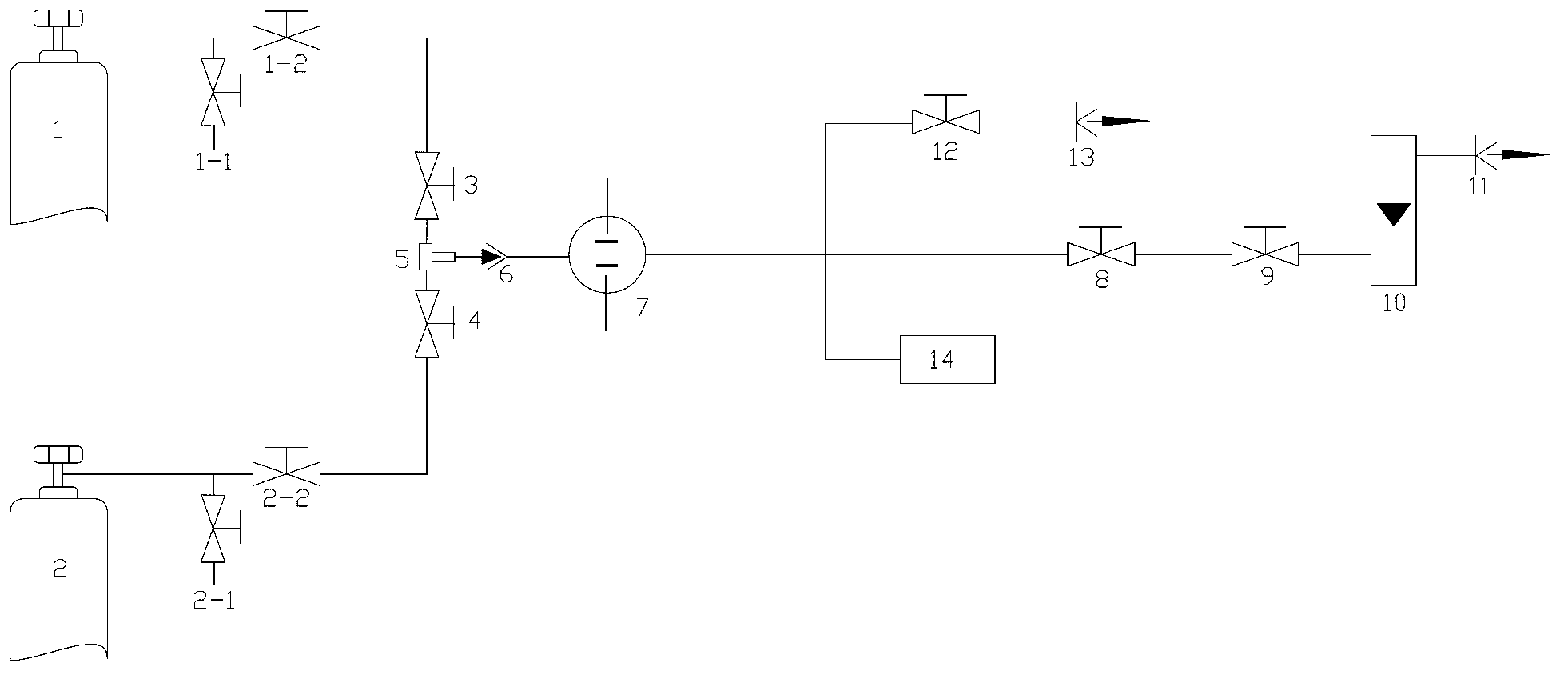

[0015] Gas cylinder 1 and gas cylinder 2 in the figure are high-pressure bottled gases under inspection and to be inspected. After the detection gas cylinder 1 is extracted and washed by the sampler drain valve 1-1, it enters the instrument inlet switch valve 3 from the on-off valve 1-2 through the gas pipeline, and the valve 3 is opened, and the gas sample passes through the tee 5 and the instrument inlet connector 6 into the detector 7 for moisture detection. The detected gas sample enters the inlet of the on-off valve 9 through the flow regulating valve 8, and the valve 9 is opened. The gas sample that has been reduced to normal pressure enters the measuring flowmeter 10 according to the set flow rate of the regulating valve, and then flows through the interface 11. empty.

[0016] When the gas cylinder 1 is detected, the gas sample of the gas cylinder 2 is extracted through the drain valve 2-1 of the sampler. At this time, the switch valve 2-2 of the sampler and the instr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com